Patents

Literature

55 results about "Central tire inflation system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

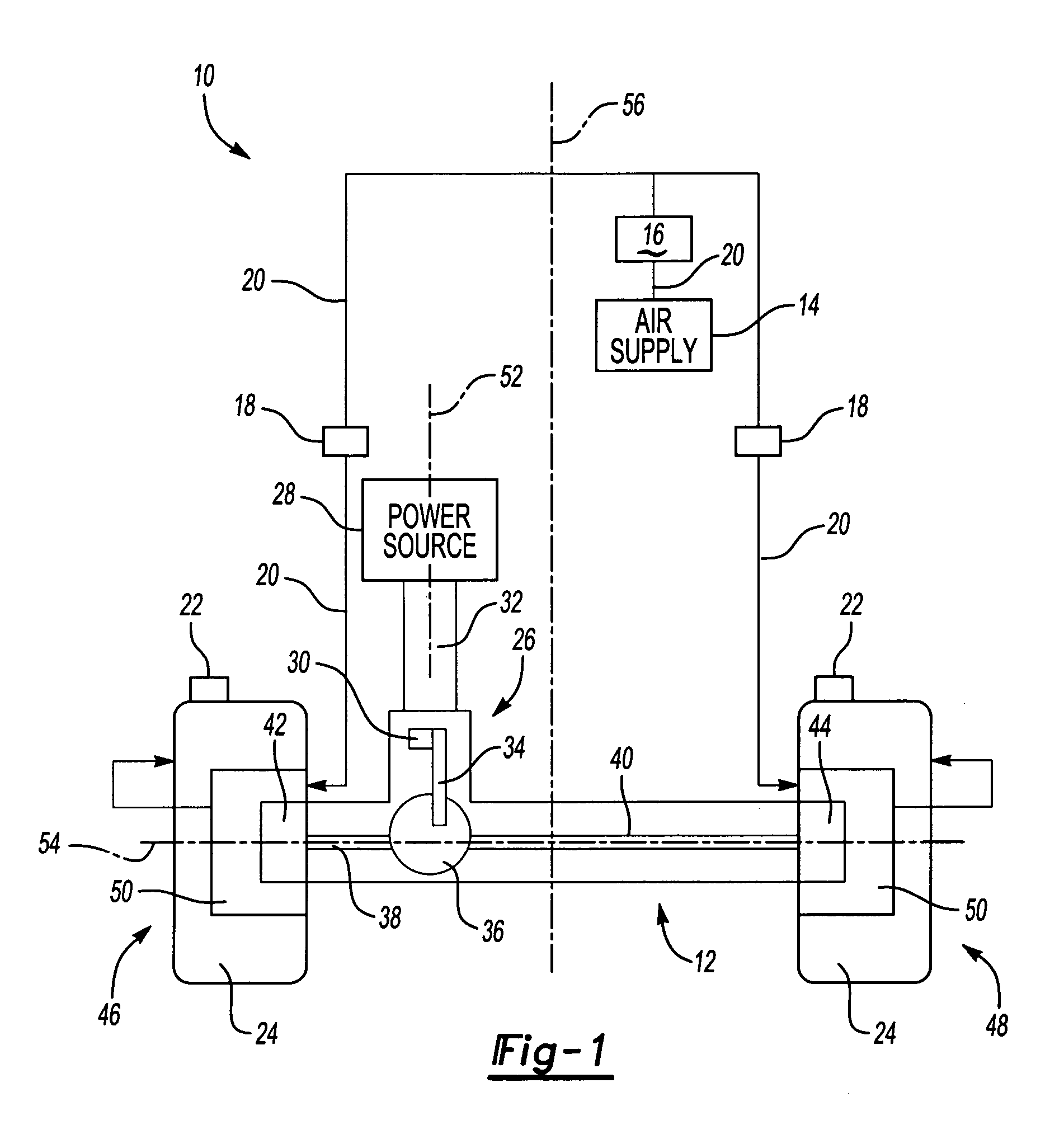

A central tire inflation system (CTIS) is a system to provide control over the air pressure in each tire of a vehicle as a way to improve performance on different surfaces. For example, lowering the air pressure in a tire creates a larger area of contact between the tire and the ground and makes driving on softer ground much easier. It also does less damage to the surface. This is important on work sites and in agricultural fields. By giving the driver direct control over the air pressure in each tire, maneuverability is greatly improved.

