Treating equipment for waste containing sludge

A technology for processing equipment and waste, which is used in water/sludge/sewage treatment, ceramic wastewater treatment, solid waste removal, etc., and can solve the problems of increasing sewage sludge treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

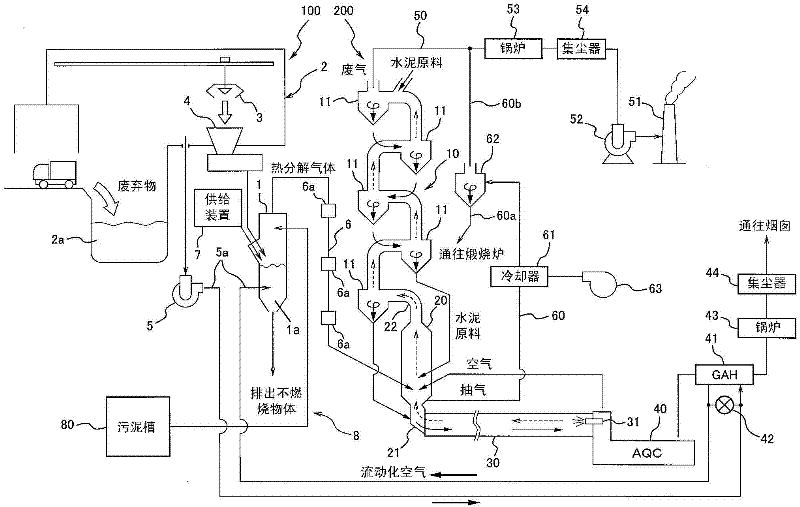

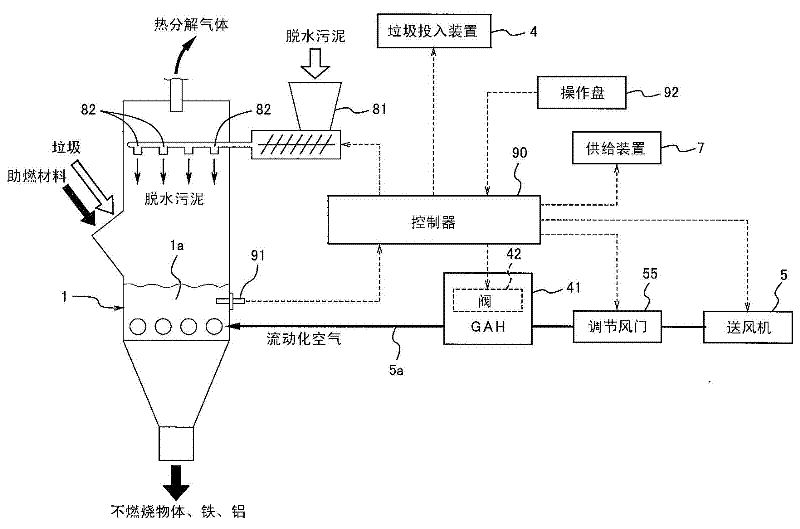

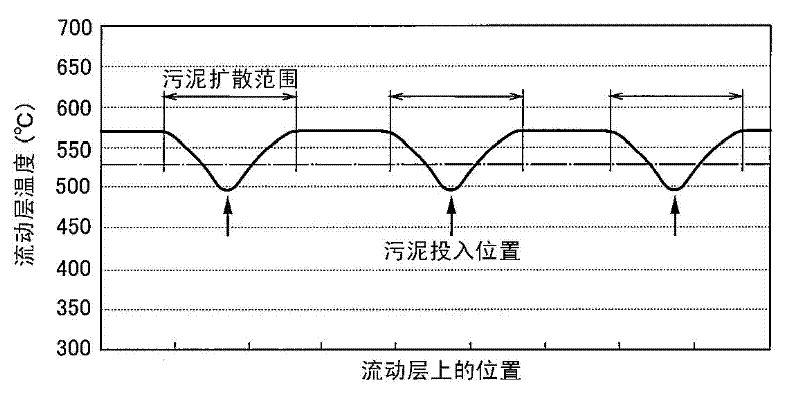

[0059] Preferred embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an overall system diagram of the waste disposal facility 100 of the first embodiment and the cement manufacturing facility 200 installed adjacent thereto. figure 1 The waste treatment facility 100 shown on the left side of the center thermally decomposes waste in the gasification furnace 1 and uses the generated gas (pyrolysis gas) for mixed combustion in the cement firing process. The amount of the pyrolysis gas is, for example, 20,000 to 30,000 Nm 3 / h, and the exhaust gas volume of the cement manufacturing equipment shown in the figure 200 (for example, 300,000 Nm 3 / h) is much less, so the waste treatment plant 100 can be built next to an existing cement plant with little or no modification to the existing cement plant.

[0060] Waste Treatment Equipment

[0061] In the waste treatment facility 100, for example, waste from households, waste plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com