Spray coating apparatus and spray coating method

A technology of spraying device and spraying direction, which is applied to spraying device, spraying device, spraying discharge device and other directions, can solve the problems of unpractical spraying, disordered pattern, change of atomization angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. But it does not constitute any limitation to the present invention.

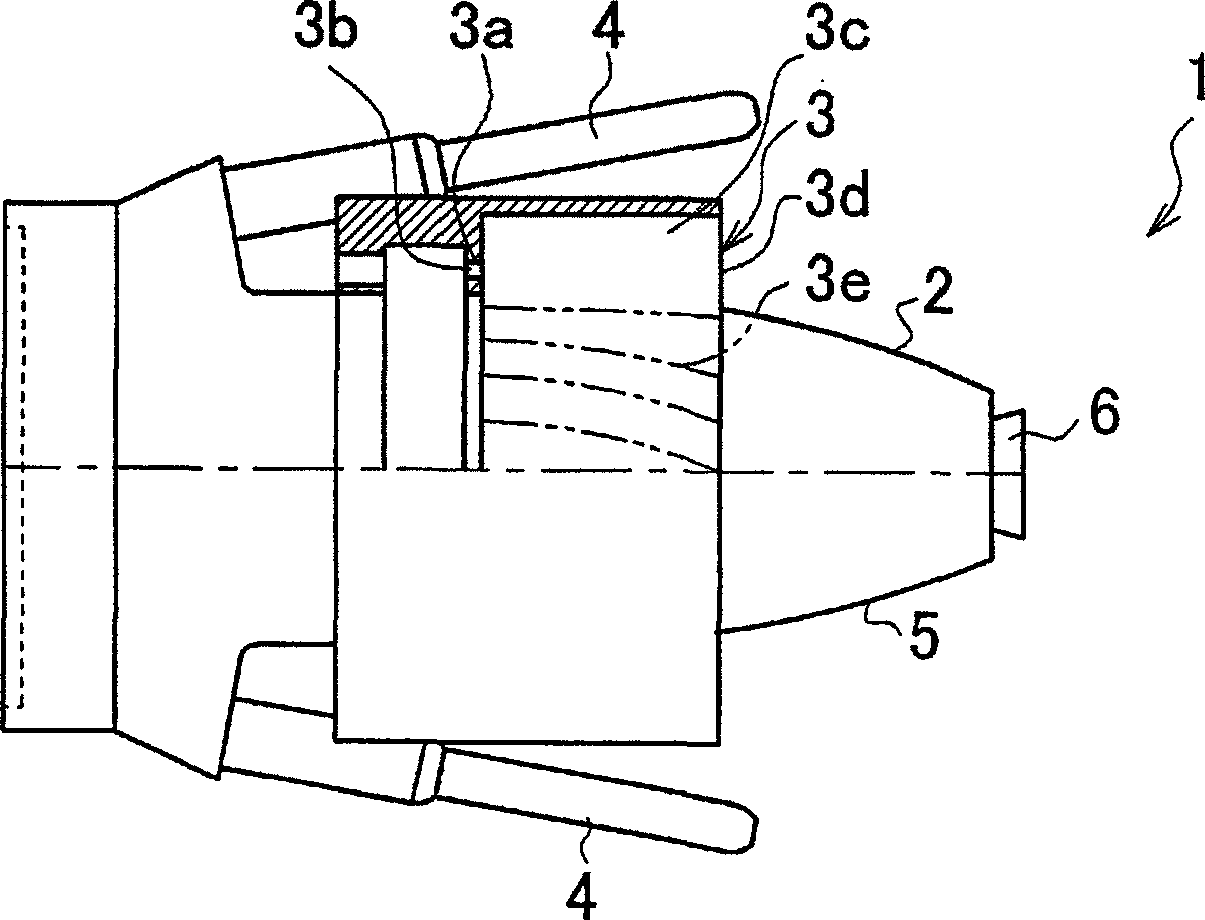

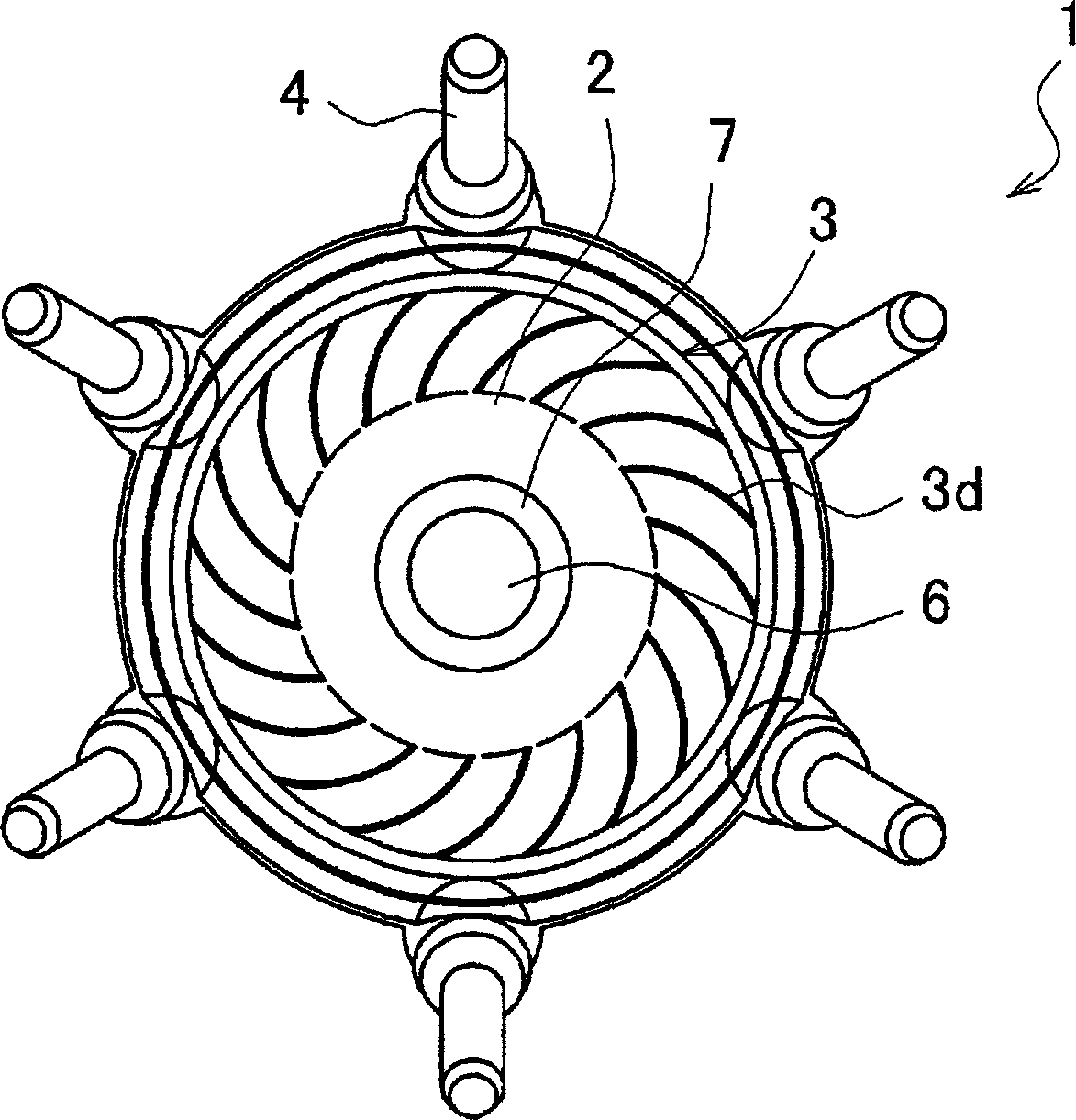

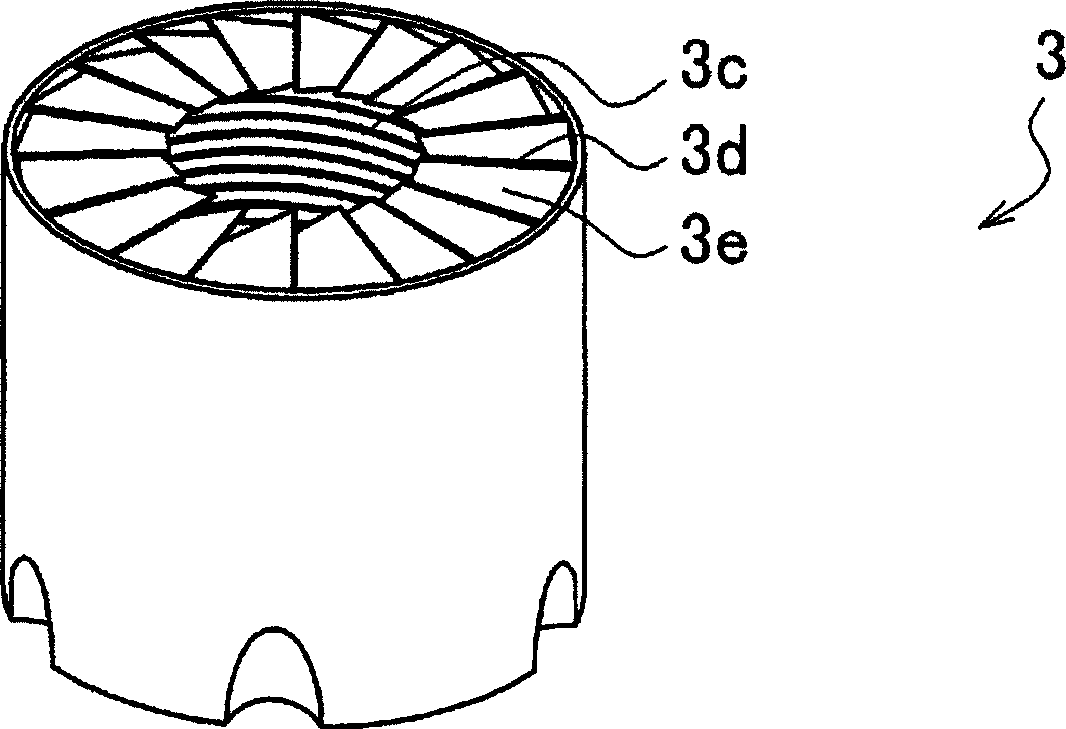

[0125] figure 1 is a partial sectional side view of the first embodiment of the spraying device of the present invention, figure 2 yes figure 1 Fig. 3 is a first distributor provided in the first embodiment, (a) is a perspective view, (b) is a front view, and (c) is a bottom view. However, in these drawings, dimensions are appropriately adjusted for easy understanding.

[0126] Spraying device 1 of the present invention, as figure 1 and figure 2 As shown, it is mainly composed of a sprayer body 2 , a first distributor 3 and a plurality of electrodes 4 (six in this embodiment). The main body 2 of the spraying machine is, for example, made of an insulating material such as polytetrafluoroethylene, which is formed by forming a cylindrical sleeve, and a nozzle 6 is provided at its front end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com