Process and device for cement clinker production

A technology of cement bricks and brick furnaces, applied in the field of manufacturing cement bricks and devices, to achieve the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

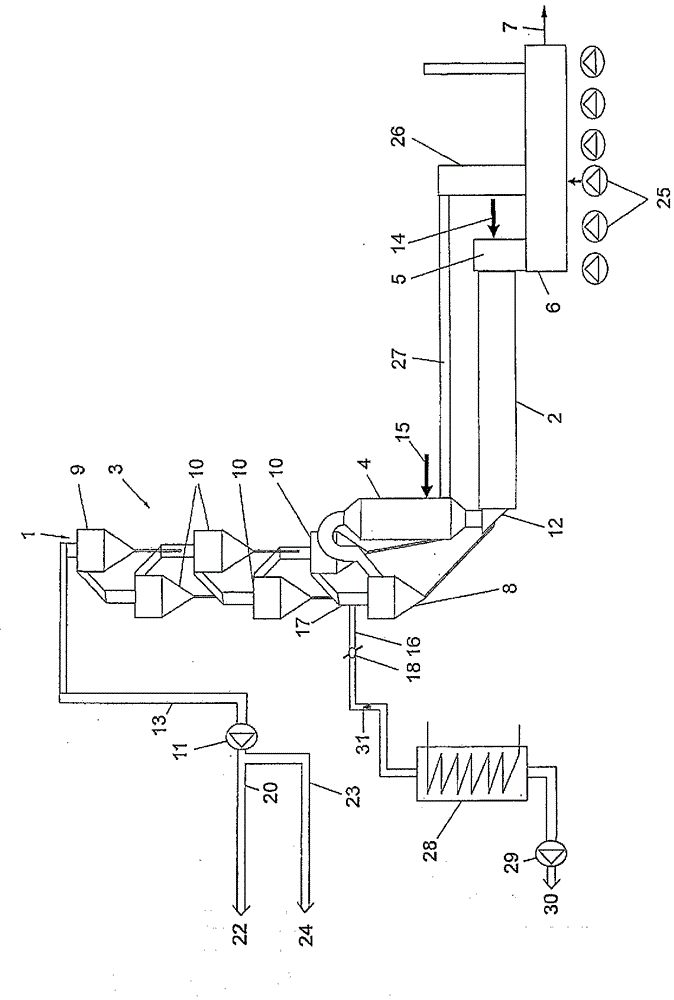

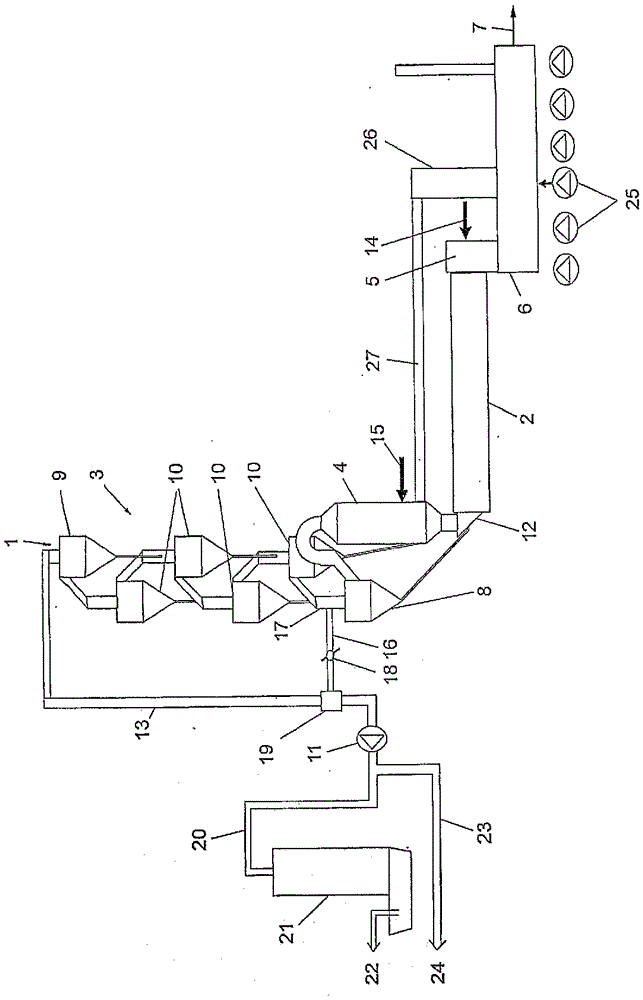

[0026] exist figure 1 A cement brick production plant is shown in , in which the raw material powder fed at the point indicated schematically with 1 is preheated in the preheater 3 in the countercurrent flow of the hot exhaust gases of the brick furnace 2 and heated in the calciner 4 Calcined. The bricks leave the brick oven 2 at the point indicated at 5 and are cooled in a brick cooler 6 . The cooled bricks leave the brick cooler 6 at the point indicated at 7 .

[0027] The preheater 3 can have one or more preheating sections. A section is shown in the drawing. This section has a plurality of vortex-suspended air heat exchangers connected in sequence, wherein the first suspended air heat exchanger is indicated by 8, the last suspended air heat exchanger is indicated by 9 and the suspended air heat exchange between them is The device is represented by 10. The furnace blower 11 generates the required negative pressure, whereby the furnace exhaust gas flowing out on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com