Magnetic adsorption type singeing production line

A magnetic adsorption, production line technology, applied in singeing, textile and papermaking, fabric surface trimming, etc., can solve the problems of easily hurting the fabric, not collecting waste in time, easily hurting the main body of the fabric, etc. Gross efficiency and smooth falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

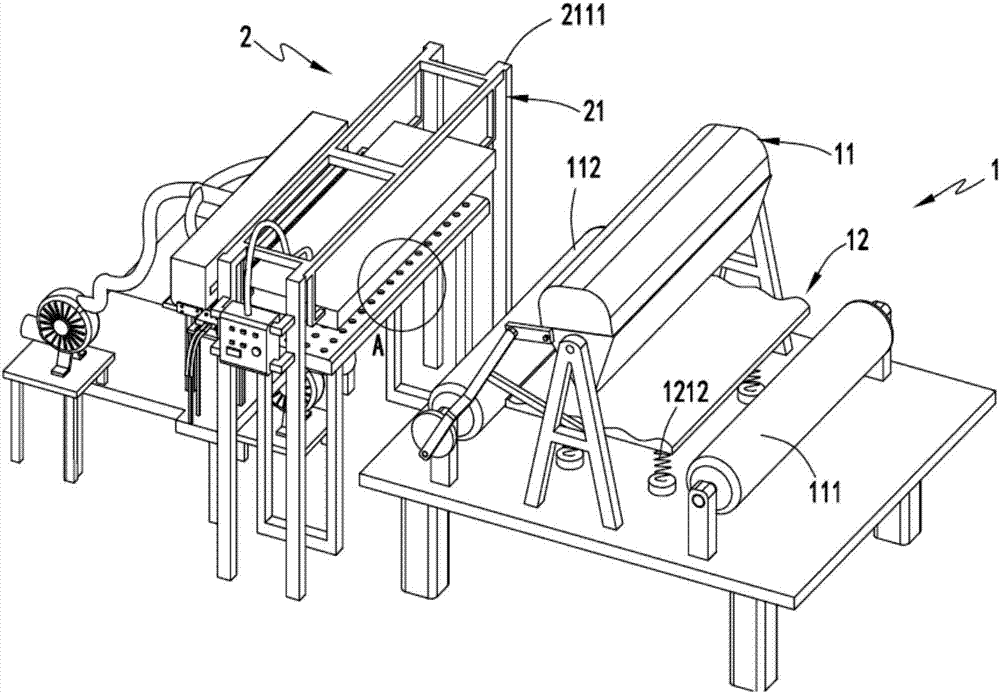

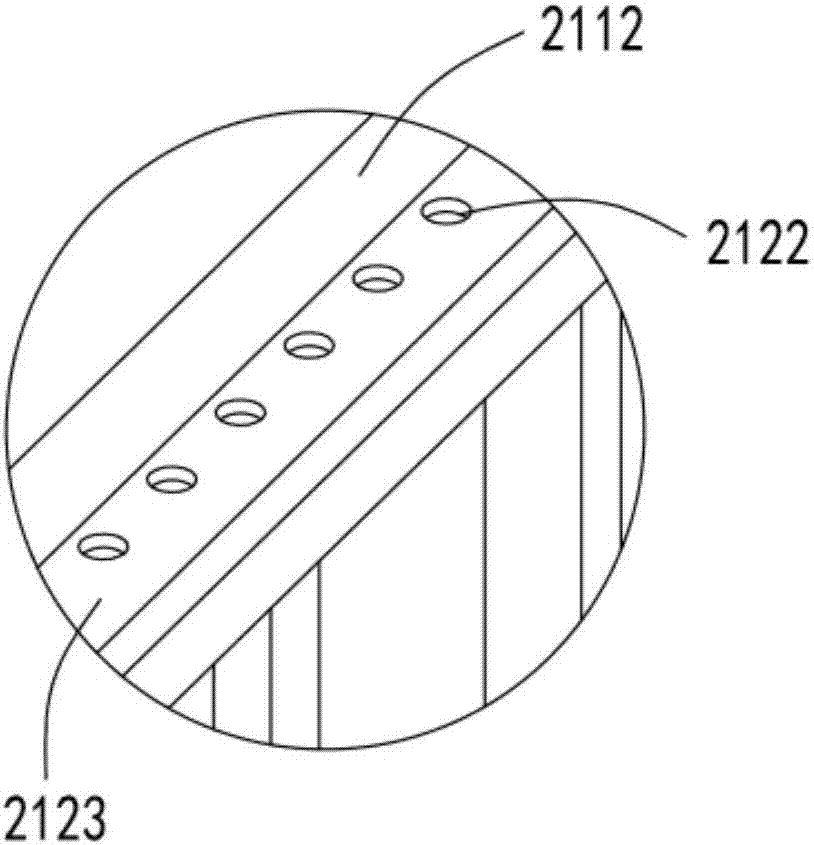

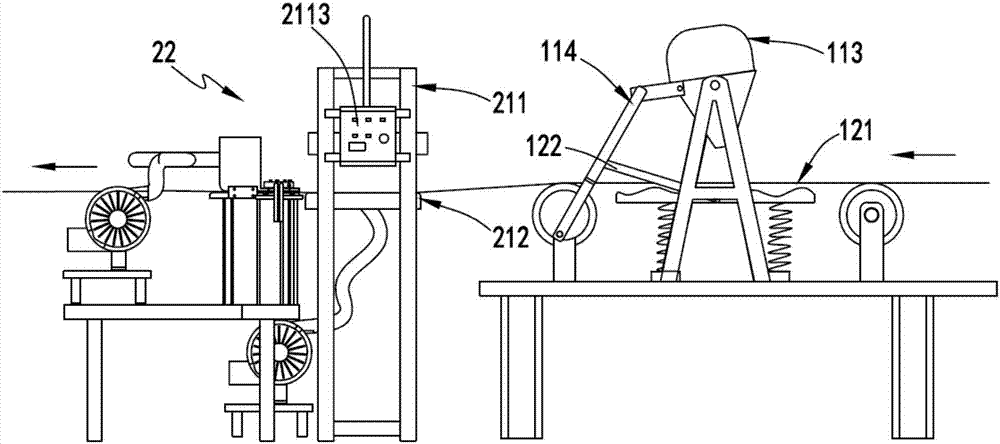

[0035] figure 1 It is a structural schematic diagram of a singeing production line with fast carding function, figure 2 It is a partial enlarged structural schematic diagram of the combing mechanism, image 3 It is a schematic front view of the singeing production line with fast carding function, Figure 4 It is a schematic diagram of the top view structure of the singeing mechanism, Figure 5 It is a partial cross-sectional schematic diagram of the singeing mechanism, Image 6 It is a schematic diagram of the structure when the cloth passes through the transmission channel, Figure 7 It is a schematic diagram of the structure of the spreading mechanism, Figure 8 It is a schematic diagram of the structure of the singeing mechanism, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a magnetic adsorption type singeing production line includes a feeding part 1, and the feeding part 1 includes a material s...

Embodiment 2

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that: the fixed shaft 1133 is provided with a number of agitating rods 1136, and the agitating rods 1136 are arranged along the length direction of the fixed shaft 1133 with their ends vertically facing downward.

[0055] By setting the agitating rod 1136 in the hopper 1134, the agitating rod 1136 continuously agitates the metal particles in the hopper 1134 during the swinging process of the hopper 1134, so as to ensure the smooth falling of the metal particles.

[0056] Working process: the textile fabric is transported backward t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com