Apparatus for electricity generation by refuse incineration and hot air flow

A technology of waste incineration and power generation equipment, applied in the field of thermodynamic theory, can solve the problems of unsatisfactory economic benefits of waste power plants, difficult control of steam temperature and pressure, and large amount of coal for combustion, so as to reduce the investment per kilowatt and eliminate secondary Effects of environmental pollution and economic benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

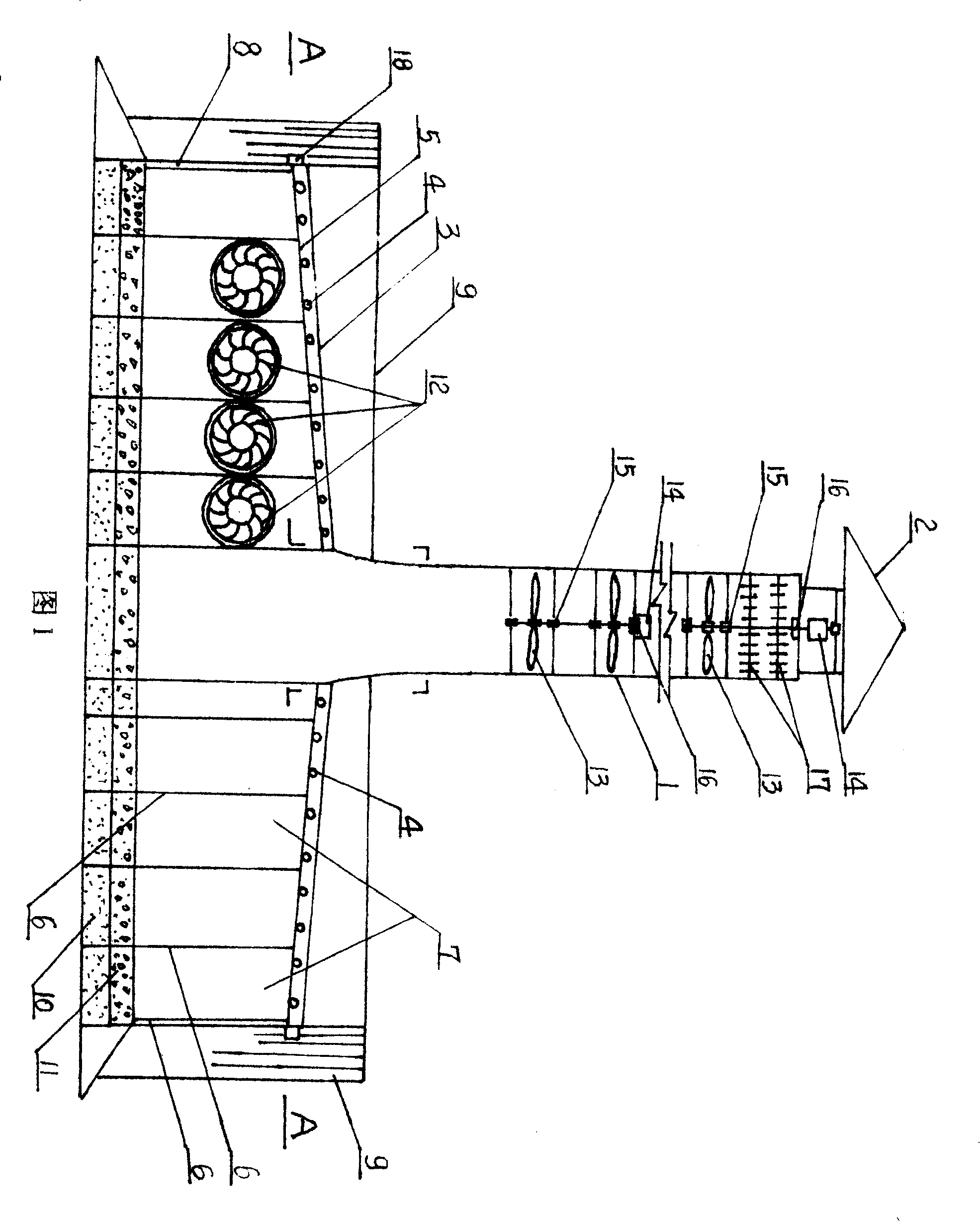

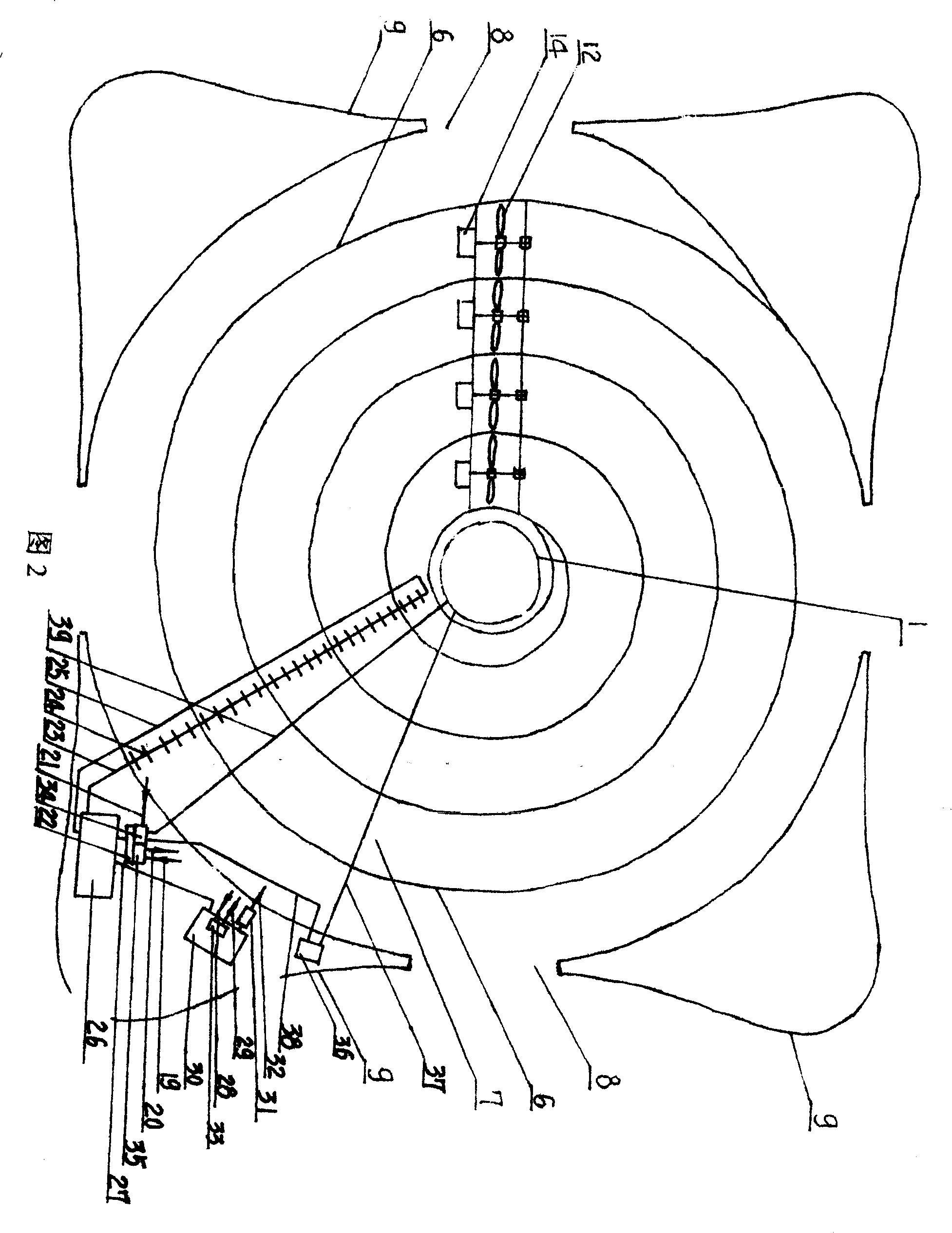

[0019]In Fig. 1 and Fig. 2, there are solar heat collection system, waste drying and incineration combustion-supporting system, air flow collection and heating to form hot air flow system, heat storage and release system, waste incineration system, hot air flow power generation system, heat energy recovery and reuse system .

[0020] The solar heat collecting system is composed of a solar heat collecting chamber (3), a heat absorbing pipe (4) and a heat absorbing pipe support (5). The air flow is collected and heated to form a thermal air flow system. The solar heat collection chamber (3) is made of a light-transmitting glass cover, and its bottom is connected with the wind tunnel (7). The function of the solar heat collection chamber (3) is to capture and collect solar heat energy. The heat-absorbing pipe (4) is made of copper pipe, and several heat-absorbing pipes (4) are arranged in the solar heat-collecting chamber (3), and the several heat-absorbing pipes (4) are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com