Winding drum type singeing mechanism

A reel and cylinder technology, applied in the field of reel-type singeing mechanism, can solve problems such as easy shaking, inability to fully comb the fluff on the cloth surface, incomplete singeing, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

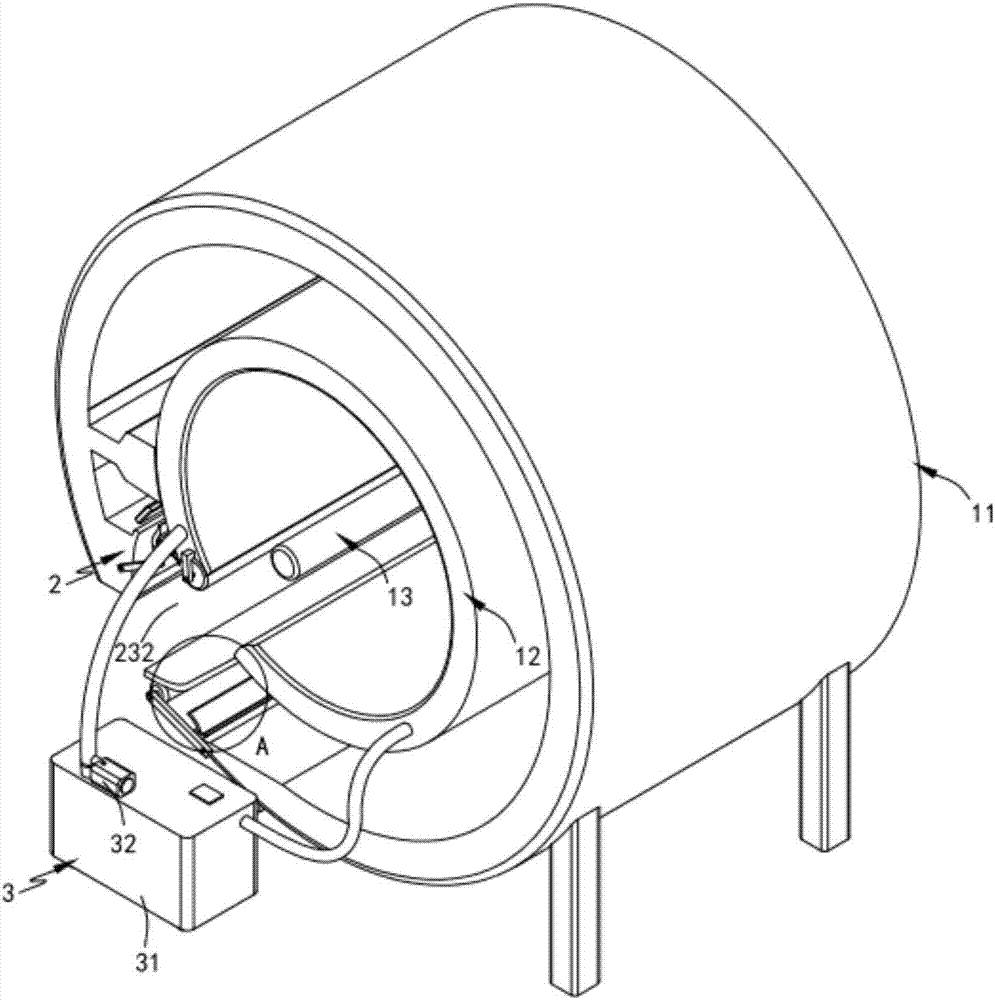

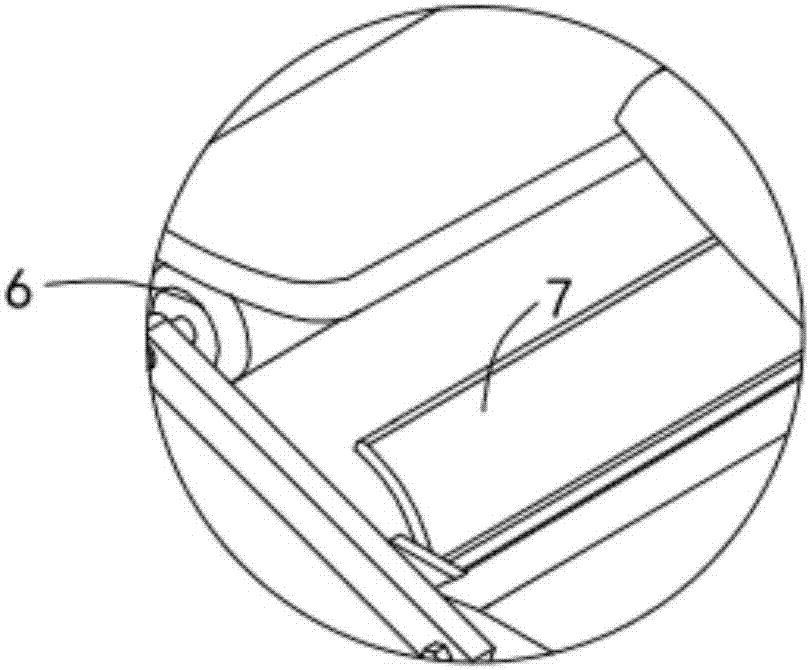

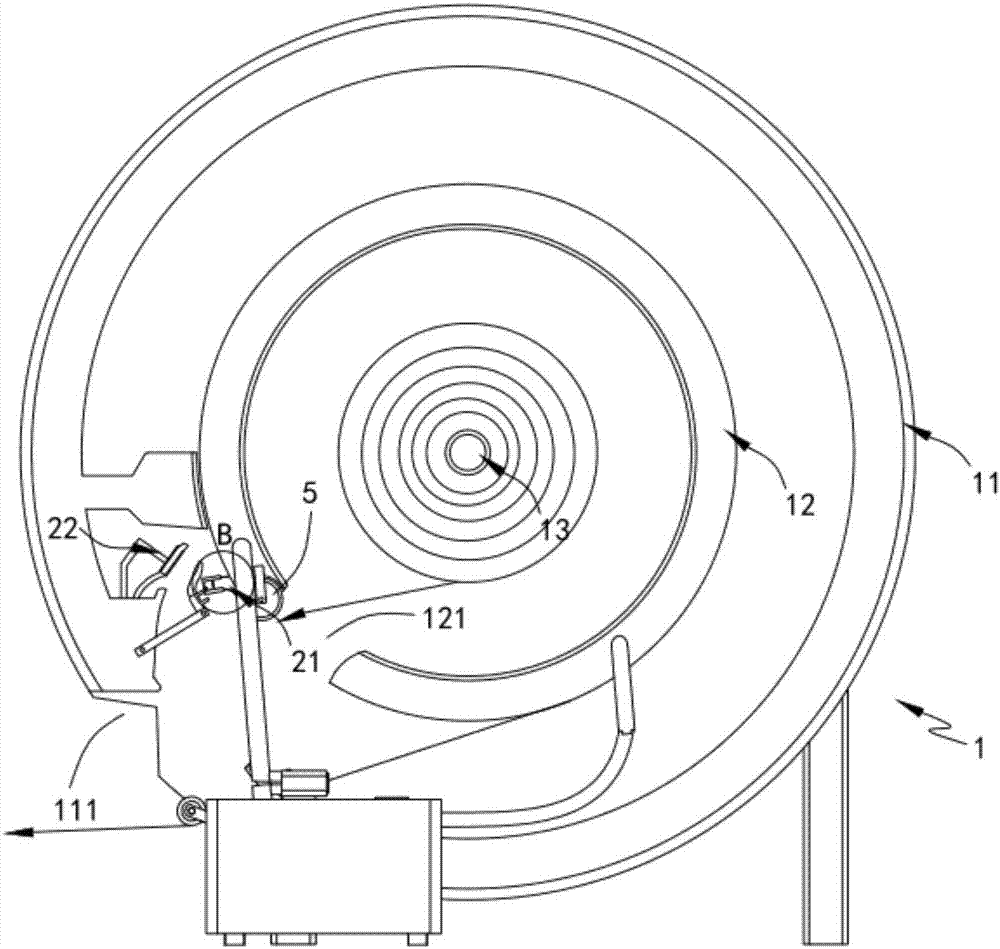

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a drum-type singeing mechanism includes a main body mechanism 1, and the main body mechanism 1 includes a first cylinder 11, a second cylinder 12 arranged in the first cylinder 11, and a second cylinder 12 arranged in the second cylinder. The unwinding roller 13 in 12, the side of the first cylinder 11 is provided with a first outlet 111, the side of the second cylinder 12 is provided with a second outlet 121, the first cylinder 11 and A transmission channel 10 is formed between the second cylinders 12;

[0031] And singeing mechanism 2, described singeing mechanism 2 comprises the combing device 21 that is arranged on the first outlet 111 side for combing the hair on the cloth surface to one side, and is arranged on the first cylinder 11 and the second cylinder. Between the cylinder 12 and the singeing device 22 at the rear end of the combing device 21.

[0032] By s...

Embodiment 2

[0042] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that it further includes a cooling device 3, the cooling device 3 includes a water tank 31 and a water pump 32 arranged on the water tank 31 and one end communicated with the inside of the water tank 31; The inside of the second cylinder 12 is provided with a cooling cavity 122 , the water inlet 123 of the cooling cavity 122 communicates with the water pump 32 through a pipeline, and the water outlet 124 of the cooling cavity 122 communicates with the inside of the water tank 31 through a pipeline.

[0043] By setting the cooling device 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com