Patents

Literature

37results about How to "Improve singeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

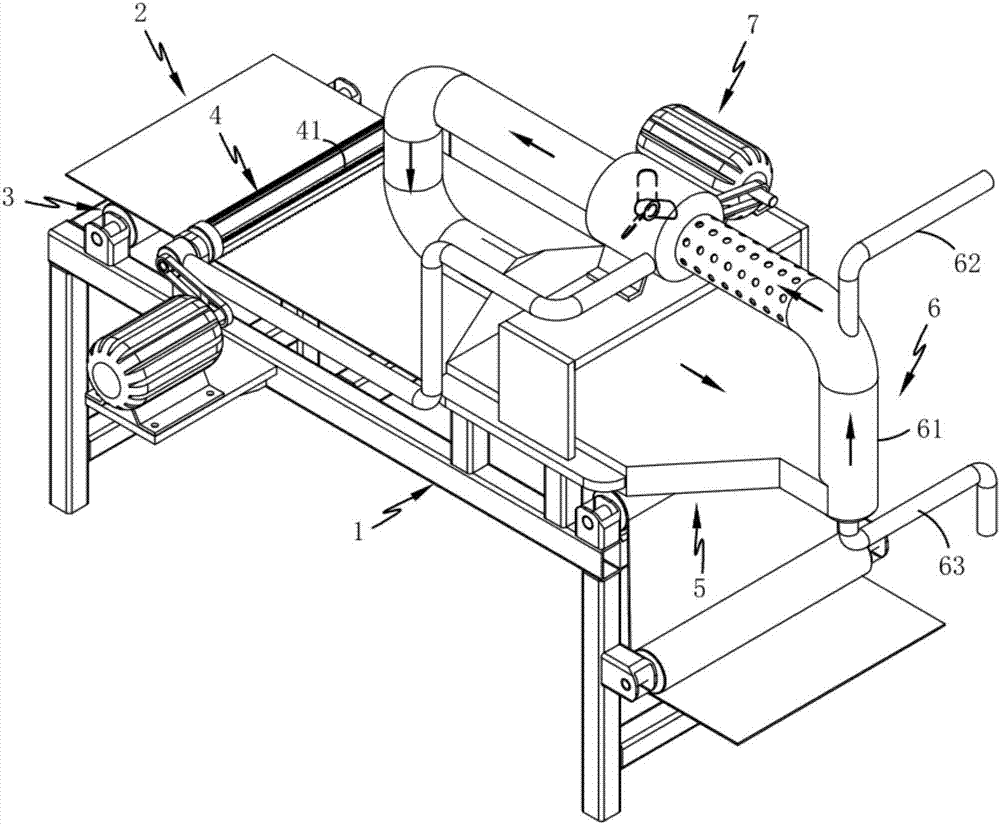

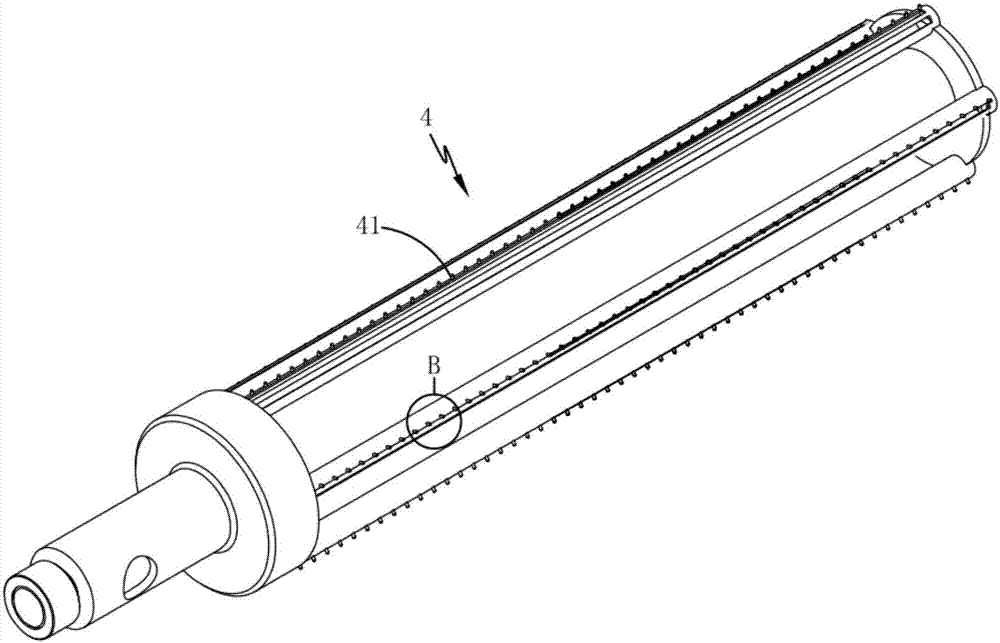

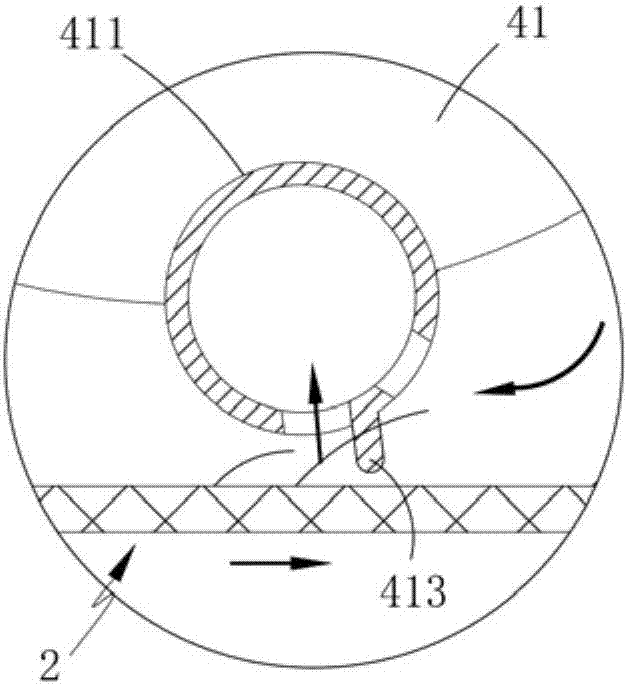

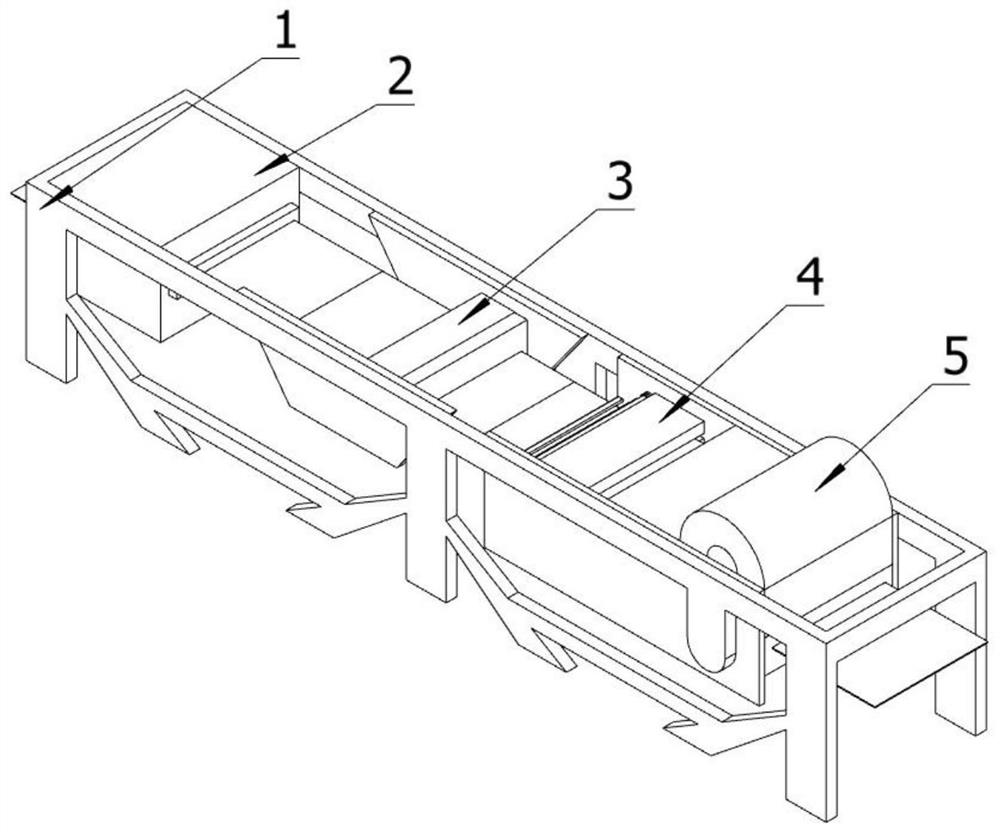

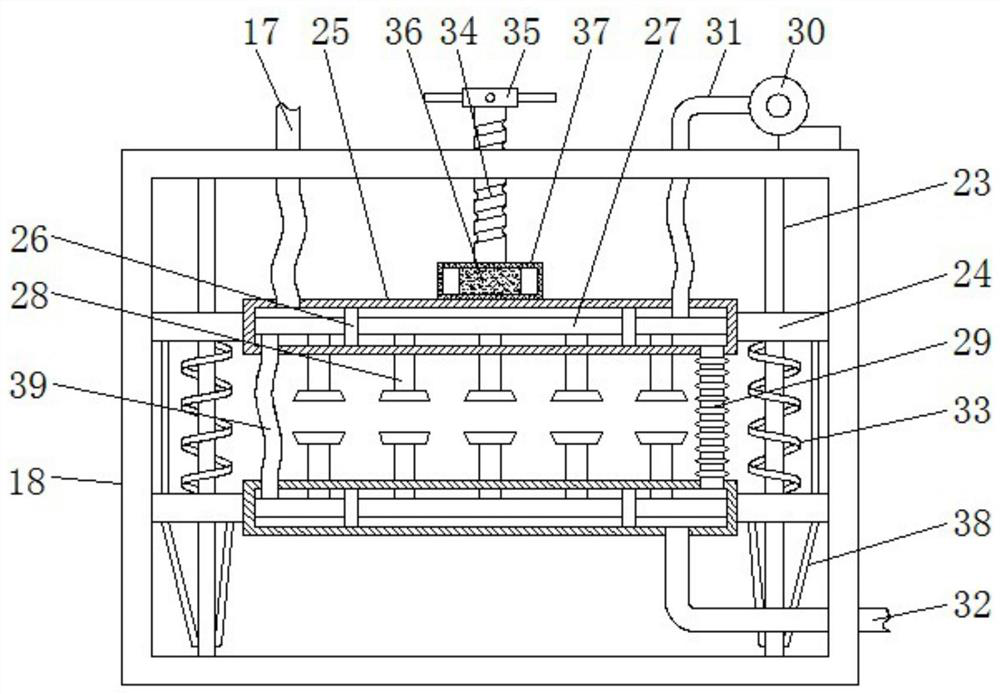

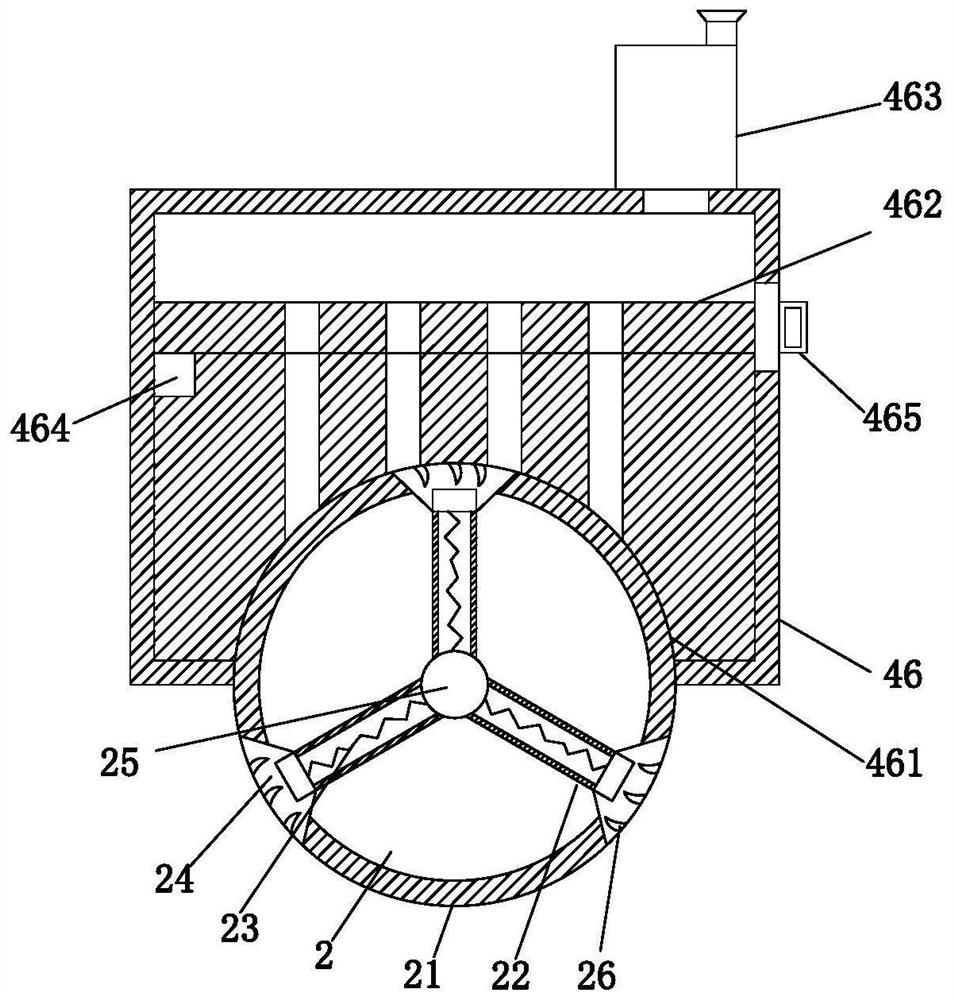

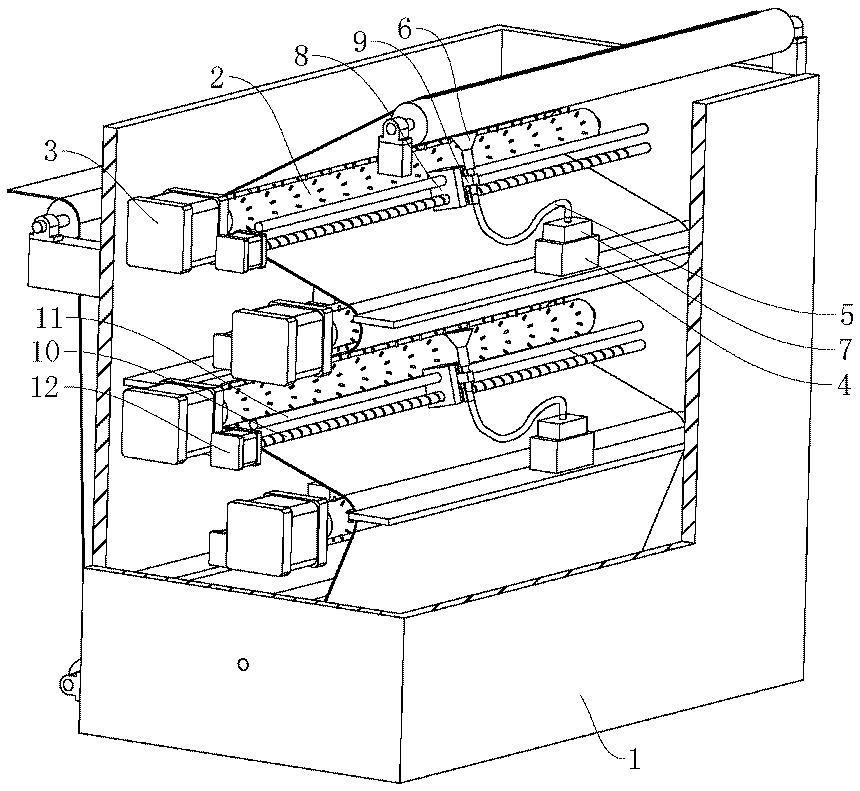

Cloth negative pressure finishing singeing device

InactiveCN107217436AAvoid cloggingSingeing orderlyMechanical cleaningPressure cleaningFiberEngineering

The invention relates to a cloth negative pressure finishing singeing device, which comprises a frame, a cloth guide roller, a carding assembly and a negative pressure hair removal assembly. During the rotation, the fibers attached to the surface of the cloth are erected, adsorbed and pulled; there is a fluff shaping space between the negative pressure hair removal component and the cloth. And the adsorption holes and the deflectors and heating wires respectively arranged on both sides of the removal pores, the airflow flows along the hair removal chamber and is guided by the deflectors to form an airflow acceleration zone, and a negative pressure zone is formed between the deflectors and the adsorption holes; The carding component erects the fiber and shapes it, and then pulls the fiber with the adsorption force to contact the heating wire to realize singeing. At the same time, the broken fiber is collected by the airflow conduction separation component, which solves the problems existing in the prior art. Poor singeing effect and inconvenient dust removal technical problems.

