Stereoscopic surface woodgrained ceramic tile, stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and decoration technology

A ceramic tile and surface wood technology, applied in the field of ceramics, can solve the problems of large screen aperture, poor surface texture, unsmooth pattern edges, etc., achieve good printing performance and firing performance, simple and convenient operation, and easy to control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with accompanying drawing:

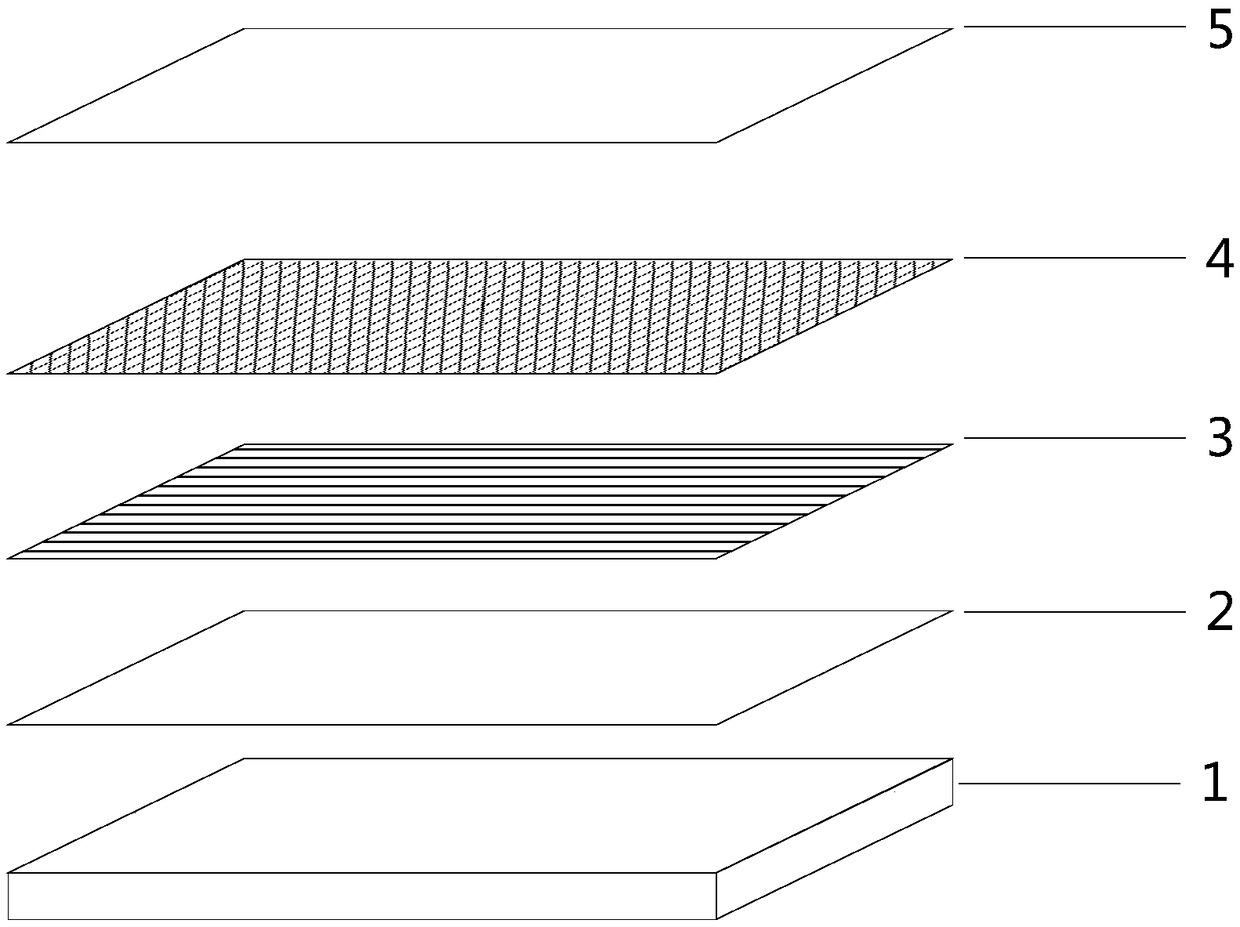

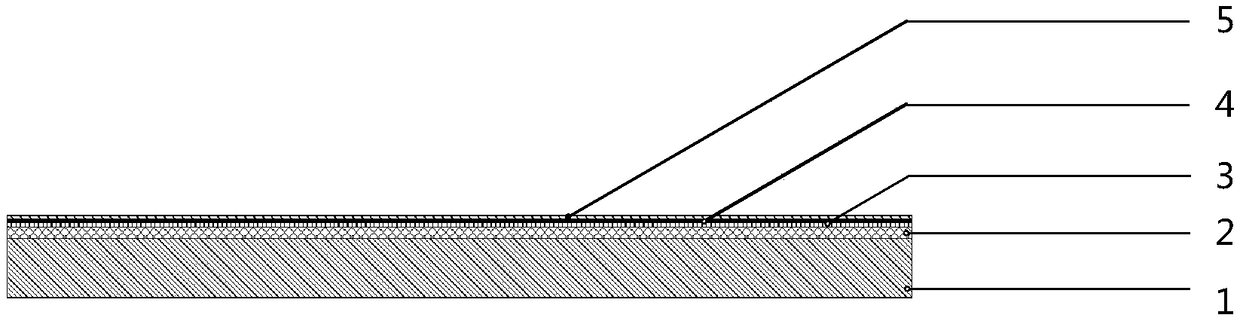

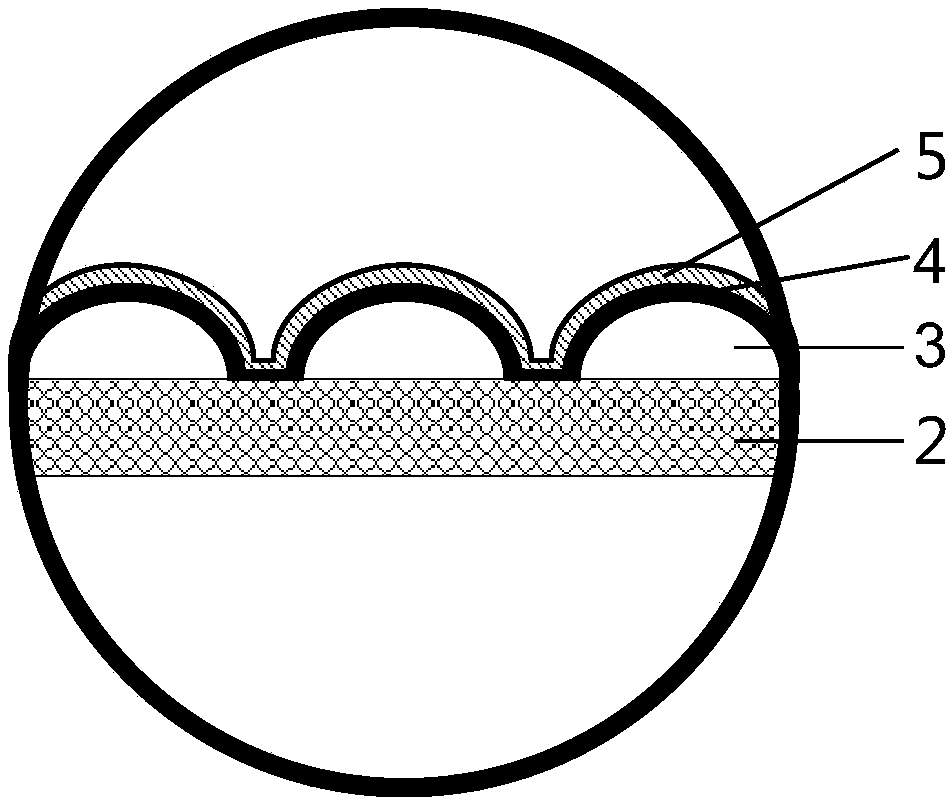

[0041] figure 1 , figure 2 , image 3 The three-dimensional surface wood grain ceramic tile of the present invention is shown.

[0042] Please refer to the accompanying drawings, the three-dimensional surface wood-grain ceramic tile is composed of a body layer 1, a surface glaze layer 2, a relief effect glaze layer 3, a pattern decoration layer 4, and a surface protection glaze layer 5 sequentially compounded.

[0043] In this embodiment, the embossed effect glaze layer of the three-dimensional wood-grained ceramic tile includes the following raw materials in parts by weight:

[0044]

[0045] In this embodiment, the embossed effect glaze layer of the three-dimensional surface wood grain ceramic tile contains the following chemical components in the weight content:

[0046]

[0047] In this embodiment, the decoration process of the three-dimensional sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com