Conversion of coal-fired power plants to co-generate cement

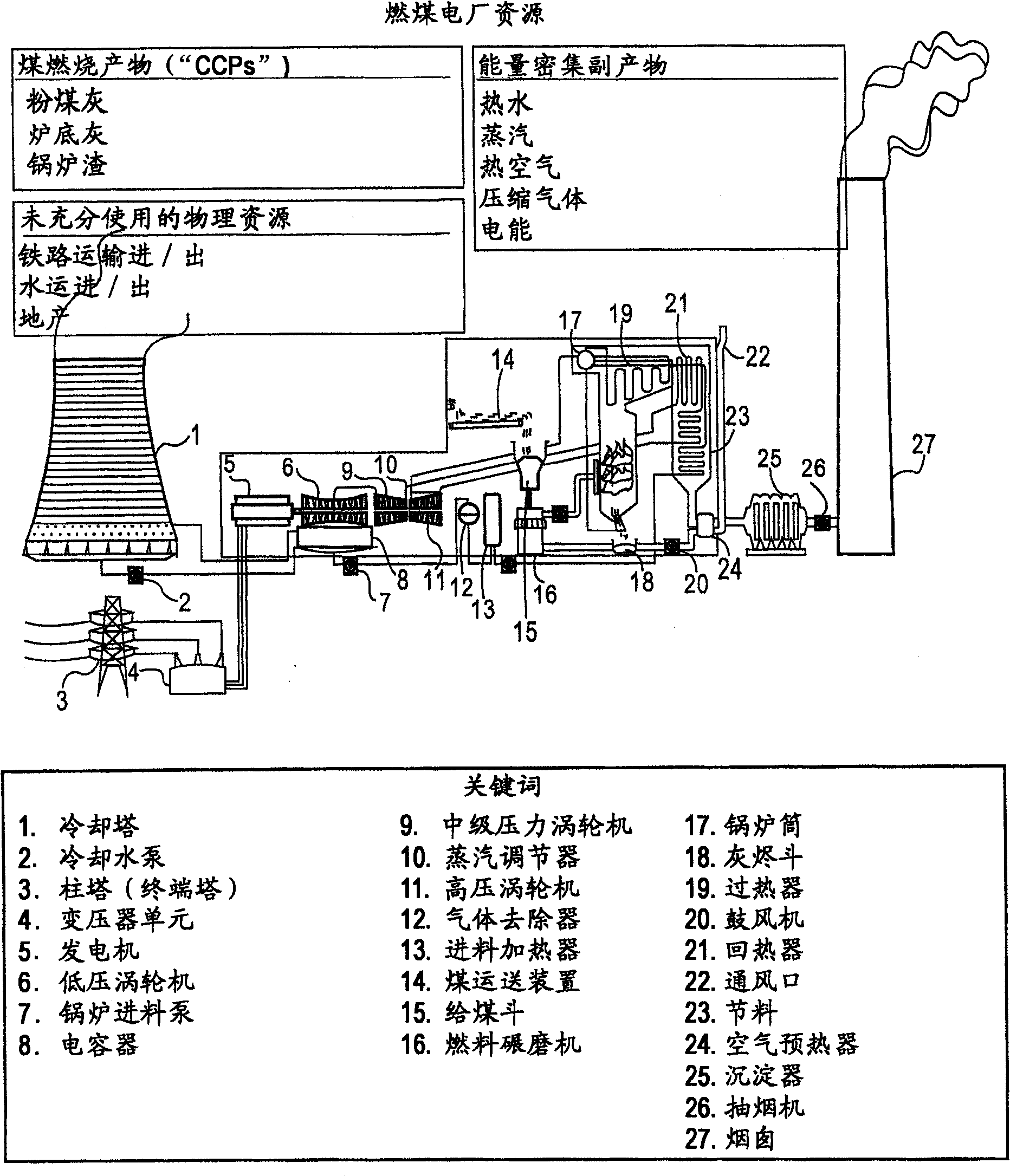

A technology for coal-fired power plants and cement, applied in cement production, manufacturing tools, clinker production, etc., can solve problems such as large railway transportation and water transportation resources, consumption of CFPPs, etc., to eliminate demand, reduce emissions, and cost-competitive. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

