Al4SiC4 enhanced silicon carbide honeycomb ceramic and preparation method thereof

A silicon carbide honeycomb and silicon carbide powder technology, applied in the field of honeycomb ceramics, can solve the problems of uneven size and distribution of micropores in the wall, poor mechanical properties of products, and high thermal expansion coefficient, and achieve good microstructure and strong thermal fatigue resistance. , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

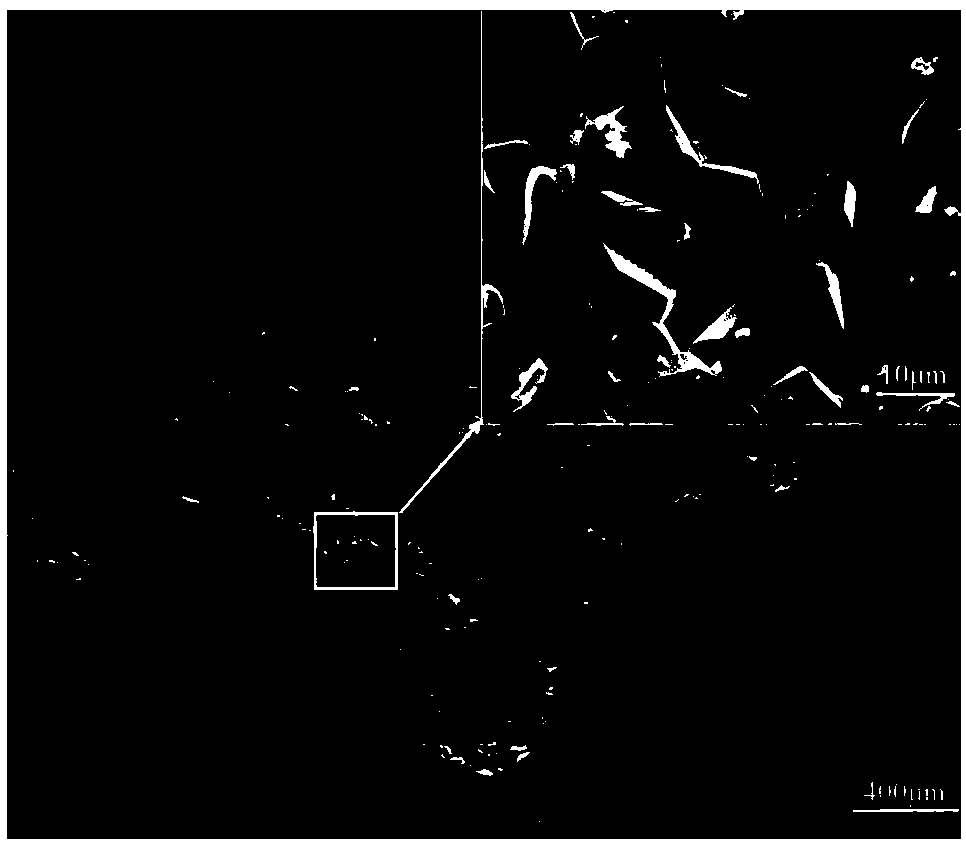

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

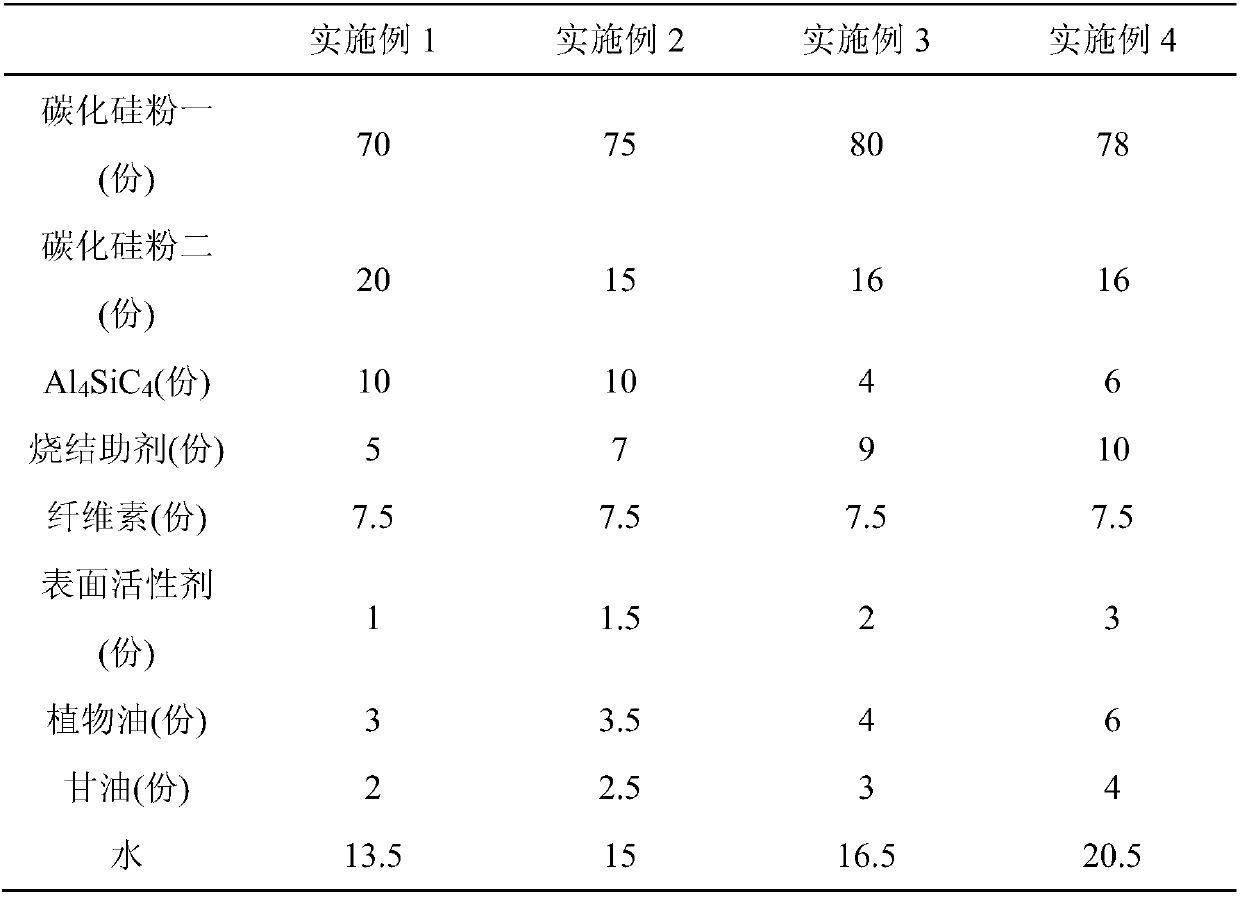

[0025] In the following examples, Al 4 SiC 4 The raw material components of reinforced silicon carbide honeycomb ceramics include: 70-80 parts of silicon carbide powder, 10-20 parts of silicon carbide powder, Al 4 SiC 4 2 to 10 parts, 5 to 15 parts of sintering aid, 12.5-15.5 parts of binder and 12.5-15.5 parts of water, the said parts are parts by mass, wherein the silicon carbide powder 1 has a purity of 99wt% and a particle size of 5 ~50μm, the manufacturer is Anyang Jinsheng Metallurgical Materials Co., Ltd.; the purity of silicon carbide powder II is 99wt%, the particle size is 0.05~0.5μm, the manufacturer is Anyang Jinsheng Metallurgical Materials Co., Ltd.; Al 4 SiC 4 The purity is 99wt%, and the particle size is 30-80μm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com