Nano wood-imitating floor and manufacturing method thereof

A technology of imitation wood floor and manufacturing method, applied in the direction of building structure, building, floor, etc., can solve the problems of non-recyclability, short service life, easy cracking, deformation, etc., and achieve far-reaching historical significance and market value. , The effect of requiring low equipment and strong thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

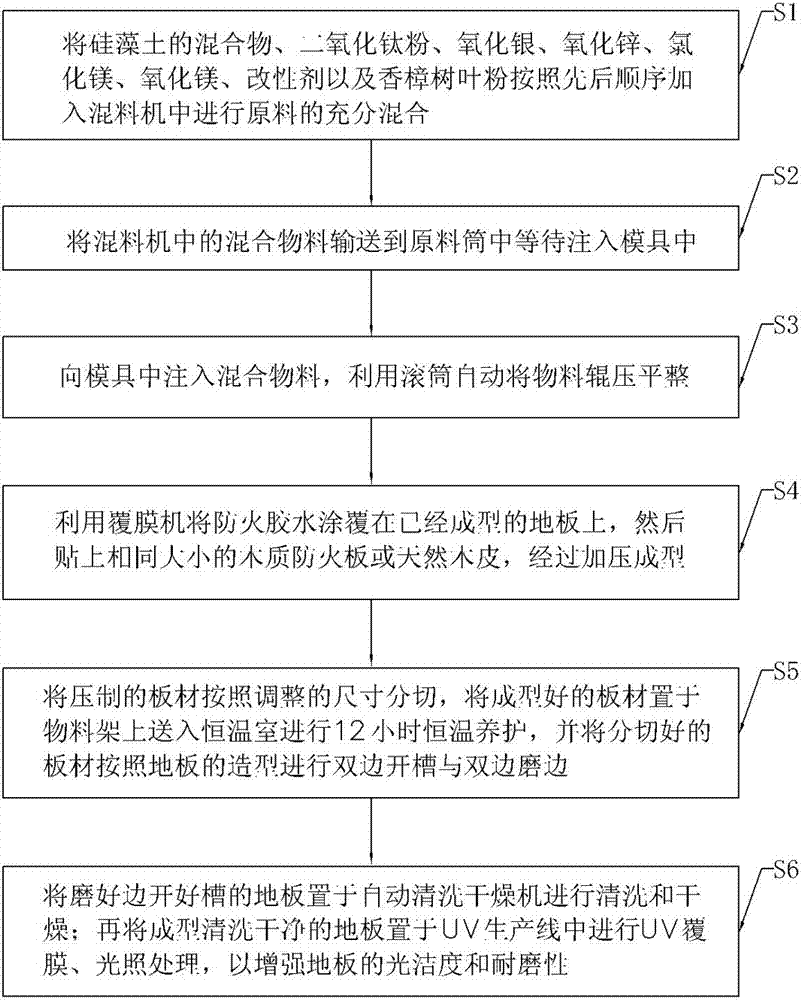

Method used

Image

Examples

no. 2 example

[0050] A kind of nano imitation wood floor of the present invention, in parts by weight, comprises following composition:

[0051] 2 parts of diatomaceous earth, 1 part of nano-silica, 0.1 part of zirconia, 0.1 part of zinc oxide, 2 parts of mugwort leaf powder, 1 part of mint powder, 1 part of camphor leaf powder, 1 part of mosquito repellent powder, 0.1 part of lemon powder, 0.1 part of lavender powder, 0.1 part of ginger powder, 0.1 part of borneol powder, 0.1 part of borax powder, 1 part of sea salt powder, 5 parts of nano titanium dioxide powder, 0.1 part of silver oxide, 10 parts of magnesium chloride, 10 parts of magnesium oxide, and modifier 2 15 parts, camphor tree leaf powder or straw.

no. 3 example

[0053] A kind of nano imitation wood floor of the present invention, in parts by weight, comprises following composition:

[0054] 6 parts of diatomite, 3 parts of nano-silica, 1 part of zirconia, 1 part of zinc oxide, 4 parts of mugwort leaf powder, 3 parts of mint powder, 3 parts of camphor leaf powder, 3 parts of mosquito repellent grass powder, 1 part of lemon powder, 1 part of lavender powder, 1 part of ginger powder, 1 part of borneol powder, 1 part of borax powder, 2 parts of sea salt powder, 30 parts of nano diatomite, 15 parts of nano titanium dioxide powder, 1 part of silver oxide, 30 parts of magnesium chloride, 30 parts of magnesium oxide parts, and 4 parts of modifiers, 20 parts of camphor tree leaf powder or straw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com