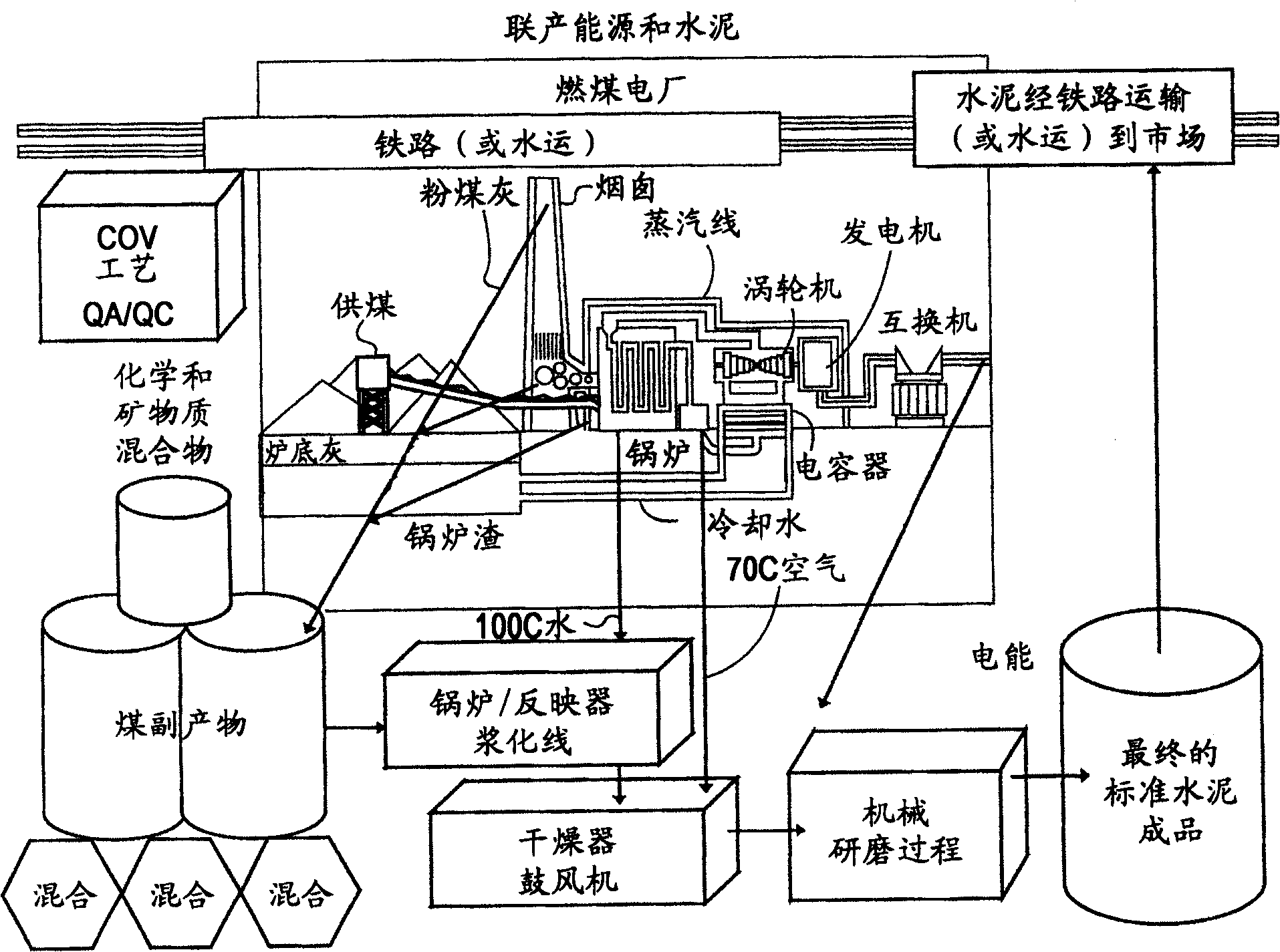

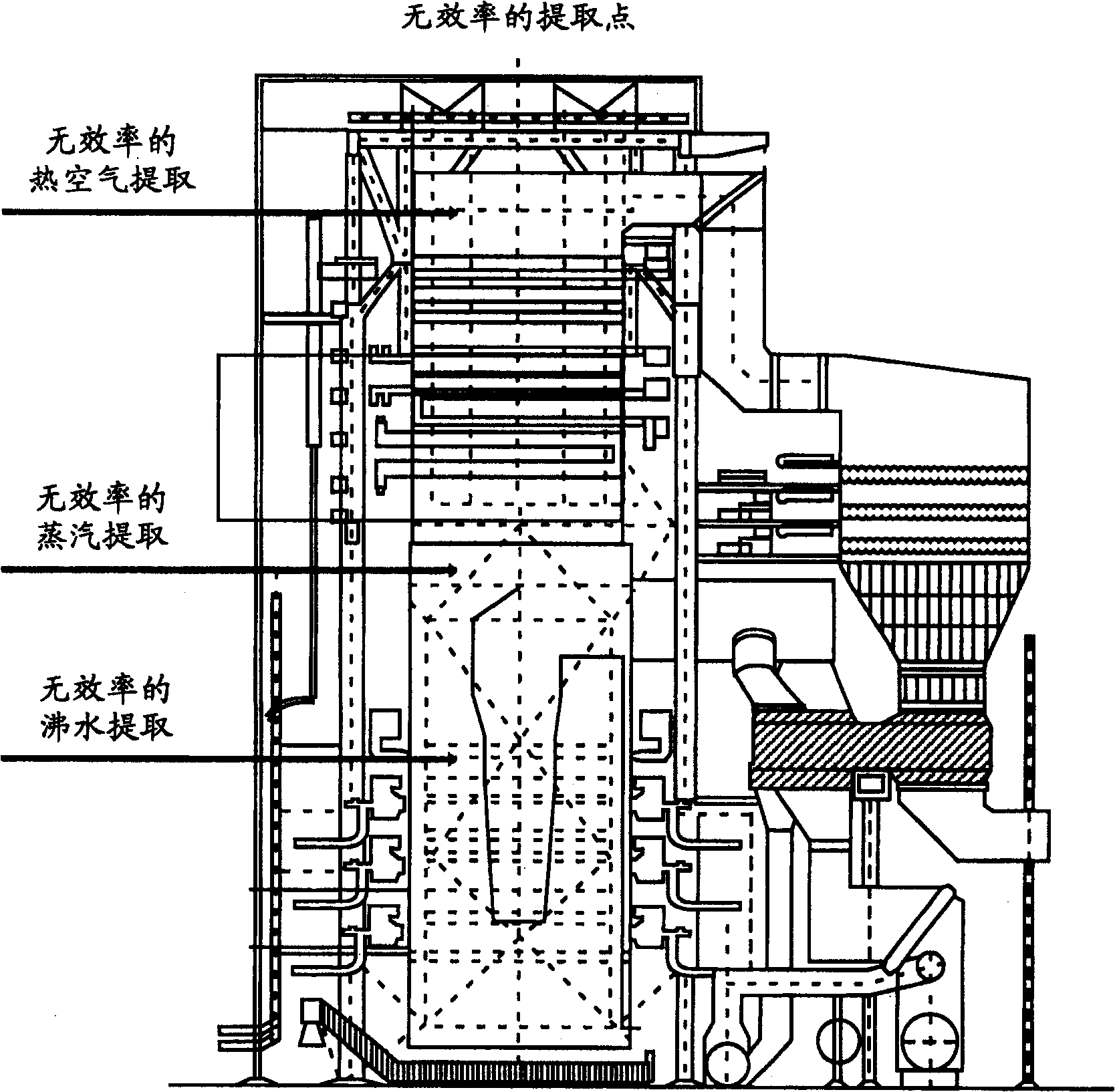

[0028]The present invention provides systems, processes and methods for the cogeneration of energy and cement. A variety of cements can be produced using CCPs, other valuable resources, and related by-products of CFPPs. In this application, the term "polygeneration" includes by-products produced using thermal energy in cement production. Polygeneration includes, but is not limited to, cogeneration, such as the production of cement by utilizing by-products produced in thermal energy production (eg CFPP electricity production). Furthermore, as described herein, polygeneration includes the production of resources (eg, by-products) from one industrial process and is itself useful for other industrial processes. Furthermore, polygeneration includes the combined utilization of various resources and / or by-products from one industrial process (eg cogeneration of heat / electricity) to implement a second industrial process (eg production of cement, concrete, etc.).

[0029] The present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com