A high-efficiency and energy-saving cleaning singeing device

A high-efficiency, energy-saving and clean technology, applied in high-pressure cleaning, singeing, mechanical cleaning, etc., can solve problems such as poor singeing effect, achieve the effect of improving singeing effect and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

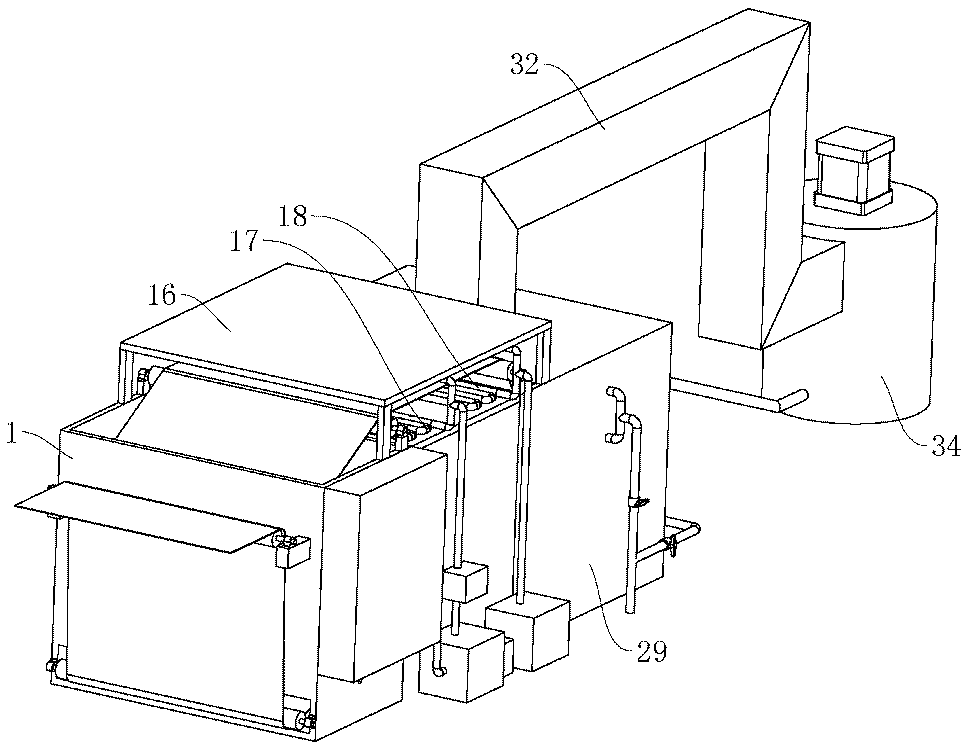

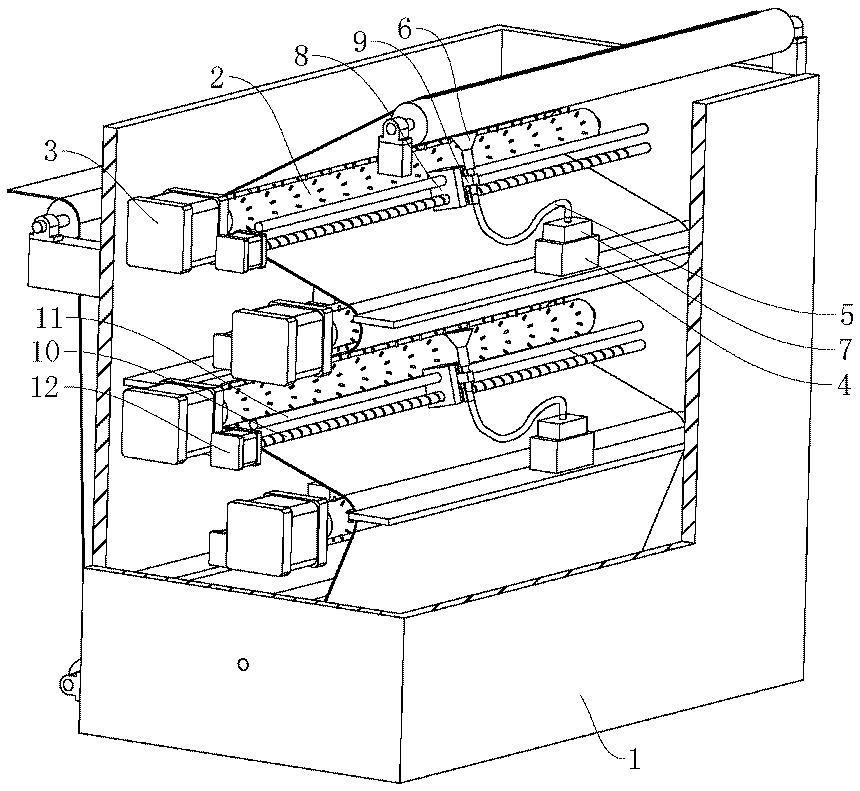

[0040] The embodiment of the application discloses a high-efficiency and energy-saving cleaning singeing device. Referring to Figure 1, energy efficient cleaning singeing

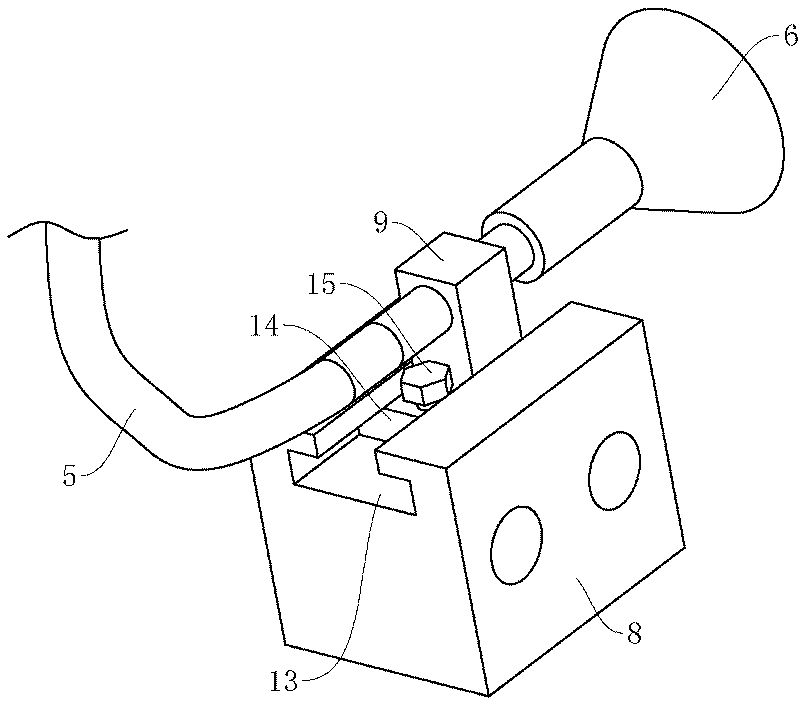

[0043] When the bristle roller 2 brushes the fluff on the cloth, a part of the fluff is easily scattered around the bristle roller 2. At this time, start the

[0056] In order to recycle the water in the cooling water tank 44, a connecting pipe 45 is connected to the outside of the cooling water tank 44.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com