Production method for producing cement and sulfuric acid from phosphogypsum

A production method, phosphogypsum technology, applied in cement production, chemical instruments and methods, sulfur compounds, etc., can solve problems such as suboptimal energy consumption, low gas concentration, large air, etc., to optimize the quality of cement products and increase economical Benefit, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

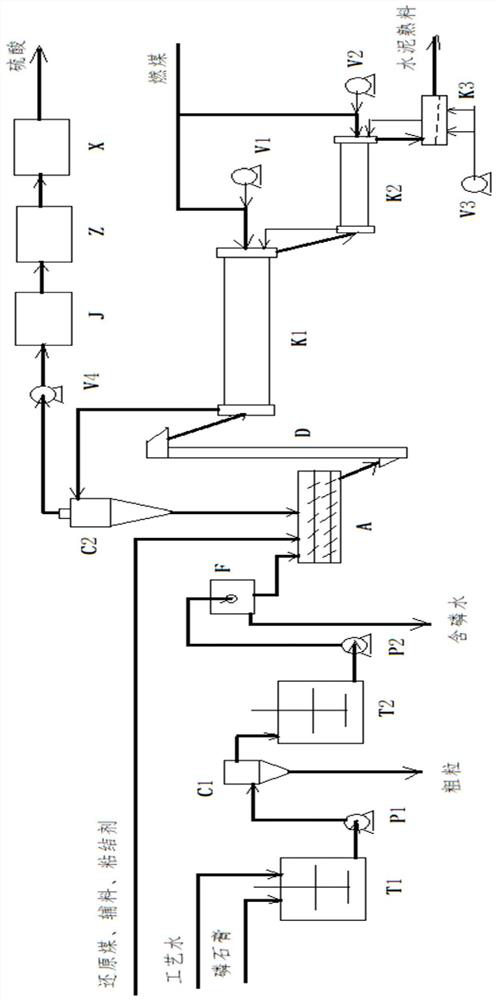

[0055] Such as image 3As shown, the phosphogypsum filter cake from the phosphoric acid production filter and the production process water safety ratio 1:2.5 are continuously sent to the beating tank T1 for beating, and the beating slurry is continuously sent to the C1 separator through the pump P1 for separation. Coarse granular materials are returned to the phosphate ore grinding process of the phosphoric acid production process; the fine slurry is separated and entered into the slurry storage tank T2, and then sent to the filter press F by the pump P2 for filtration, and the filtrate is phosphorus-containing water and returned to the phosphoric acid factory to produce phosphoric acid During the washing of the filtered phosphogypsum, the filter cake is pressed through a diaphragm and dried by air to obtain purified dehydrated phosphogypsum. The composition before and after purification is shown in Table 1. Purified phosphogypsum filter cake, reducing agent coke and other pul...

Embodiment 2

[0065] Such as image 3 As shown, the phosphogypsum filter cake from the phosphoric acid production filter and the production process water safety 1:2.0 are continuously sent to the beating tank T1 for beating, and the beating slurry is continuously sent to the C1 separator through the pump P1 for separation. Coarse granular materials are returned to the phosphate ore grinding process of the phosphoric acid production process; the fine slurry is separated and entered into the slurry storage tank T2, and then sent to the filter press F by the pump P2 for filtration, and the filtrate is phosphorus-containing water and returned to the phosphoric acid factory to produce phosphoric acid During the washing of filtered phosphogypsum and replenishment of wet grinding pulp, the filter cake is squeezed through a diaphragm and dried by air to obtain purified dehydrated phosphogypsum. The composition before and after purification is shown in Table 4. Purified phosphogypsum filter cake, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com