Method for manufacturing thermal shock resistant movable nozzle brick

A sliding nozzle and manufacturing method technology, which is applied to manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems of low thermal shock resistance, end of service life, and steel leakage of sliding nozzle bricks, and achieve thermal shock resistance. Moreover, the effect of improving thermal shock resistance and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

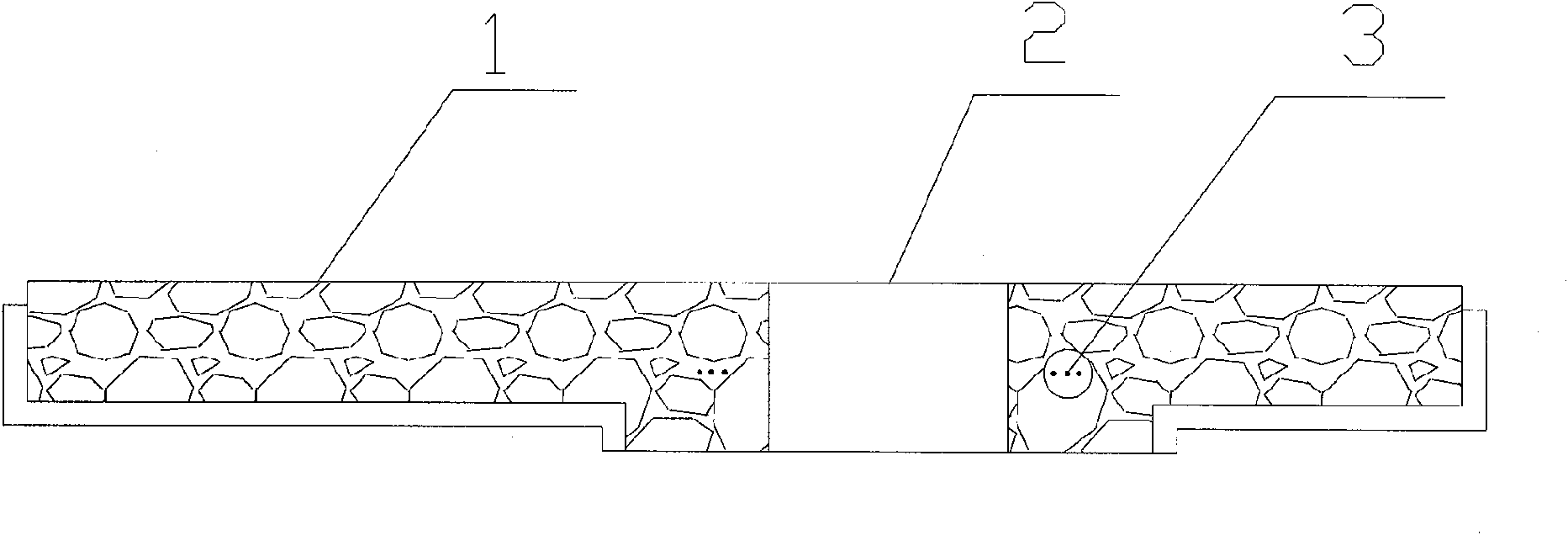

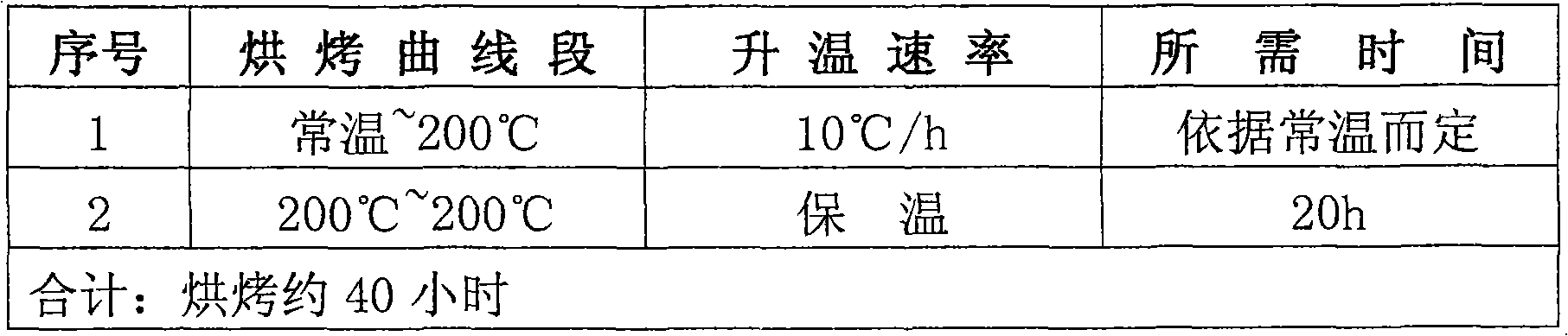

[0019] The heat-shock resistant sliding nozzle brick of the present invention undergoes technical processes such as raw material selection, pre-mixing, stirring and mixing, pressing and molding, baking and drying, and inspection and warehousing. The specific instructions are as follows:

[0020] 1. Selection of raw materials: Select tabular corundum, corundum micropowder, Al 2 o 3 Micropowder, graphite, composite additives, and thermosetting resin are used as raw materials, of which:

[0021] Tabular alumina Al 2 o 3 >99%, corundum fine powder Al 2 o 3 >99%, specification particle size <5um,

[0022] a-Al 2 o 3 Micropowder: technical requirements: Al 2 o 3 >99% specifications: particle size <2um,

[0023] Graphite: C>98% Specifications: Particle size<5um,

[0024] Composite additives: Al>55%, Mg>35%, specifications: particle size<5um,

[0025] Resin binder: technical requirements: powder degree 4000-12000 (room temperature) centipoise,

[0026] Residual solid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com