Owner:长兴天赫纺织科技有限公司

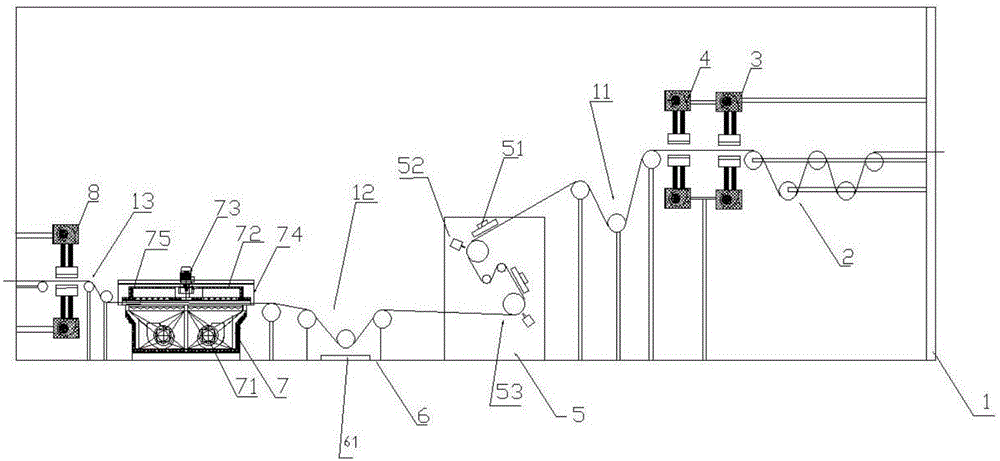

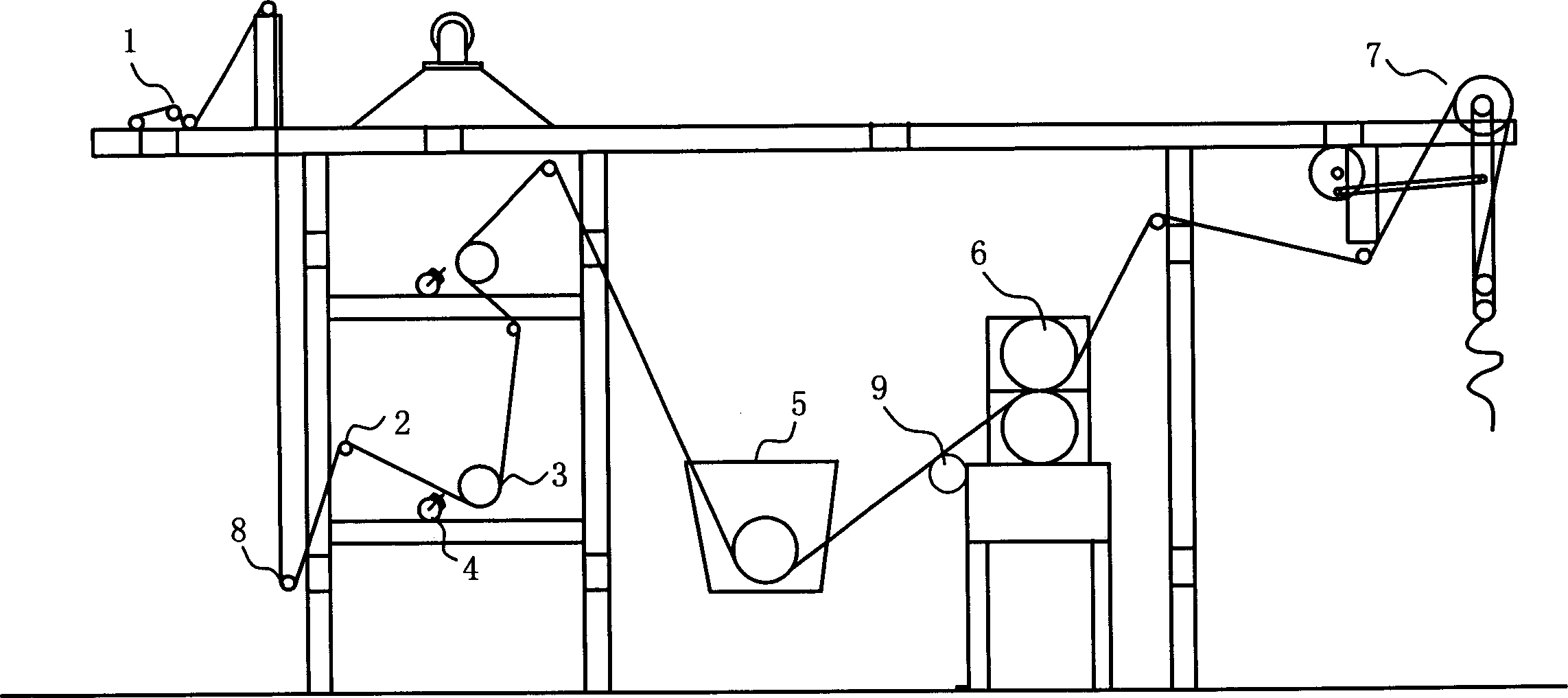

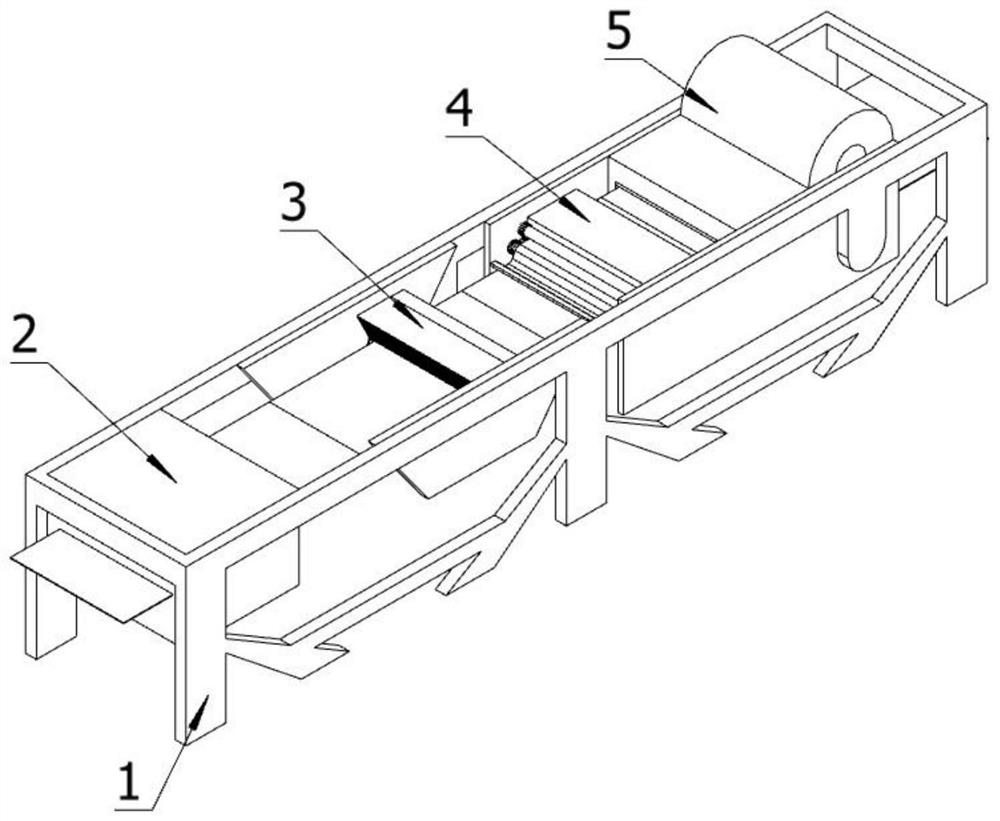

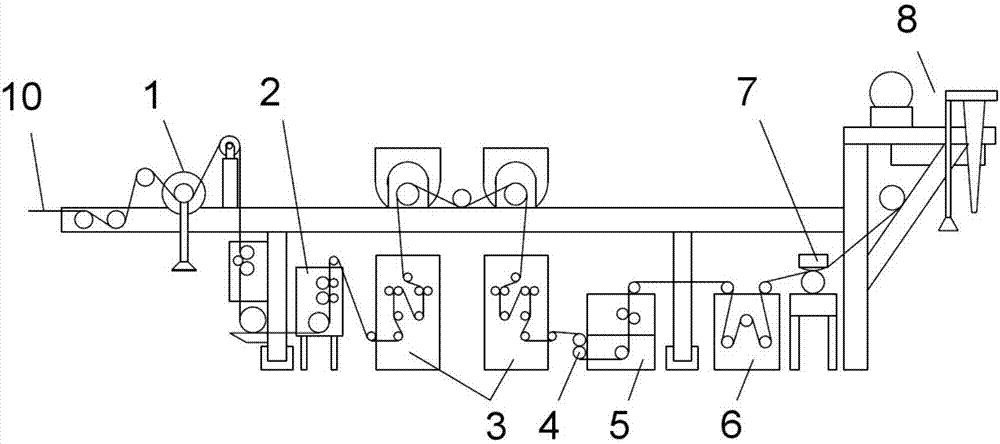

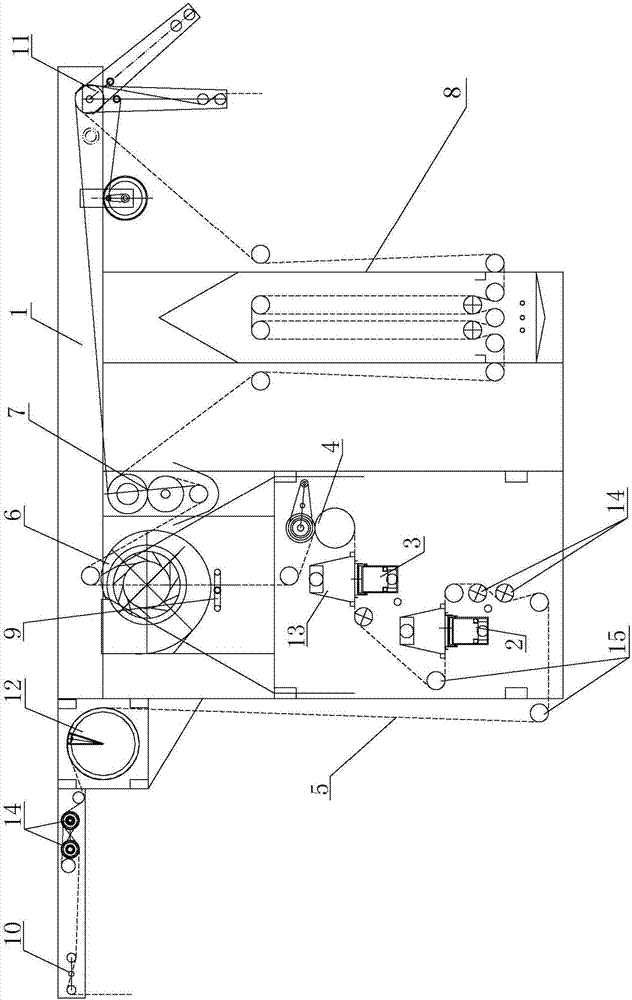

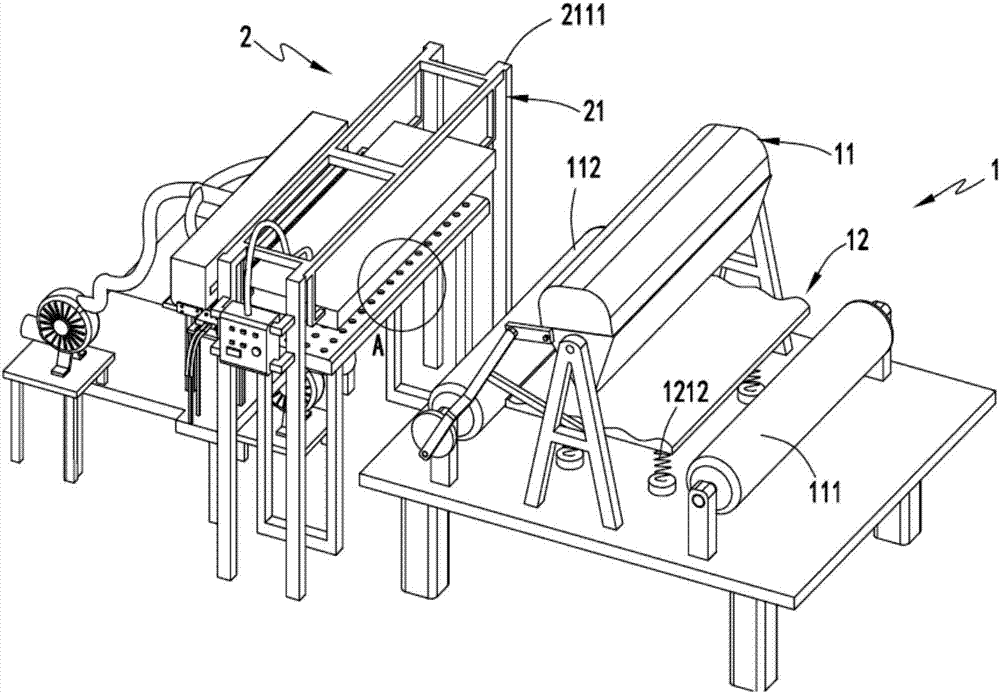

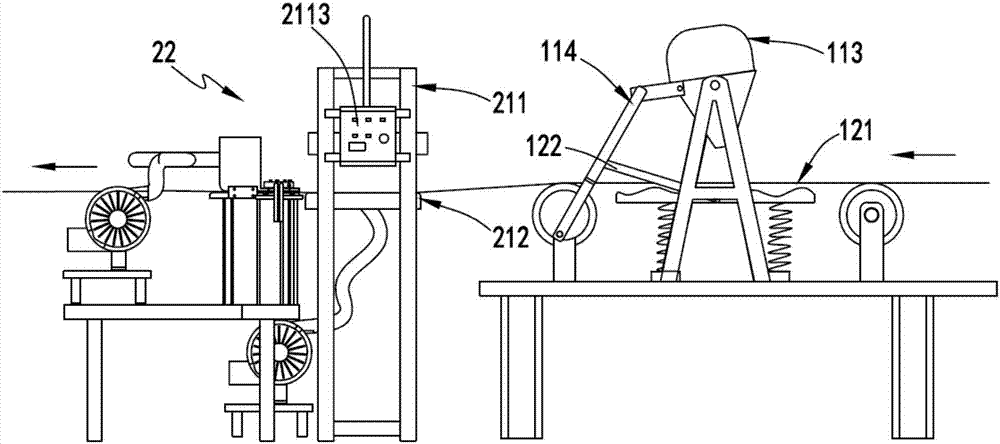

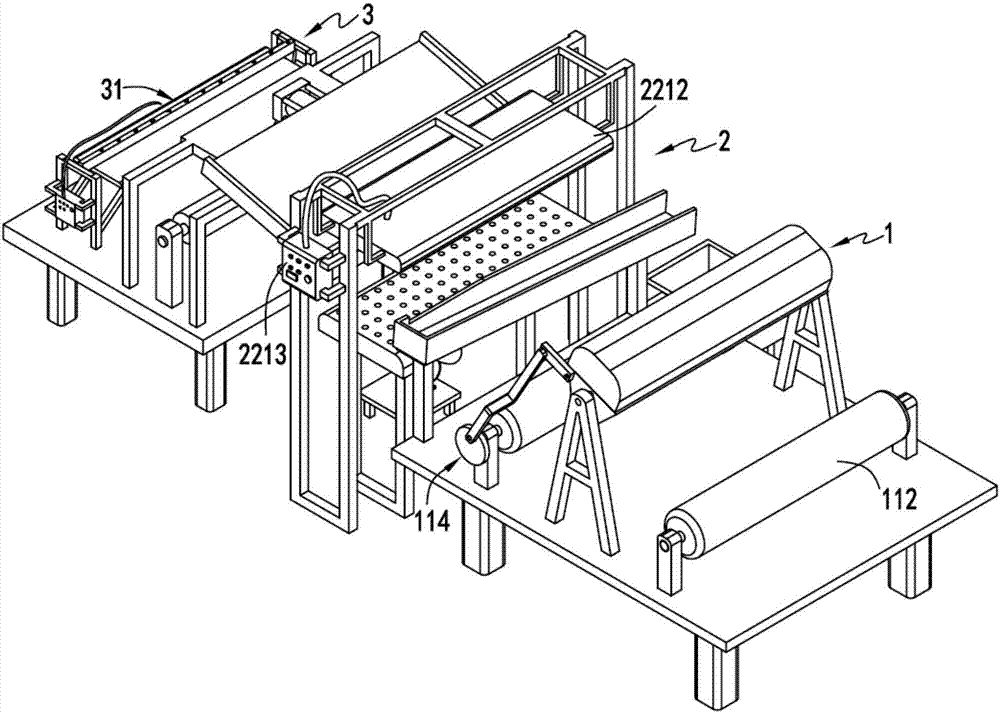

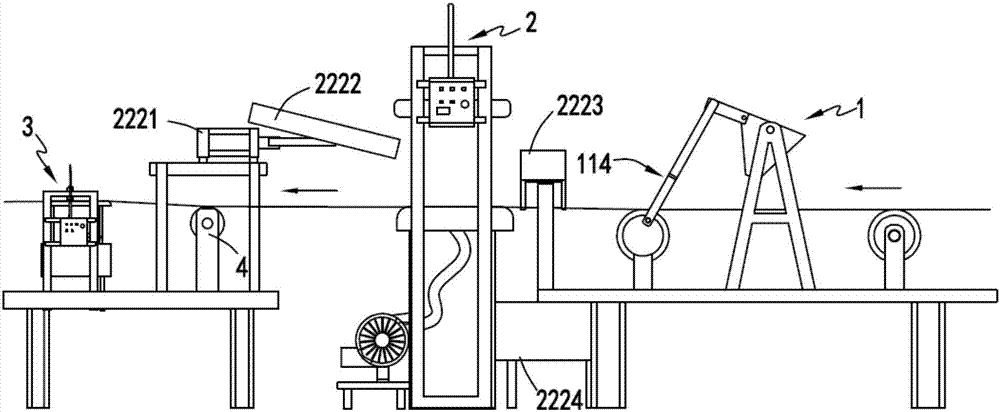

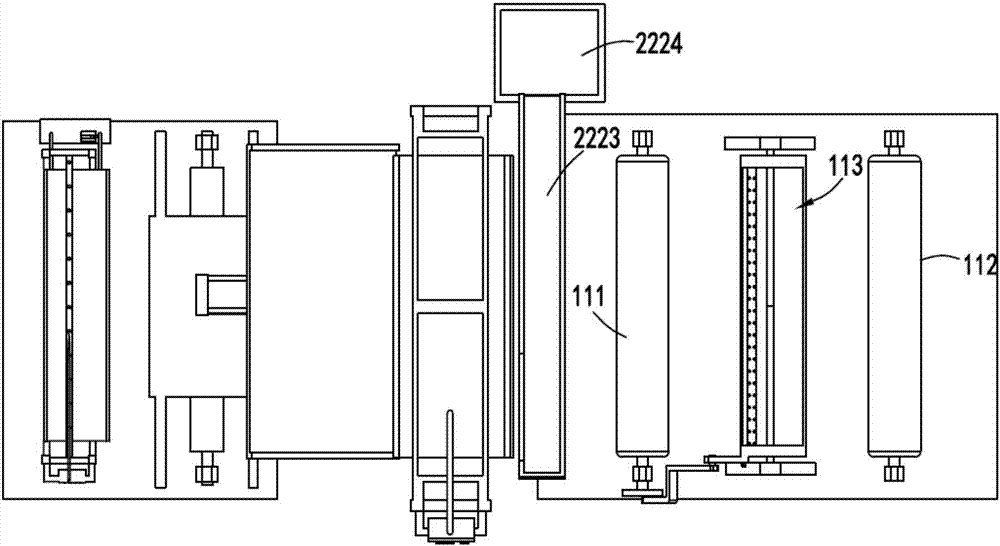

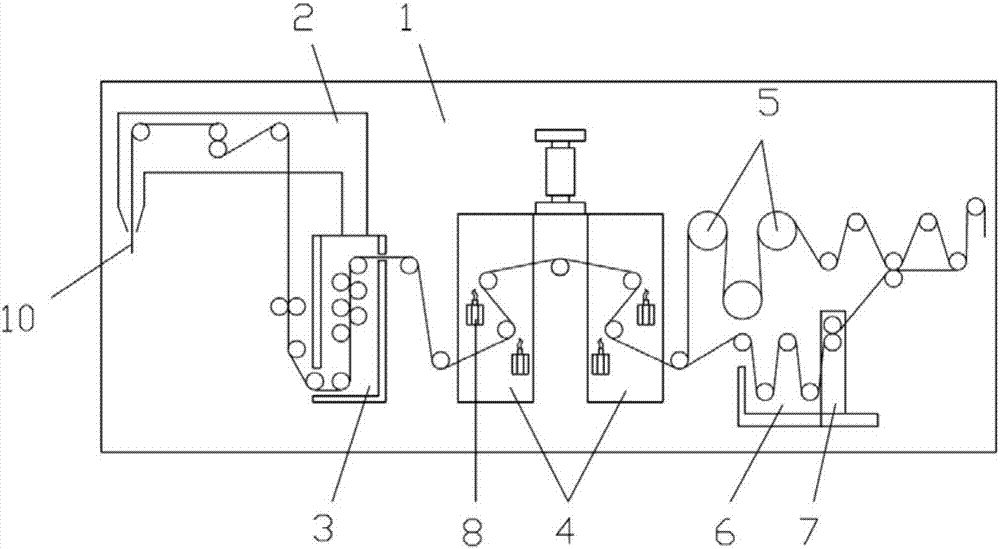

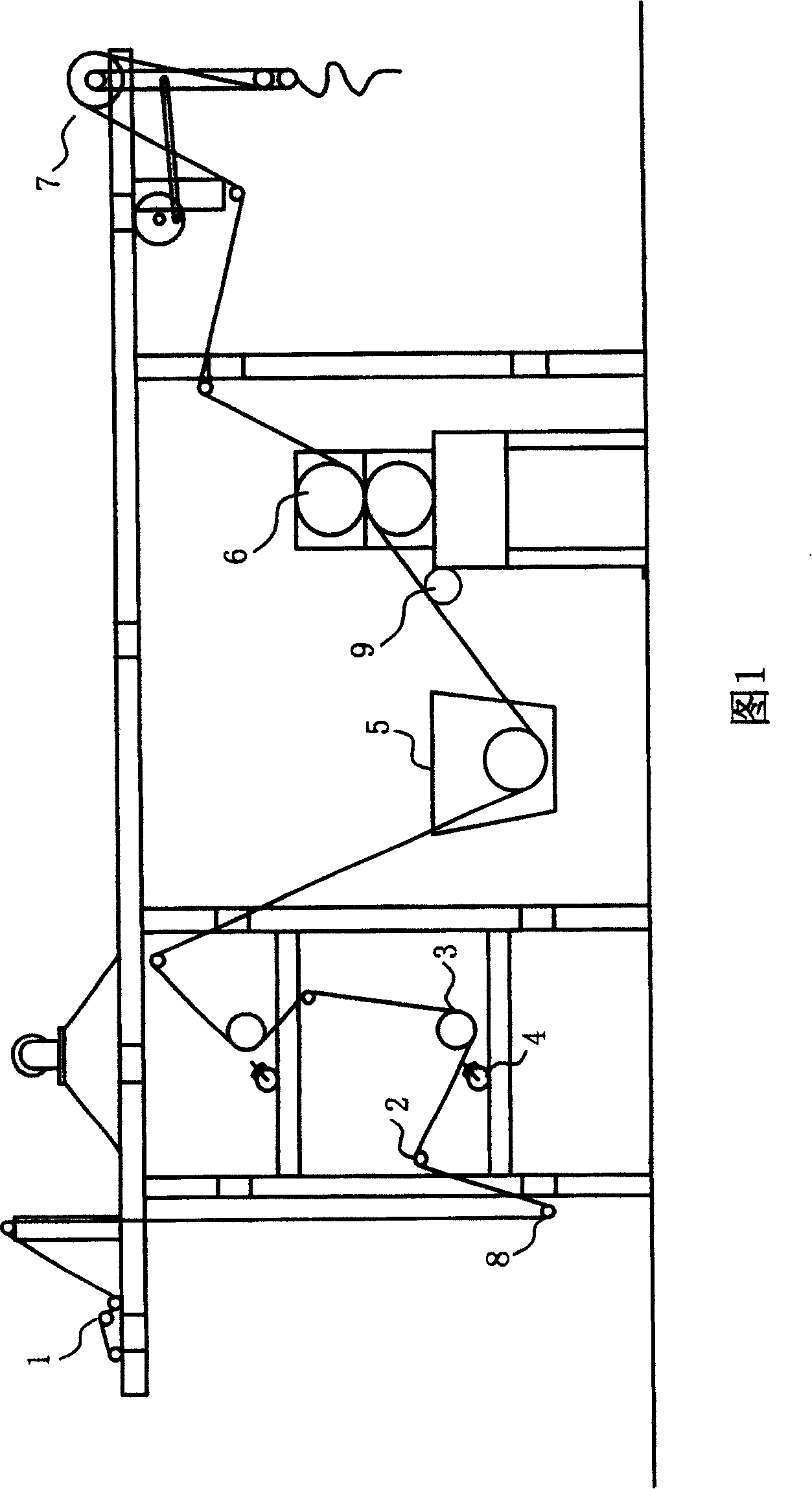

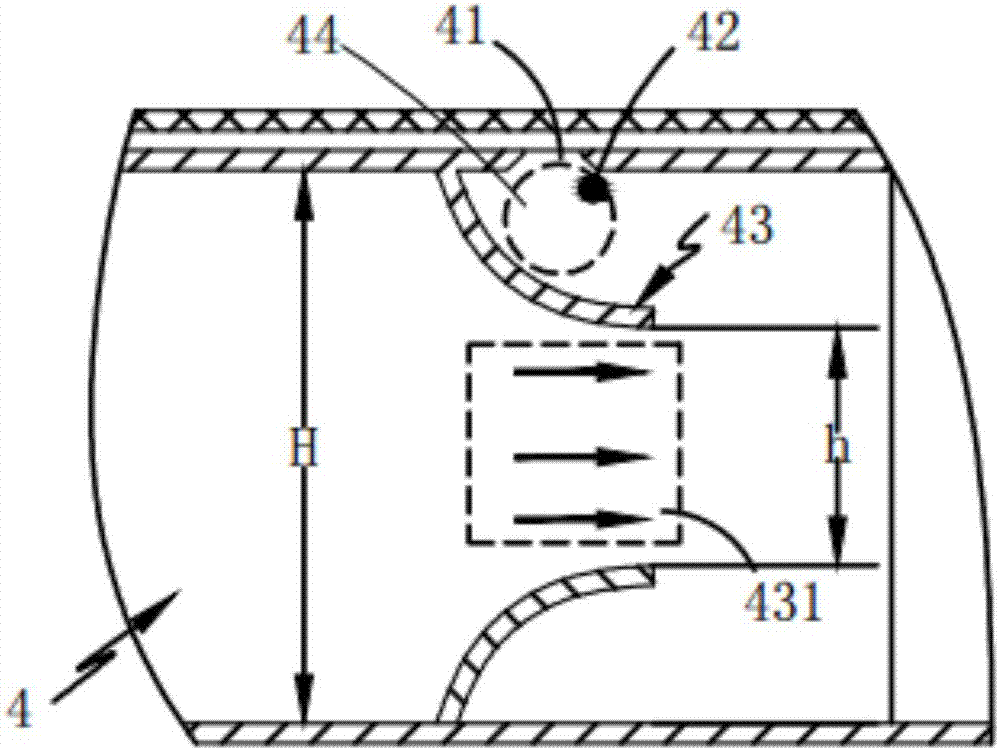

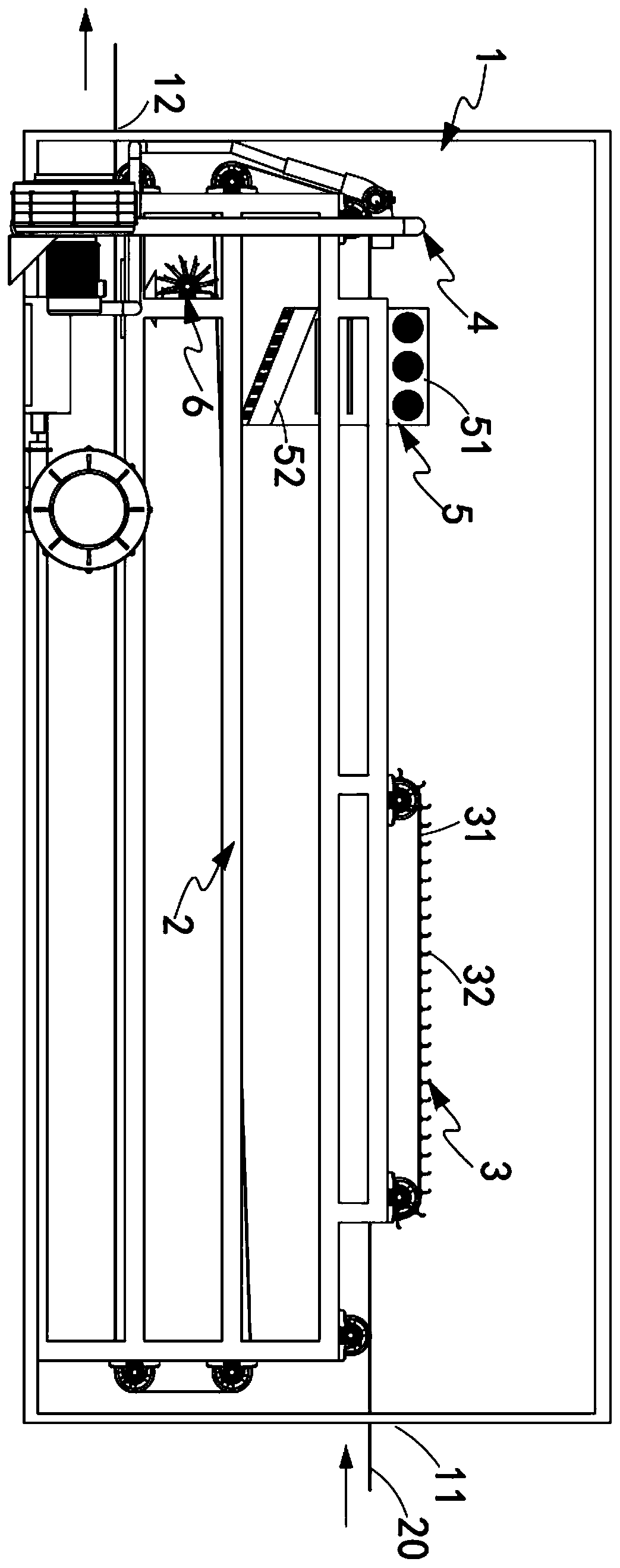

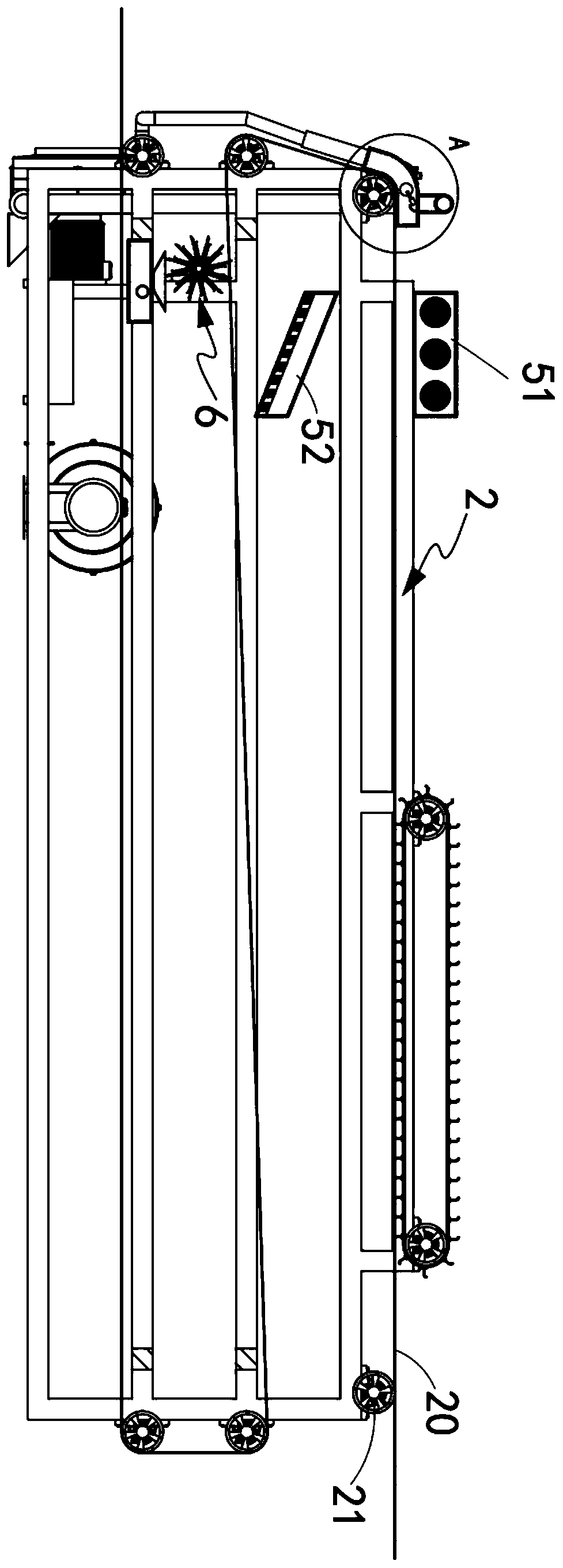

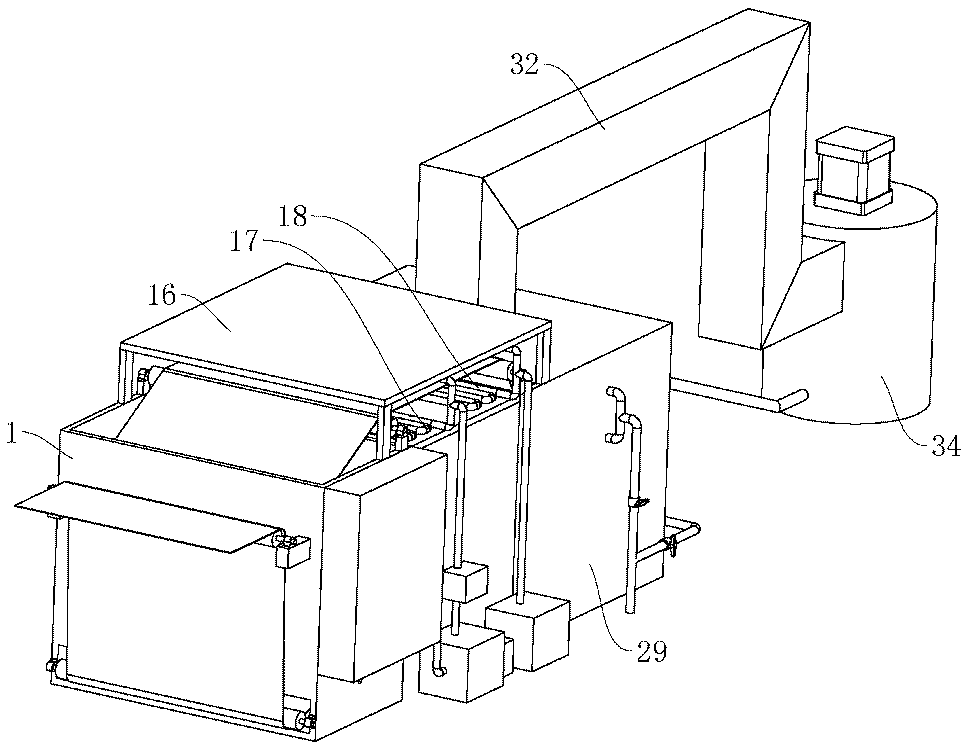

Cloth singeing production line

ActiveCN106283470AGood effectGood removal effectSingeingLiquid/gas/vapor removalMegasonic cleaningTextile

The invention discloses a cloth singeing production line, which relates to the technical field of textiles. The cloth singeing production line comprises a machine body, wherein a tension adjusting roller group, a dust collection fan group, a preheating fan group, a singeing chamber, a washing trough, a drying oven and a cooling fan group are successively arranged in the machine body, wherein a conveyor roller group I for conveying the cloth is arranged between the preheating fan group and the singeing chamber, a conveyor roller III for conveying the cloth to be washed in the washing trough is arranged between the singeing chamber and the drying oven, and a conveyor roller group IV for conveying the cloth is arranged between the cooling fan group and the drying oven. The cloth singeing production line has the beneficial effects that the singeing is performed after heat collection, preheating and the treatment of an electrostatic generation apparatus, so that the singeing effect is better, the subsequent ultrasonic washing step and the drying and cooling steps can well remove ash attached to the surface of the cloth after the singeing, and the dried cloth can be flattened.

