Repairing fusion type heart stent and manufacturing method thereof

A heart and skeleton technology, applied in the field of medical materials, can solve the problems of intravascular atherosclerotic plaque fragmentation and shedding, coronary heart disease attack again, late stent thrombosis, etc., to solve the problem of dissolving blockage and shedding, eliminating rejection inflammation, The effect of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

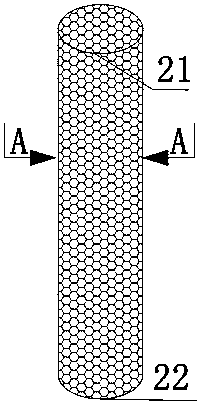

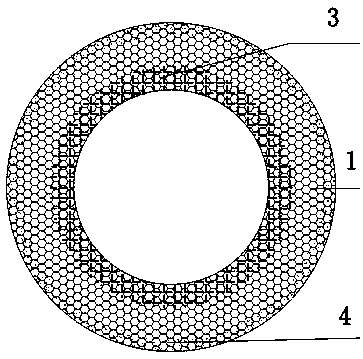

[0025] Such as Figure 1-3 As shown, the present invention provides a stent for repairing a fusion type heart, which is composed of a stent skeleton 1, a skeleton opening 2, a skeleton inner layer 3, and a skeleton outer layer 4. The wall thickness of the bracket belongs to 40-65 nanometers.

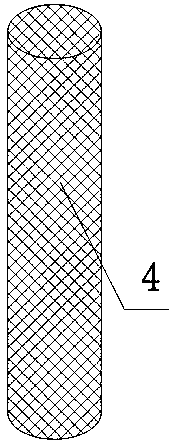

[0026] The frame of the stent is made of fluorocarbon silicon and fusion materials. The openings of the frame are open at both ends, such as the opening 21 and the opening 22. The outer layer of the frame is inhibiting and repairing drugs. The layer is antithrombotic drugs, the outer layer is coated on the skeleton, the inner layer is polymerized on the skeleton, and the scaffold is a mesh structure such as an elliptical polygonal mesh (see figure 1 ), quadrilateral (see image 3 )Wait.

[0027] The skeleton is a flexible and elastic material with a certain strength suitable for the human body, which is formed by the polymerization of fluorine-modified carbon-silicon materials and fus...

Embodiment 2

[0033] Such as Figure 1-3 Shown on the basis of Example 1, a more preferred embodiment of the present invention will be described below. The present invention provides a stent for repairing a fusion type heart, such as figure 2 As shown, the appearance of its skeleton is an elliptical polygonal mesh. The fluorocarbon silicon material and the fusion type material are made of acrylic acid fluoroalkyl acetate skeleton material, and the thickness of the skeleton is 32nm to achieve its strength and toughness. The antithrombotic drug of the polymer in layer 3 is a chain or cyclic isodiene diterpene derivative, the thickness of the inner layer 3 is 6nm, and the outer layer 4 of the skeleton is an adhesive antithrombotic drug: pentamycin, Paint substances such as acetylspiramycin and tacrolimus, the thickness of the outer layer 4 is 2nm, the openings 21 and 22 at both ends have a diameter of 2mm, and the two ports 2 and the elliptical polygonal mesh The surface of the structure is ...

Embodiment 3

[0038] Such as Figure 1-3 Shown on the basis of Example 1, a more preferred embodiment of the present invention will be described below. The present invention provides a stent for repairing a fusion type heart, such as image 3 As shown, the appearance of its skeleton is a quadrilateral network, and the fluorocarbon silicon material and the fusion type material are made of fluoroalkyl lactate skeleton material, and the thickness of the skeleton is 50nm, so as to realize its elasticity and melt toughness. The inner layer of the skeleton is 3 The polymer inhibitory antithrombotic drugs are paclitaxel analogues,

[0039] Paclitaxel is described below. Paclitaxel is a broad-spectrum anti-cancer and cell-repair drug extracted from the bark of the yew tree. It has attracted the attention of the chemical and medical circles because of its novel chemical structure and unique anti-tumor mechanism of repair cells. In order to reduce The toxic and side effects of paclitaxel, improve it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com