Graphitizing furnace liner structure

A graphitization furnace and lining technology, applied in the field of furnace lining structure, to achieve the effect of ensuring long-term stable operation, good corrosion resistance and erosion resistance, and no impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

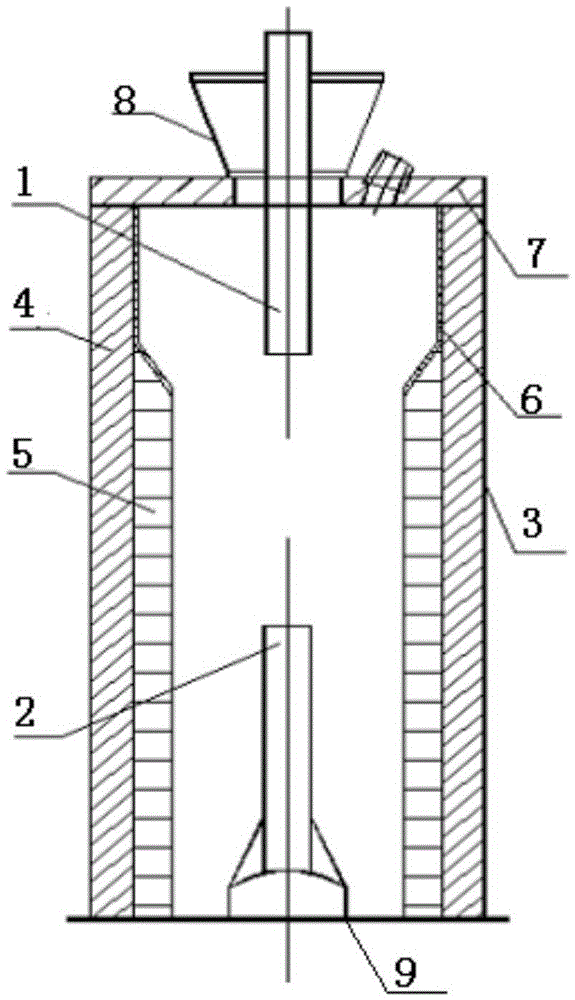

[0034] The total height of the furnace body of the electric calciner is 7900 mm, and its outer diameter is 3000 mm, including the inner lining structure of the graphitization furnace. The structure includes a furnace shell 3 , an external lining 4 and a carbon brick lining 5 in sequence from outside to inside. The furnace shell 3 adopts steel structure to make a cylindrical type, and the thickness of the furnace shell 3 is 8mm; the outer lining 4 is made of high alumina bricks, aluminum silicate plates, and clay bricks from the inside to the outside, and the high alumina brick layer is The thickness of the aluminum silicate plate layer is 15-20mm, and the thickness of the clay brick layer is 230mm; The slope section of the lining 4 transition, the top of the slope section is located at a distance of 6m from the bottom of the furnace, the vertical height of the slope section is 600mm, and the vertical height of the slope section accounts for 6 / 79 of the height of the entire fur...

Embodiment 2

[0042]The total height of the furnace body of the electric calciner is 7900 mm, and its outer diameter is 3000 mm, including the inner lining structure of the graphitization furnace. The structure includes a furnace shell 3, an external lining 4 and a carbon brick lining 5 from outside to inside. The furnace shell 3 is made of cylindrical steel structure, and the thickness of the furnace shell 3 is 8mm; the outer lining 4 is made of high alumina bricks, aluminum silicate plates, and clay bricks from the inside to the outside, and the high alumina brick layer is The thickness of the aluminum silicate plate layer is 15-20mm, and the thickness of the clay brick layer is 230mm; The slope section of the lining 4 transition, the top of the slope section is located at a distance of 6m from the bottom of the furnace, the vertical height of the slope section is 400mm, and the vertical height of the slope section accounts for 4 / 79 of the height of the entire furnace body. The slope surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com