Owner:JIANGSU SHUANGYING TEXTILE TECH

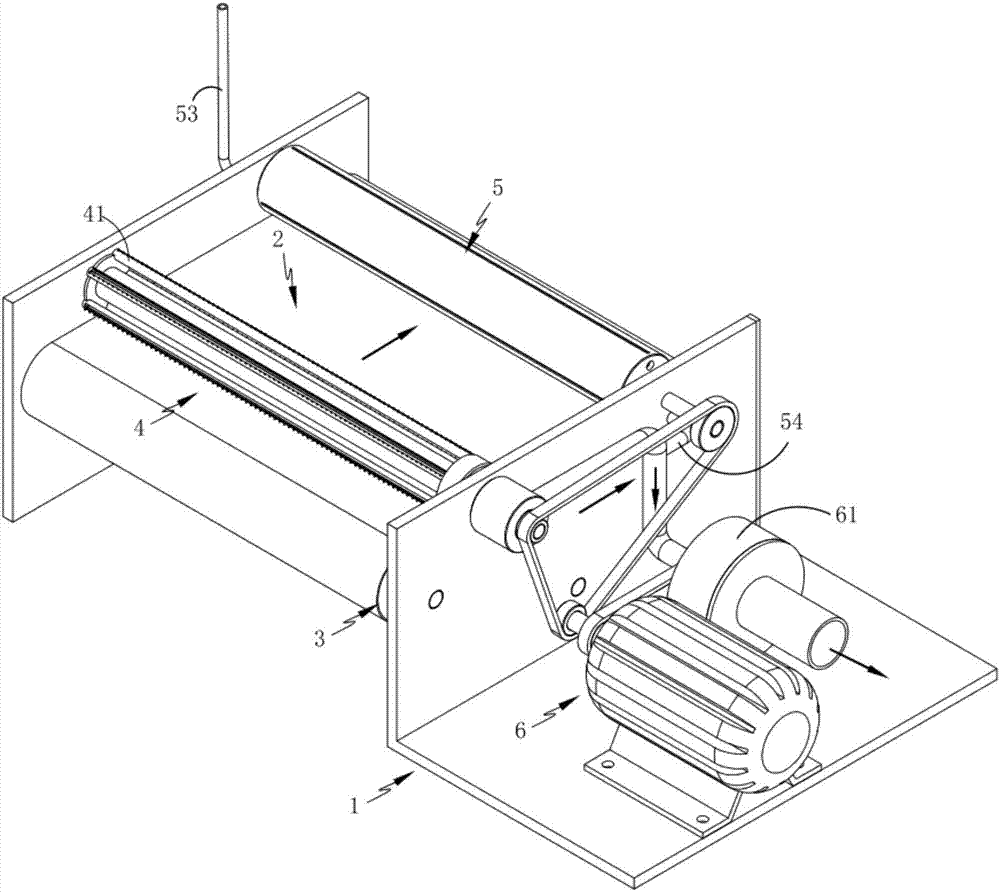

Small scale singeing machine for textile

InactiveCN1786325AImprove singeing effectMeet singeing treatmentSingeingSteam pressureElectric machine

The invention discloses a mini gassing frame. It is made up of distribution box, two frequency changing electric machines, cloth sending tension roll, breadth staying roller, cooling roller, burner opening, quench box, air pressing cloth roller, exhaust fan, cloth laying and falling plant, incendiary agents atomization plant, steam pressure generating plant. It can reach the effect of reasonable design, simple operation, and good gassing. And it is fit for different thickness fabric gassing.

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD

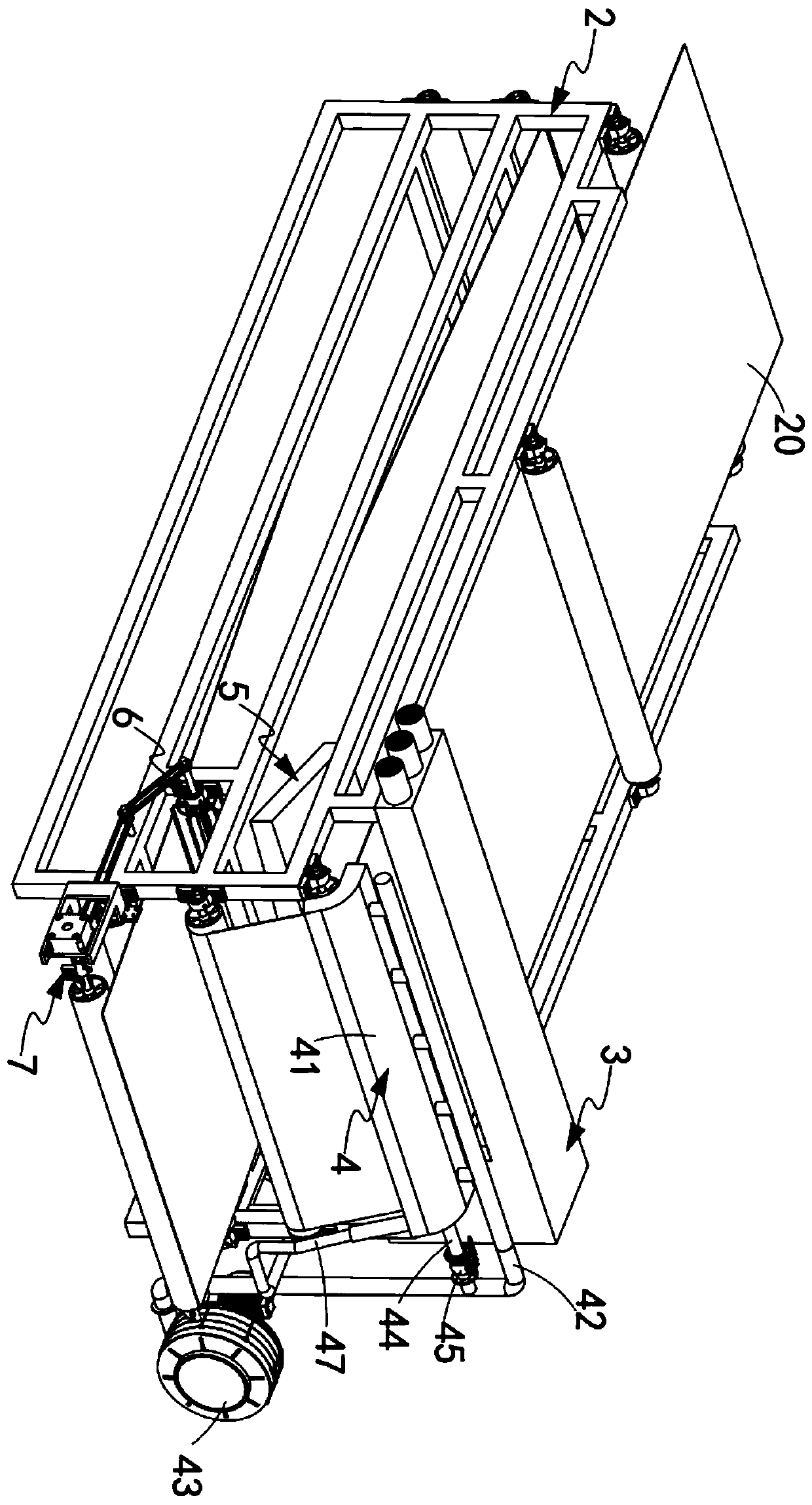

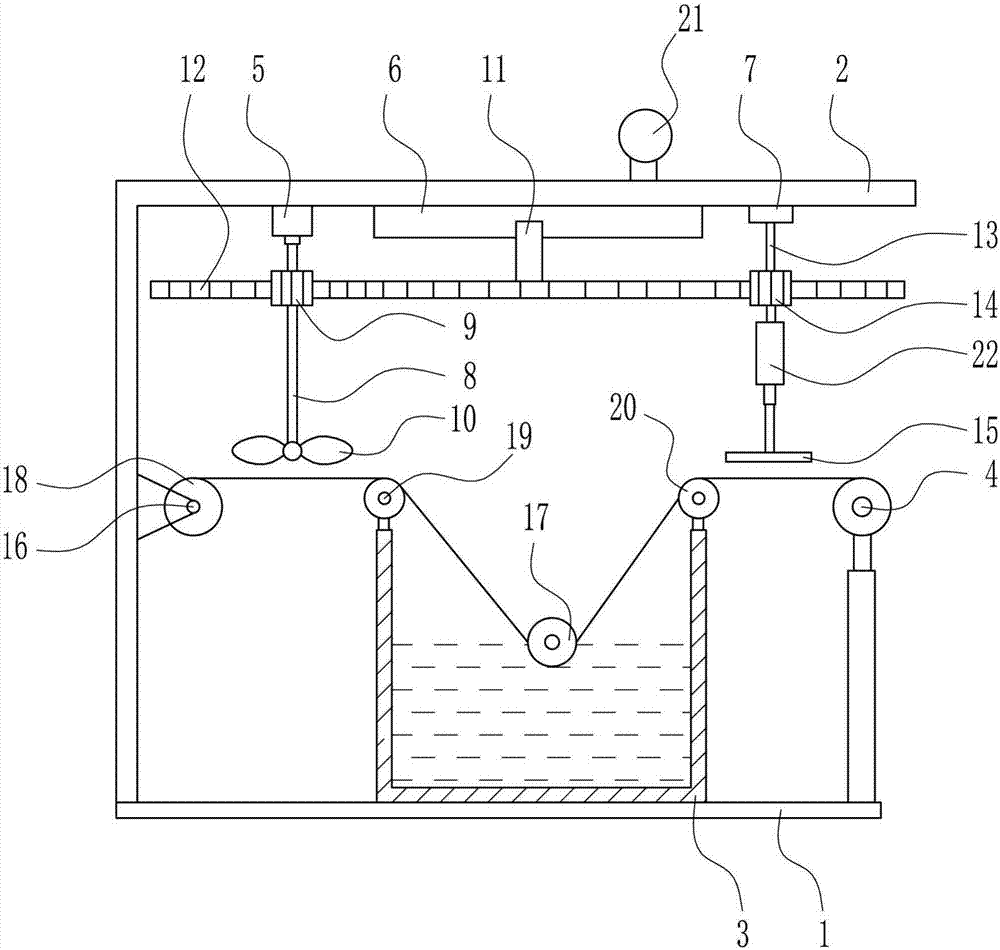

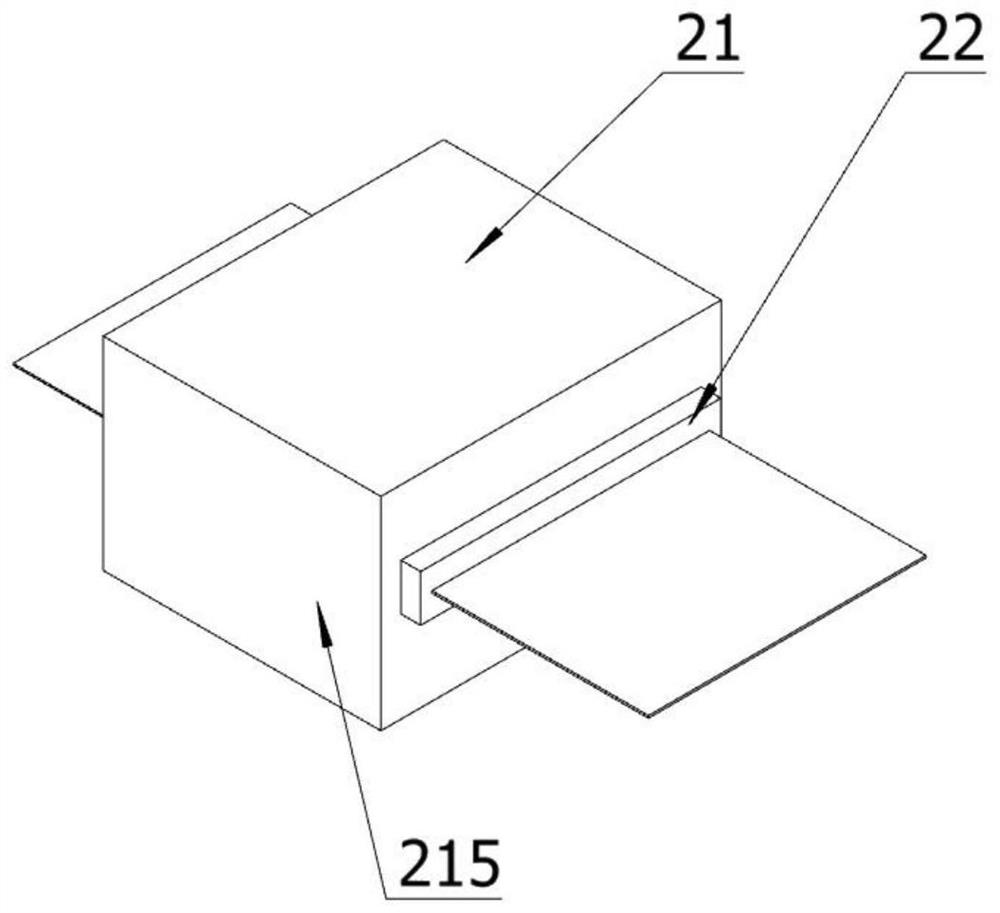

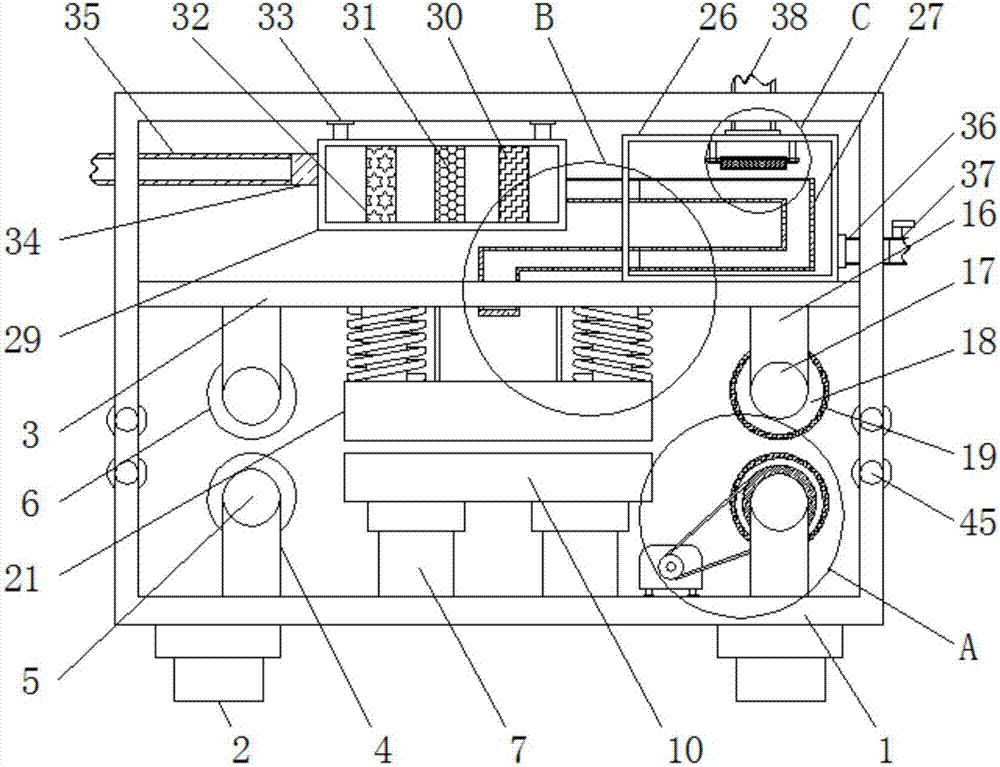

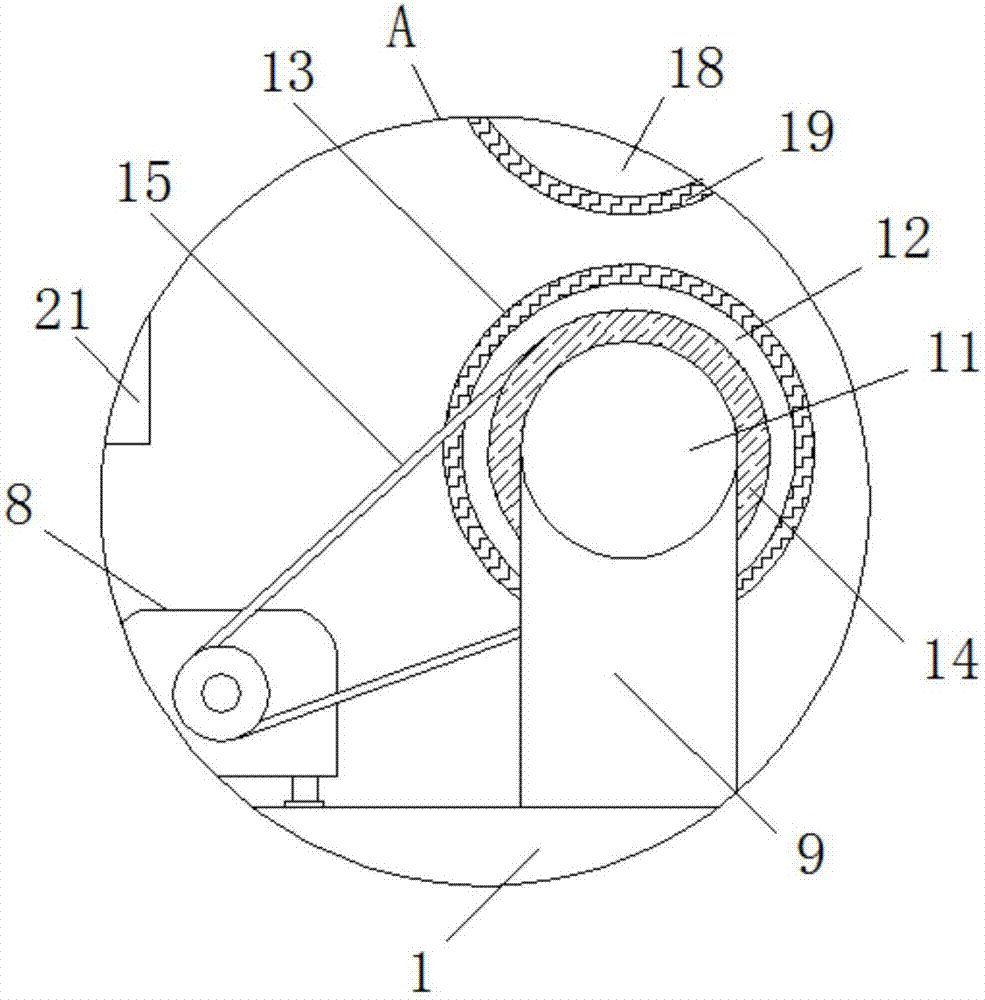

Textile fabric shaping, production and processing device

InactiveCN110067105AGuaranteed flatnessGuaranteed cleanlinessMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention provides a textile fabric shaping, production and processing device. The textile fabric shaping, production and processing device comprises a processing box, wherein a mounting frame ismounted in the processing box; and a fabric is conveyed on the mounting frame, a negative-pressure neatening mechanism, an incineration mechanism, a smoothening mechanism and a dust cleaning mechanismare separately mounted on the mounting frame in the fabric conveying direction, a rolling mechanism is installed outwards during processing, and after being subjected to singeing treatment, home textile fabrics are subjected to rotary scraping cleaning of ash incineration by using the dust cleaning mechanism before rolling; and during cleaning, rotation switching of the dust cleaning mechanism isutilized, a pressing roller is used for carrying out rolling and tensioning adjustment and smoothening treatment on the fabric to be rolled, the fabric is always smooth in a rolling process, and theproblem that the fabric has wrinkles in the rolling process after singeing is solved.

Owner:浙江常鑫纺织品有限公司

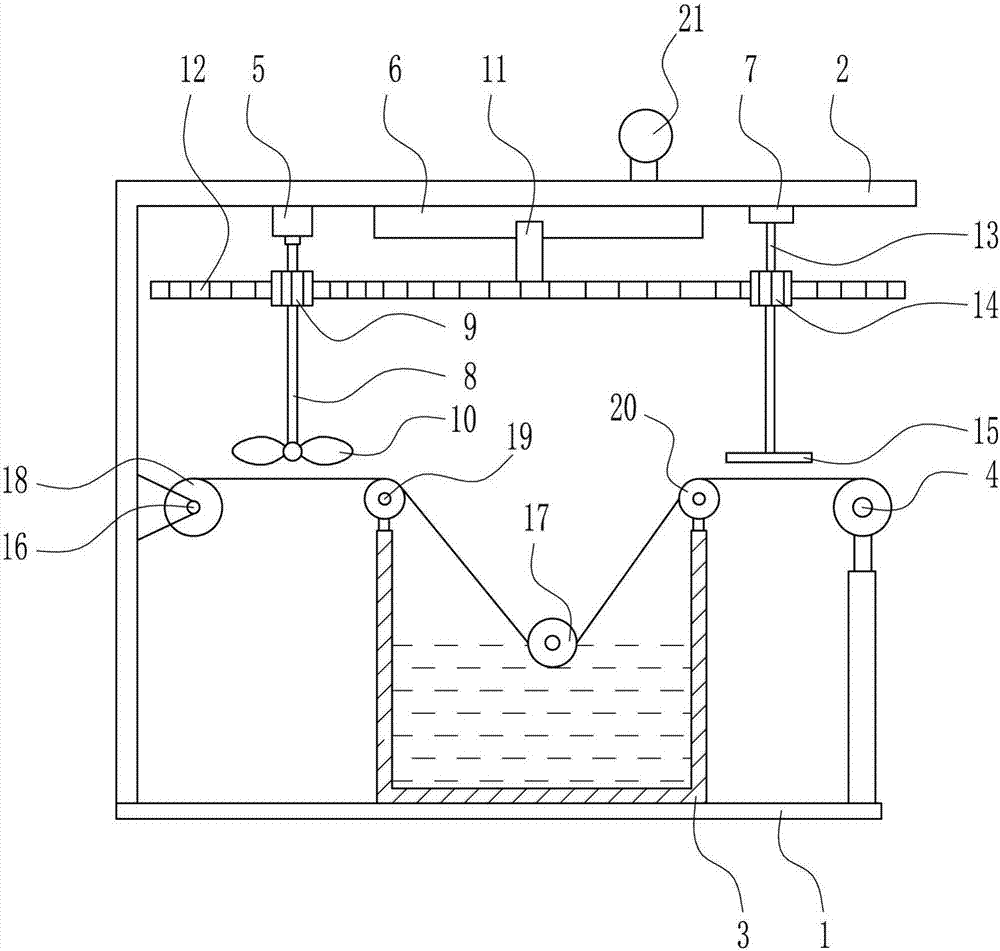

Textile high-efficiency dyeing device

PendingCN107974783AControl the degree of singeingImprove singeing effectSingeingLiquid/gas/vapor removalMechanical engineeringDyeing

The invention relates to a textile high-efficiency dyeing device, in particular to a textile high-efficiency dyeing device. The technical problem to be solved is to provide a textile high-efficiency dyeing device which is high in dyeing efficiency, is good in dyeing effect, and can achieve singeing and air drying at the same time. To solve the technical problem, the invention provides a textile high-efficiency dyeing device including a bottom plate, an L-shaped support, a dyeing pool, a releasing roller, a first motor, a first sliding rail, a first bearing seat, a first rotation rod, a first gear and first vanes; the L-shaped support, the dyeing pool, and the releasing roller are arranged on the bottom plate from left to right; and the first motor, and the first sliding rail and the firstbearing seat are successively arranged on an inner horizontal plane of the L-shaped support. The textile high-efficiency dyeing device uses the first motor and a second motor as a drive so as to allowthe first vanes and a heating plate to rotate in a positive and negative alternate manner, and can perform air-drying and singeing on the textile.

Owner:绍兴明业印染有限公司

Textile printing and dyeing equipment and using method

PendingCN112030396AImprove securityQuality assuranceMechanical cleaningPressure cleaningPolymer chemistryEngineering

The invention discloses textile printing and dyeing equipment, and relates to the field of printing and dyeing. The textile printing and dyeing equipment comprises a bracket, a dehumidifying mechanism, a singeing mechanism, a sweeping wheel mechanism and a printing and dyeing mechanism. After cloth enters the dehumidifying mechanism, the cloth is tidied and dried, and fluff on the surface of the cloth is erected by static electricity; after the cloth enters the singeing mechanism, the fluff is blown out through front upper-layer hot air to improve the fluff erecting effect; the fluff is suckedby a suction port in a lower layer, coked and brought into a collecting box by an air suction port; the singed cloth enters the sweeping wheel mechanism, so that possibly remaining fluff coke balls or other impurities are swept away; and then the cloth is dyed by the printing and dyeing mechanism and is dried, so that the printing and dyeing effect is guaranteed.

