Blast furnace slag thermal fracture centrifugal drying method granulation device and method

A technology for dry granulation and blast furnace slag, which is applied in the improvement of process efficiency, recycling technology and other directions, can solve the problems of high-value sensible heat contained in slag that cannot be effectively recycled, huge energy waste, and large energy consumption. , to achieve the effect of obvious water saving effect, promotion of energy saving and environmental protection, and reduction of acid gas pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

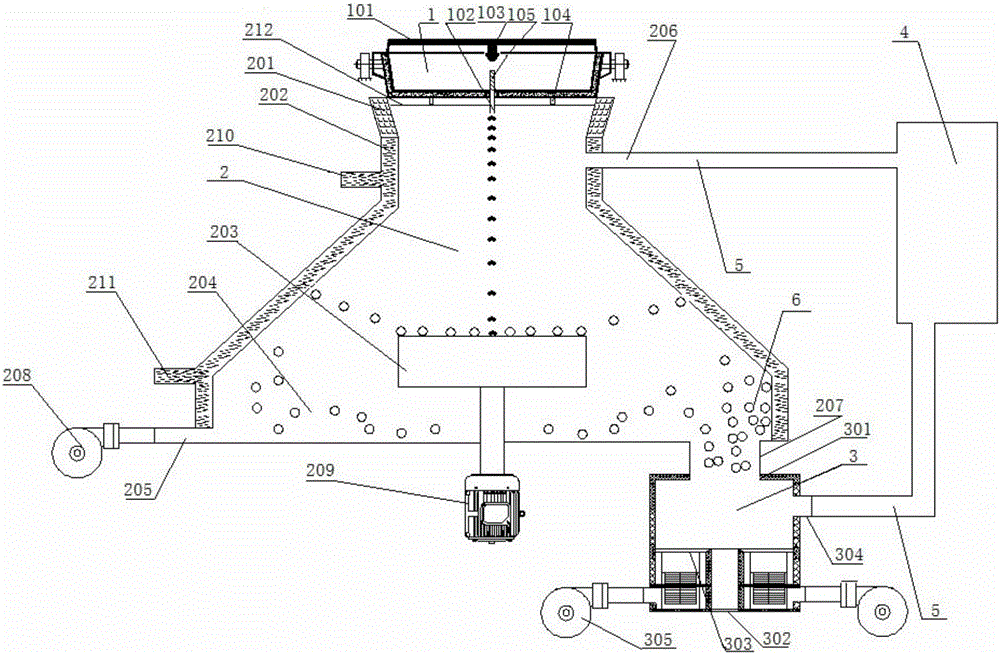

[0045] A blast furnace slag thermal breaking centrifugal dry granulation device, such as figure 1 As shown, it includes a tundish 1, a granulation chamber 2, a filled countercurrent heat exchanger 3 and a high-temperature air collection and purification device 4;

[0046] The intermediate tank 1 is a hollow body, the top of the tank is provided with a tank cover 101, the bottom of the tank is provided with a slag outlet 102, the inner wall of the tank cover 101 is provided with a heating device 103, and the inner wall of the tank is provided with a heat preservation device. Lining; several load cells 104 are provided at the bottom of the tundish, and a diversion control valve 105 is provided at the slag outlet, and the diversion control valve 105 is used to adjust the supply speed of the blast furnace slag, and the load cell 104 is used to monitor the blast furnace slag The flow rate; the heating device 103 is provided with a hole on the inner wall of the tundish cover 101, an...

Embodiment 2

[0051] A method for thermal breaking centrifugal dry granulation of blast furnace slag, utilizing the device described in Embodiment 1, comprising the following steps:

[0052] 1) centrifugal cooling

[0053] Open the slag outlet, and the liquid blast furnace slag particles with a temperature of 1450-1500°C flow from the tundish into the turntable of the granulation chamber at a flow rate of 800kg / min. The rotation speed of the turntable is 2000r / min. Under the action of centrifugal force, it flies out along the edge of the turntable, passes through the cyclone chamber and flies to the water-cooled outer cone;

[0054] In the process of flowing into the turntable and during the flight, the inflow volume is 100000Nm blasted from the granulation chamber 3 Under the action of cold wind per hour, the liquid blast furnace slag particles are in full contact with the cold wind to undergo heat exchange, and the temperature of the slag particles drops sharply. The core is still molte...

Embodiment 3

[0063] A method for thermal breaking centrifugal dry granulation of blast furnace slag, utilizing the device described in Embodiment 1, comprising the following steps:

[0064] 1) centrifugal cooling

[0065] Open the slag outlet, and the liquid blast furnace slag particles with a temperature of 1550-1600°C flow from the tundish into the turntable of the granulation chamber at a flow rate of 300kg / min. Under the action of centrifugal force, it flies out along the edge of the turntable, passes through the cyclone chamber and flies to the water-cooled outer cone;

[0066] In the process of flowing into the turntable and during the flight, the influx is 45000Nm blasted from the granulation chamber 3 Under the action of cold wind per hour, the liquid blast furnace slag particles are in full contact with the cold wind to undergo heat exchange, and the temperature of the slag particles drops sharply. The core is still molten;

[0067] When the blast furnace slag particles fly to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com