Jean topical finish injecting type damping device

A post-finishing and jetting technology, used in spray/jet textile material processing, textile material processing, textiles and papermaking, etc., can solve problems such as waste of manpower and material resources, reduce the number of clean water replacements, and save drying energy , the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

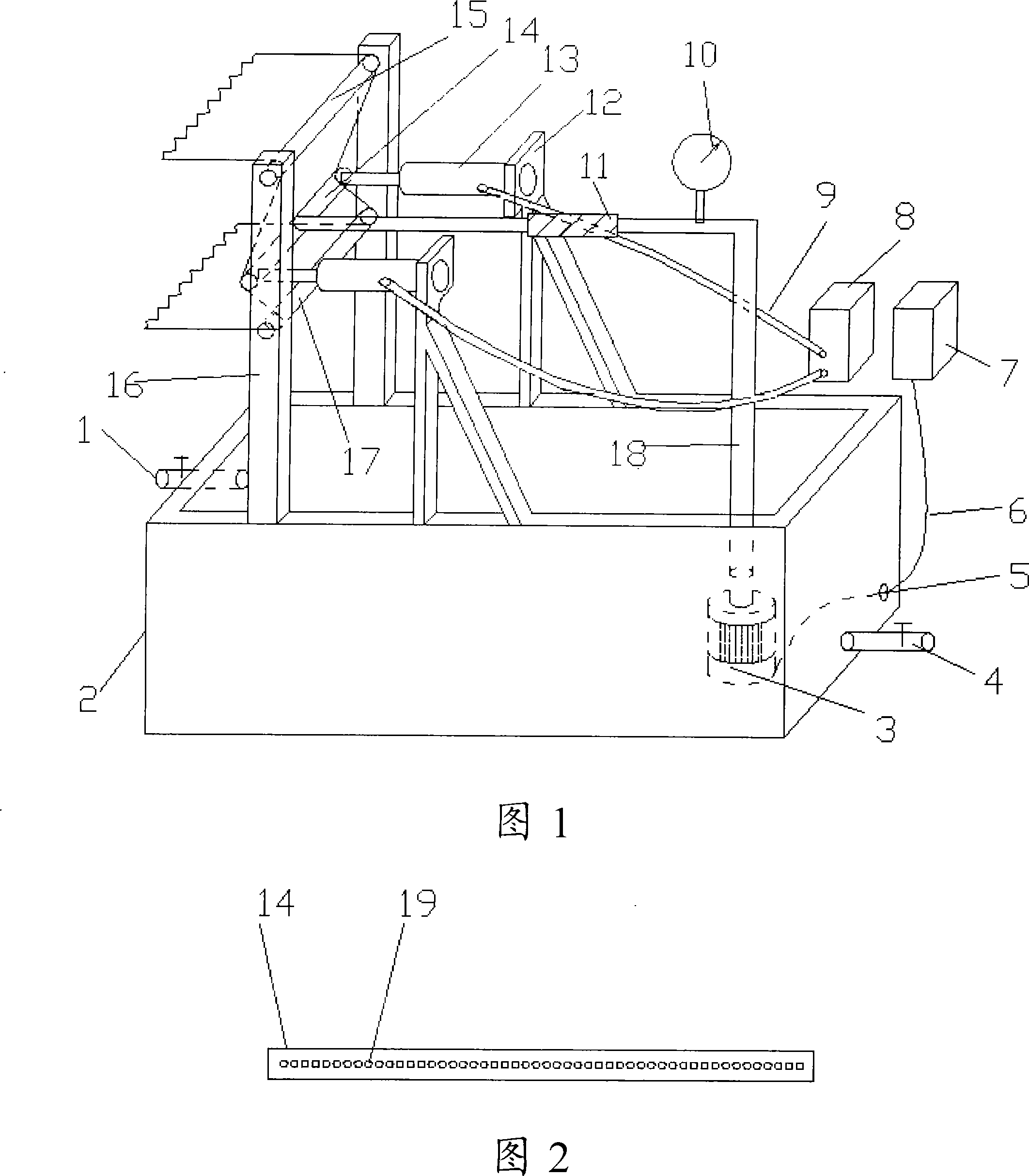

[0008] The present invention has a water tank 2, the water tank 2 has a water inlet pipe 1 and a water outlet pipe 4, and is characterized in that there is a submersible pump 3 in the water tank 2, and the water outlet of the submersible pump 3 passes through a stainless steel pipe 18, a telescopic hose 11 and a nozzle 14 connected, a pressure gauge 10 is installed on the upper part of the stainless steel pipe 18, a row of spray holes 19 is arranged on the nozzle pipe 14, and a hydraulic cylinder 13 is respectively installed at both ends of the nozzle pipe 14, and the hydraulic cylinder 13 is installed on the two sides of the water tank 2 respectively. On the support 12, the liquid input port of the hydraulic cylinder 13 communicates with the liquid output port of the hydraulic pump 8 through the pipeline 9, and the two sides of the water tank 2 are respectively installed in parallel to the left. Roller 17, cloth guide roller 15 is housed between the top of these two pillars 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com