Owner:苏州云刚智能科技有限公司

Printed and dyed fabric singeing device

The invention discloses a singeing device for printing and dyeing fabrics, which is arranged in a singeing chamber to perform singeing treatment on fabrics, including a cloth feeding assembly, a front-end brushing box, a singeing machine unit, and a cooling water roller arranged in sequence from left to right , rear-end brush box, dry cleaning box, rolling car and cloth drop frame assembly; the front-end brush box and the rear-end brush box have the same structure, and there are brush roller sets inside, and the brush roller sets include multiple brush rollers arranged oppositely. There are bristles on the top, and the outside of the bristles has an electrostatic adsorption layer for absorbing dandruff; the singeing machine unit includes two side-by-side first singeing space and second singeing space, the first singeing space and the second singeing space have the same structure. The present invention performs singeing and brushing twice, which can effectively improve the singeing effect and make the fabric more regular and flat. At the same time, the flame generator is provided with a flow regulating valve, which can set the flow rate according to the needs of use to meet different needs. Fabric singeing needs.

Owner:HUNAN JICHANG SILK

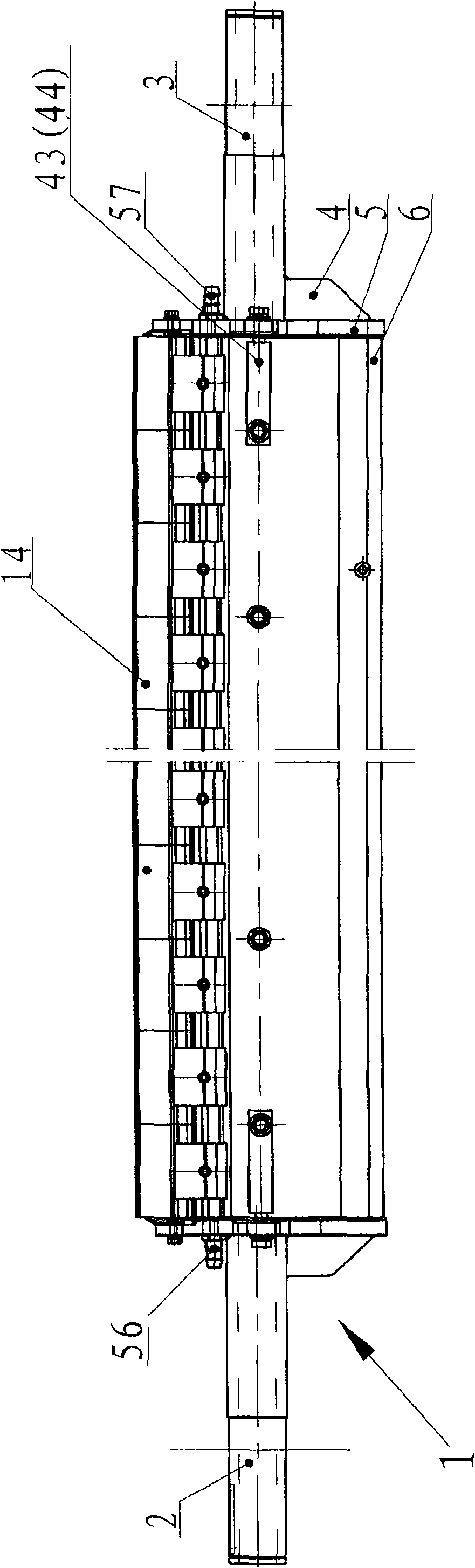

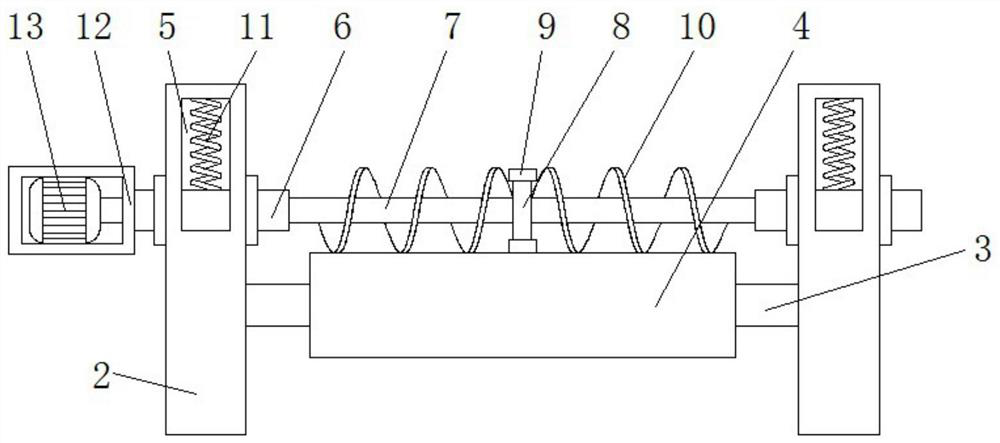

Fuel gas infrared textile singeing frame and singeing method thereof

The invention relates to a fuel gas infrared textile singeing frame and a singeing method thereof. The singeing frame comprises a rack, a rolling roller group, a first infrared combustor, a second infrared combustor and a textile transmission device, wherein the textile transmission device is used for driving a textile to move along the rolling roller group; the textile sequentially passes through the first infrared combustor and the second infrared combustor; the first infrared combustor acts on a front surface or a back surface of the textile; correspondingly, the second infrared combustor acts on the back surface or the front surface of the textile; the infrared is rapidly warmed and pre-heated by utilizing a rapid thermal radiation conduction and penetration capability of infrared rays; residual flame generated in a combustion process of the infrared combustors is used for rapidly igniting fluff on yarn surfaces, which are sufficiently heated, of the textile, so that the fluff on the front and back surfaces of the textile and the yarn surfaces in the textile are singed and the optimal singeing effect is realized; a production speed is rapid and a machine is simple to operate; singeing traces are not remained by infrared singeing and the loss on the textile is less than 0.5 percent; dust is generated on the surface of the textile and is easy to clean, so that production requirements are met.

Owner:DONGGUAN ZHONGXIN TEXTILE MACHINERY

Contact singeing frame

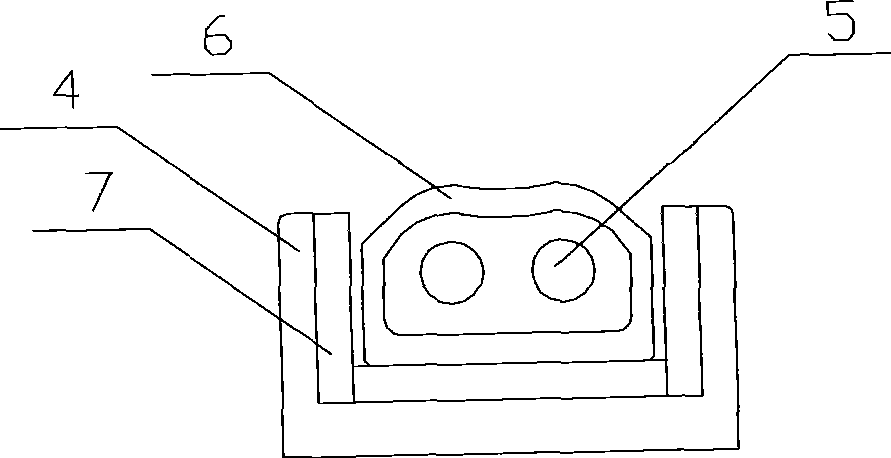

The invention relates to a contact type singeing machine for textile, comprising a machine body, a driving rubber roller disposed on the machine body, and a plurality of cloth guidance rollers disposed on and inside the machine body, and a contact type singeing device inside the machine body. The contact type singeing device comprises a concaving shaped case and two electrically heating rod disposed therein, a high temperature alloy steel body for forming a high temperature radiation zone is assembled by covering peripheral of the electrically heat rod. Firstly, due to electrically heating singeing mode, production cost is greatly reduced under the circumstance that price of oil and gas raise day by day; secondly, by installing a stentering heating board above the electrically heating rod, and forming high temperature radiation zone, not only floss on the surface of the fabric is burned, but also floss in intervals formed by warp and weft of the fabric is burned; meanwhile, heat energy recovery device is adopted, energy is saved; and lifting fabric passing device is designed, and shortcoming of cloth burning and electricity break and stop is thoroughly eliminated.

Owner:QINGDAO JINDING MACHINERY

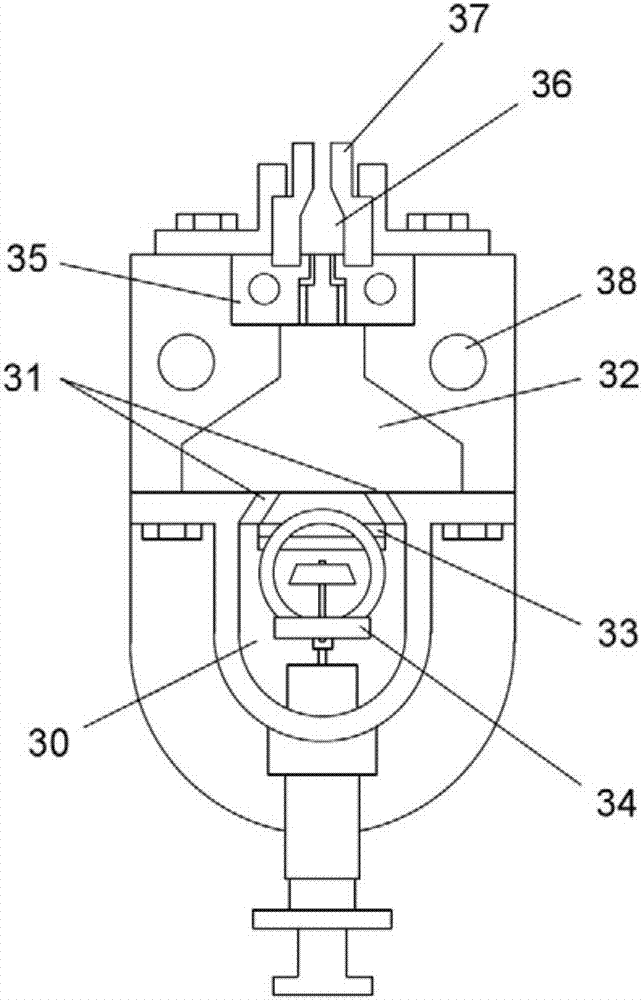

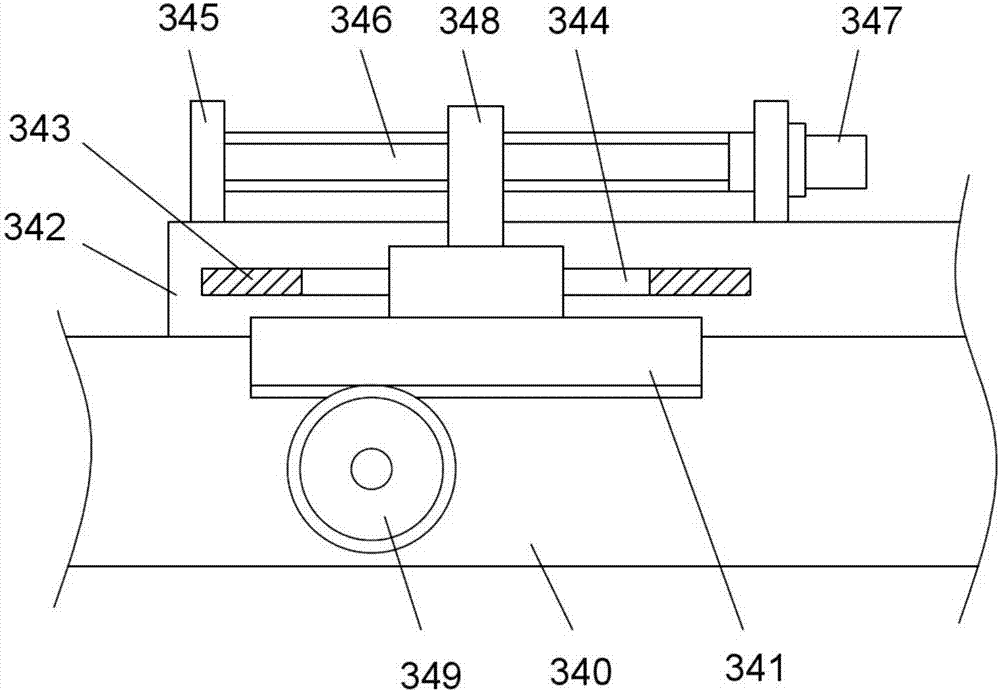

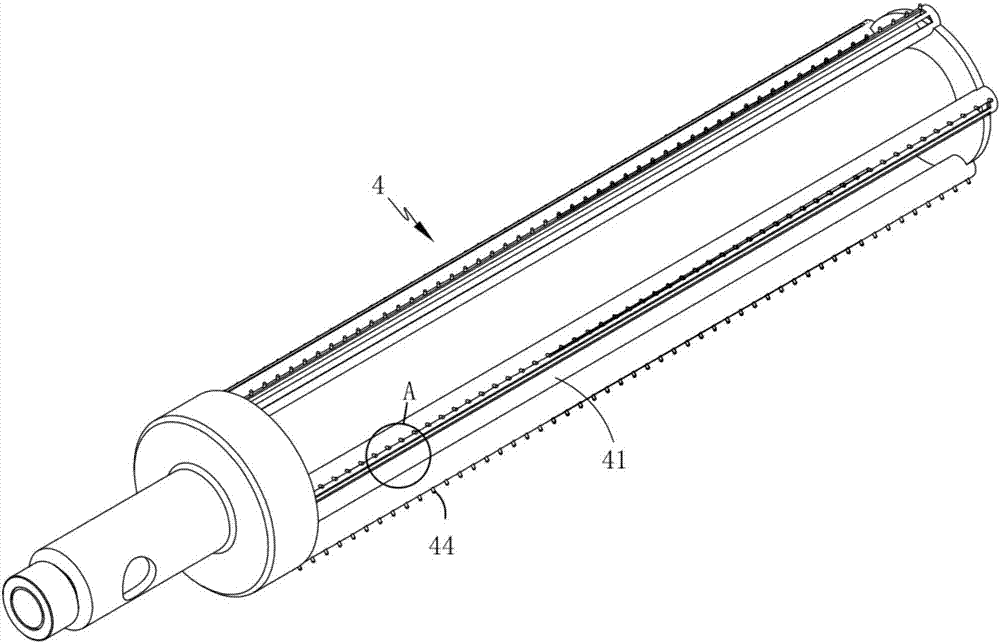

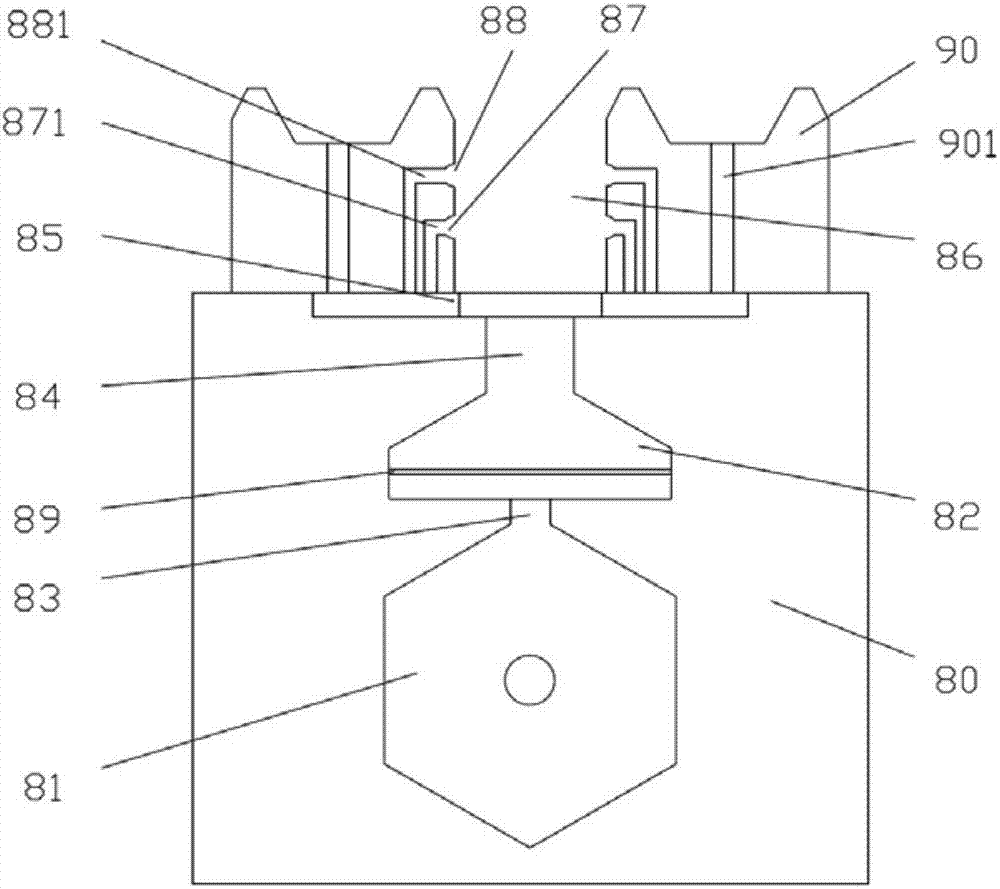

Winding drum type singeing mechanism

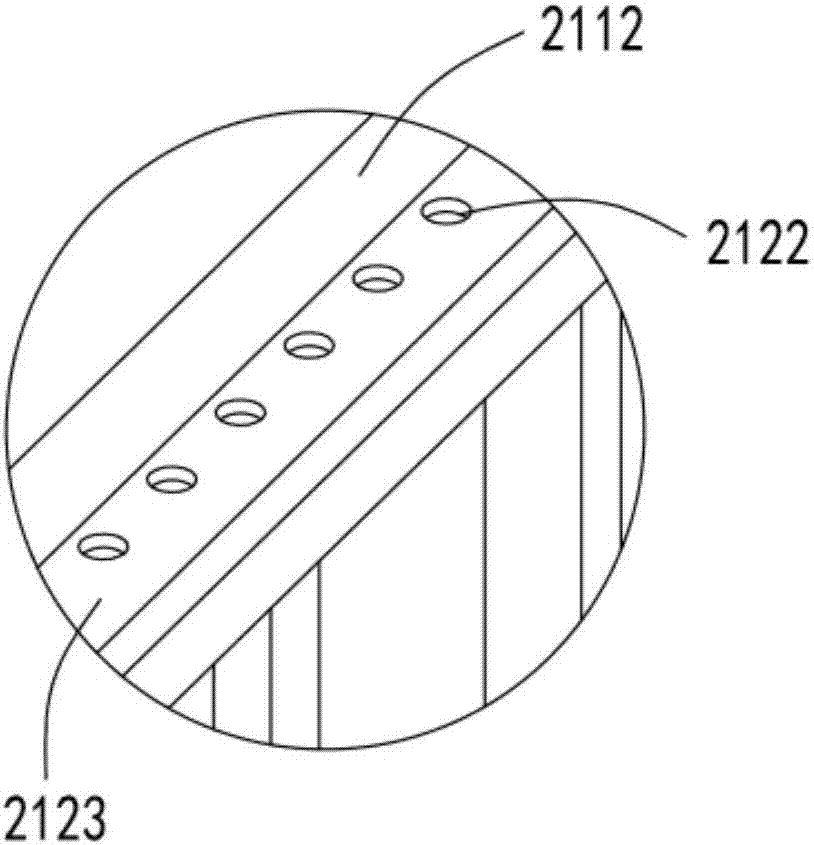

InactiveCN107217431AEasy to put inWon't hurtMechanical cleaningPressure cleaningEngineeringConductor Coil

The invention relates to a drum-type singeing mechanism, which includes a main body mechanism, the main body mechanism includes a first cylinder, a second cylinder arranged in the first cylinder, and an unwinding roller arranged in the second cylinder , the side of the first cylinder is opened with a first outlet, the side of the second cylinder is opened with a second outlet, and a transmission channel is formed between the first cylinder and the second cylinder; and burning The wool mechanism, the singeing mechanism includes a combing device arranged on the first outlet side for combing the hair on the surface of the cloth to one side, and a combing device arranged between the first cylinder and the second cylinder and behind the combing device. The singeing device at the end; the invention overcomes the problem that the fluff on the cloth surface cannot be fully combed, and the hair on the fabric cannot be supported and easily shakes during the singeing process, resulting in incomplete singeing.

Owner:CHANGXING DEHONG MACHINERY CO LTD

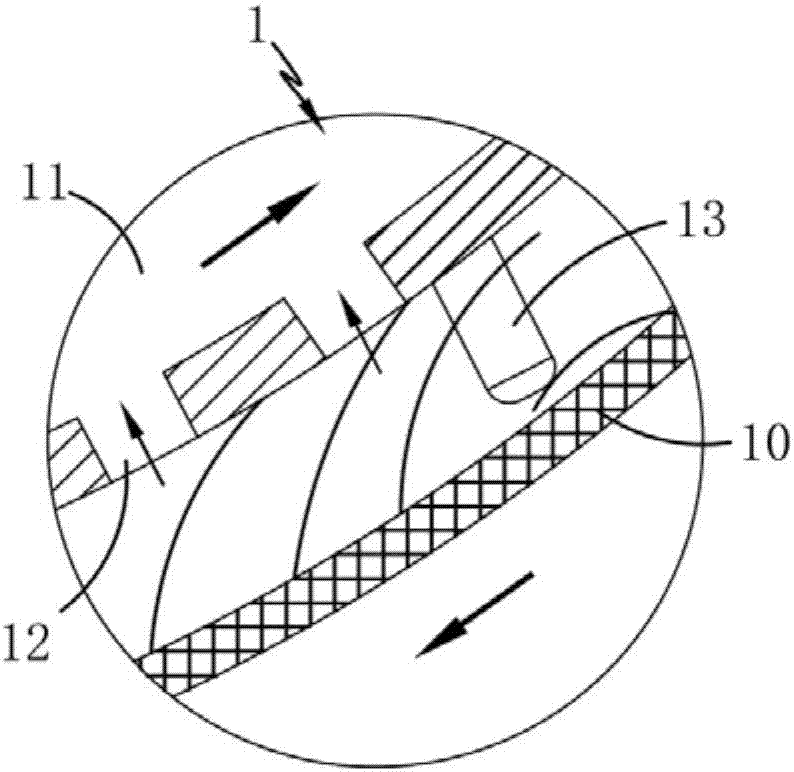

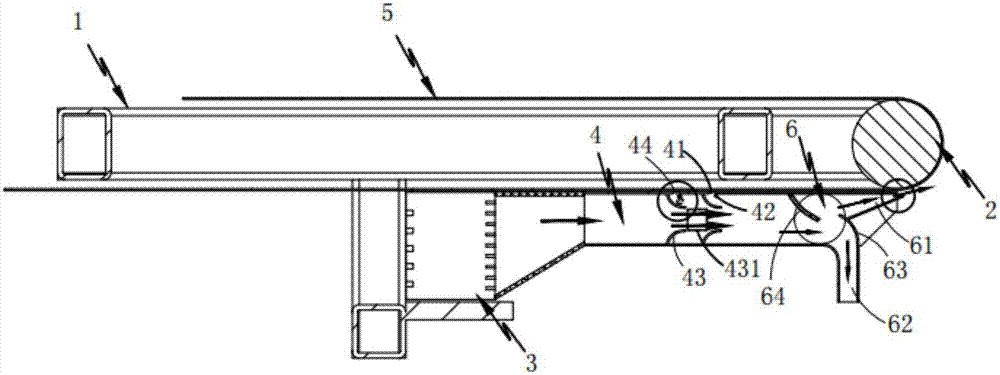

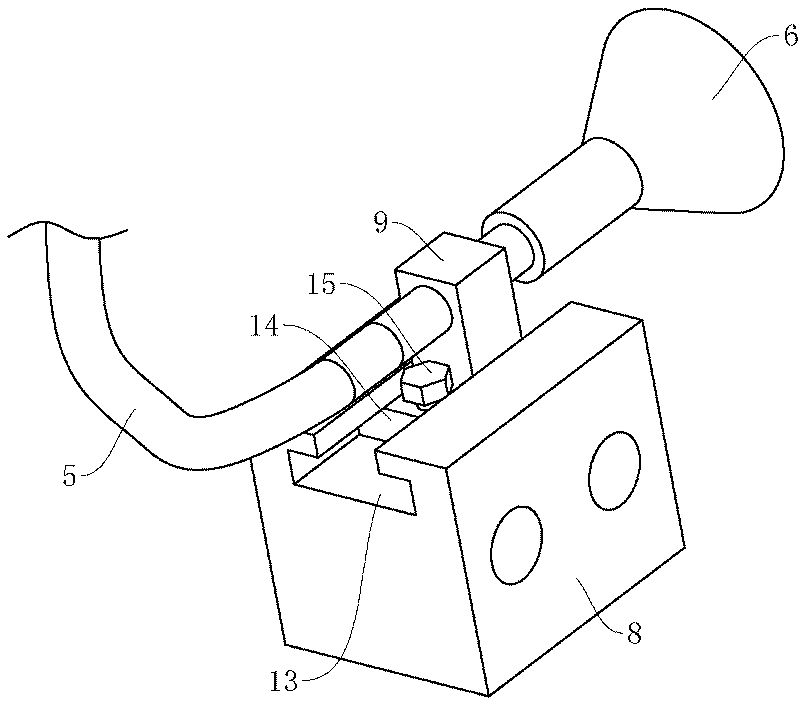

Adsorbed fabric singeing equipment

InactiveCN107227579AReduce circulation spaceAchieve hair removalSingeingRougheningFiberInsertion stent

The invention relates to adsorbed fabric singeing equipment. The adsorbed fabric singeing equipment comprises a support, a fabric guiding roller, an air current channel, a blowing and sorting channel and a collecting channel, wherein the air current channel is located below a fabric and comprises an adsorption hole formed in the top of the air current channel, a baffle which is fixedly arranged on one side of the adsorption hole and an electric heating wire arranged on one side of the adsorption hole; an air current accelerating area is formed between the baffle and an air current channel wall opposite to the baffle; air current flows along the air current channel and forms a negative pressure area at the adsorption hole via the air current accelerating area; the blowing and sorting channel is located below the fabric guiding roller and is communicated with the air current channel; gas penetrating through the air current channel forms a gas curtain at an air outlet of the blowing and sorting channel via the blowing and sorting channel; the gas curtain is arranged to be tangent to the fabric guiding roller; the collecting channel and the air current channel are arranged in a communicating manner, and the collecting channel is located below the blowing and sorting channel; a diversion plate is arranged between the blowing and sorting channel and the collecting channel; fibers located at the bottom of the air current channel are driven by the air current and are guided by the diversion plate for collecting residues.

