3D printing preparation method and device for heterogeneous bidirectional gradient aperture porous ceramic

A technology of 3D printing and porous ceramics, which is applied to ceramic products, ceramic molding machines, manufacturing tools, etc. It can solve the problems of micro-cracks, splitting, shrinkage and deformation of photosensitive resin in the porous layer, and achieve short production cycle, increase strength, eliminate Effect of localized microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

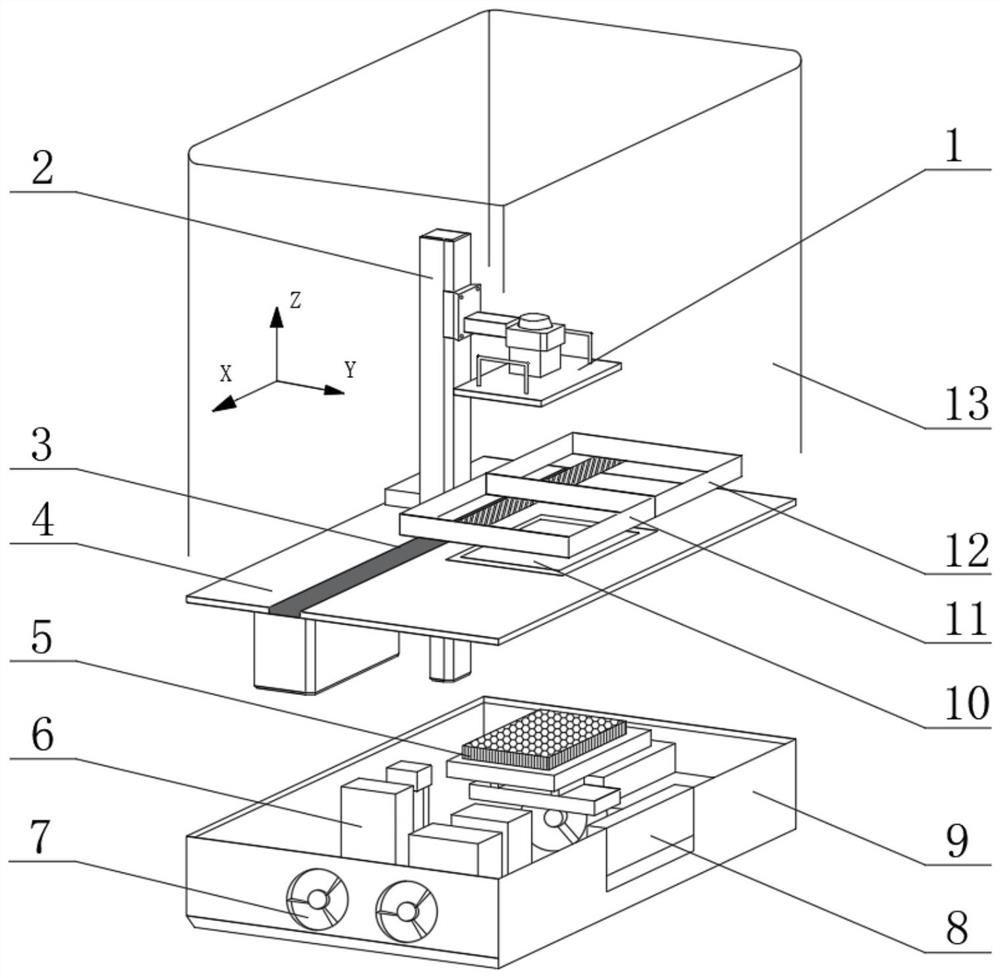

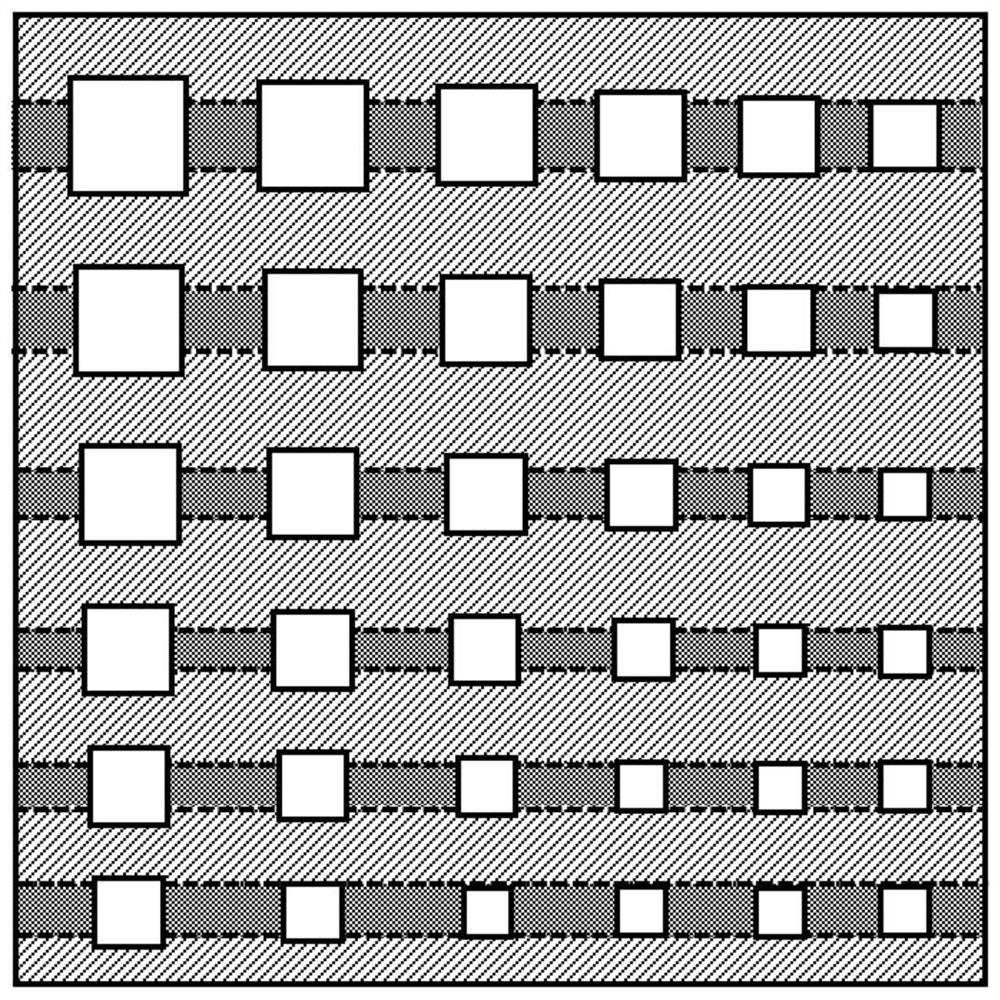

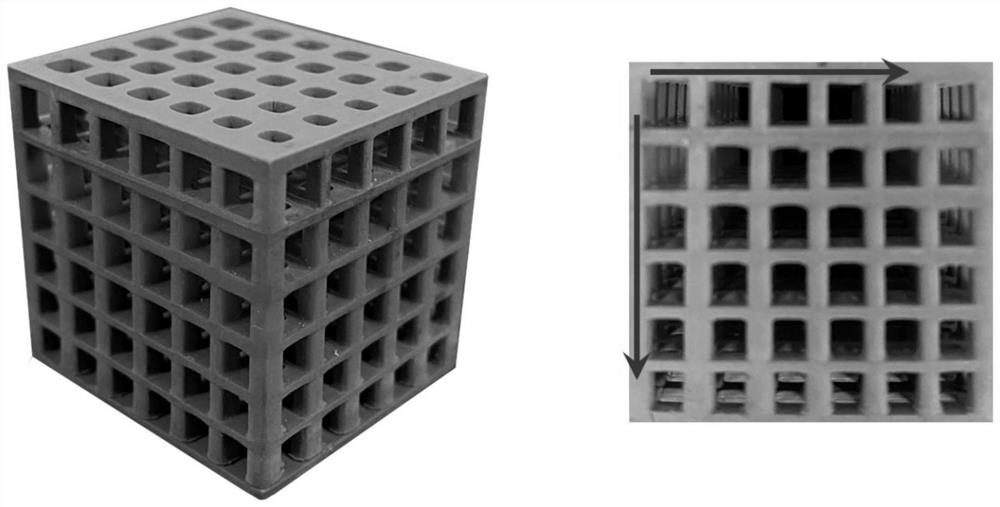

[0044] First prepare the first precursor ceramic slurry and the second precursor ceramic slurry, specifically, the components of the first precursor ceramic slurry are 70wt% of photosensitive resin, 15wt% of silicon carbide powder, particle size is 4000 mesh, amorphous Silicon powder 5wt%, particle size 5000 mesh, alumina and yttrium oxide 4wt%, KOS110 2wt%. The second precursor ceramic slurry components are photosensitive resin 70wt%, silicon carbide powder 10wt%, particle size 4000 mesh, amorphous silicon powder 10wt%, particle size 5000 mesh, alumina and yttrium oxide 4wt%, KOS110 2wt%. And mechanically stirred for 1 hour at a rotational speed of 2000r / min, respectively, and placed in the first resin liquid tank 11 and the second resin liquid tank 12 . Secondly, the two-way gradient porous structure was designed through the SolidWorks 3D modeling software, and the STL format file was exported to the light-curing slicing software ChiTuBox. The slice thickness was set to 30 ...

Embodiment 2

