Preparation method of high temperature adhesive used for carbon-based composite material

A technology of high-temperature adhesives and composite materials, which is applied in the field of preparation of high-temperature adhesives for carbon-based composite materials, which can solve the problems of unsatisfactory thermal shock resistance and achieve low preparation costs and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

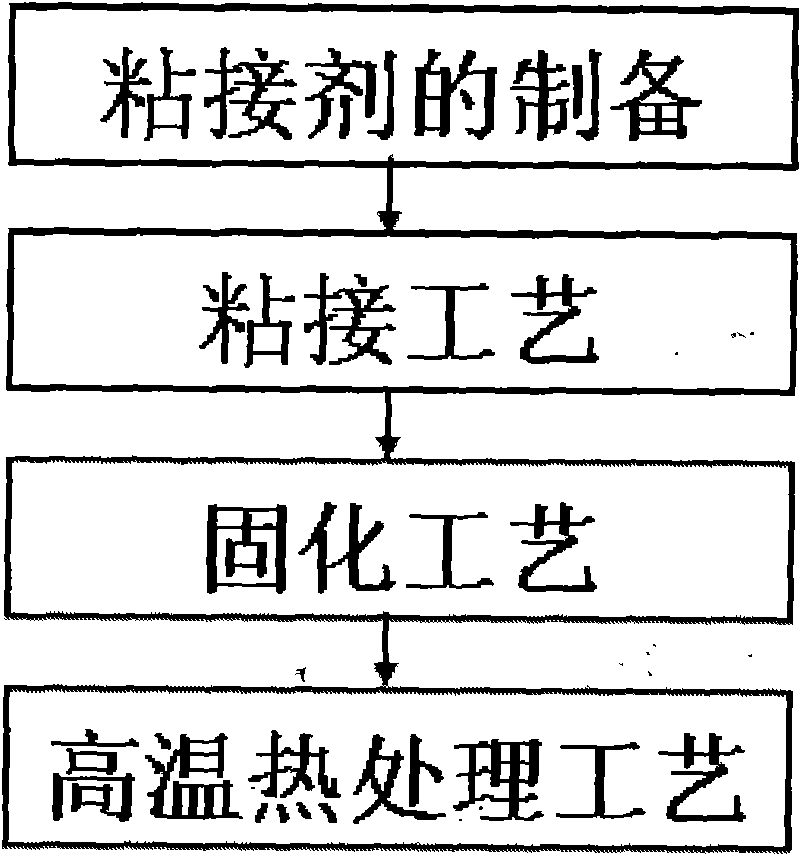

[0028] The present invention is a method for preparing a high-temperature (300-1700° C.) adhesive for carbon-based composite materials. The specific steps of the method are as follows:

