Singeing device for printing and dyeing

A ceramic heater and guide rail technology, applied in singeing, textile and papermaking, fabric surface trimming, etc., can solve the problems of high production cost, easy-to-damage fabrics, and many types of equipment, and achieve energy saving and uniform temperature distribution. , excellent singeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

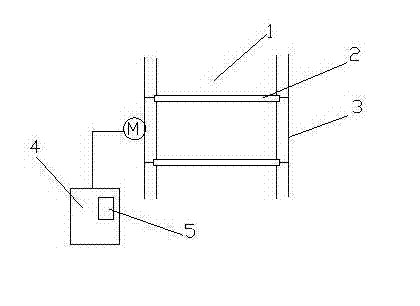

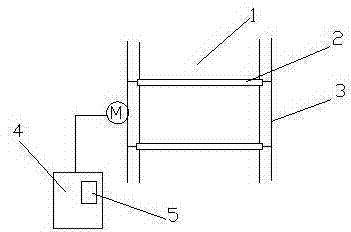

[0010] Now in conjunction with the accompanying drawings, the specific embodiments of the present invention will be further described.

[0011] The singeing device includes two parallel guide rails 3, on which the two ends of the ceramic heater 2 are respectively arranged; one side of the guide rail 3 is provided with a control cabinet for adjusting and controlling the temperature and speed of the ceramic heater 2. Two heaters are set on the guide rail 3, and the temperature of the two ceramic heaters is adjusted respectively through the control cabinet 4. The temperature is set according to the needs of the fabric. The temperature of the front ceramic heater is higher than that of the rear heater. The temperature of the device is too high, causing the probability of the surface of the fabric 1 being burned and damaged, and energy is also saved.

[0012] When working, the fabric first contacts the front ceramic heater with a slightly higher temperature to burn off most of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com