Graphite and ceramic composite material and preparation method thereof

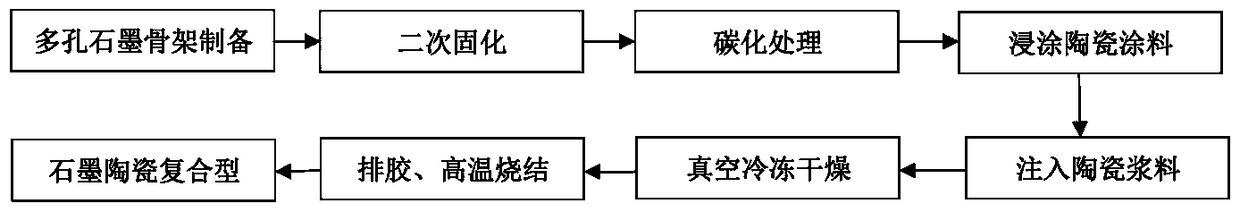

A composite and ceramic technology, applied in the direction of additive processing, etc., can solve the problems of water glass sand recovery, low reuse rate, harmful surrounding environment, complicated and lengthy process route, etc., achieve good chemical stability and improve cutting The effect of processing manufacturability and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

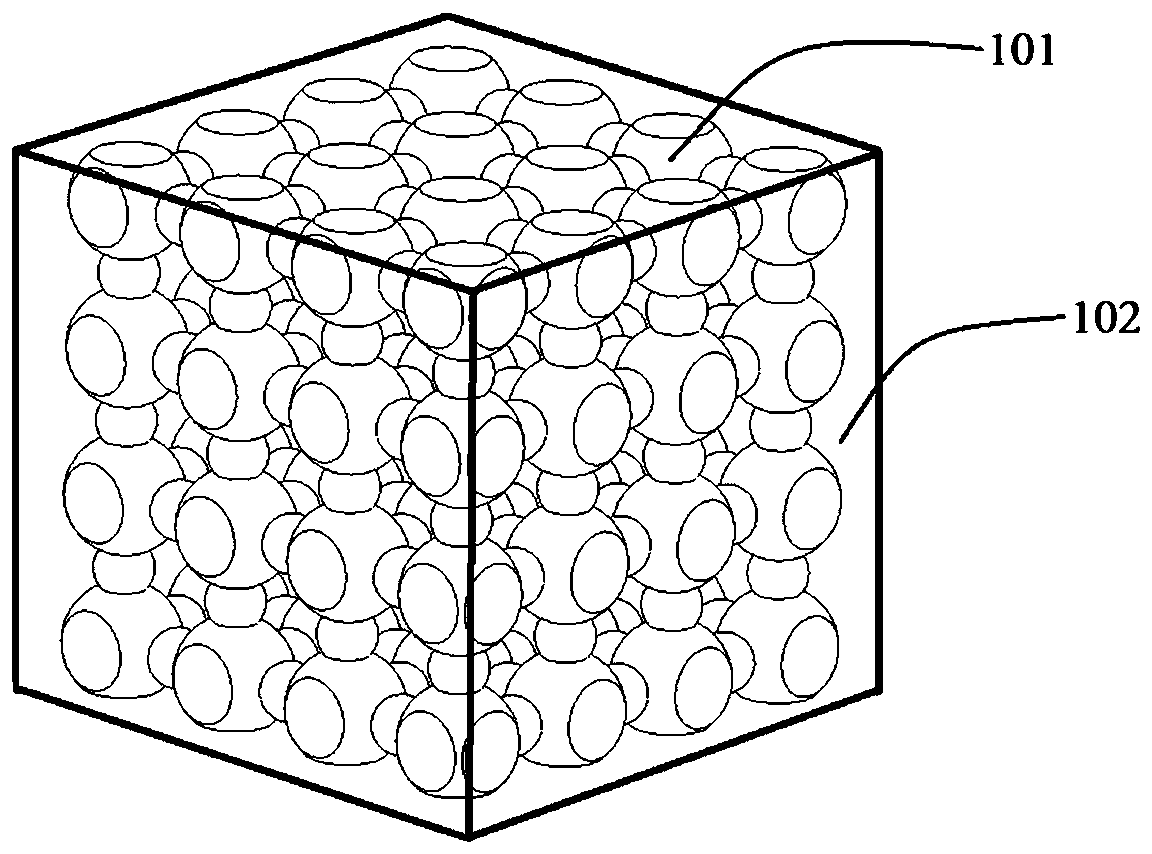

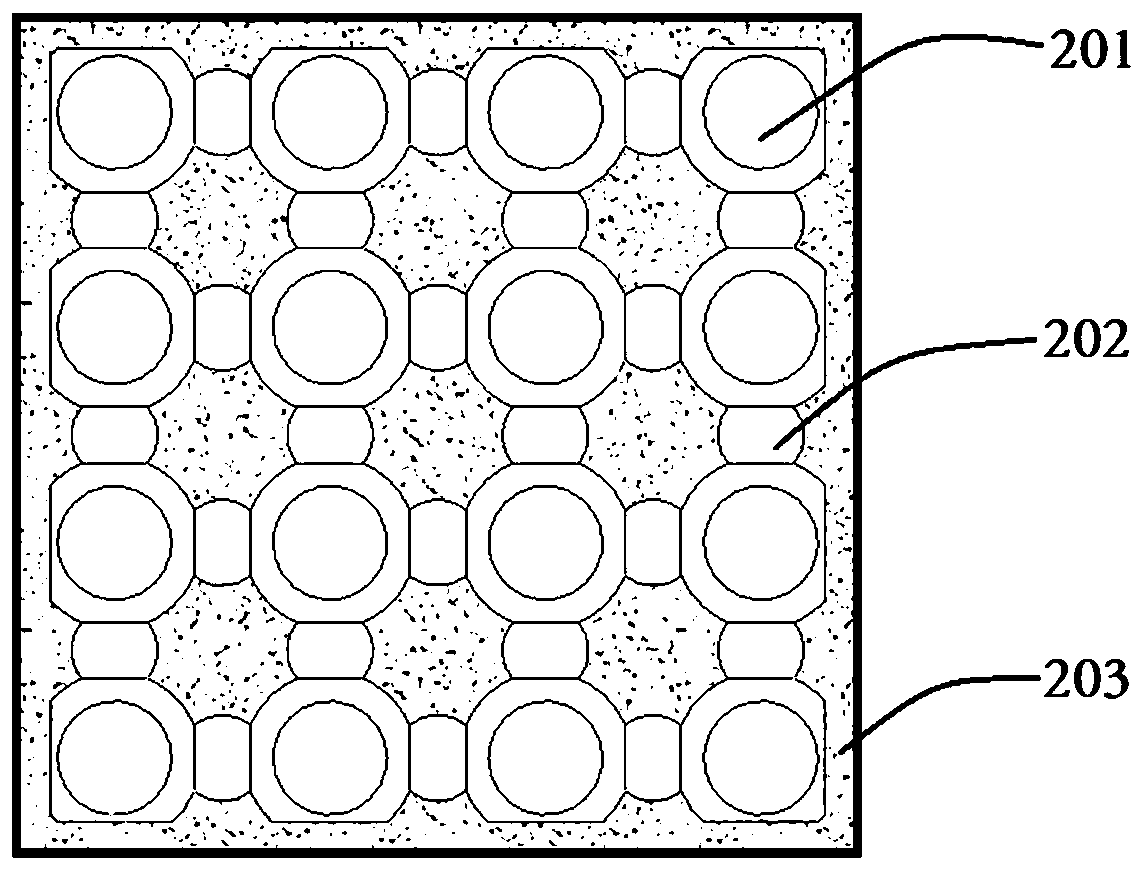

[0042] Taking the combination of two types of spheres as the basic feature unit, the porous graphite skeleton structure 101 is designed through spatial array, wherein the diameter of the base ball 201 is 10 mm, and the diameter of the connecting ball 202 is 5 mm.

[0043] Put 99.5% carbon content, 270-mesh natural flake graphite powder, 500-mesh thermosetting phenolic resin and 99%, 200-mesh high-purity silicon powder into the dry-process high-efficiency roller ball mill in batches according to the mass ratio of 55:35:10. Make it mix evenly, the volume fraction of porous graphite skeleton is 60%.

