Closed efficient waste heat utilization circulating system of humid air turbine compressor

A circulatory system, wet air technology, applied in mechanical equipment, machines/engines, spray evaporation, etc., can solve the problems of large energy waste, energy waste, and difficulty in waste gas and dust control, achieve automatic control, reduce production costs, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

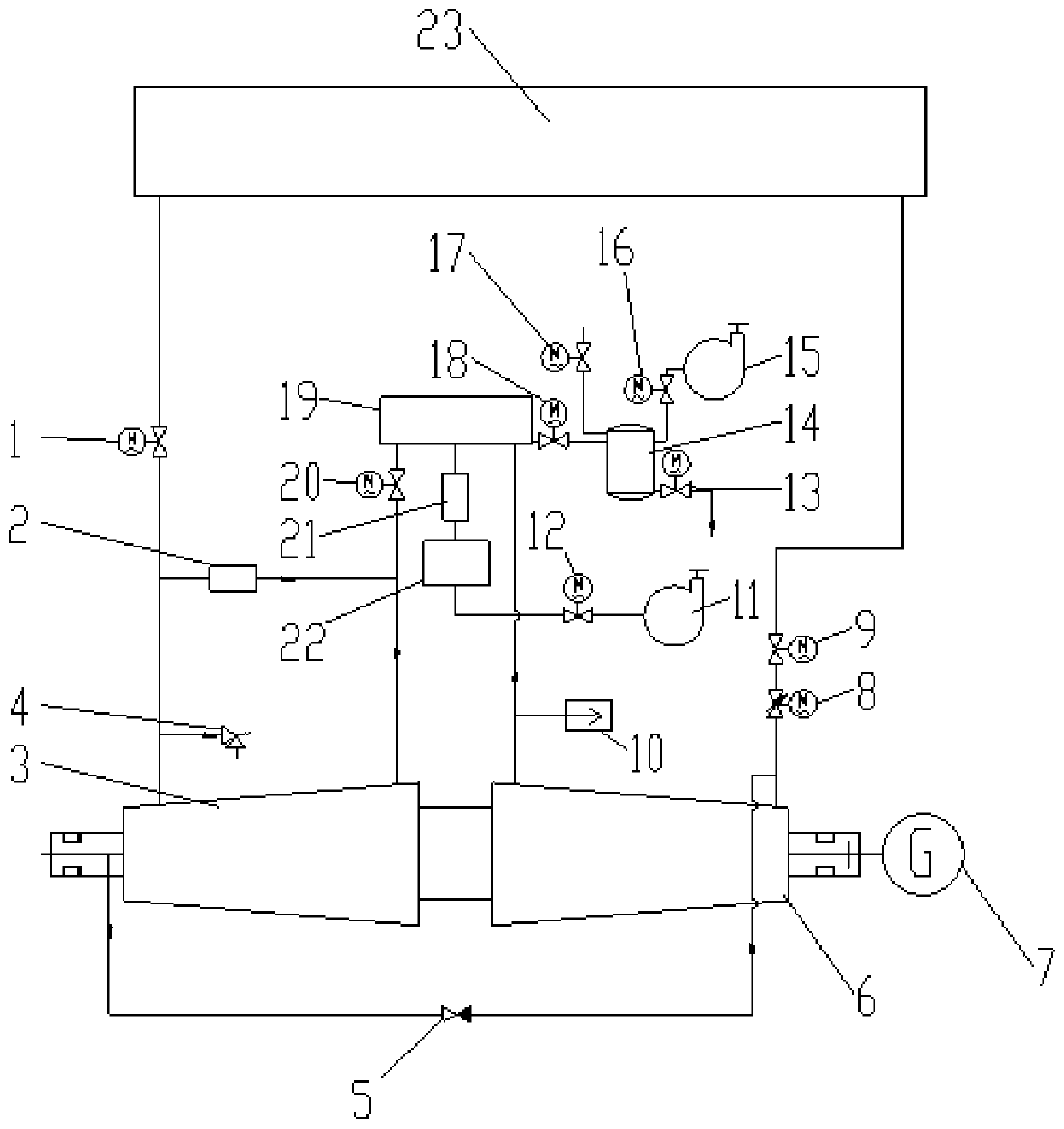

[0024] Such as figure 1 As shown, in this embodiment, a humid air turbine compressor closed-type high-efficiency waste heat utilization cycle system includes a humid air compressor turbine compression-expansion system and a wet air gas-water separation system;

[0025] The humid air compressor turbine compression-expansion system includes a cut-off valve I9, a regulating valve 8 and a wet air turbine 6 that are communicated with the outlet of the drying chamber 23 through pipelines in sequence according to the flow direction of the medium; The compression-expansion system also includes a moist air compressor 3 communicated with the inlet of the drying chamber 23 through a shut-off valve VIII1;

[0026] The wet air gas-water separation system includes a wet air gas-water separator 19 connected between the wet air turbine 6 outlet and the wet air compressor 3 inlet, and the wet air gas-water separator 19 is connected with a vacuum water storage tank 14.

[0027] The high tempe...

Embodiment 2

[0040] On the basis of the above-mentioned embodiments, in this embodiment, a humid air turbine compressor closed-type high-efficiency waste heat utilization cycle system also includes a humid air high-vacuum pressure stabilizing system, and the humid air stabilizing system includes The pressure-stabilizing valve 21, the pressure-stabilizing tank 22, the shut-off valve II12 and the vacuum pump I11 which are communicated with the second outlet pipeline of the humid air gas-water separator 19 through pipelines in sequence.

[0041]During normal operation, the shut-off valve II12 and the vacuum pump I11 are closed, and the vacuum pump I11 is used to evacuate the surge tank 22 so that the vacuum degree in the surge tank 22 is higher than that of the wet air gas-water separator 19. According to the wet air gas-water separator 19 and the pressure difference of the surge tank 22 and adjust the valve opening of the pressure regulator valve 21, thereby maintaining the pressure in the we...

Embodiment 3

[0046] On the basis of the above-mentioned embodiments, in this embodiment, a cut-off valve VI18 is set between the humid air gas-water separator 19 and the vacuum water storage tank 14, and the first outlet of the vacuum water storage tank 14 communicates with There is a shut-off valve V17, the first outlet of the vacuum water storage tank 14 is connected with a shut-off valve III13, the second outlet of the vacuum water storage tank 14 is connected with a shut-off valve V17, and the vacuum water storage tank 14 passes through the shut-off valve IV16 It is connected with vacuum pump II15. During normal operation, the stop valve Ⅵ18 is in the open state, and the stop valve Ⅳ16, the stop valve Ⅴ17 and the stop valve Ⅲ13 are in the closed state. The stop valve VI18, the stop valve V17, the stop valve IV16 and the stop valve III13 are all electromagnetic valves.

[0047] When the water level of the vacuum water storage tank 14 reaches the water discharge level, the stop valve VI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com