Drying system for gypsum boards without paper surface

The technology of a gypsum board and drying system is applied in the field of drying equipment for gypsum boards without a paper surface, which can solve the problems of energy consumption, difficult construction and high cost, and achieve the effects of saving drying energy and reducing drying costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

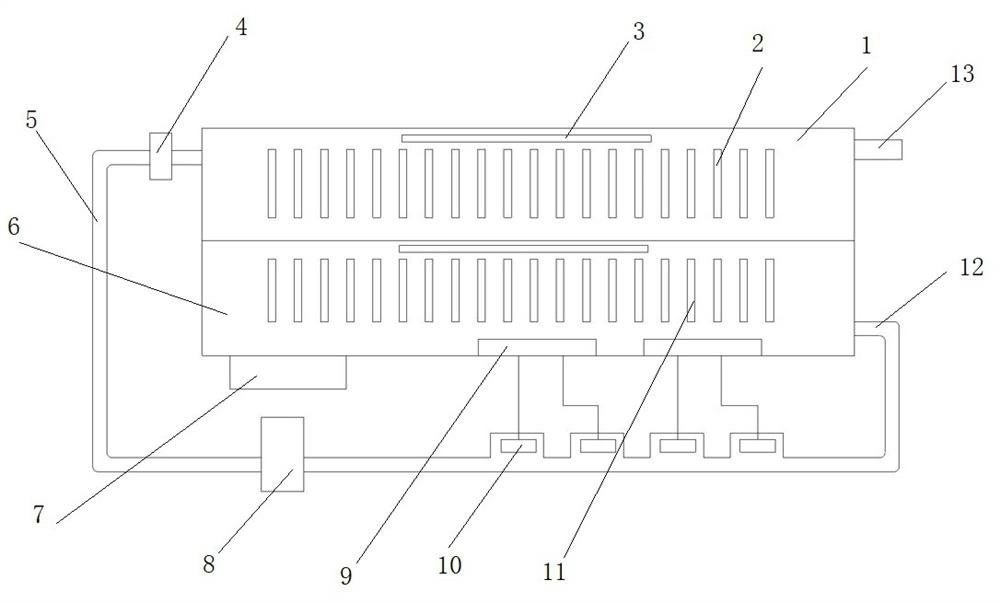

[0017] In order to better illustrate the technical solution of the present invention, the specific implementation manner of the present invention is further described in conjunction with the accompanying drawings, as figure 1 In this example, the production method of paperless gypsum board proposed by the Chinese patent (application number: 2020111610779) previously applied for is used as an example to illustrate the specific implementation of the present invention; The paper-free gypsum board of the formwork is sent into the gypsum board solidification plant 1 of the application. In this example, the width of the gypsum board solidification plant is 9 meters, and the length is a rectangular cross-section plant of 60 meters. The roof adopts glass or transparent plastic. The surrounding wall adopts an opaque structure in the lower half and a transparent structure in the upper half, and there are doors at both ends of the length; the gypsum board drying and conveying equipment co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com