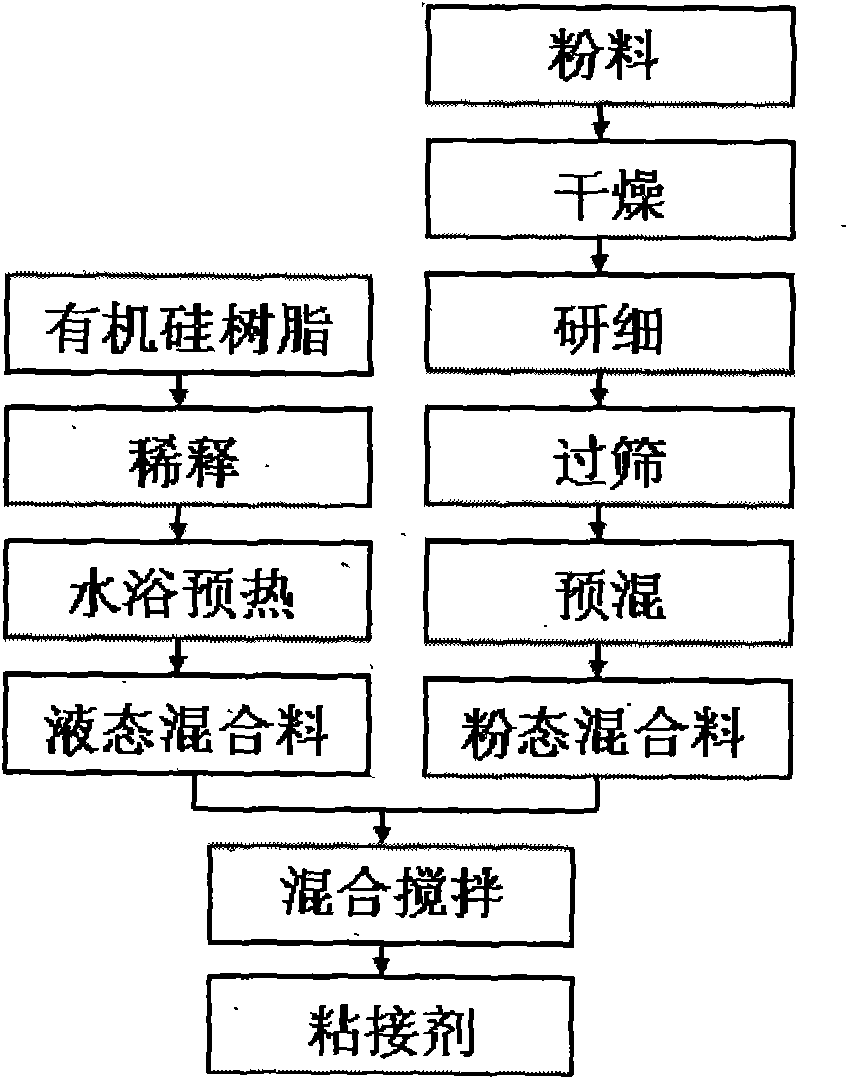

[0029] Step 1: Preparation method of high temperature adhesive

[0030] In the present invention, the adhesive consists of 35wt.% organic silicon resin tetraethyl orthosilicate, 30wt.% 350 mesh low melting point filler ceramic powder, 15wt.% 200 mesh boron powder, 19.8wt.% 200 mesh silicon powder And 0.2wt.% carbon fiber composition, its preparation steps are as figure 2 shown. Among them, tetraethyl orthosilicate and ceramic powder are industrial standards, and others are analytically pure standards. Mix ceramic powder, boron powder and silicon powder according to the above percentages, dry at 140°C for 2 hours, then grind for 1 hour and sieve to obtain a uniform solid mixture, then mix it with carbon fiber to prepare a powder mixture; Ethyl ester and acetone are mixed according to the vo...

Embodiment 2

[0039] The present invention is a method for preparing a high-temperature (300-1700° C.) adhesive for carbon-based composite materials. The specific steps of the method are as follows:

[0040] Step 1: Preparation method of high temperature adhesive

[0041] In the present invention, the adhesive consists of 35wt.% organic silicon resin tetraethyl orthosilicate, 25wt.% 350 mesh low melting point filler ceramic powder, 15wt.% boron powder 200 mesh, 24.6wt.% silicon powder 200 mesh And 0.4wt.% carbon fiber composition, its preparation steps are as figure 2 shown. Among them, tetraethyl orthosilicate and ceramic powder are industrial standards, and others are analytically pure standards. Mix ceramic powder, boron powder and silicon powder according to the above percentages, dry at 140°C for 2 hours, then grind for 1 hour and sieve to obtain a uniform solid mixture, then mix it with carbon fiber to prepare a powder mixture; Ethyl ester and acetone are mixed according to the vo...

Embodiment 3

[0050] The present invention is a method for preparing a high-temperature (300-1700° C.) adhesive for carbon-based composite materials. The specific steps of the method are as follows:

[0051] Step 1: Preparation method of high temperature adhesive

[0052] In the present invention, the adhesive consists of 40wt.% organic silicon resin tetraethyl orthosilicate, 30wt.% 350 mesh low-melting filler ceramic powder, 15wt.% 200 mesh boron powder, 14.6wt.% 200 mesh silicon powder And 0.4wt.% carbon fiber composition, its preparation steps are as figure 2 shown. Among them, tetraethyl orthosilicate and ceramic powder are industrial standards, and others are analytically pure standards. Mix ceramic powder, boron powder and silicon powder according to the above percentages, dry at 140°C for 2 hours, then grind for 1 hour and sieve to obtain a uniform solid mixture, then mix it with carbon fiber to prepare a powder mixture; Ethyl ester and acetone are mixed according to the volume r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com