Owner:长兴天赫纺织科技有限公司

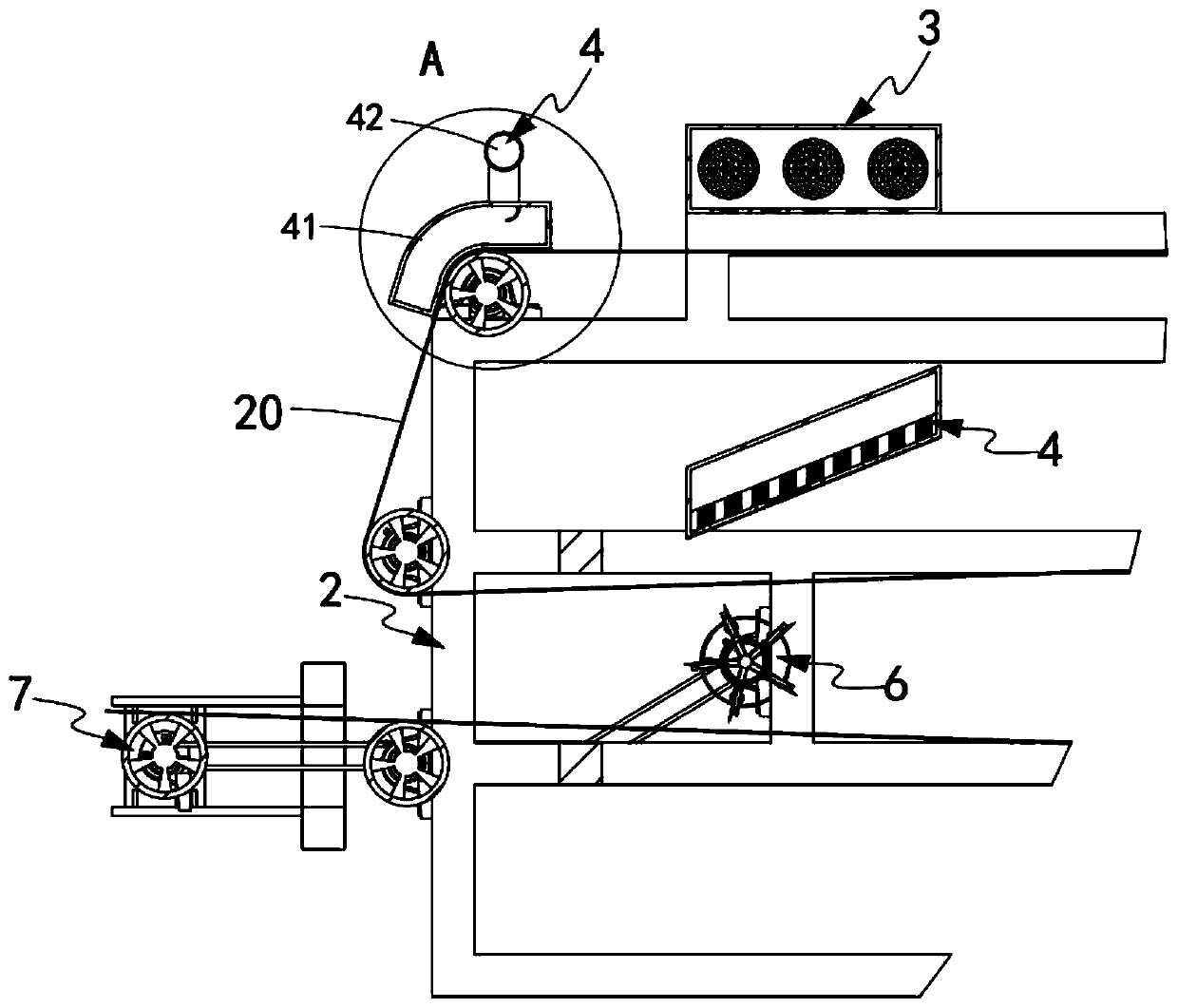

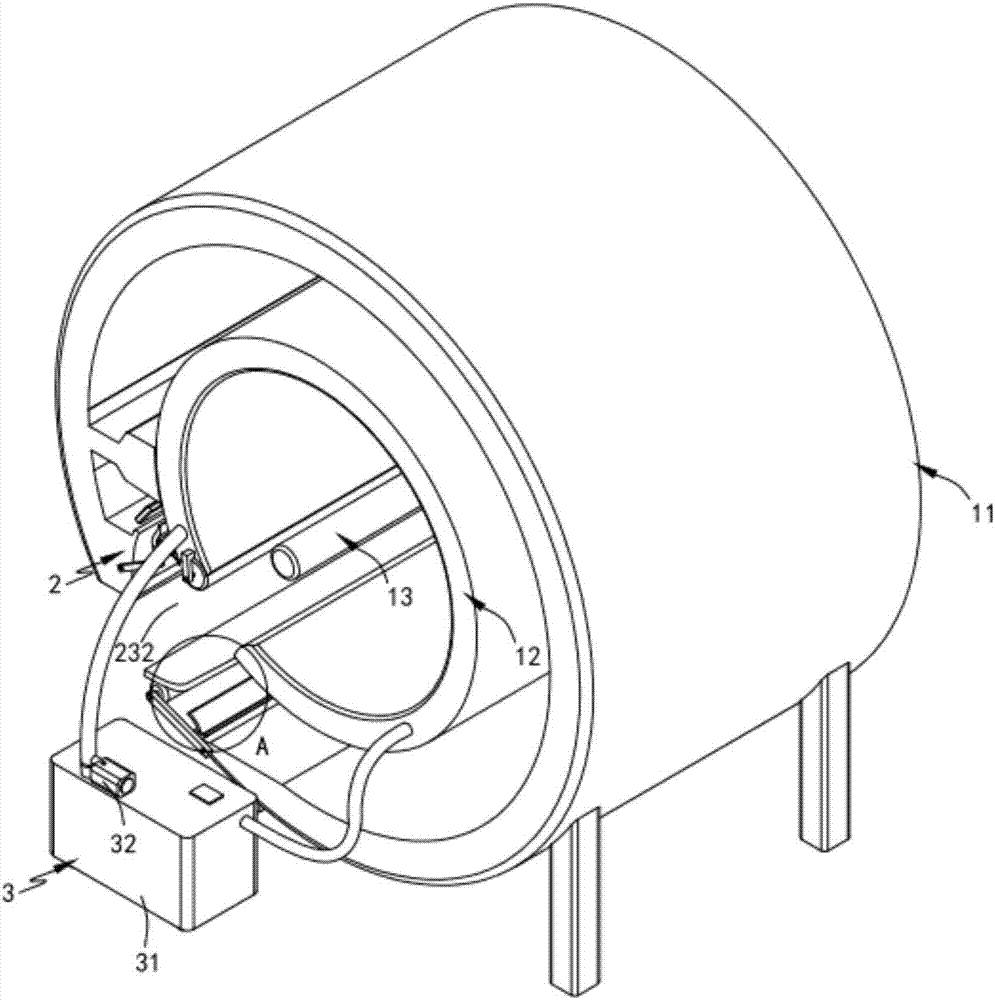

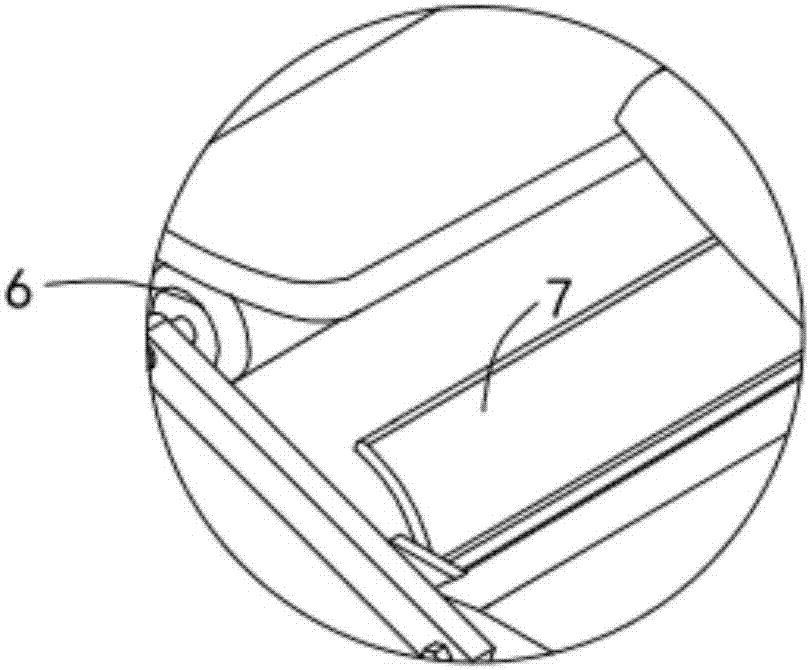

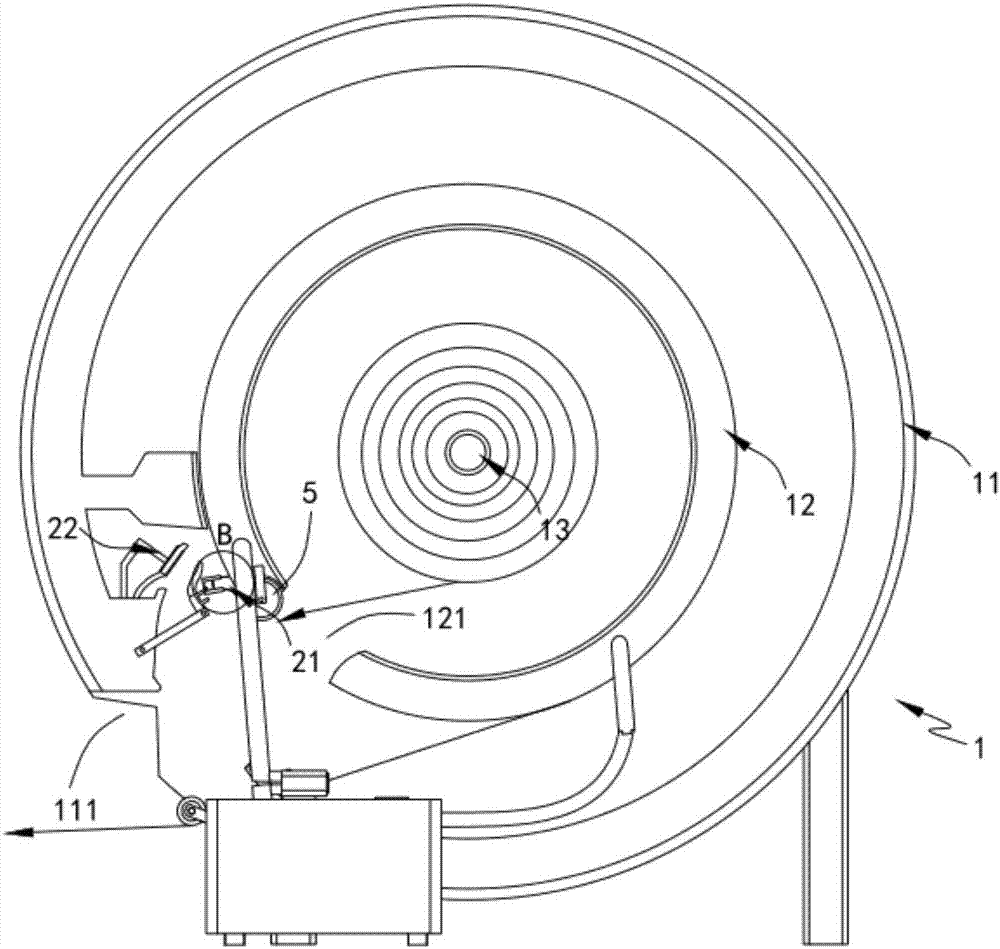

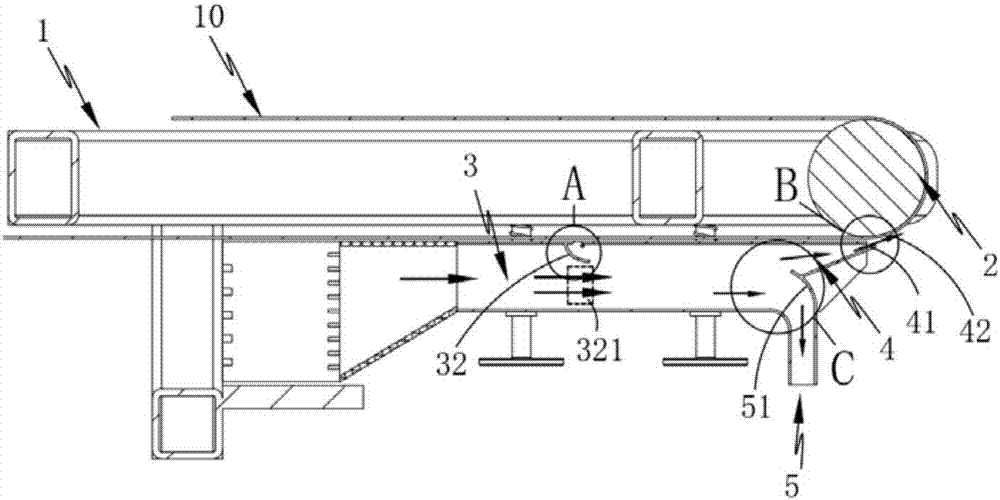

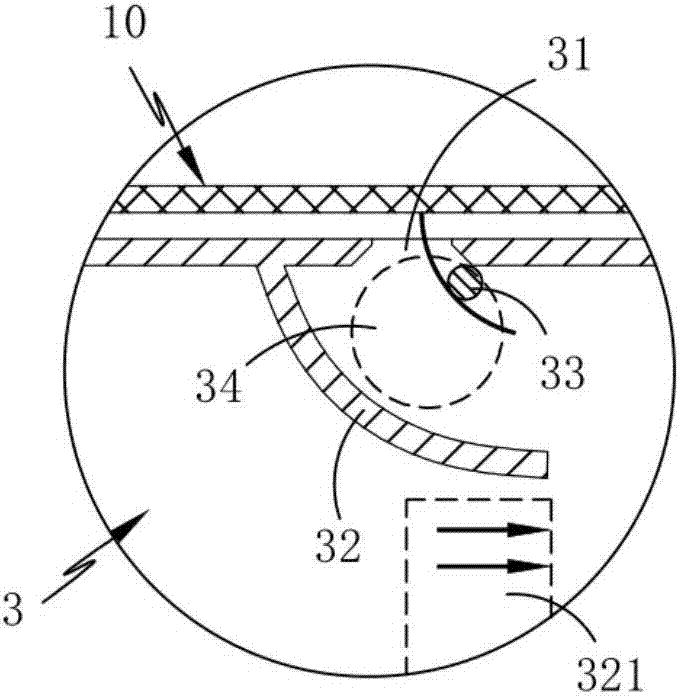

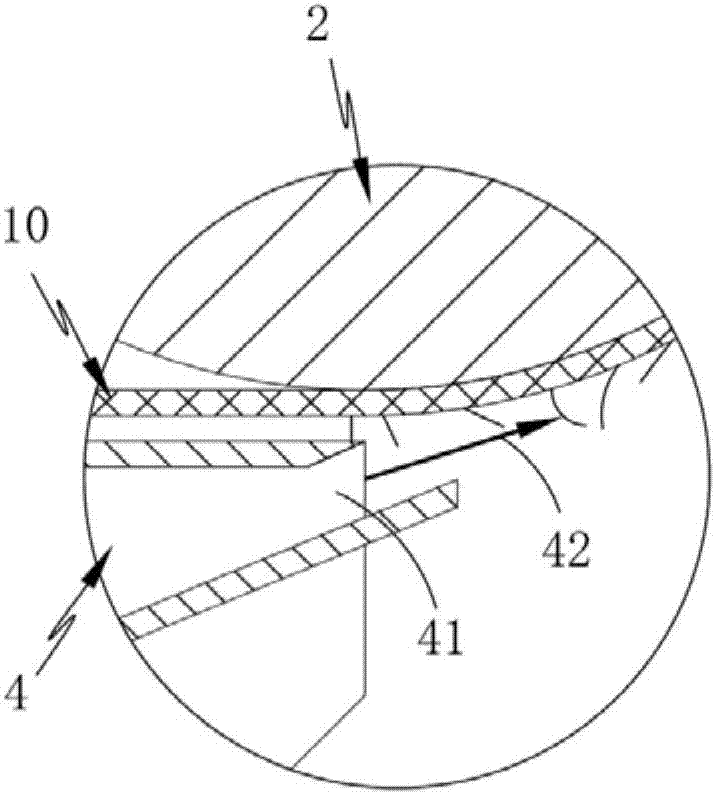

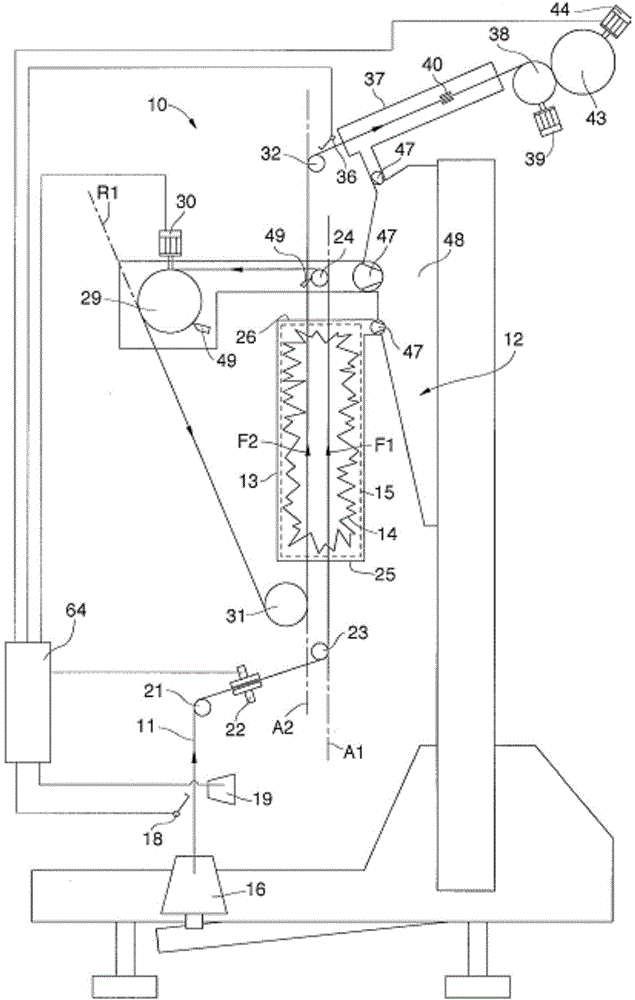

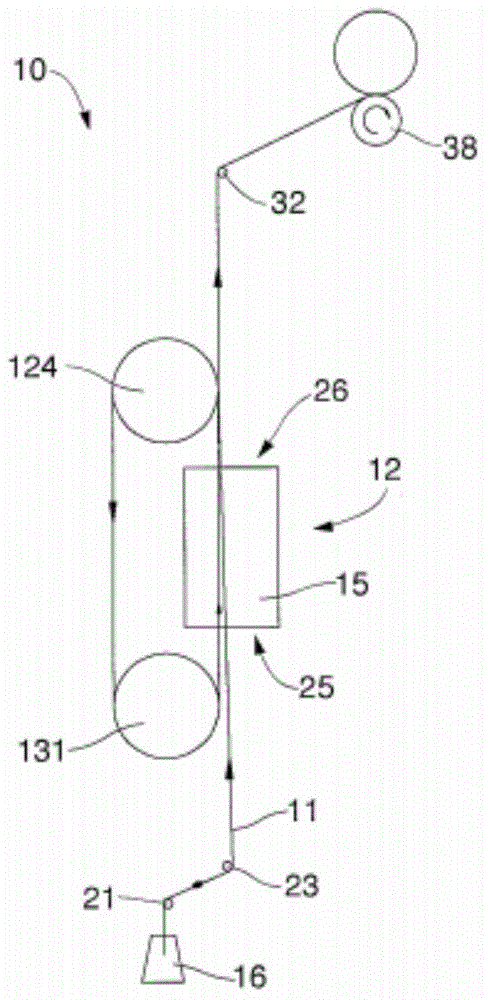

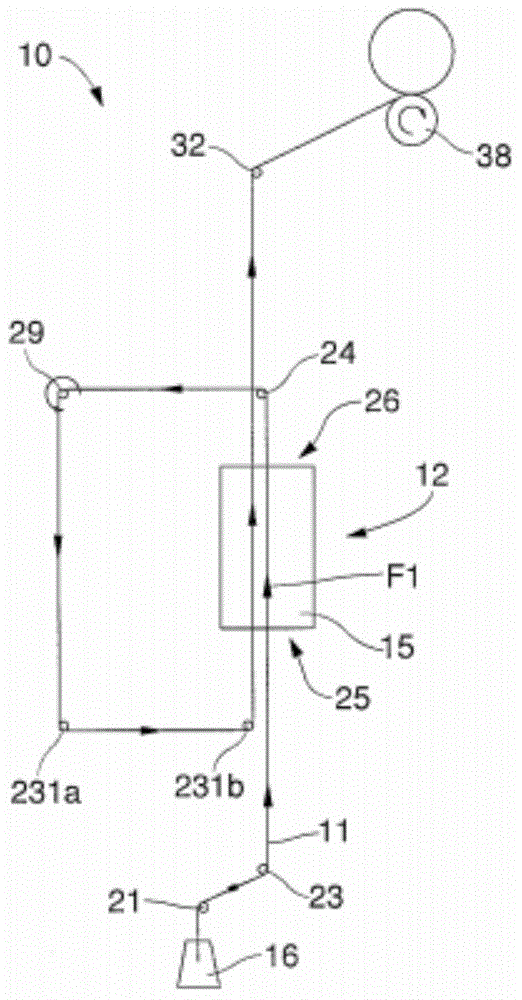

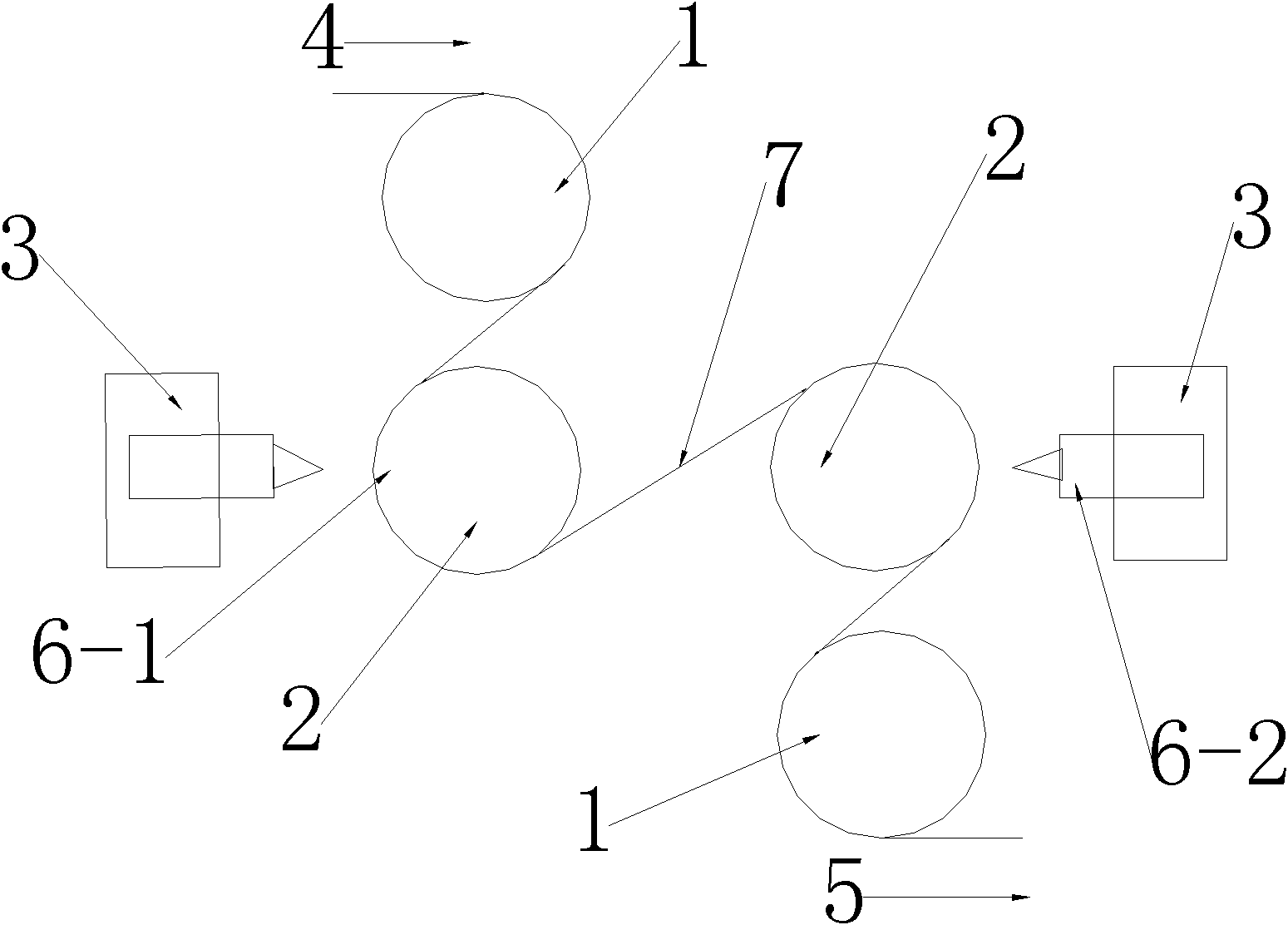

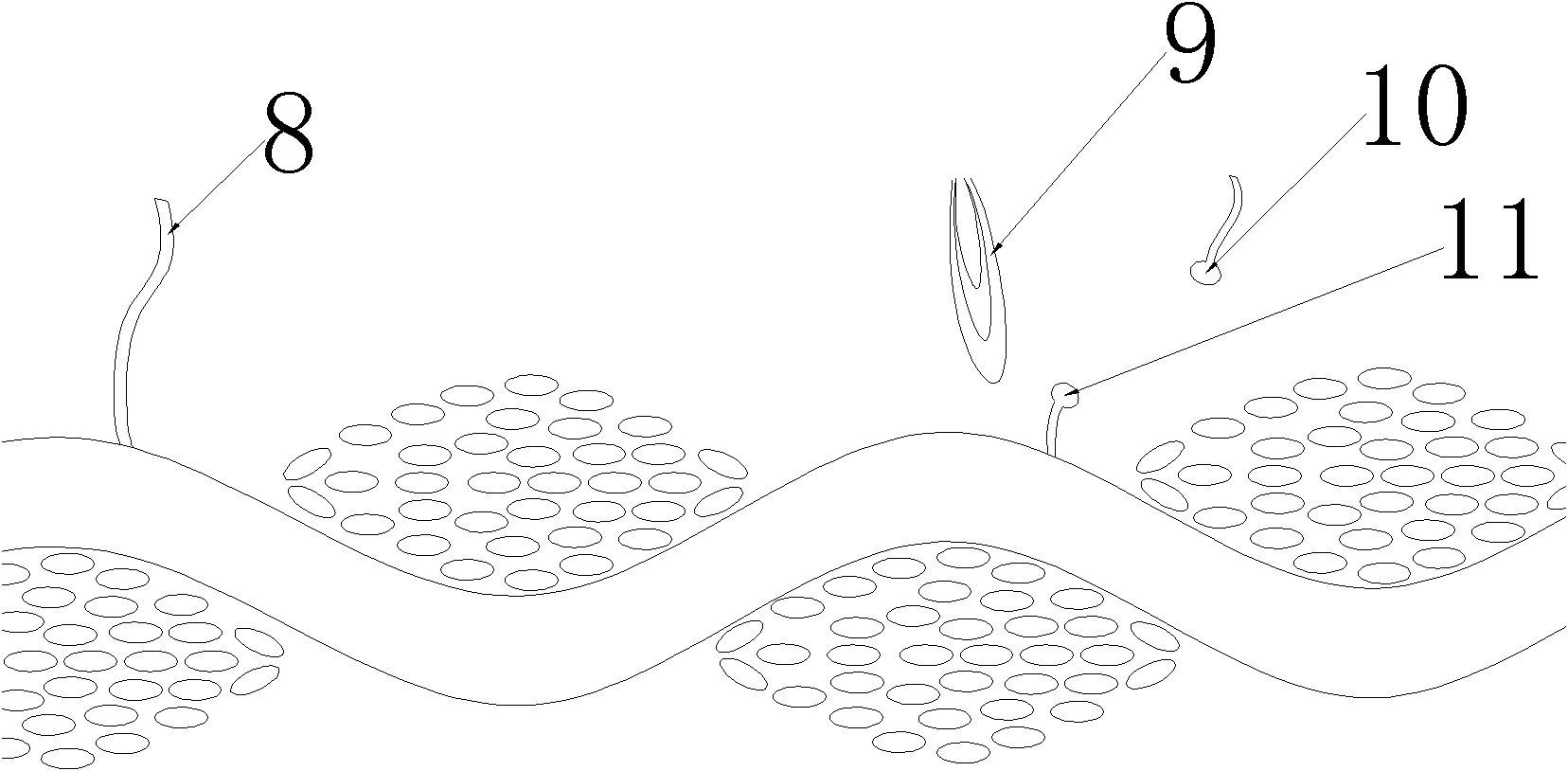

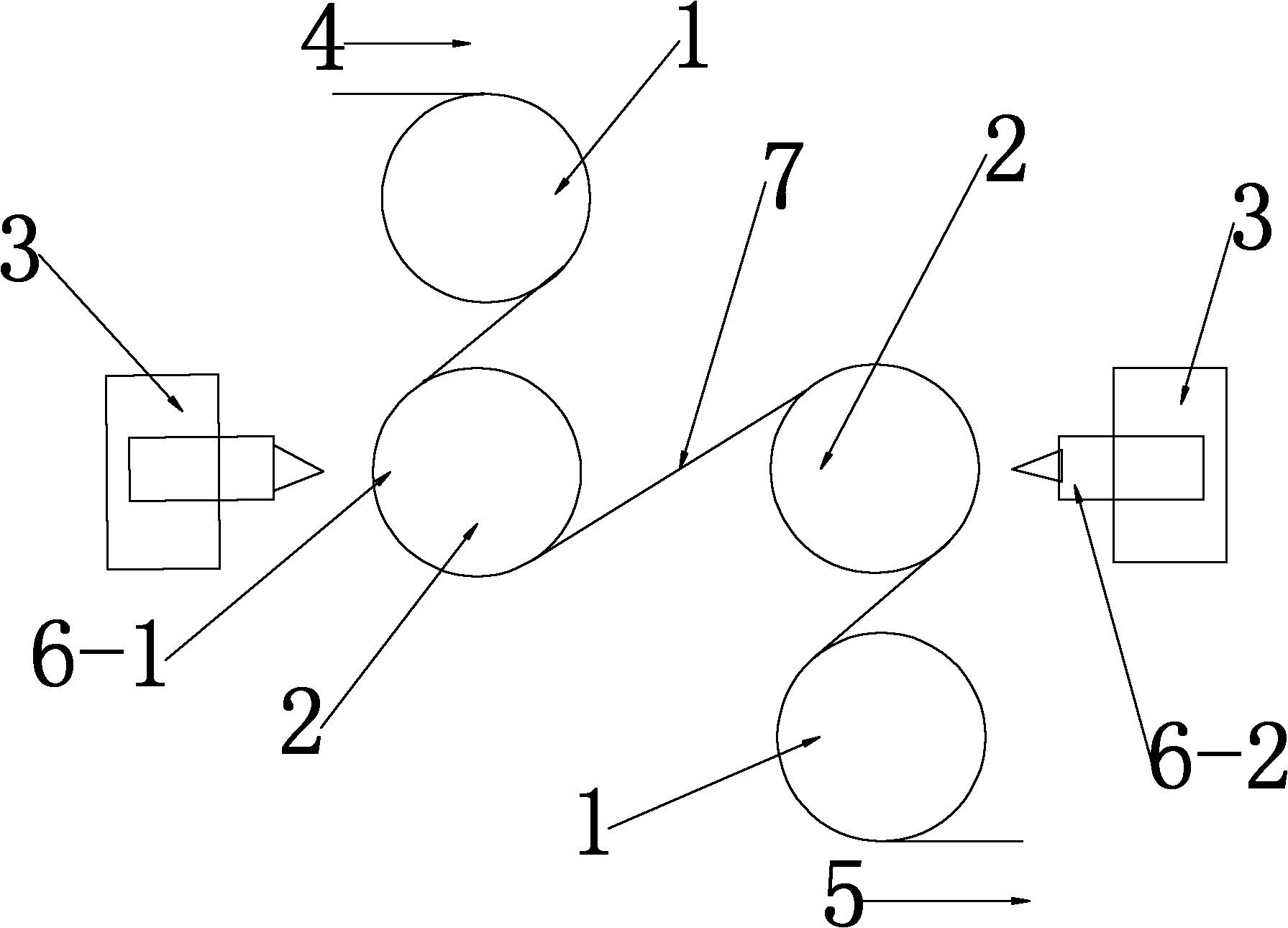

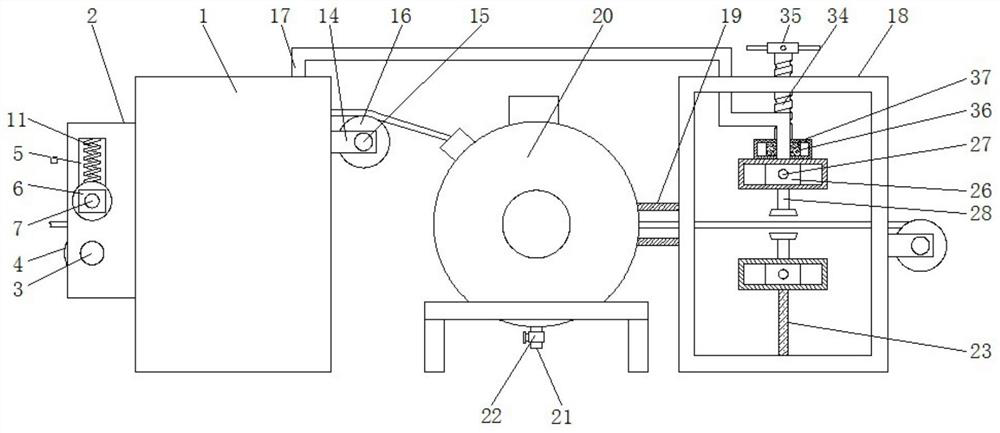

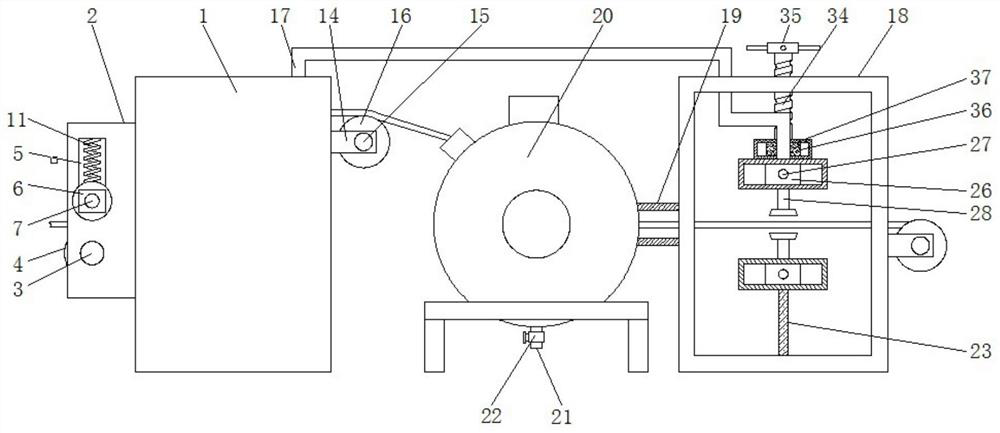

Device and method to eliminate fluff from a yarn

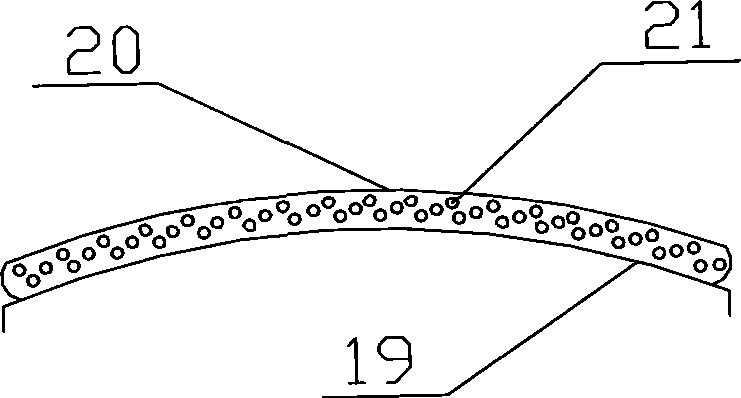

InactiveCN104379824AProlongs the effect of proximity to flamesIncreased efficiency of the singeing processSingeingYarnEngineering

The method to eliminate fluff from a yarn (11) comprises a first step in which the yarn (11) is made to transit in a processing zone (15) of a singeing machine (12) in which a source of high intensity energy (14) is positioned in order to carry out a first pass of removing the fluff. The method comprises a second step in which the yarn (1 1), exiting from said processing zone (15), is picked up again and diverted in order to be made to transit substantially continuously at least a second time inside the processing zone (15), in proximity to the source of energy (14), in order to carry out a second pass of removing the fluff. The second pass occurs in a direction concordant with the first pass. A control and adjustment is provided of the tension of the yarn (11) in at least one point of the diversion, guide and return path, between the first pass (F1) and the second pass (F2).

Owner:SSM萨罗瑞士麦特雷有限公司

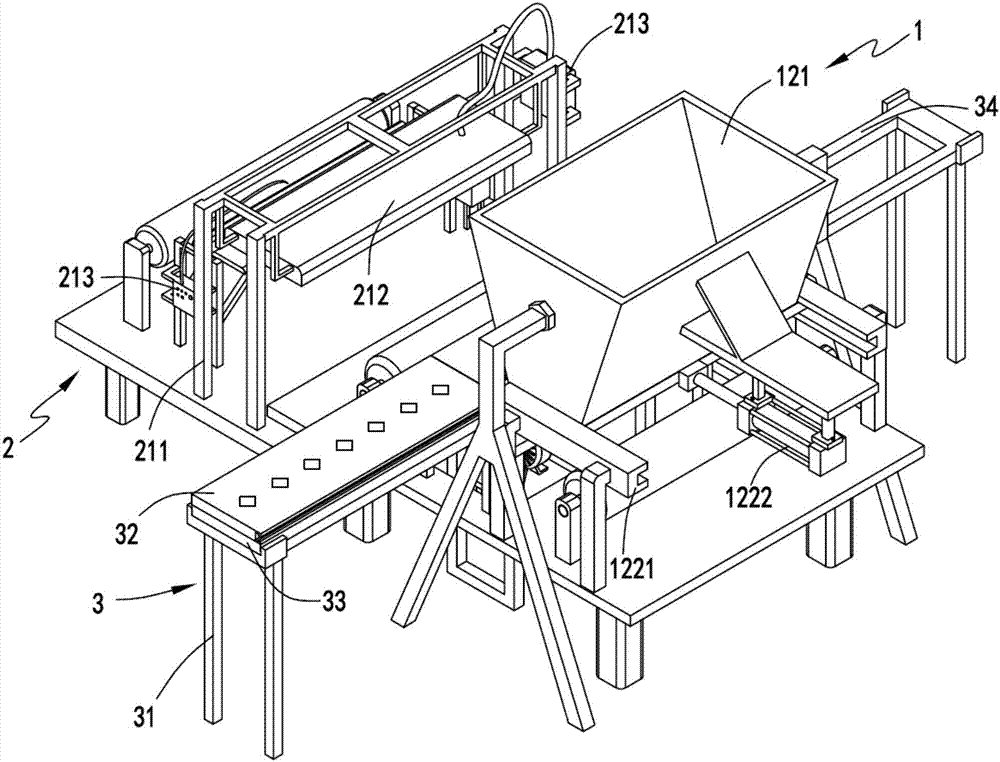

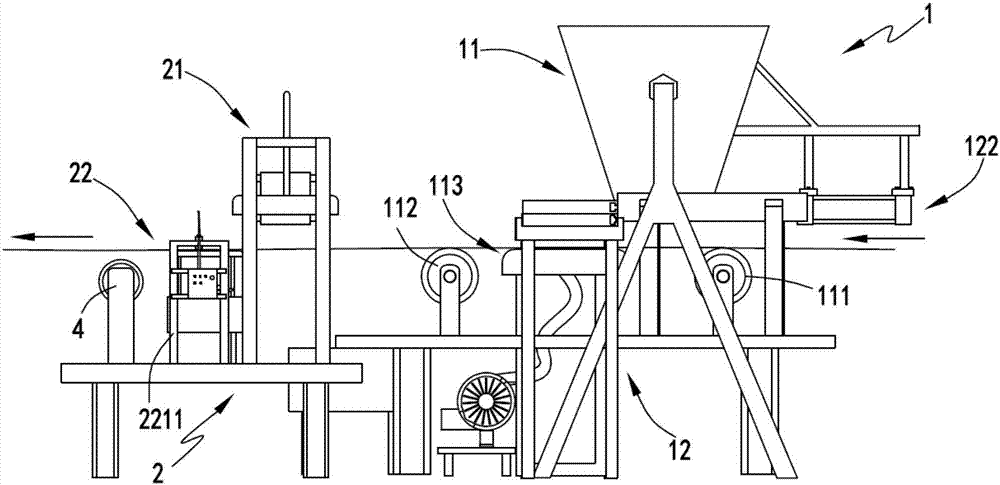

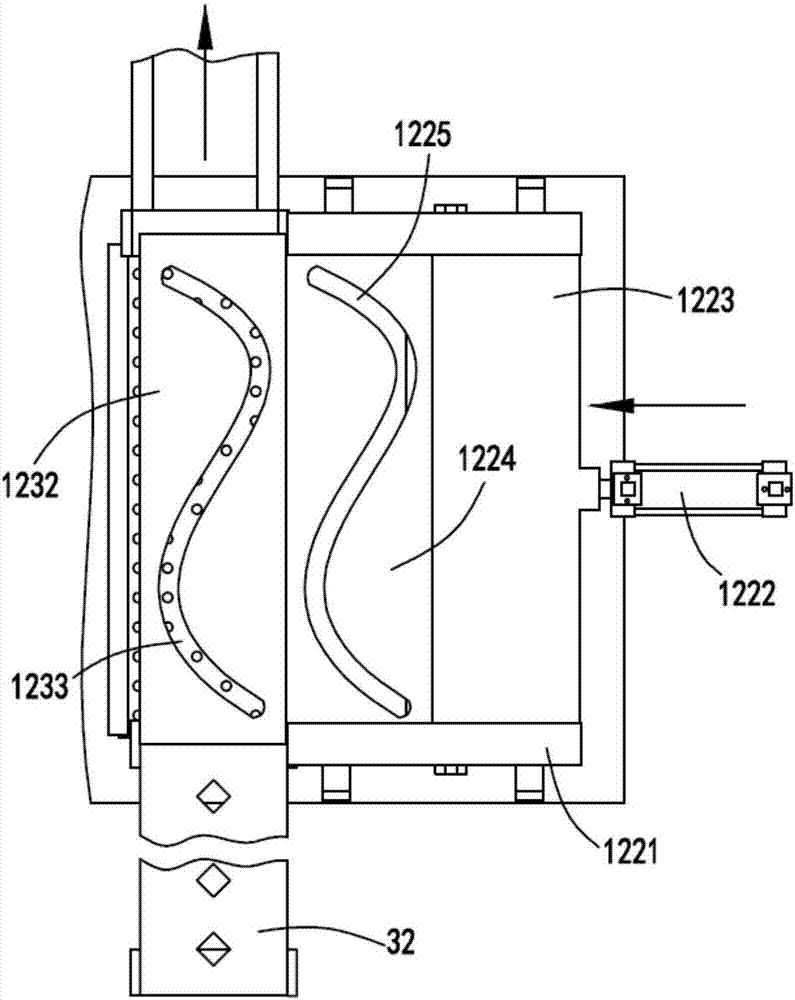

Magnetic adsorption type singeing production line

The invention relates to a magnetic adsorption type singeing production line, which includes a feeding part, which includes a spreading mechanism for spreading metal particles on the surface of textile fabrics during transmission and a shaking mechanism arranged under the fabrics to shake the fabrics The dehairing part, the dehairing part includes a combing mechanism arranged at the rear end of the feeding part and a singeing mechanism arranged at the rear end of the combing mechanism. Burn off the stand-up wool, and collect the waste debris generated during the burning process; the invention overcomes the problem that traditional carding equipment cannot ensure that most of the hair is fully erected during the combing process and the combing process It is easy to damage the fabric and the main body of the fabric during the singeing process, and the waste generated by singeing cannot be collected in time and remains on the fabric.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

Integrated singeing mechanism for spinning

The invention relates to a textile integrated singeing mechanism, which includes a carding assembly, a singeing assembly and a dust removal assembly. The carding assembly includes a negative pressure chamber, an adsorption port and combing teeth; the singeing assembly includes a combustion chamber, which is set on the wall of the combustion chamber The burner, the gas pipe fixed on one side of the burner, and the igniter fixed inside the combustion chamber, the combustible gas in the gas pipe is released through the diffuser channel opened