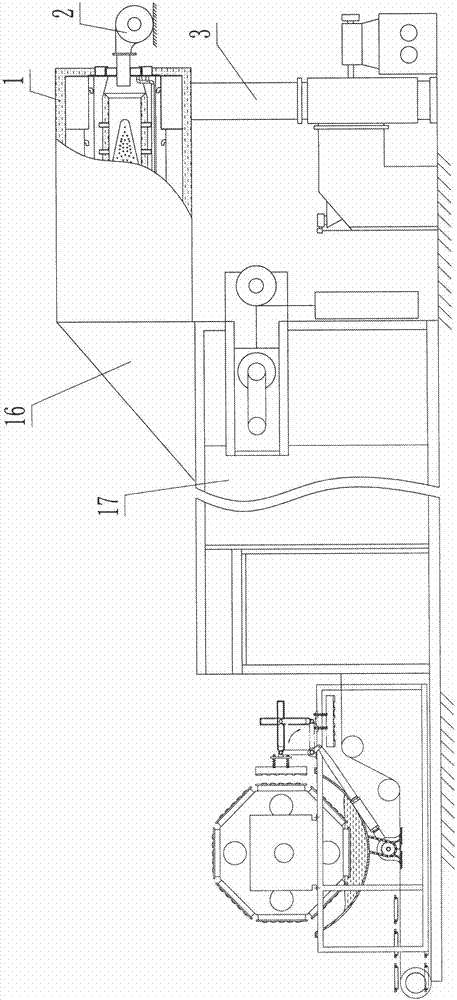

Combustion-supporting device in the combustion chamber of the drying box of the egg tray machine

A combustion chamber and drying box technology, applied in drying, drying machines, heating devices, etc., can solve the problems of insufficient combustion, pollution, waste of drying energy, etc., and achieve the effect of saving drying energy and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

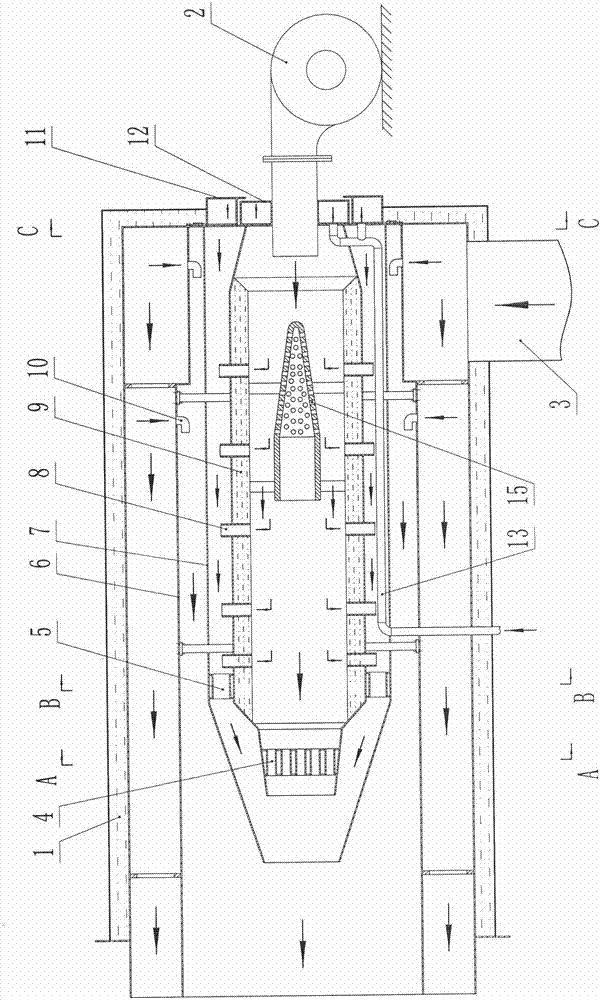

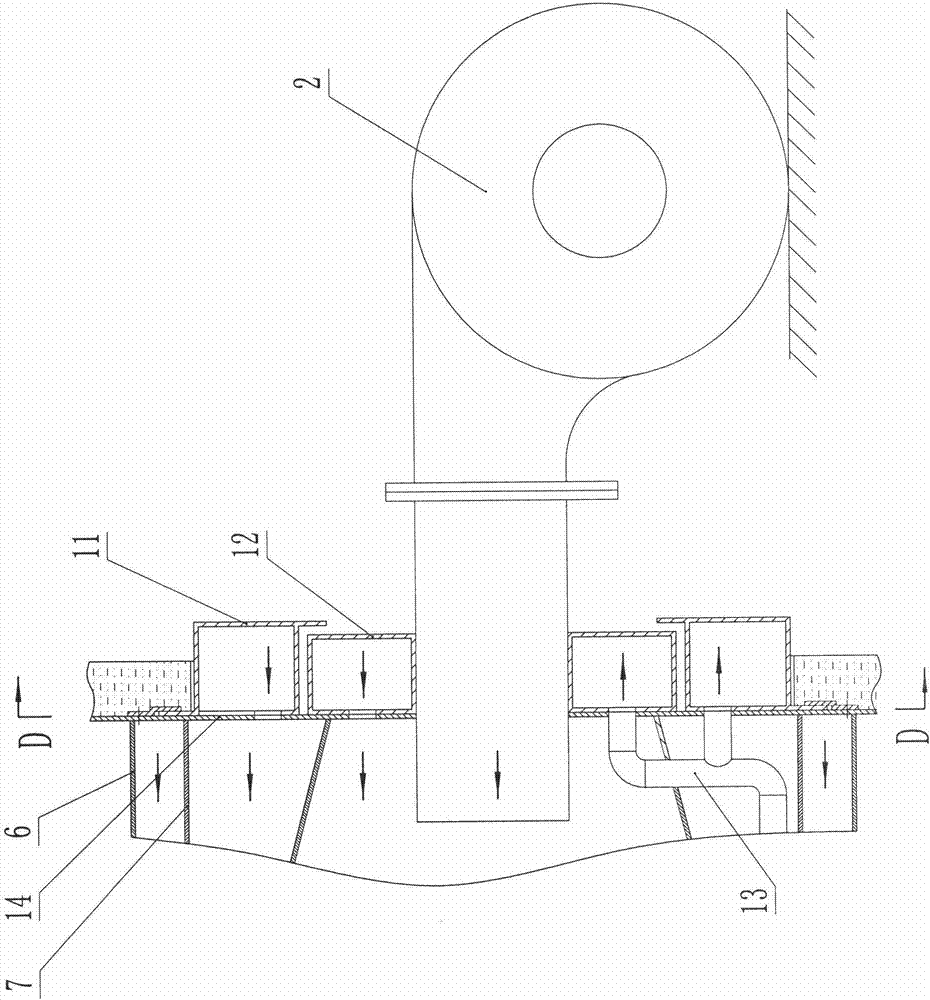

[0014] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the examples given are only used to explain the present invention, and do not constitute a specific limitation to the patent protection scope of the present invention.

[0015] The combustion-supporting device ( Figure 1-Figure 7 Shown), comprise housing 1 lumen spacer ring sleeve and be connected with cylindrical combustion chamber 6; It is to be connected with outer combustion-supporting chamber 7 in the inner cavity interval of described combustion chamber; Inner combustion chamber 9. In order to increase the temperature at which the pyrotechnics in the internal combustion-supporting chamber are fully combusted, the shell of the internal combustion-supporting chamber 9 adopts a heat storage layer ( figure 2 shown). The outer and inner combustion-supporting chambers 7 and 9 are all connected to each other wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com