Aluminum alloy rotary mixing amplitude adjustable double fire nozzles for printing-dyeing singeing machine

An aluminum alloy and crater technology, which is applied to the field of aluminum alloy rotary mixing adjustable amplitude double craters, can solve the problems of insufficient flame stability, deformation of the crater body, heavy weight, etc., and achieves improved singeing effect, flame stability, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

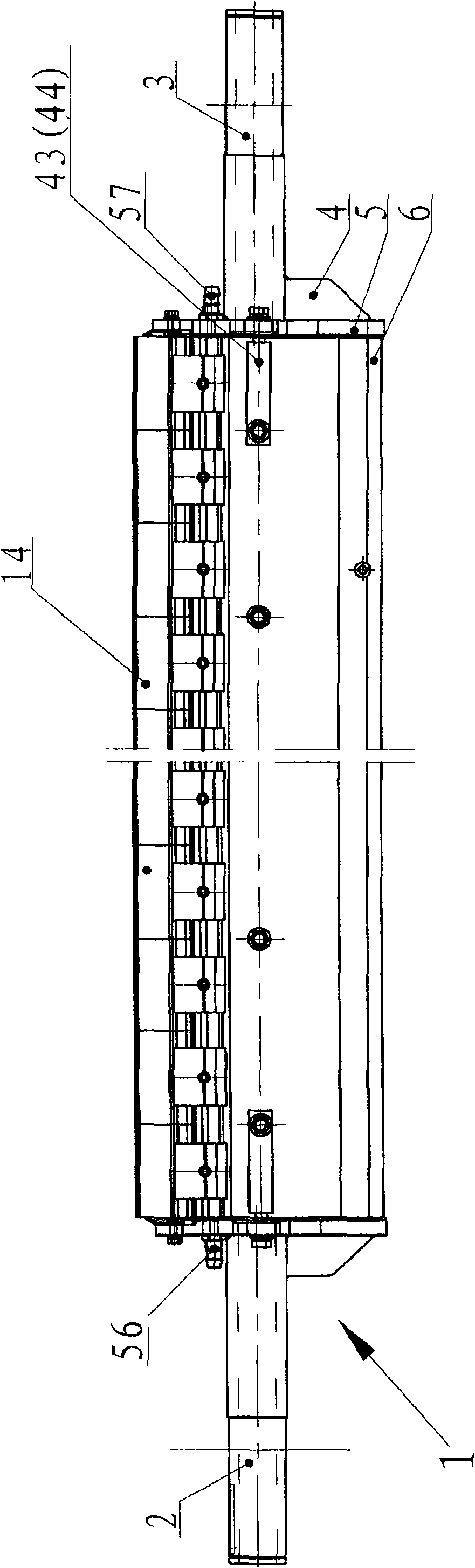

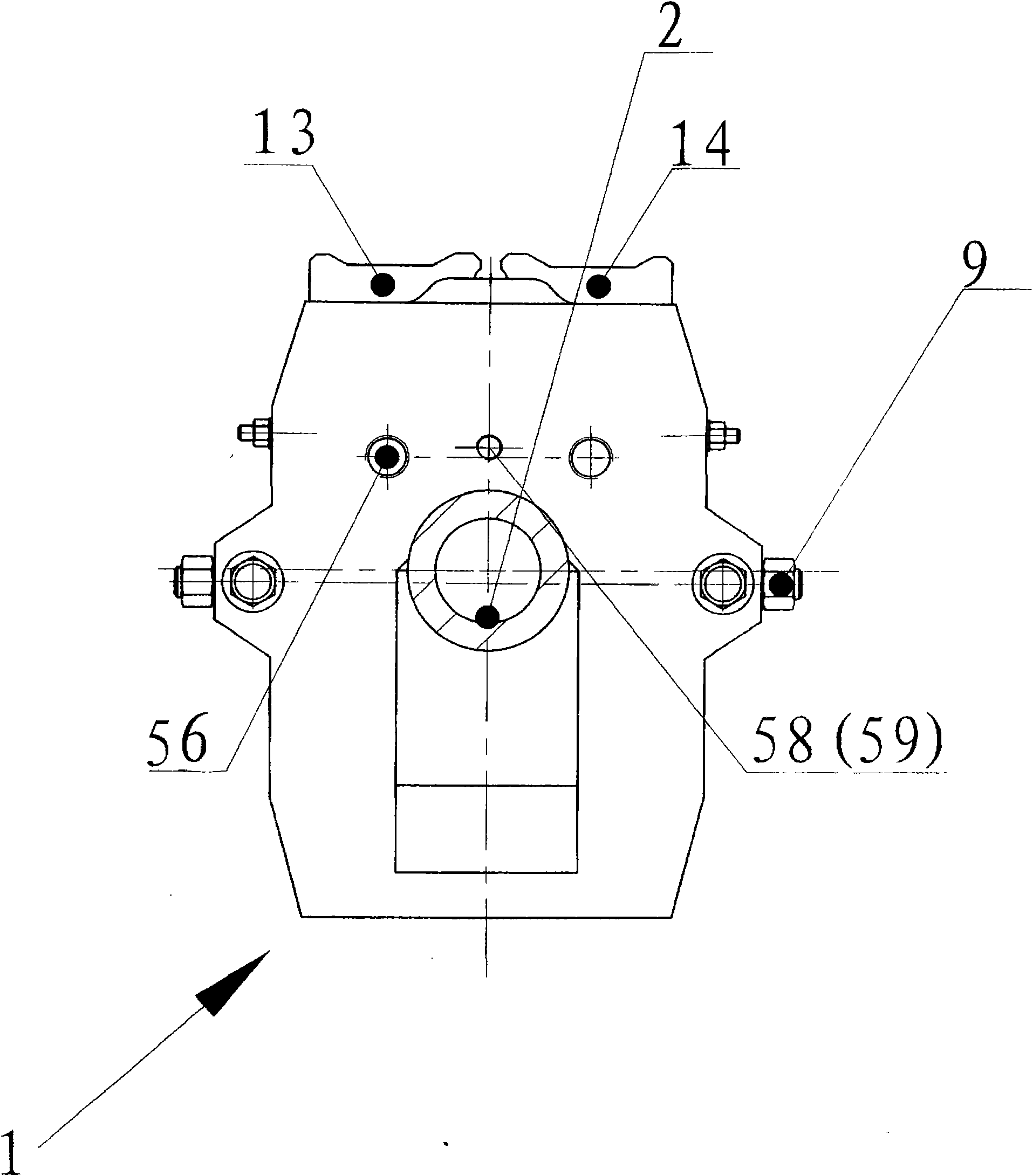

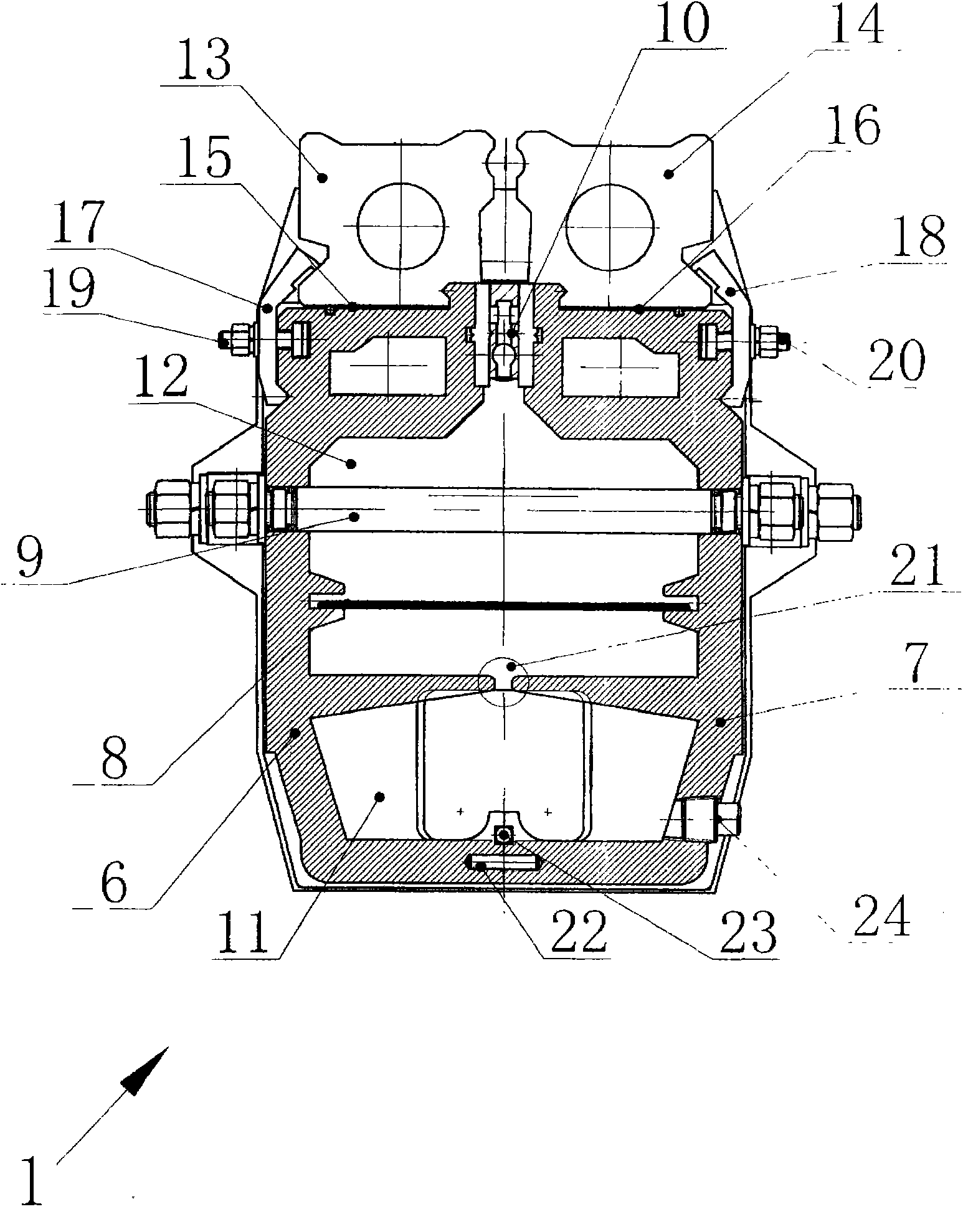

[0034] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, printing and dyeing singeing machine with aluminum alloy rotary mixing double nozzle 1 consists of left shaft head 2, right shaft head 3, air intake box 4, connecting flange 5, left burner body 6, right burner body 7, filter screen 8 , crater rail spout assembly 10, left heat shield 15, right heat shield 16, left crater brick 13, right crater brick 14 and positioning pin 22, left shaft head 2 and right shaft head 3 are welded to air intake box 4 respectively Together, one end of the connecting flange 5 is welded with the air intake box 4, and the other end is connected to the burner body; the burner body is connected by the left burner body 6 and the right burner body 7 through stud bolts 9, and the left side Between the burner body 6 and the right side burner body 7, a burner rail double nozzle assembly 10 is installed between the two upper parts of the burner body, and the left side rail 45 and the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com