on it and communicated with the combustion chamber. , the flame is ejected through the burner port to form a singeing area; the dust removal component includes a dust removal chamber and a dust suction port opened on the dust removal chamber; the combing component, singeing component and dust removal The fiber is adsorbed and erected, and the fibers are singed with adjustable intermittent fire spraying multiple times, and then the dust after the singeing is collected by negative pressure, which solves the unsatisfactory fiber erection, complex structure and uncontrollable singeing in the prior art technical problems.

Owner:长兴天赫纺织科技有限公司

Textile fabric singeing and printing production line

InactiveCN107217519AGood shaping effectEasy to shapePattern makingTextile decorationEngineeringManufacturing line

The invention relates to a singeing printing production line for textile fabrics, which includes a shaping part, which is used to put metal particles into the hair gap on the surface of the cloth according to the shape of the cloth to be embossed, and the shaping part includes a Support the adsorption mechanism and the upper metal particle mechanism arranged above the cloth; the adsorption hot stamping mechanism, the adsorption hot stamping mechanism is arranged at the rear end of the shaping part, and the adsorption hot stamping mechanism includes a magnetic force mechanism for absorbing the metal particles on the cloth And the singeing mechanism that is arranged on the rear side of the magnetic mechanism and is used to burn off the hair that stands up under the action of the magnetic mechanism; the present invention overcomes the difficulty in setting the shape when the surface of the fabric needs to be burnt according to a predetermined pattern during the singeing process, Inaccurate shaping leads to irregular patterns and low production efficiency.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

Quick singeing equipment

InactiveCN107217433AAchieve the effect of singeing the side bottomNot easy to damageSingeingMaterial scatteringEngineering

The invention relates to quick singeing mechanism. The quick singeing mechanism comprises an upper metal particle part, a magnetic force fluff combing part and a singeing part, wherein the upper metal particle part comprises a material scattering mechanism for scattering metal particles on a surface of a textile fabric; the magnetic force fluff combing part is arranged at rear end of the upper metal particle part and comprises a negative pressure adsorption mechanism which is used for adsorbing a lower surface of the textile fabric and a magnetic fluff combing mechanism which is arranged above the negative adsorption mechanism and is used for adsorbing the metal particles on the textile fabric; the singeing part is arranged at rear end of the magnetic force fluff combing part and comprises a singeing mechanism which is used for removing vertical fluffs on the surface of the textile fabric and a cooling mechanism which is arranged under the singeing mechanism and is used for cooling the surface of a textile fabric main body. According to the quick singeing mechanism, the problems that by adopting conventional fluff combing equipment, full standing of a large part of fluffs cannot be ensured in a fluff combing process so as to finally cause incomplete of the subsequent singeing and the fabrics are easily damaged by conventional fluff combing equipment in a fluff combing process are solved.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

