Contact singeing frame

A contact type, singeing machine technology, applied in singeing, textiles and papermaking, fabric surface trimming, etc., can solve the problems of poor energy saving effect, poor singeing effect, etc., achieve air pollution improvement, energy saving, and production cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

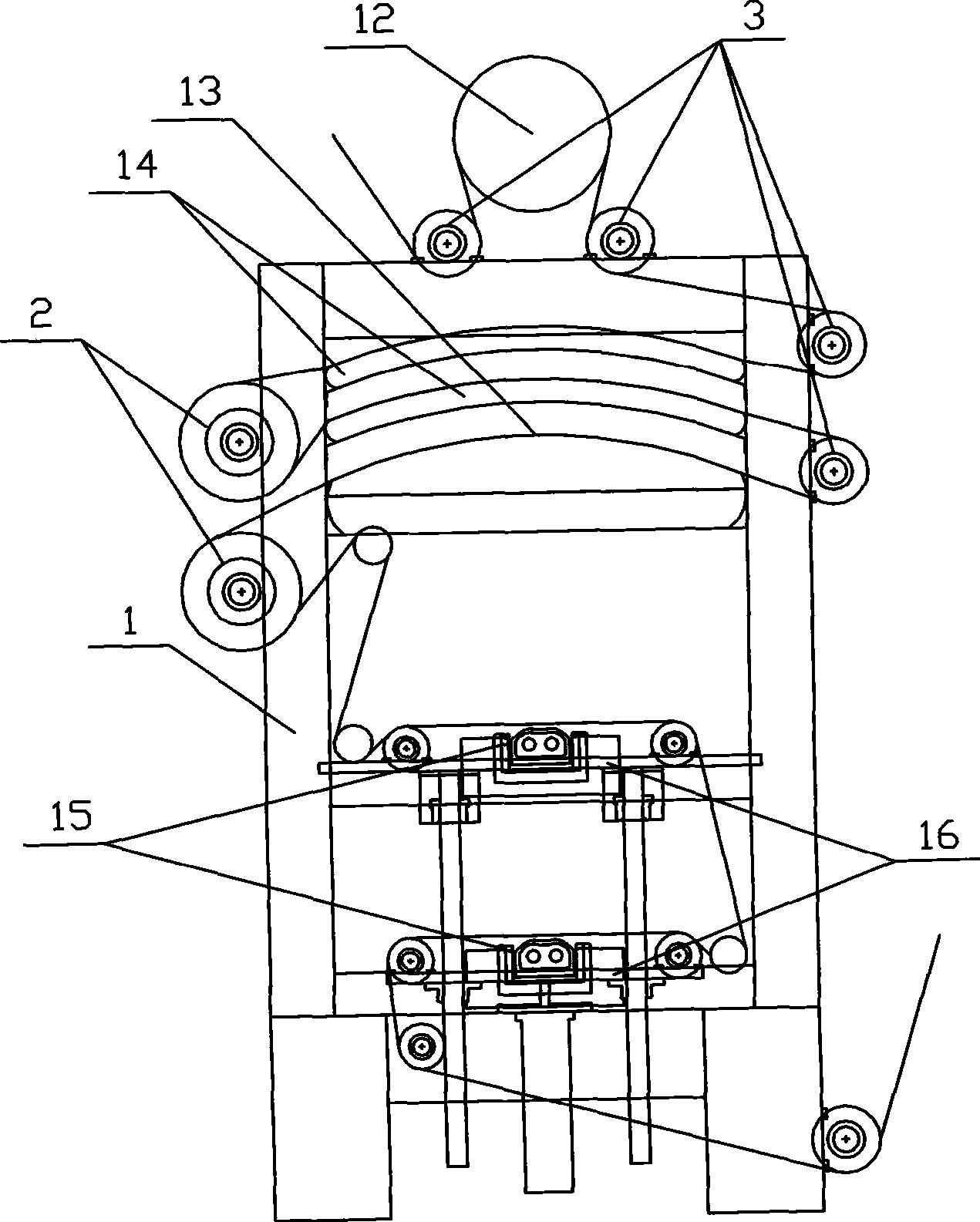

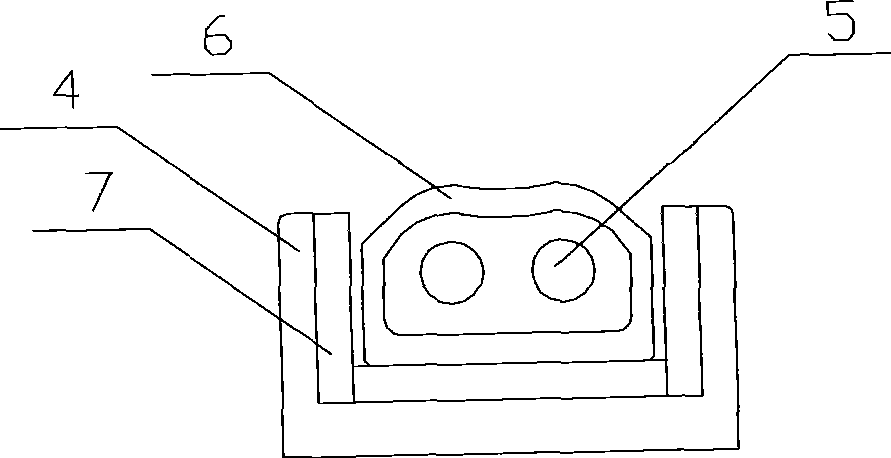

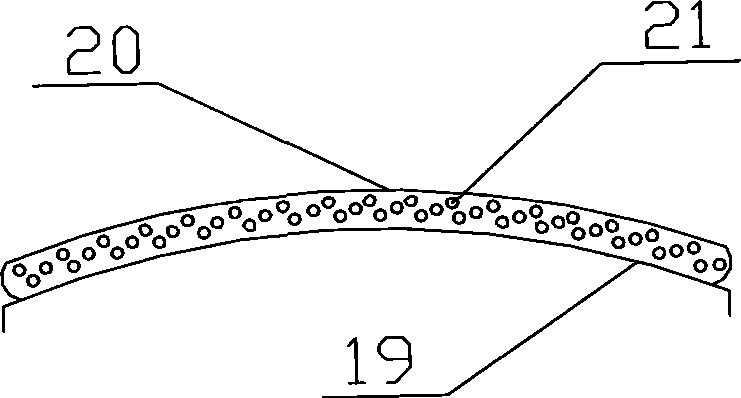

[0019] Such as Figure 1 to Figure 5 The specific embodiment of the present invention shown is a contact type singeing machine, comprising a body 1, a power rubber roller 2 arranged on the body, and a plurality of cloth guide rollers 3 arranged on the body 1 and inside the body 1. The upper and lower two-stage contact singeing devices are installed in the hair machine, and the contact singeing device includes a concave housing 4 and at least two electric heating rods 5 arranged inside the housing 4, the electric heating rods 5 A high-temperature alloy steel body 6 forming a high-temperature radiation zone is installed on the periphery. An insulating layer 7 is provided between the high-temperature alloy steel body 6 and the shell 1 . The electric heating rod 5 is a silicon carbide heating rod. The body 1 is provided with a lifting and passing cloth device, which includes a support rod 11 and a two-stage lifting platform 8 fixedly installed on the supporting rod. Mopping roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com