Preparation method of plate type rubber sealing part of radiator of engine cooling system

A technology for engine cooling and rubber seals, applied in the field of new materials, can solve the problems of aging resistance, permeability and wear resistance, which restrict the development of the automobile industry, and the seals have not been improved accordingly. Or destroy the adhesion, improve the performance and service life, and not easy to leak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

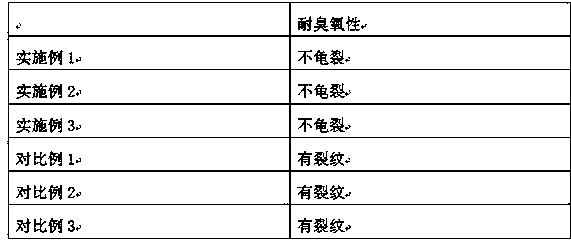

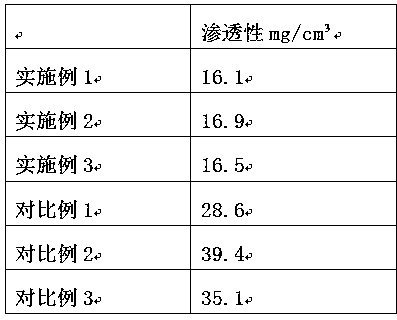

Examples

Embodiment 1

[0019] A method for preparing an engine cooling system radiator plate rubber seal, comprising the following steps:

[0020] (1) After uniformly mixing 65 parts of EPDM rubber and 35 parts of polybutadiene rubber in parts by weight, add them to the open mixer for mastication to obtain plasticized rubber; Refining, plasticizing time is 1.5 hours;

[0021] (2) Mix sodium-based bentonite and ethanol uniformly at a mass ratio of 1:20, stir at 1200r / min for 20min to obtain a sodium-based bentonite suspension, and then add 11.5% of its mass of illite powder and 5 % bamboo charcoal fiber powder, after stirring evenly, pour into the reaction kettle, evacuate the reaction kettle to a vacuum, let it stand for 30min, then adjust the temperature to 70°C, pressurize to 0.5MPa, keep it for 1 hour, and then ventilate Add 1.8% didecyldimethylammonium chloride and 5.2% epoxy soybean oil to the reaction kettle, stir at 120r / min for 3 hours at 55°C, and then filter. Dried to constant weight to ...

Embodiment 2

[0031] A method for preparing an engine cooling system radiator plate rubber seal, comprising the following steps:

[0032] (1) After uniformly mixing 70 parts of EPDM rubber and 40 parts of polybutadiene rubber in parts by weight, add them to the open mixer for mastication to obtain plasticized rubber; Refining, plasticizing time is 1.5 hours;

[0033] (2) Mix sodium-based bentonite and ethanol uniformly at a mass ratio of 1:20, stir at 1200r / min for 20min to obtain a sodium-based bentonite suspension, and then add 11.5% of its mass of illite powder and 5 % bamboo charcoal fiber powder, after stirring evenly, pour into the reaction kettle, evacuate the reaction kettle to a vacuum, let it stand for 30min, then adjust the temperature to 70°C, pressurize to 0.5MPa, keep it for 1 hour, and then ventilate Add 1.8% didecyldimethylammonium chloride and 5.2% epoxy soybean oil to the reaction kettle, stir at 120r / min for 3 hours at 55°C, and then filter. Dried to constant weight to ...

Embodiment 3

[0043] A method for preparing an engine cooling system radiator plate rubber seal, comprising the following steps:

[0044] (1) After uniformly mixing 66 parts of EPDM rubber and 38 parts of polybutadiene rubber in parts by weight, add them to the open mixer for mastication to obtain plasticized rubber; Refining, plasticizing time is 1.5 hours;

[0045] (2) Mix sodium-based bentonite and ethanol uniformly at a mass ratio of 1:20, stir at 1200r / min for 20min to obtain a sodium-based bentonite suspension, and then add 11.5% of its mass of illite powder and 5 % bamboo charcoal fiber powder, after stirring evenly, pour into the reaction kettle, evacuate the reaction kettle to a vacuum, let it stand for 30min, then adjust the temperature to 70°C, pressurize to 0.5MPa, keep it for 1 hour, and then ventilate Add 1.8% didecyldimethylammonium chloride and 5.2% epoxy soybean oil to the reaction kettle, stir at 120r / min for 3 hours at 55°C, and then filter. Dried to constant weight to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com