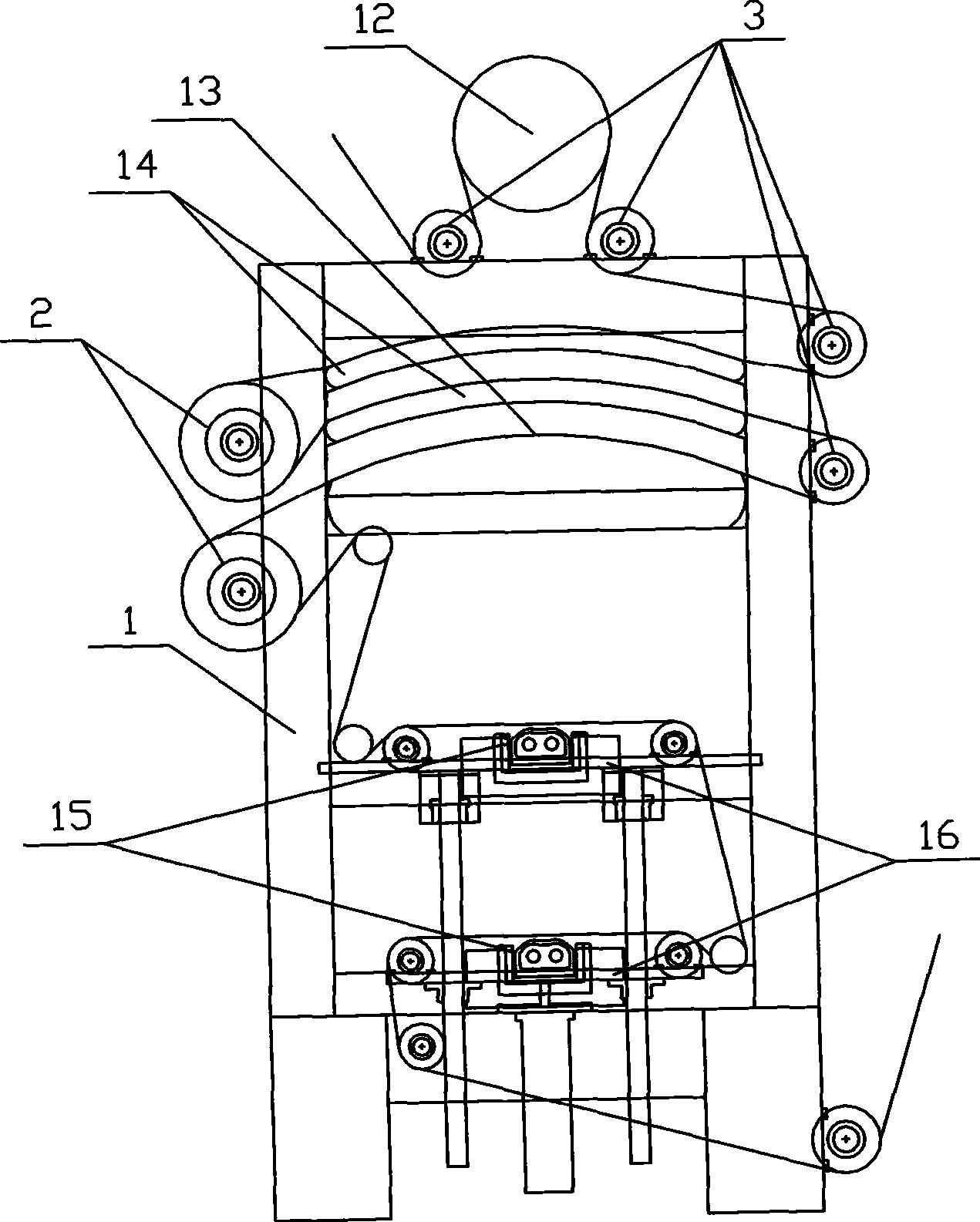

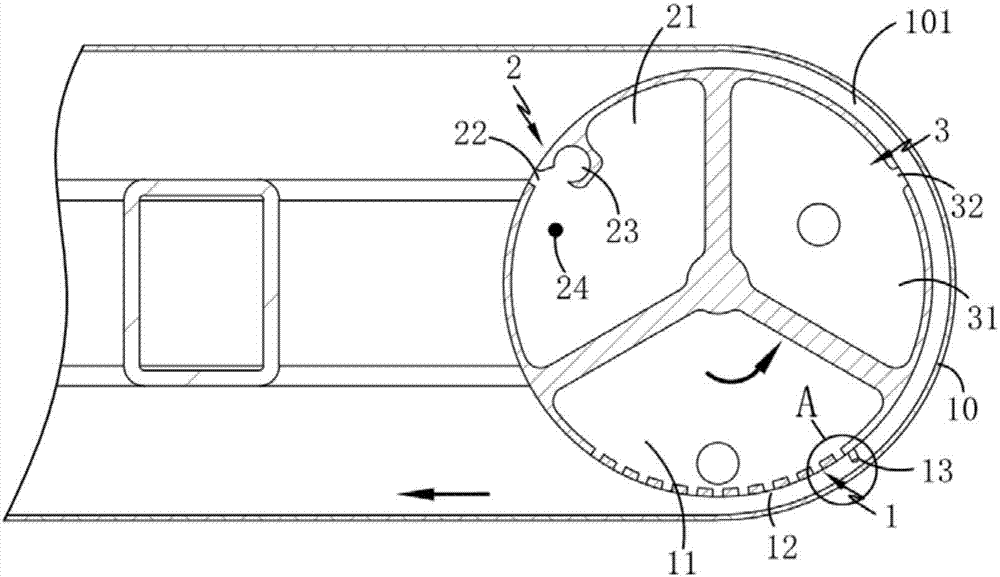

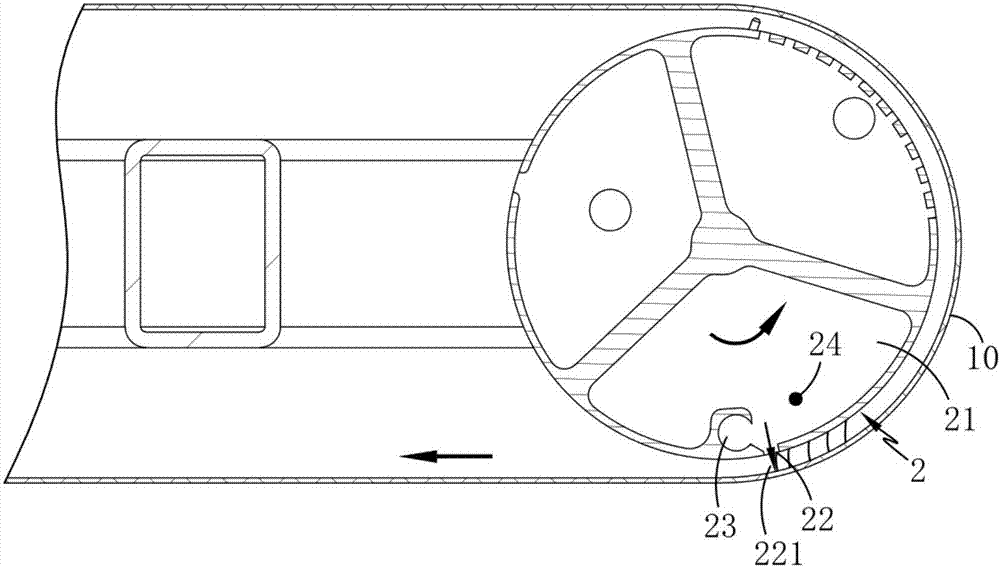

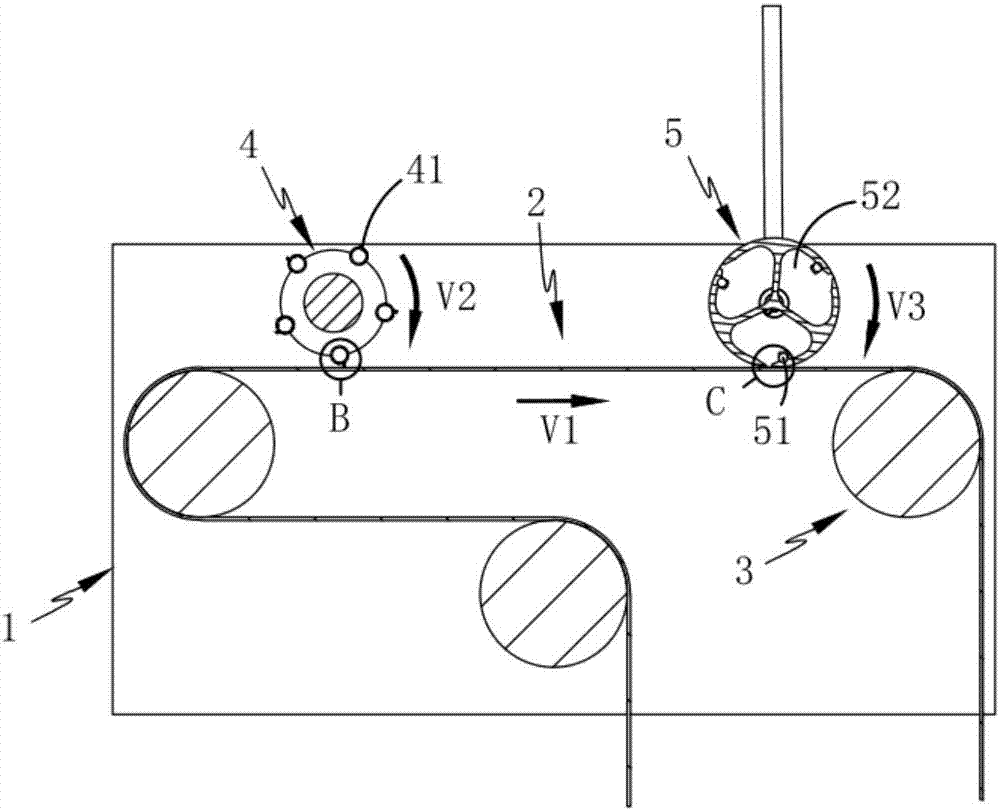

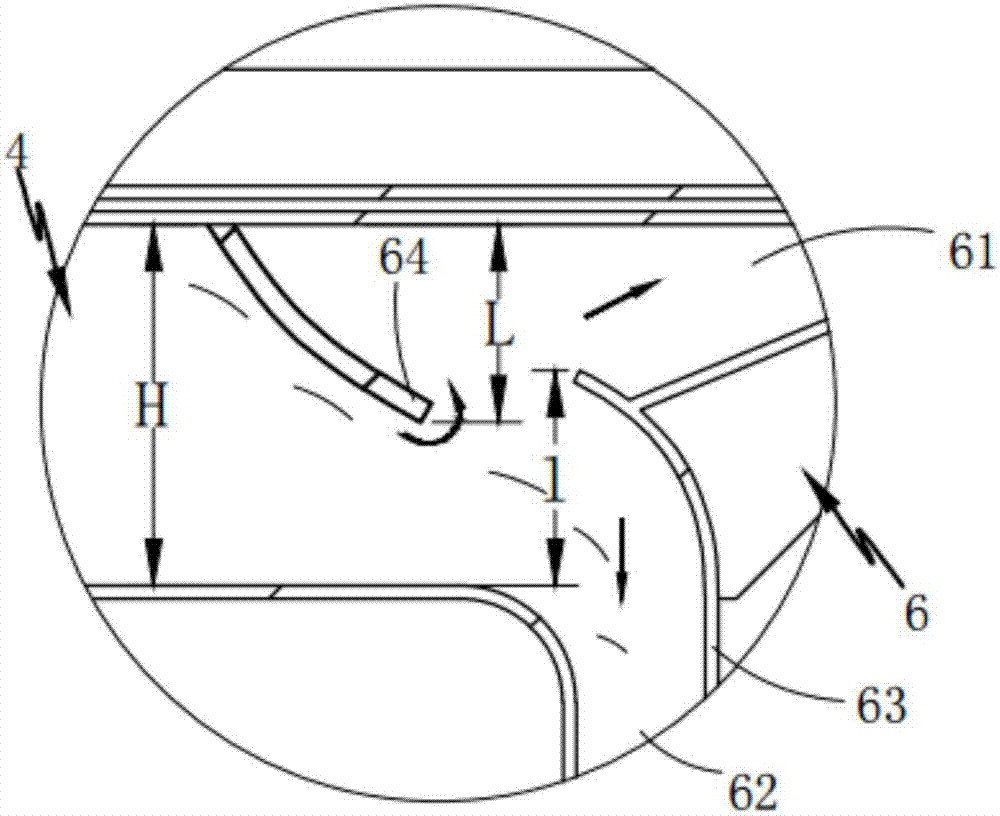

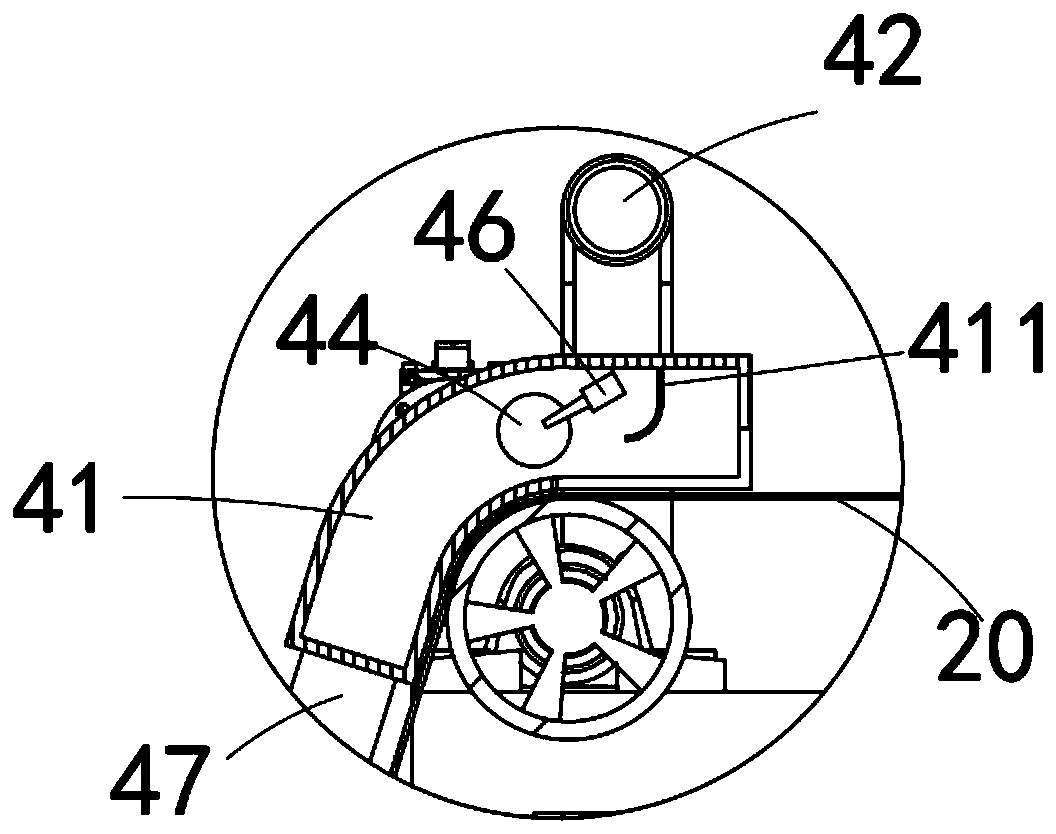

Rotary contact type cloth singeing mechanism

The invention relates to a rotary contact type cloth singeing mechanism, which includes a bracket and a cloth guide roller, and also includes: a finishing assembly, a singeing assembly and a driving assembly. The adsorption channel on it carries out the traction of fibers, and then performs secondary fiber adsorption through the shaping suction port; the singeing assembly is located at the lower station end of the finishing assembly, and the combustion chamber and buffer chamber set inside it are respectively connected with the gas pipe and the suction pipe. Intermittent communication, the combustible gas enters the combustion chamber through the gas pipe, and after being ignited by the spark plug set at one end, the flame is ejected along the burner port to form a singeing area. Cleaning of impurities on the cloth; while the driving component drives the finishing component and the singeing component to rotate, it also drives the exhaust fan connected to the adsorption pipe and the suction pipe to rotate; solves the problem of poor singeing quality and production problems in the prior art Inefficient technical problems.

Owner:长兴天赫纺织科技有限公司

Glass fiber cloth singeing technology and production mechanism using same

The invention relates to a glass fiber cloth singeing technology. Glass fiber grey cloth is primarily sized, high-pressure flames are directly injected on the cloth surface of the glass fiber grey cloth through spraying guns to melt glass fiber hairiness erecting on the cloth surface. A production mechanism using the glass fiber cloth singeing technology mainly comprises transmission rollers, a cloth inlet and a cloth outlet, wherein the two transmission rollers are arranged between the cloth inlet and the cloth outlet, a left singeing device and a right singeing device are arranged between the two transmission rollers in an eudipleural way and respectively comprise a singeing roller and a row of spraying guns, the spraying guns of the left singeing device are arranged at the left of the singeing roller, and the spraying guns of the right singeing device are arranged at the right of the singeing roller. The glass fiber cloth singeing technology and the production mechanism using the same can effectively remove the hairiness on the surface of the glass fiber cloth. The invention has simple operation and obvious effect and can greatly improve the insulation performance of the glass fiber cloth.

Owner:JUSHI P D ELECTRONICS BASE MATERIAL

Dyeing process of bamboo viscose fiber

InactiveCN106283461AGood moisture absorption and air permeabilityHigh removal rateTextile storage in superimposed formBiochemical fibre treatmentFiberSlurry

The invention discloses a dyeing process of bamboo viscose fiber, and relates to the technical field of bamboo fiber fabric production. The process comprises five process steps of singeing, pretreatment, dyeing, post treatment and pre-shrinkage. By optimizing the speed and the gasoline quantity, the singeing effect is good; in the pretreatment process, a mixed solution of caustic soda and hydrogen peroxide is used as a rinsing solution; the oxygen bleaching effect is improved; in addition, through the later stage puffing, swelling and fabric slurry and impurity degradation, cotton impurities are removed through steam steaming and water washing; the cotton impurity removal rate is high; the cloth damage is small; in the dyeing work procedure, the dyeing is sufficient; the effect is good; in addition, a cold batch dyeing process is used; the energy source consumption is reduced; the production efficiency is improved; the whole technical process is simple; the technical parameter controllability is good; the texture of the dyed fabric is soft; the moisture absorption and ventilation performance is good.

Owner:ANQING XUANZHU TECH

Energy-saving and environment-friendly singeing device for printing and dyeing

InactiveCN107326597ATo achieve the purpose of energy saving and environmental protectionImprove cleanlinessCombination devicesGas treatmentToxic gasEngineering

The invention discloses an energy-saving and environment-friendly singeing device for printing and dyeing, which comprises a fixed plate, an air intake pipe is connected through the middle of the inner cavity of the fixed plate, one end of the air intake pipe is fixedly connected with a suction fan, and one end of the air intake pipe penetrates and extends to The inner cavity of the water tank, the water tank is fixed on the top of the fixed plate, one end of the air intake pipe is fixedly connected with a heat pipe, one end of the heat pipe is fixedly connected with an air pipe, and the end of the air pipe away from the heat pipe runs through the inner cavity of the water tank and extends to the water tank Externally, the end of the gas delivery pipe away from the heat pipe is fixedly connected to the air inlet on one side of the filter box. This energy-saving and environment-friendly singeing device for printing and dyeing can not only clean up all the toxic gases generated during singeing, but also remove The residual heat inside the poisonous gas produced during singeing is fully utilized, so that the singeing device for printing and dyeing can achieve the purpose of energy saving and environmental protection.

Owner:梅明会

Singeing device for printing and dyeing

The invention discloses a singeing device for printing and dyeing, which comprises two parallel guide rails. Both ends of ceramic heaters are respectively arranged on the guide rails. A control cabinet for regulating and controlling temperatures and moving speeds of the ceramic heaters is arranged at one side of the guide rail. The device has a simple structure. Due to the adoption of the round ceramic heaters, the temperature is uniformly distributed. The temperatures of different heaters are set in a stepped mode. Resources are saved. The singeing effect is excellent.

Owner:WUJIANG NO 2 SILK SCOURING DYEING

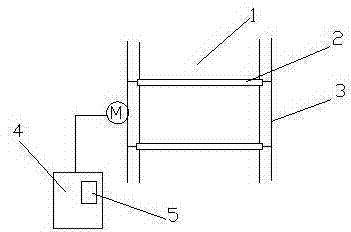

Garment printing device for textile

ActiveCN111806079APrinting does not affectImprove singeing effectSingeingDrying gas arrangementsTextile printerRotational axis

The relates to the technical field of printing equipment for textile industry, and discloses a garment printing device for textile. The garment printing device comprises a singeing machine. One side of the singeing machine is fixedly connected with two side plates. The bottoms of the two side plates are provided with a first rotating shaft in a movable and sleeved mode. The middle part of the first rotating shaft is fixedly sleeved by a first cloth-guiding roller mounted between the two side plates. The top of each of the side plates is respectively provided with a sliding slot. The interior of each of the two sliding slots is sleeved by a movable pipe in a movable mode. The middle parts of the movable pipes are sleeved by a rotating shaft in a movable mode. The middle part of the rotatingshaft is fixedly sleeved by a positioning plate. The garment printing device for textile enables the bottom of a spiral blade to be matched with the top of the first cloth-guiding roller to press textile tightly through the elasticity of a spring, and uses the rotating shaft to drive the spiral blade to turn, so that the textile is always in a flat state, thus the high effect of singeing the textile is ensured and the dyeing of the textile cannot be affected.

Owner:晋江市嘉艺服装织造有限公司

Gas singeing machine for printed and dyed fabric

The invention discloses a gas singeing machine for printing and dyeing fabrics, which is arranged in a singeing chamber to perform singeing treatment on fabrics. The gas singeing machine for printing and dyeing fabrics comprises a brush box, a gas singeing machine, a cooling water roller, The dipping tank and the liquid rolling mechanism are provided with a bristle roller group in the bristle box, and the bristle roller set includes a plurality of bristle rollers arranged oppositely. The bristle rollers are provided with bristles, and the outside of the bristles has an electrostatic adsorption layer for absorbing shavings; the bristle box and The dust suction air duct is connected, and an electrostatic precipitator is arranged at the end of the dust suction air duct. The invention is provided with one main flame generating part and two auxiliary flame generating parts, which can effectively and completely singe the fabric, and not only have relatively high singeing efficiency, but also have relatively good singeing effect.

Owner:HUNAN JICHANG SILK

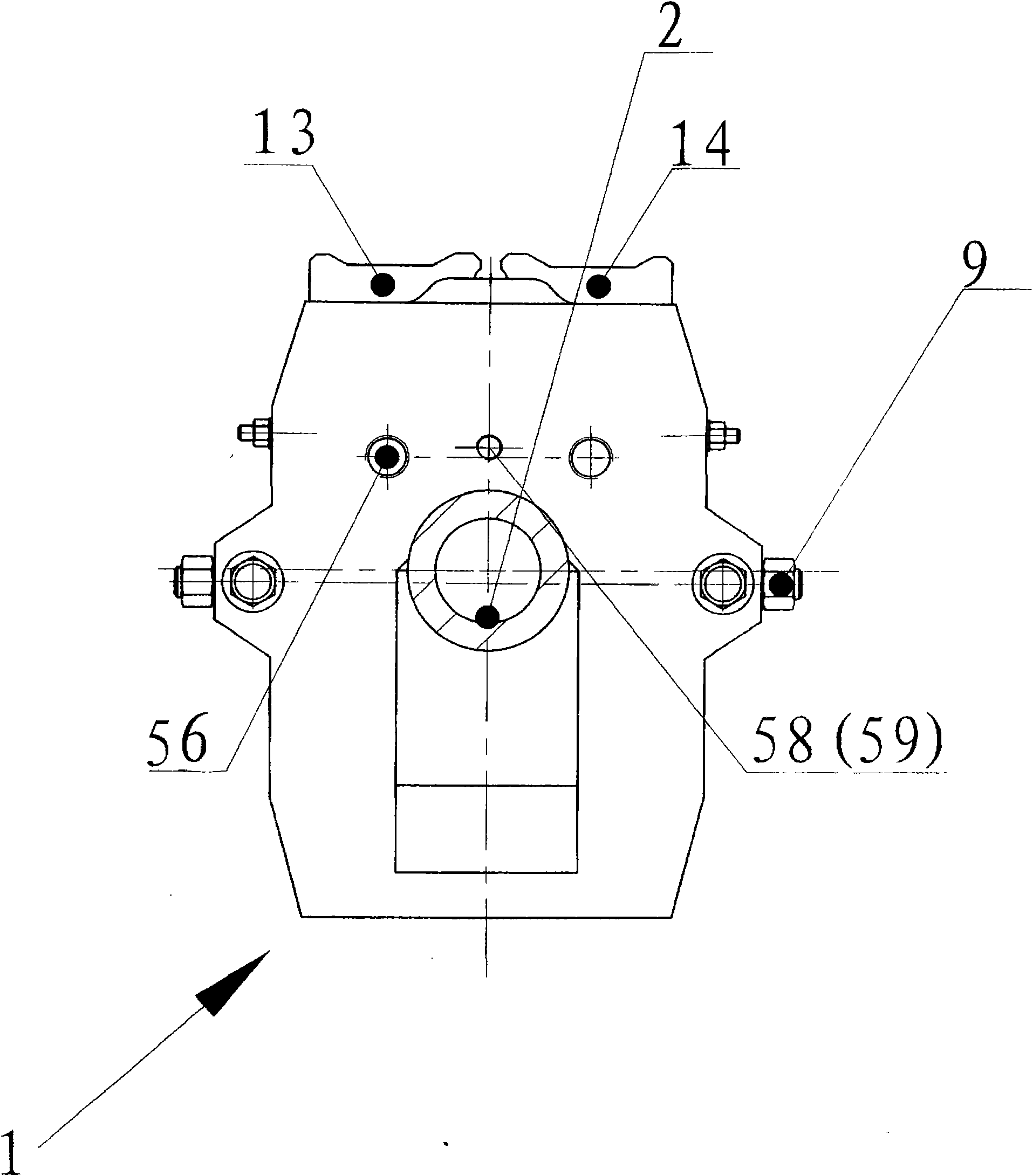

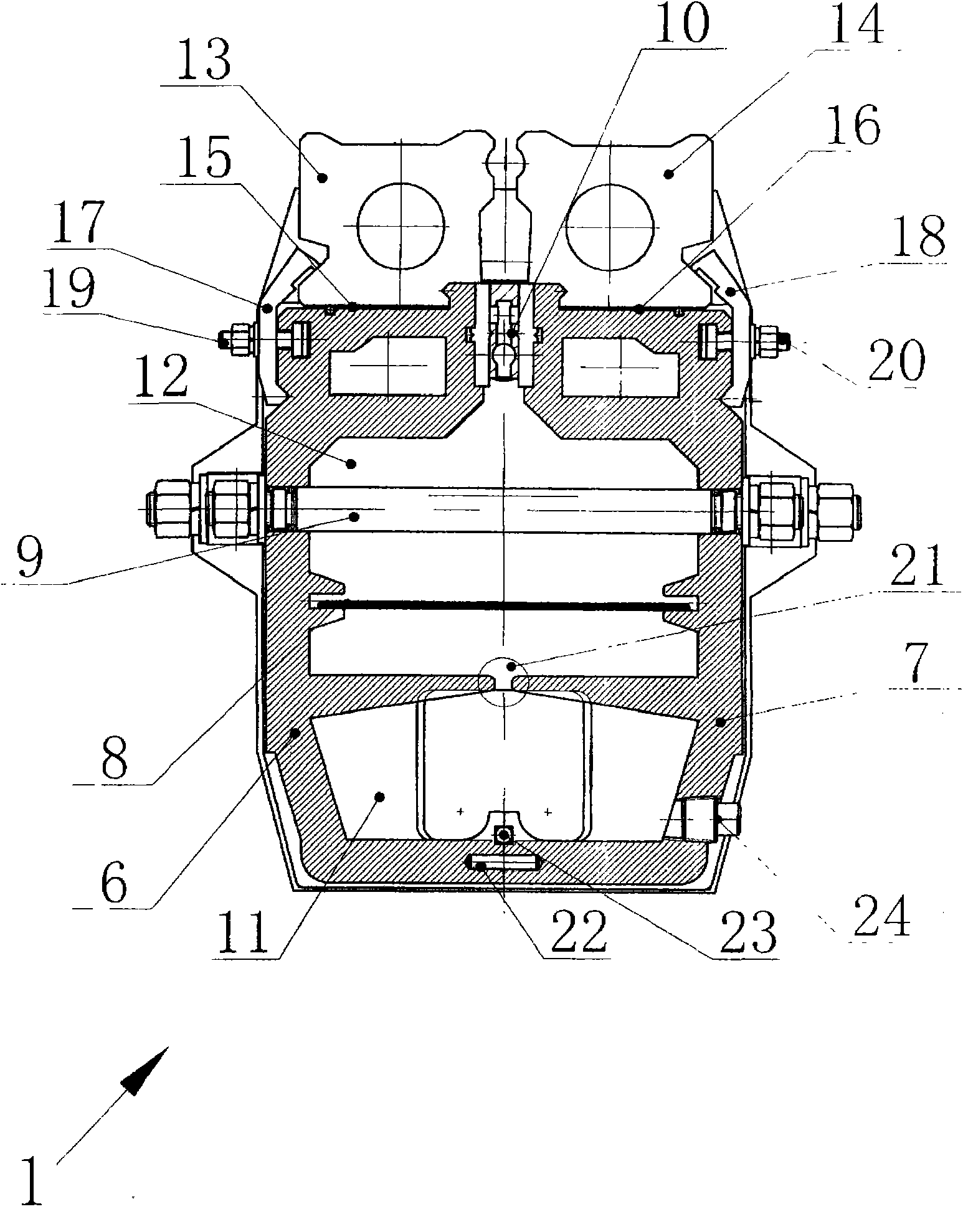

Aluminum alloy rotary mixing amplitude adjustable double fire nozzles for printing-dyeing singeing machine

The invention discloses aluminum alloy rotary mixing amplitude adjustable double fire nozzles for a printing-dyeing singeing machine, and relates to the field of a fire port with rotary mixing amplitude adjustable double nozzles on the printing-dyeing singeing machine. A left shaft head (2) and a right shaft head (3) of the aluminum alloy rotary mixing amplitude adjustable double fire nozzles (1) are welded with an air inlet box (4) together; a connecting flange (5) welded with the air inlet box (4) is connected with a fire port body; a left fire port body (6) and a right fire port body (7) are connected through a stud (9); two sides of a middle rail (47) of a fire port rail double-nozzle assembly (10) are provided with a left rail (45) and a right rail (46), and a left nozzle (48) and a right nozzle (49) are formed on the upper part of the middle rail; and a left fire port brick (13) and a right fire port brick (14) are arranged on a left heat insulation plate (15) and a right heat insulation plate (16) at the tops of the left fire port body (6) and the right fire port body (7). The aluminum alloy rotary mixing amplitude adjustable double fire nozzles for the printing-dyeing singeing machine have the advantages of high strength, energy conservation, high flame temperature, no excursion and clean singeing.

