Method for welding shaft of portable exothermic welding shaft welder

A portable, thermite technology, applied in thermite welding equipment, welding equipment, metal processing equipment, etc., can solve problems affecting combat effectiveness and achieve the effects of improving combat effectiveness, restoring usability, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

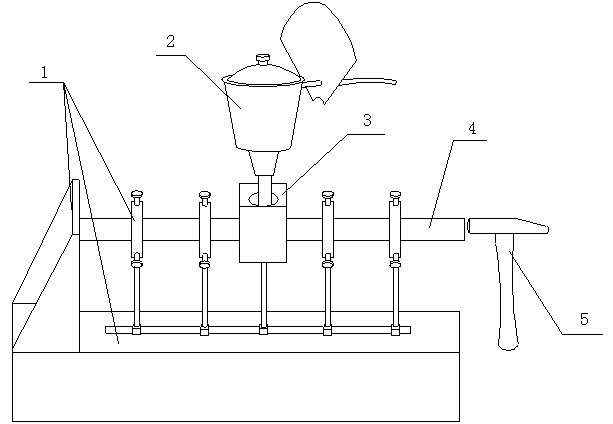

[0031] see figure 1 , figure 1 It is a schematic diagram of the overall structure of the portable thermite welding shaft welding device of the present invention. Depend on figure 1 It can be seen that the portable thermite welding shaft welding device of the present invention includes a broken shaft fixer 1, a mold 3 and a self-propagating welding pot 2;

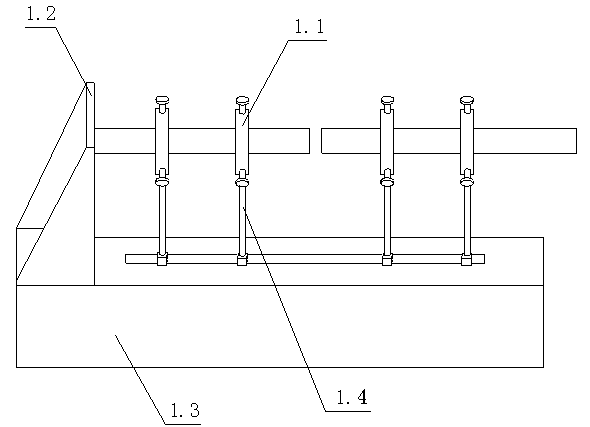

[0032] The structure of the broken shaft fixer 1 is as follows: figure 2 As shown, it includes a base 1.3, a supporter 1.4, a baffle 1.2 and a ring holder 1.1, and the base is mainly used to fix the supporter and the baffle. There is a rectangular slot on the base for the supporter 1.4 to slide or be fixed on it, so as to adjust the gap between the two broken shafts. There are multiple supporters 1.4, and the multiple supporters 1.4 are divided into two groups, one on the left and one on the other. , the baffle plate 1.2 is fixedly arranged on the base 1.3, and placed on the left side of the supporter 1.4, the ring hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com