Device for cleaning and recycling circuit boards

A recovery device and circuit board technology, applied in cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of long drying process time, large energy consumption, and residual cleaning liquid. Achieve the effect of reducing cleaning fluid residue, eliminating the need for rinsing process, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

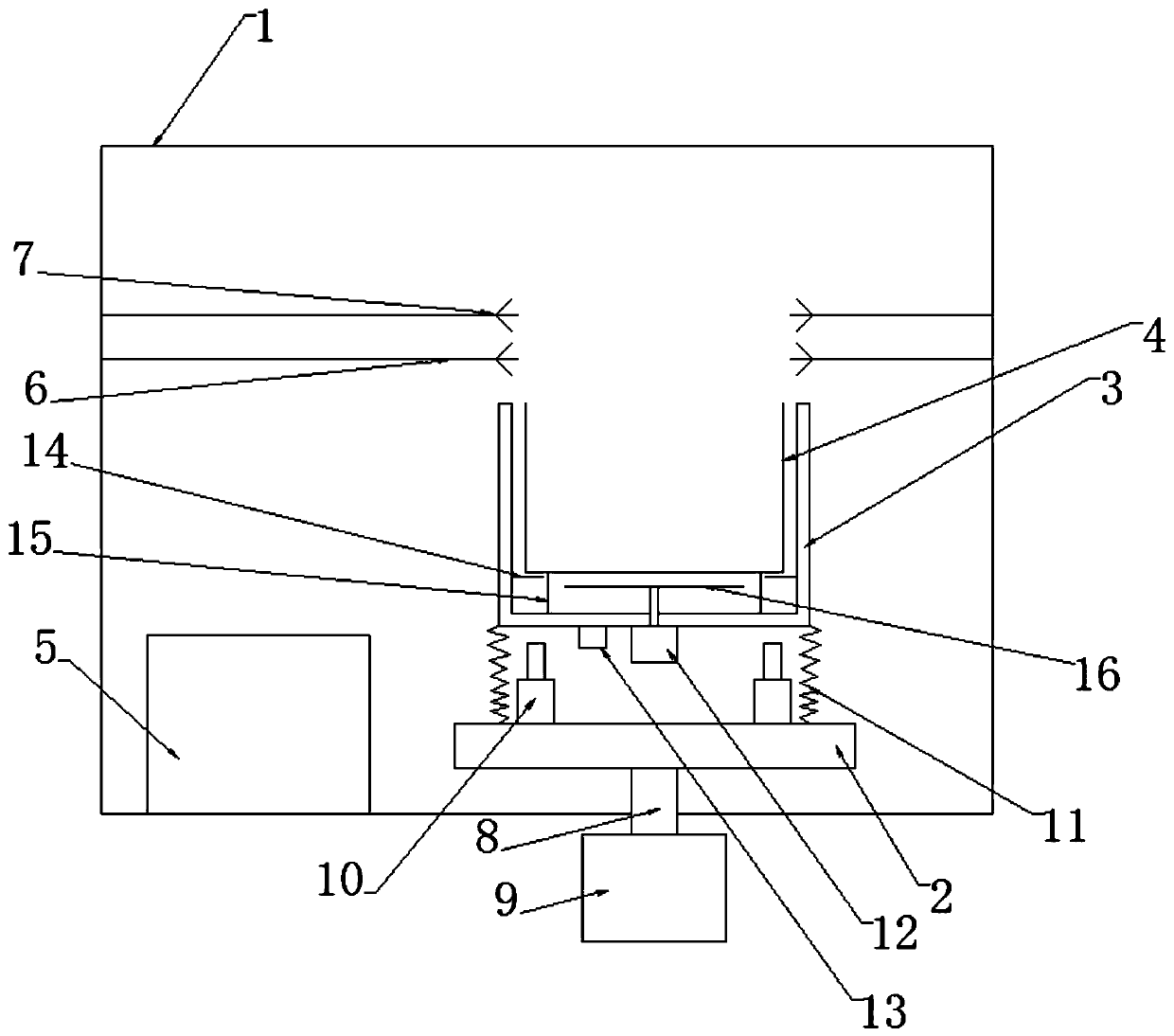

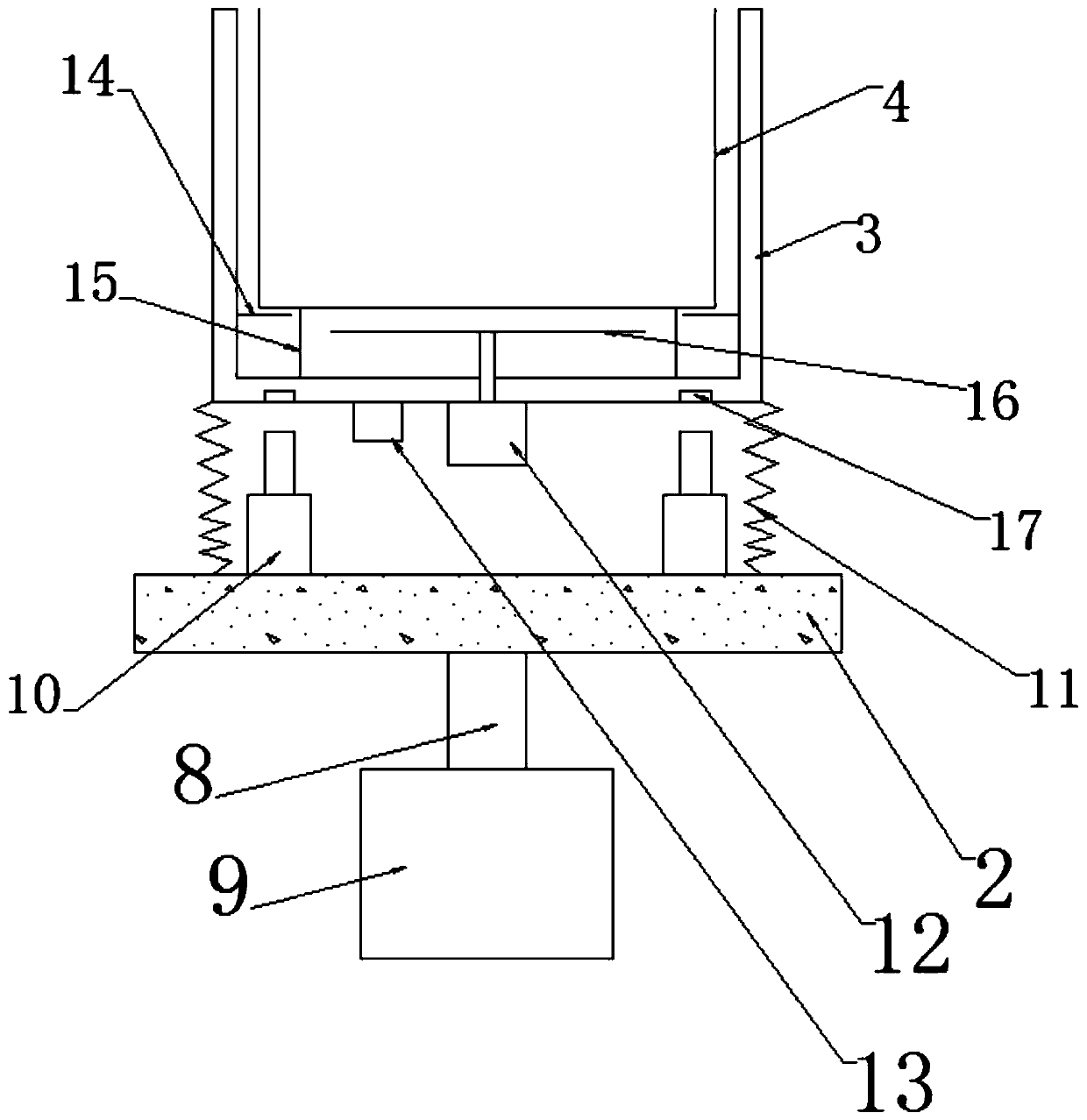

[0032] As a circuit board cleaning and recovery device according to an embodiment of the present invention, the circuit board cleaning and recovery device includes a box body 1, a horizontal turntable 2, a cleaning tank 3, a tank-shaped filter screen 4, and a cleaning liquid storage tank 5, 8-16 A cleaning fluid nozzle 6, an air pump and 8-16 air nozzles 7;

[0033] The inside of the box 1 is hollow, the upper part of the box is provided with an openable top cover, the outer bottom of the box is provided with supporting legs, the bottom of the supporting legs is provided with a steering wheel, and the steering wheel is provided with a braking mechanism ;

[0034] The horizontal turntable 2 is fixed on the inside bottom of the box body 1 for horizontal rotation, and the center of the bottom of the horizontal turntable 2 is fixedly connected with a vertical shaft 8, and the vertical shaft is driven by a first motor 9, and the upper part of the horizontal turntable is fixed verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com