Owner:泰州印染机械有限公司

Small scale singeing machine for textile

InactiveCN100392170CImprove singeing effectMeet singeing treatmentSingeingSteam pressureElectric machine

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD

Cloth singeing and dedusting mechanism

The invention relates to a cloth singeing and dedusting mechanism, which includes a support, a cloth guide roller and an air blowing assembly, and also includes a singeing chamber and a separation assembly with gas inside, the singeing chamber is located below the cloth and is arranged in a gap with it. The singeing chamber includes an adsorption port and singeing devices and air guide plates respectively arranged on its upper and lower sides. The air guide plate is arc-shaped and its extension direction is the same as the flow direction of the flowing gas. An airflow acceleration zone is formed between the bottoms of the hair cavity, and a negative pressure zone is formed between the suction port and the air guide plate; the separation assembly includes an exhaust cavity, a dust fall cavity, and is arranged between the exhaust cavity and the dust fall cavity and is connected to the horizontal plane. The material guide plate set at an angle and the baffle plate set on the top of the singeing chamber; through the characteristic that the mass of the short wool is greater than the mass of the gas, the S-shaped airflow buffer channel is formed by the material guide plate and the baffle to separate the short wool from the air flow, which solves the problem There is a technical problem that the short hair after singeing is not easy to handle in the technology.

Owner:长兴天赫纺织科技有限公司

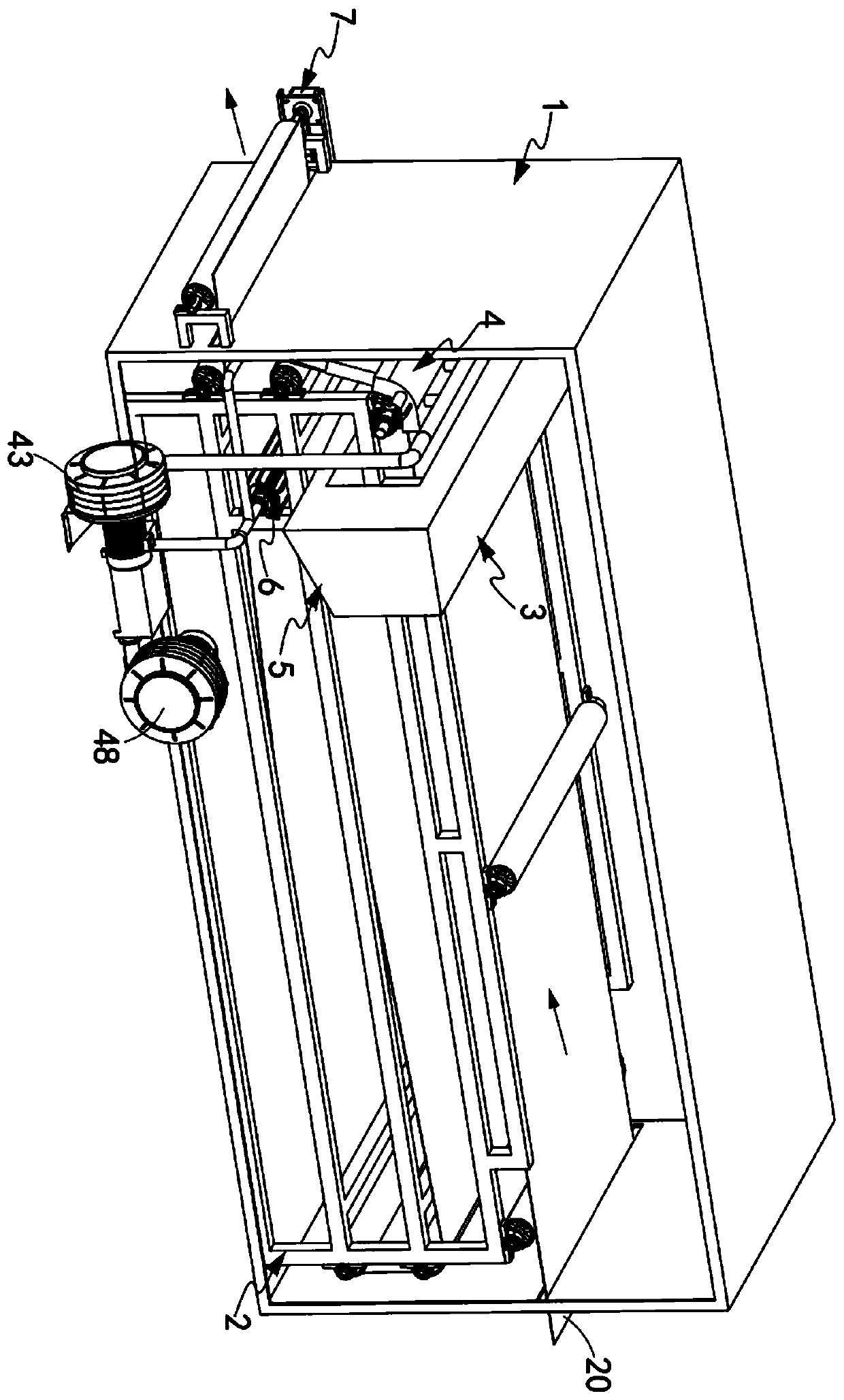

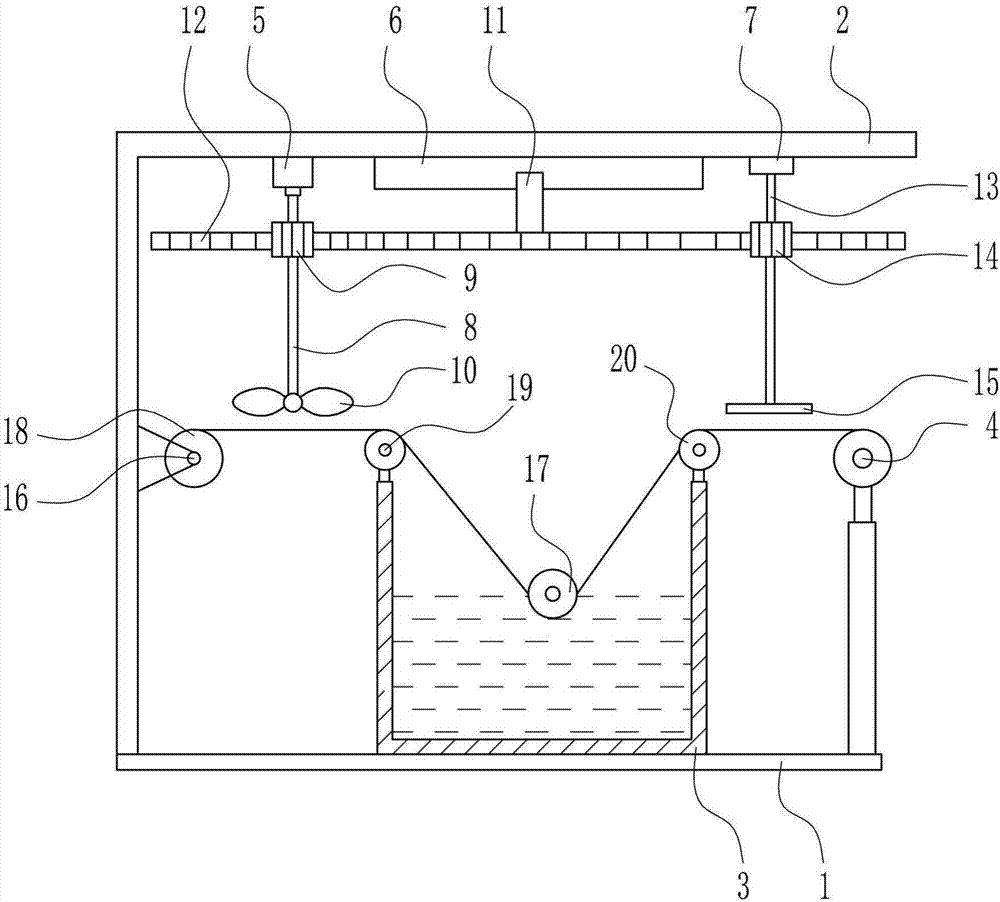

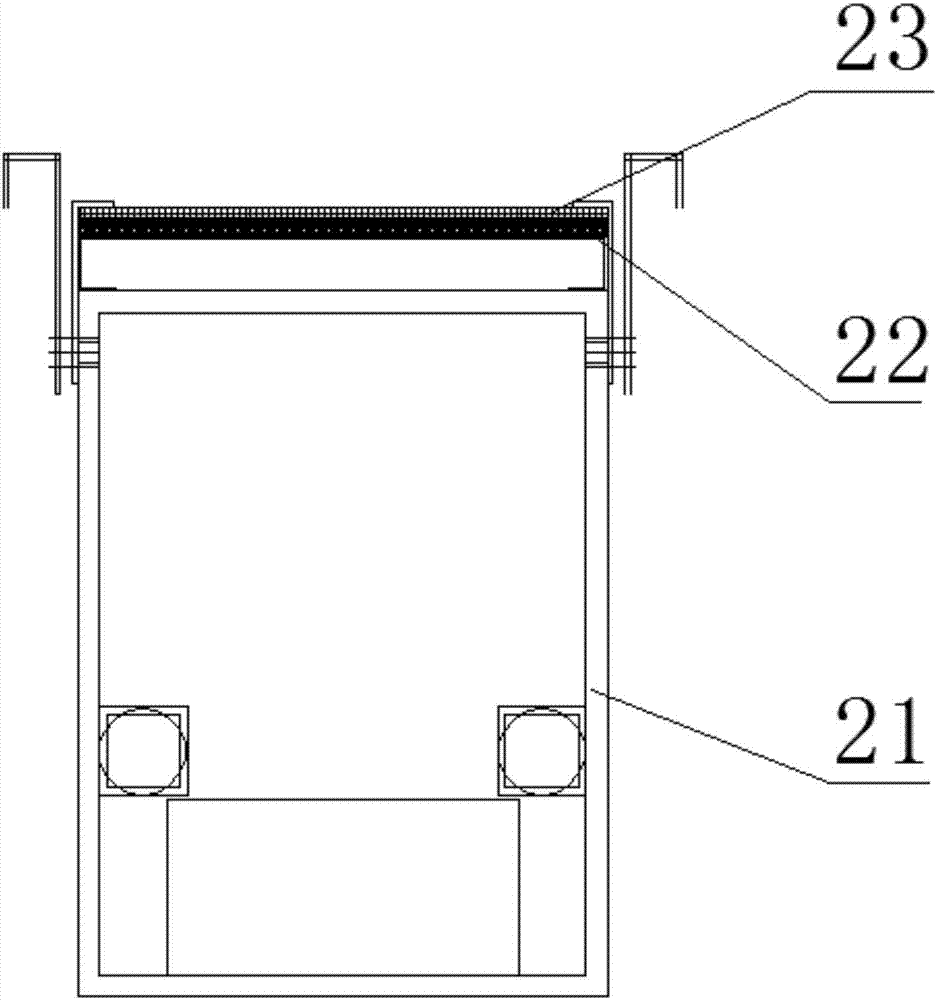

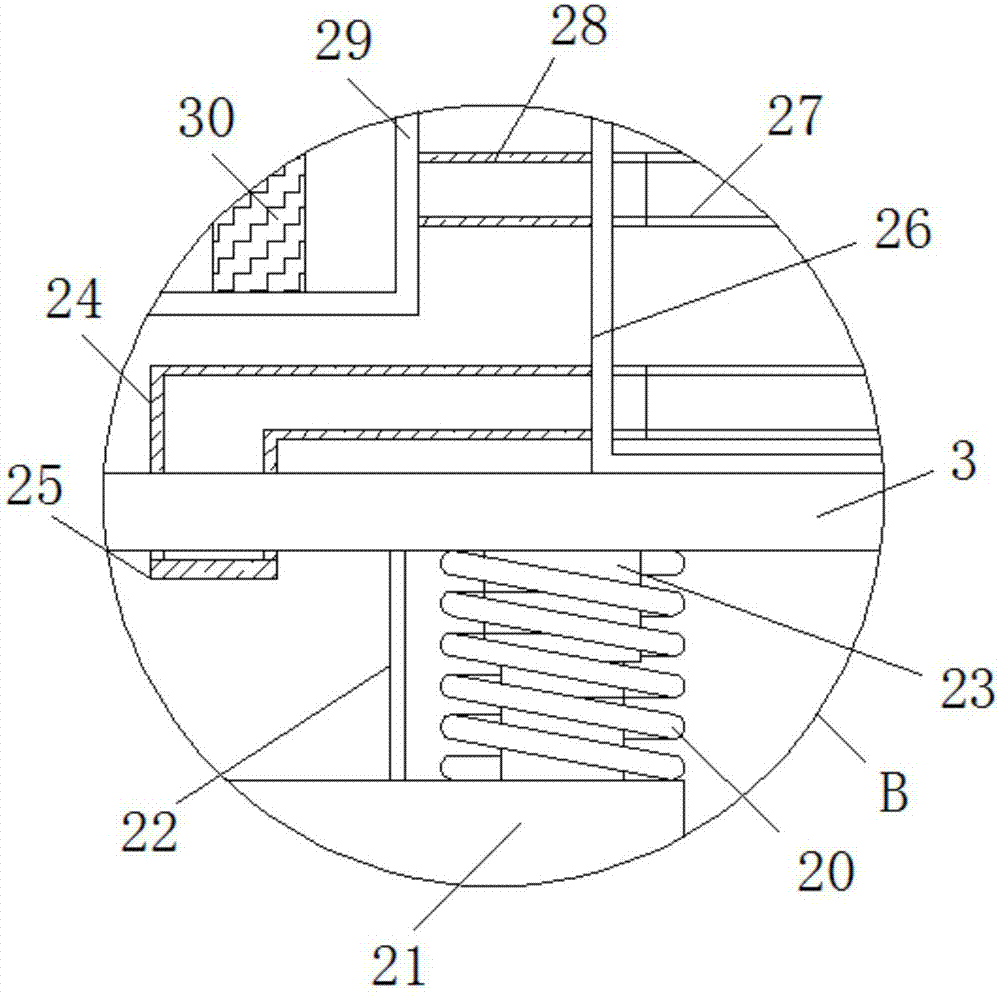

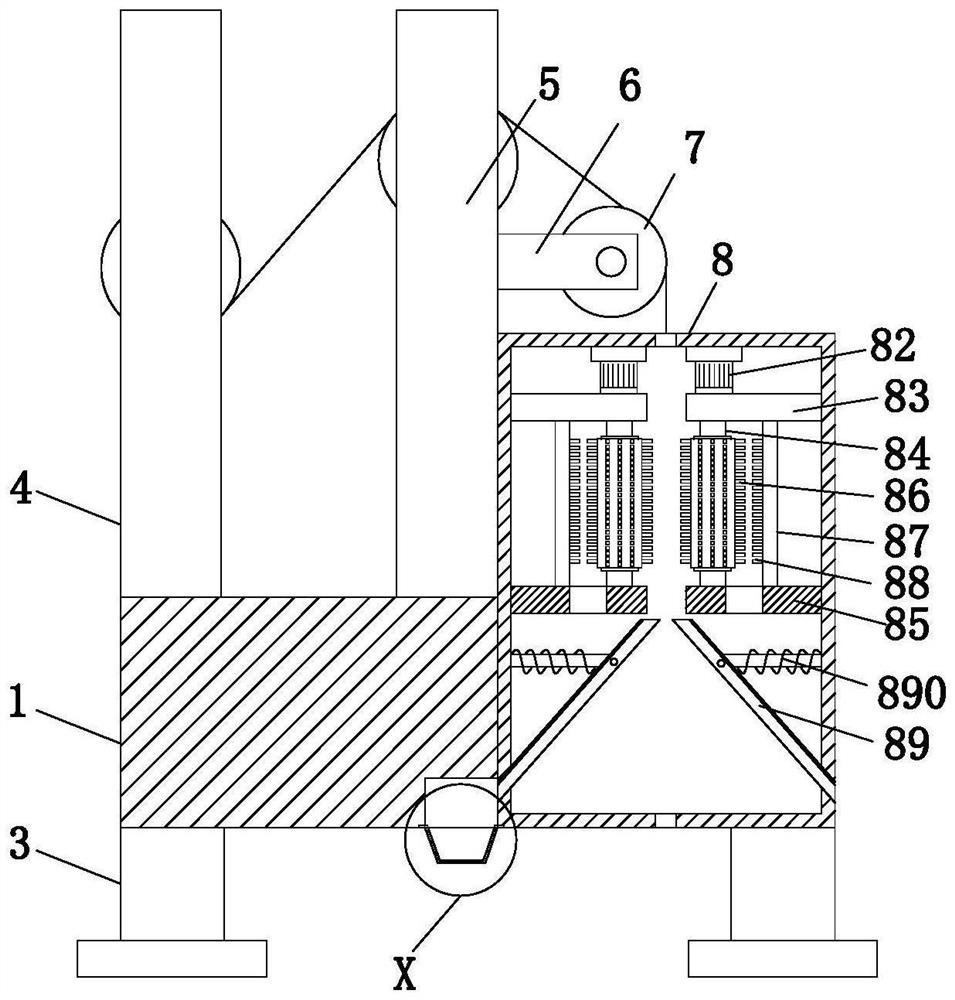

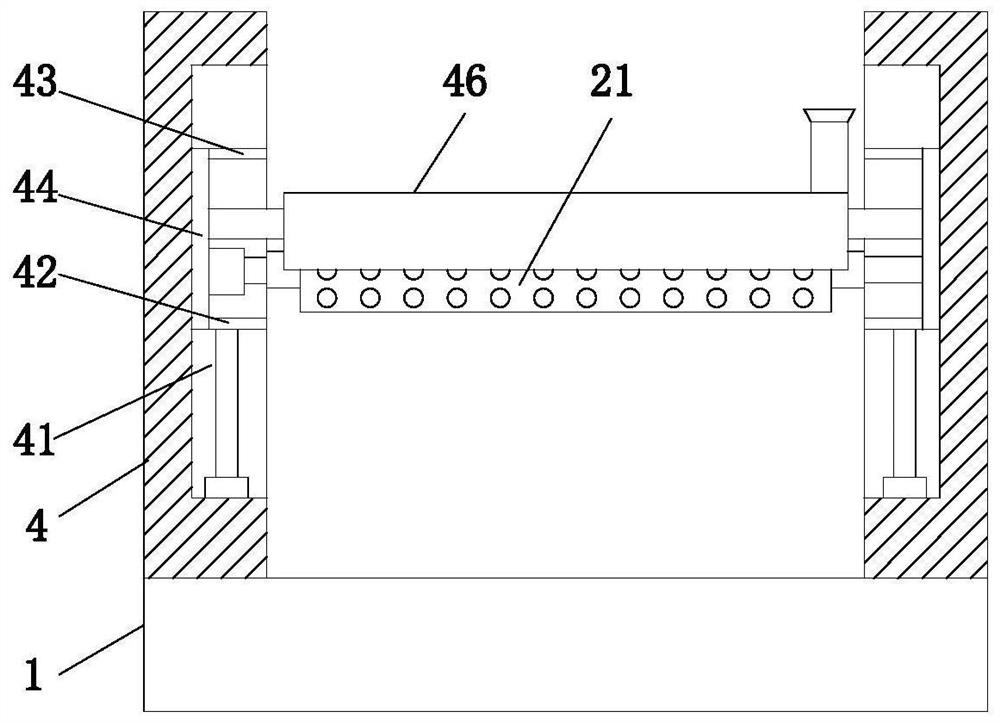

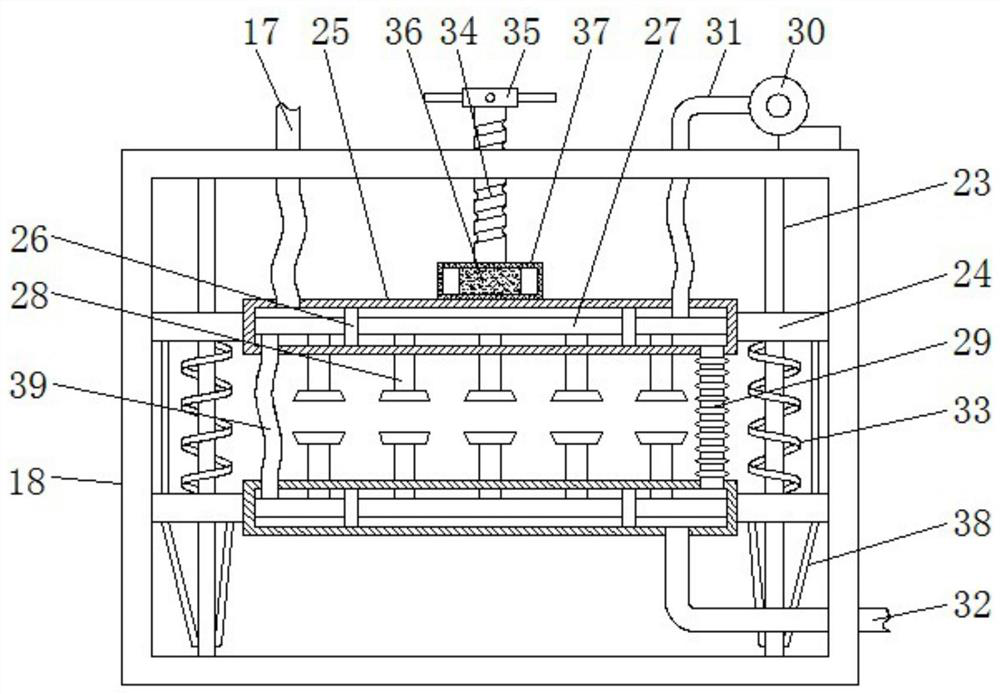

Pretreatment system and method for printing and dyeing of home textile fabric

InactiveCN110079962AImprove qualityGood removal effectMechanical cleaningPressure cleaningEngineeringHandling system

The invention provides a pretreatment system and method for printing and dyeing of home textile fabric. The system comprises a tank body, wherein a rack is arranged in the tank body; the home textilefabric is conveyed on the rack; the rack is provided with a carding mechanism, a singeing mechanism, a pre-cleaning mechanism and a cleaning mechanism respectively in the conveying direction of the home textile fabric. The method comprises the following steps: feeding in, carding, standing, singeing, pre-cleaning, shaping and discharging out. External air is heated by a draught fan and then is discharged to the home textile fabric after singeing, so that impurities remaining on the home textile fabric after singeing are removed; meanwhile, the hot air for removing the impurities is blown fromthe middle to two sides of the width direction of the home textile fabric, the home textile fabric is drawn to be flat by the hot air, and the technical problem that the impurity cleaning and flattingtreatment are synchronously performed on the home textile fabric after singeing is solved.

Owner:浙江常鑫纺织品有限公司

Automatic processing system for textile fabric preparation

InactiveCN111979745ARealize the height adjustment functionImprove singeing efficiencyMechanical cleaningPressure cleaningStructural engineeringIndustrial engineering

The invention relates to an automatic processing system for textile fabric preparation. The system includes a base, singeing mechanisms, support legs, a first fixing board, a second fixing board, a cross rod, a transition roller and a tank body. The tank body is fixedly mounted on the right end face of the base, the support legs are symmetrically mounted at the left end of the lower end face of the base and the right end of the lower end face of the tank body, the first fixing board and the second fixing board are symmetrically mounted at the left and right two ends of the upper end face of the base, and the singeing mechanisms are arranged between the inner side ends of the middle of the first fixing board and the inner side ends of the upper ends of the second fixing board. According tothe system, an efficient automatic idea is adopted to process flocks on the surface of textile fabric, the double faces of the textile fabric can be subjected to automatic singeing processing, meanwhile through the matching between an electric push rod, a sliding seat and a sliding groove, the function of height adjustment of the roller can be achieved, so that the textile fabric with different tension can be subjected to singeing processing, and the singeing efficiency of the system can be achieved.

Owner:合肥锦晟纺织科技有限公司

A high-efficiency and energy-saving cleaning singeing device

ActiveCN112481909BNot easy to retractImprove singeing effectMechanical cleaningPressure cleaningBristleEngineering

Owner:佛山市南海永其祥织染有限公司

A kind of clothing printing device for textile

ActiveCN111806079BPrinting does not affectImprove singeing effectSingeingDrying gas arrangementsTextile printerRotational axis

The invention relates to the technical field of printing equipment in the textile industry, and discloses a printing device for textile clothes, including a singeing machine, two side plates are fixedly connected to the side of the singeing machine, and the bottom ends of the two side plates are connected to each other. The movable sleeve has a first rotating shaft, and the fixed sleeve in the middle of the first rotating shaft is equipped with a first cloth guide roller located between two side plates. The tops of the two side plates are respectively provided with chute, and the two A moving tube is movably socketed inside the chute, a rotating shaft is movably socketed in the middle of the two moving pipes, and a positioning plate is fixedly socketed in the middle of the rotating shaft. The clothing printing device for textile uses the elastic force of the spring to make the bottom of the helical blade cooperate with the top of the first cloth guide roller to press the textile, and uses the rotating shaft to drive the helical blade to turn the rudder, so that the textile is always in a flat state, thus ensuring The effect of textile singeing is high, so that it does not affect the dyeing of textiles.

Owner:晋江市嘉艺服装织造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com