Integrated singeing mechanism for spinning

A technology integrating rollers and combustion chambers, applied in the field of textile production, can solve problems such as unsatisfactory fiber erection, complex structure, and uncontrollable singeing, and achieve the effects of reducing equipment volume, improving singeing quality, and improving treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

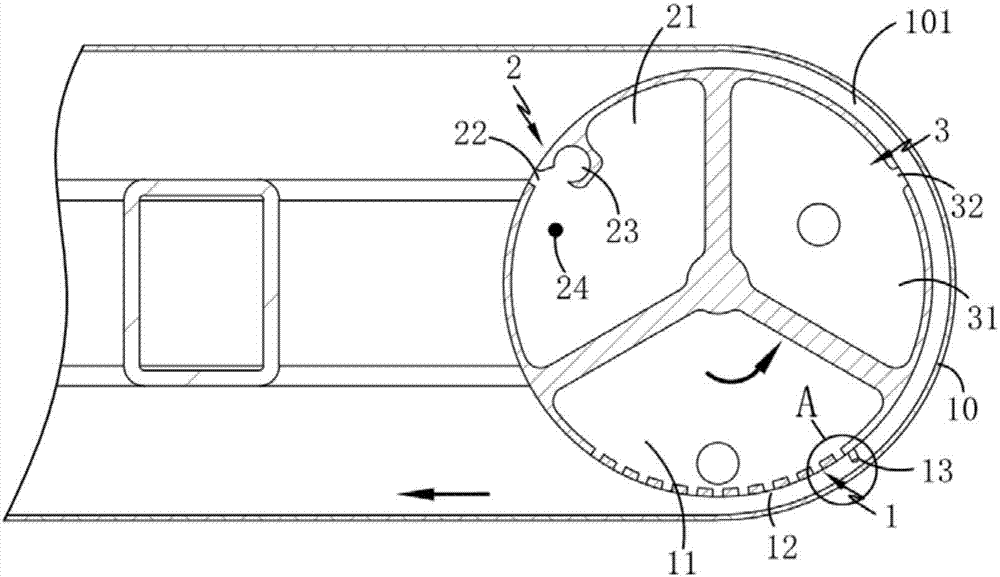

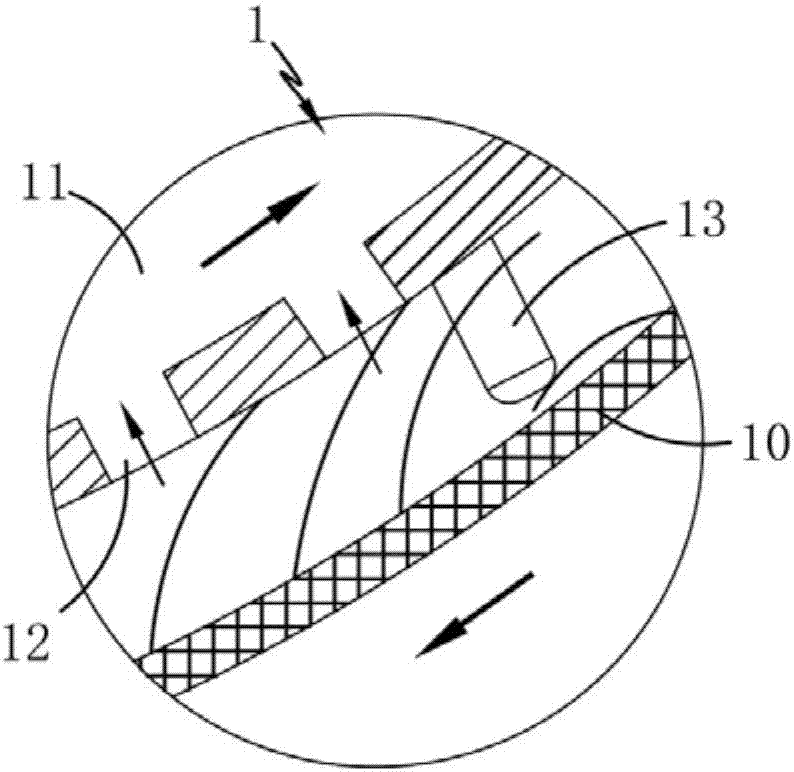

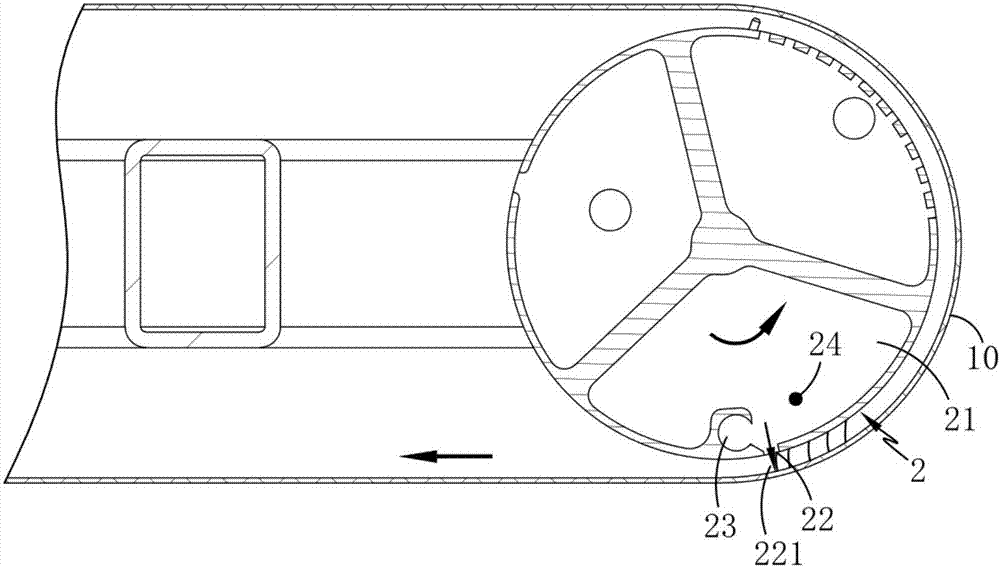

[0041] Such as figure 1 , 2 , 3 and 4, a textile integrated singeing mechanism, including carding assembly 1, singeing assembly 2 and dust removal assembly 3, said carding assembly 1 includes an internal space for negative pressure to set a negative pressure chamber 11, several openings in it The suction port 12 on the outer peripheral surface and communicated with the outside, and a number of combing teeth 13 fixedly arranged on one side of the suction port 12 for fiber carding on the surface of the cloth 10; The burner port 22 on the wall of the combustion chamber 21 and communicated with the external connection, the gas pipe 23 fixedly arranged on one side of the burner port 22 and located inside the combustion chamber 21, and the gas pipe 23 fixedly arranged inside the combustion chamber 21 for gas The igniter 24 for igniting the combustible gas in the tube 23, the combustible gas in the gas tube 23 is diffused and ignited through the gas diffusion channel 231 opened on i...

Embodiment 2

[0043]The inventor believes that in order to better implement the technical solution, further specific implementation methods are necessary, so the inventor describes the second embodiment on the basis of the first embodiment.