[0059] First prepare the first precursor ceramic slurry and the second precursor ceramic slurry, specifically, the components of the first precursor ceramic slurry are photosensitive resin 70wt%, silicon carbide powder 15wt%, particle size 3000 mesh, amorphous Silicon powder 5wt%, particle size 4000 mesh, alumina and yttrium oxide 4wt%, KOS110 2wt%. The components of the second precursor ceramic slurry are photosensitive resin 70wt%, silicon carbide powder 10wt%, particle size 6000 mesh, amorphous silicon powder 10wt%, particle size 6000 mesh, alumina and yttrium oxide 4wt%, KOS110 2wt%. And mechanically stirred for 1 hour at a rotational speed of 2000r / min, respectively, and placed in the first resin liquid tank 11 and the second resin liquid tank 12 . Secondly, the bidirectional gradient porous structure was designed by the SolidWorks 3D modeling software, and the STL format file was exported to the light-curing slicing software ChiTuBox. The slice thickness was set to 50 m...

Embodiment 3

[0063] First prepare the first precursor ceramic slurry and the second precursor ceramic slurry. Specifically, the components of the first precursor ceramic slurry are 65wt% of photosensitive resin, 15wt% of silicon nitride powder, and the particle size is 3500 mesh. Shaped silicon powder 5wt%, particle size 4500 mesh, alumina and yttrium oxide 5wt%, KOS110 5wt%. The components of the second precursor ceramic slurry are 70wt% photosensitive resin, 10wt% silicon nitride powder with a particle size of 5000 mesh, 10wt% amorphous silicon powder with a particle size of 5500 mesh, 4wt% each of alumina and yttrium oxide, KOS110 2wt%. And mechanically stirred for 1 hour at a rotational speed of 2000r / min, respectively, and placed in the first resin liquid tank 11 and the second resin liquid tank 12 . Secondly, the two-way gradient porous structure was designed through the SolidWorks 3D modeling software, and the STL format file was exported to the light-curing slicing software ChiTuB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com