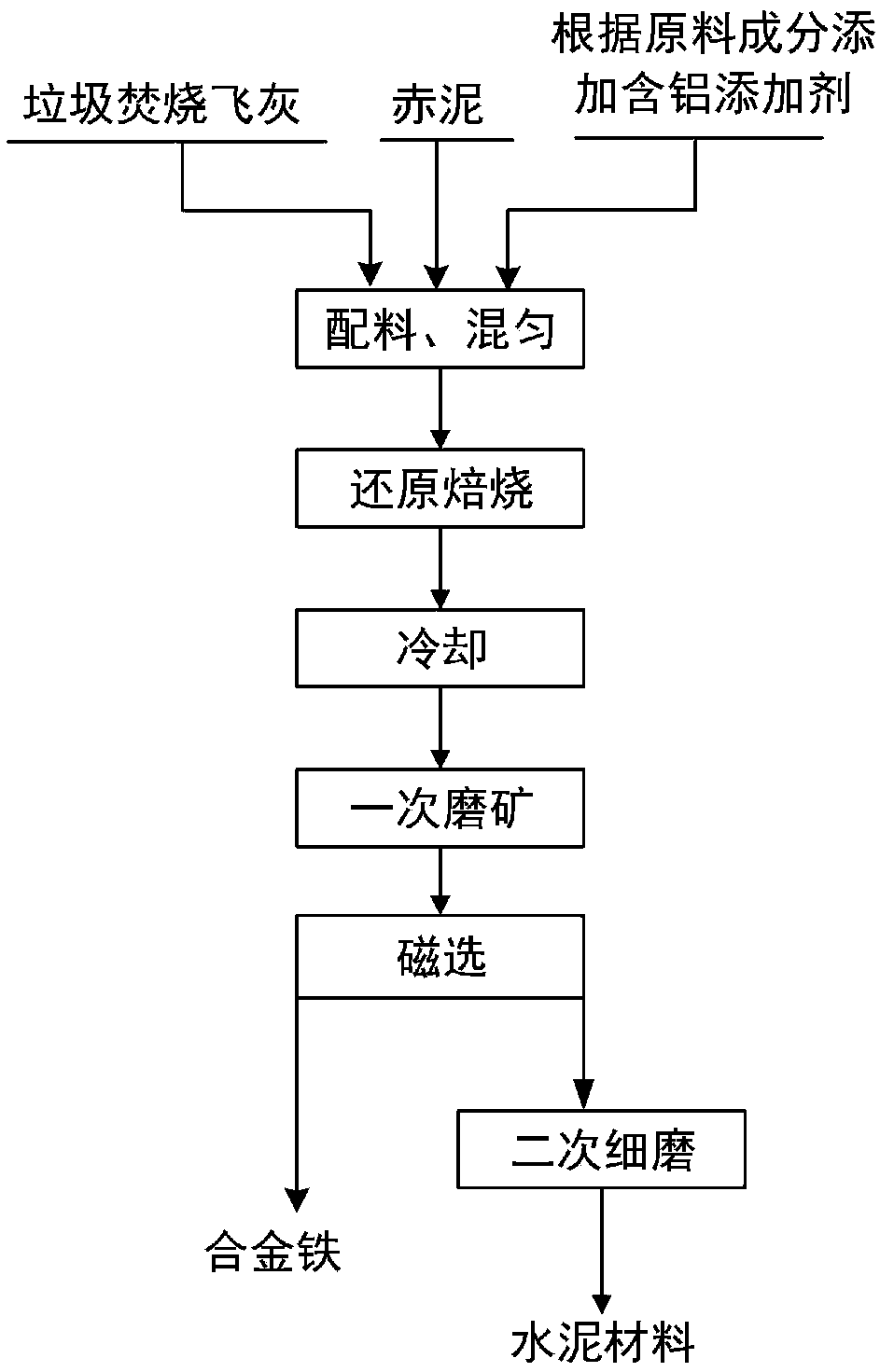

Method for preparing alloy iron and cement material

A cement material and alloy iron technology, which is applied in chemical instruments and methods, cement production, manufacturing tools, etc., can solve the problems of inability to realize red mud resource utilization and high cost, and achieve reduction and harmlessness. High and improve the effect of comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The amount of waste incineration fly ash is 35wt%, and the amount of red mud is 65wt%. Mix the waste incineration fly ash and red mud evenly according to the proportion, put them into a crucible, and place the crucible in a muffle furnace for reduction roasting at 1200°C for 90 minutes; cooling, grinding once The fineness of the product -0.043mm is 71.32%, and the obtained product is magnetically separated under the condition of a magnetic field strength of 1.8kGs, and the iron grade can be obtained with an iron grade of 92.56%, and an iron recovery rate of 83.22%. ; The non-magnetic cement material is finely ground for the second time, and the fineness is -0.043mm, which is 97.36% and the specific surface area is 480m 2 / kg of cement material, the main phase of the cement material is vitreous body and tricalcium silicate, with water glass and sodium hydroxide as alkali activator, the compressive strength of 28 days is 78Mpa.

[0044] In this embodiment, the main chemic...

Embodiment 2

[0048] The amount of waste incineration fly ash is 40wt%, and the amount of red mud is 60wt%. Mix the waste incineration fly ash and red mud evenly according to the proportion, put them into a crucible, and place the crucible in a muffle furnace for reduction roasting at 1250°C for 60 minutes; cooling, the first stage The fineness of the grinding product -0.043mm is 73.48%. The obtained product is magnetically separated under the condition of a magnetic field strength of 1.8kGs, and the iron grade is 91.96%, and the iron recovery rate is 84.13%. Alloy iron; the non-magnetic cement material is finely ground twice to obtain a fineness of -0.043mm and 94.58% specific surface area of 550m 2 / kg of cement material, the main phase of the cement material is vitreous body and tricalcium silicate, with water glass and sodium hydroxide as alkali activator, the compressive strength of 28 days is 86Mpa.

[0049] In this embodiment, the main chemical components of waste incineration fly ...

Embodiment 3

[0054] The amount of waste incineration fly ash is 34wt%, the amount of red mud is 50wt%, and the amount of alumina reagent is 16wt%. The waste incineration fly ash, red mud, and alumina reagent are mixed evenly according to the proportion, then put into the crucible, and the crucible is placed in the muffle furnace at 1350°C Lower reduction roasting 90min; Cooling, the fineness of the primary grinding product -0.043mm is 69.32%, the product obtained is magnetically separated under the condition of a magnetic field strength of 1.8kGs, and can obtain iron grade 93.73%, iron recovery rate 85.94% containing trace Ni, Alloy iron of Cu, Cr and other ferrophilic metals; the non-magnetic cement material is subjected to secondary fine grinding, and the obtained fineness is -0.043mm, which is 92.14%, and the specific surface area is 571m 2 / kg, and CaO29.34%, Al 2 o 3 51.14%, a calcium aluminate material product whose main phase is calcium aluminate, and the calcium aluminate product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com