[0044] The graphite / phenolic resin mixed powder was 3D printed by selective laser sintering technology to obtain a porous graphite skeleton blank. Selective laser sintering process parameters: filling power 20W, layer thickness 0.1mm, filling spacing 0.1mm, filling speed 2000mm / s, contour scanning filling.

[0045] Put the porous graphite skeleton blank into an electric heating fur...

Embodiment 2

[0053] Taking the combination of two types of spheres as the basic feature unit, the porous graphite skeleton structure 101 is designed through spatial array, wherein the diameter of the base ball 201 is 8 mm, and the diameter of the connecting ball 202 is 3 mm.

[0054] Put 99.5% carbon content, 300-mesh natural flake graphite powder, 800-mesh thermosetting phenolic resin and 99%, 200-mesh high-purity silicon powder into the dry-process high-efficiency roller ball mill in batches according to the mass ratio of 50:35:15. Make it mix evenly, the volume fraction of porous graphite skeleton is 70%.

[0055] The graphite / phenolic resin mixed powder was 3D printed by selective laser sintering technology to obtain a porous graphite skeleton blank. Selective laser sintering process parameters: filling power 25W, layer thickness 0.1mm, filling spacing 0.1mm, filling speed 2500mm / s, contour scanning filling.

[0056] Put the porous graphite skeleton blank into an electric heating furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com