Evaporation furnace capable of shortening distance and rapidly increasing and reducing temperature, and manufacturing method thereof

A heating and cooling, short-distance technology, applied in the field of adjustable short-distance rapid heating and cooling evaporation furnace and its manufacturing, can solve the problem of inability to solve the phenomenon of solid phase sublimation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

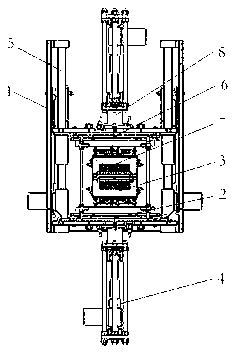

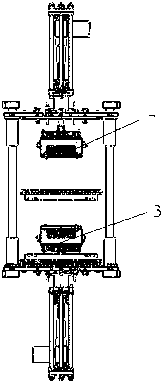

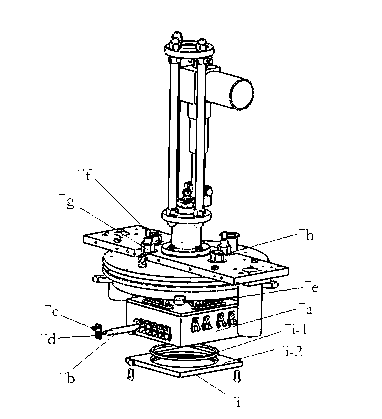

[0022] see figure 1 and figure 2 , an adjustable short-distance rapid heating and cooling evaporation furnace provided by the present invention includes a trough-shaped support 1, a lower heating table bottom plate 2 is installed in the bottom inner cavity of the trough-shaped support 1, and the upper part of the lower heating table bottom plate 2 is installed There is a lower heating table 3, and the lower part is equipped with a rotary drive device 4 that can drive the lower heating table 3 to rotate horizontally. Guide rails 5 are arranged on both sides of the grooved support 1, and an upper heating table that can move up and down along it is installed between the guide rails 5. A platform base plate 6, the bottom of the upper heating platform base plate 6 is provided with an upper heating platform 7 opposite to the lower heating platform 3, and the upper part is equipped with a mobile driving device 8 that can drive the upper heating platform 7 to move up and down;

[00...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that the sample loading stage 7i includes an internal quartz / graphite / oxide, nitride ceramic stage 7i-1, and the internal quartz / graphite / oxide, nitride The ceramic stage 7i-1 is detachably installed in the stainless steel sample stage 7i-2, and the stainless steel sample stage 7i-2 is mounted on the bottom of the upper heating stage 7 by using locking bolts.

Embodiment 3

[0028] The difference between this embodiment and Embodiment 1 is that a series of heating elements such as SiC, MoSi2, Mo, Ta or W can also be installed in the lower heating platform 3 and the upper heating platform 7 to improve the heating effect. (Short-wave infrared lamps can reach 1100°C as heating elements, SiC, MoSi 2 , Mo, Ta and W heating elements can reach a maximum temperature of 1900°C. )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com