[0044] Such as figure 1 , 2 , 3 and 4, a textile integrated singeing mechanism, comprising:

[0045] Carding assembly 1, said carding assembly 1 includes a negative pressure chamber 11 for negative pressure in the inner space, a number of suction ports 12 that are opened on its outer circumferential surface and communicate with the outside, and are fixedly arranged on one side of the suction port 12 for cloth A number of combing teeth 13 for fiber carding on the surface of 10; the negative pressure chamber 11 provided with negative pressure forms a suction force at the suction port 12, and absorbs the fibers on the cloth 10 to make it stand up from the surface of the cloth 10;

[0046] The singeing assembly 2, the singeing assembly 2 includes a combu...

Embodiment 3

[0059] Such as Figure 10 and 11 As shown, the parts identical or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the differences between the second embodiment and the second embodiment are described below; the difference between the third embodiment and the second embodiment The difference is that: it also includes a gas transfer block 5 and a negative pressure transfer block 6 fixedly arranged at both ends of the integration roller 4 respectively, and the gas transfer block 5 is provided with a gas flow port 232 which is arranged in cooperation with the gas flow port 232 The first connection groove 51 , the first connection groove 51 communicates with the gas supply pipe; the combustible gas communicates with the combustion chamber 21 through the first connection groove 51 from the gas supply pipe.

[0060] Further, as Figure 12 As shown, the negative pressure adapter blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com