Cloth singeing production line

An assembly line and fabric technology, applied in the textile field, can solve problems that affect the appearance, imperfect processing procedures, and affect the smoothness and quality of fabrics, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

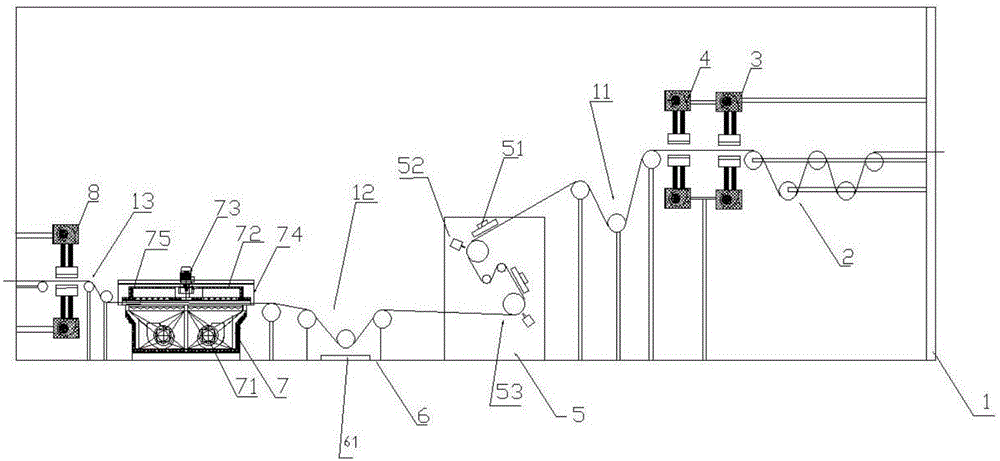

[0015] Such as figure 1 As shown, the present invention provides a cloth singeing assembly line, including a machine body 1, in which a tension adjustment roller group 2, a dust collection fan unit 3, a preheating fan unit 4, a singeing chamber 5, and a cleaning tank are sequentially arranged in the body 1 6. Oven 7, cooling fan unit 8, static electricity generating device 51, flame spraying device 52 and transfer roller group 2 53 for transferring cloth are provided in the singeing chamber 5, and ultrasonic vibrator is provided at the bottom of the cleaning tank 6. box 61, the oven 7 includes a circulation fan 71 installed at the bottom of the oven 7, a casing 74 installed outside the oven 7, a drying liner 72 is arranged below the casing 74, and the casing 74 is connected to the Stirring fans 73 are also provided on the drying liner 72, ironing boards 75 that can be lifted and lowered are provided on both sides of the passage for cloth transmission in the oven 7, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com