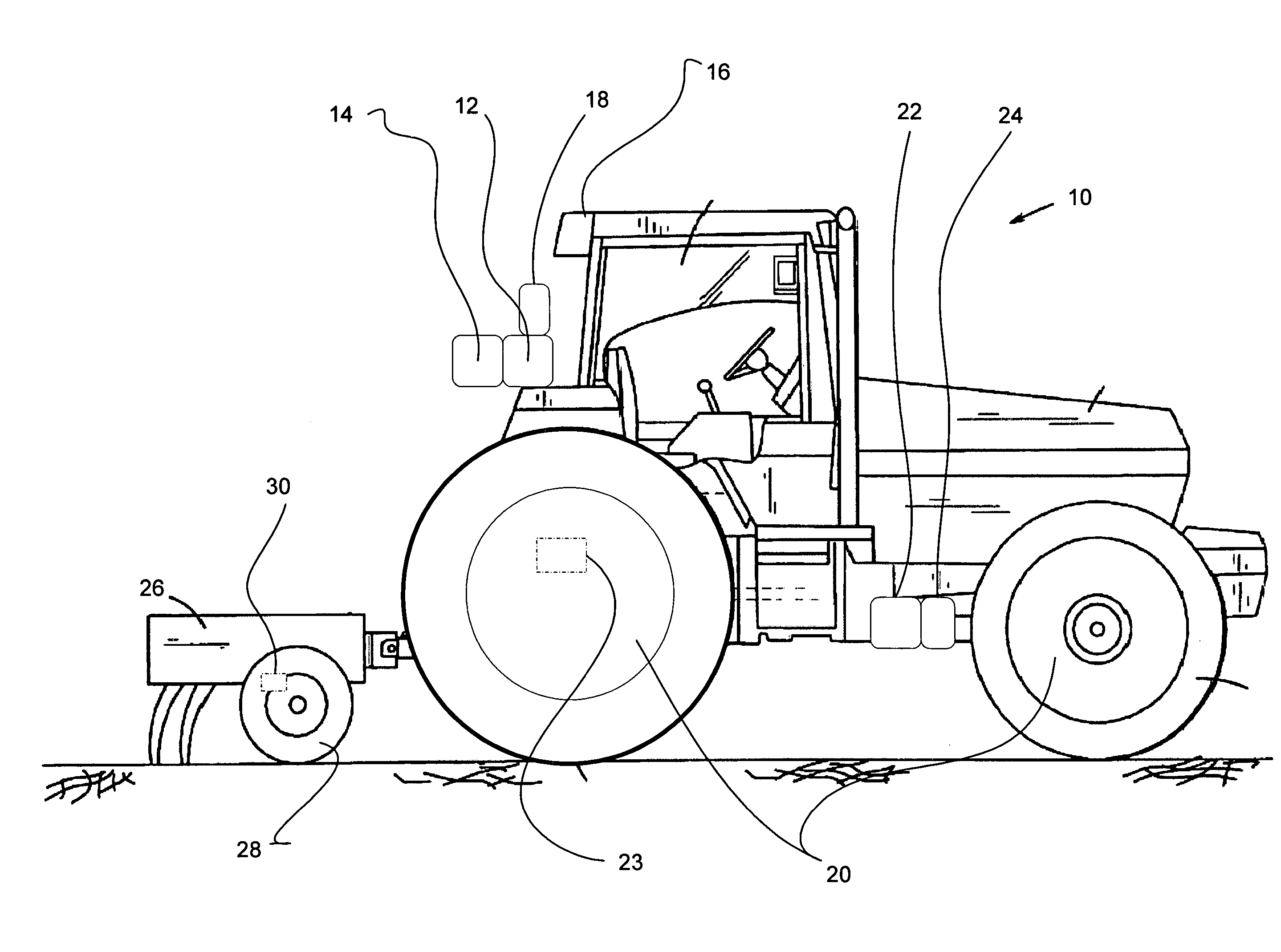

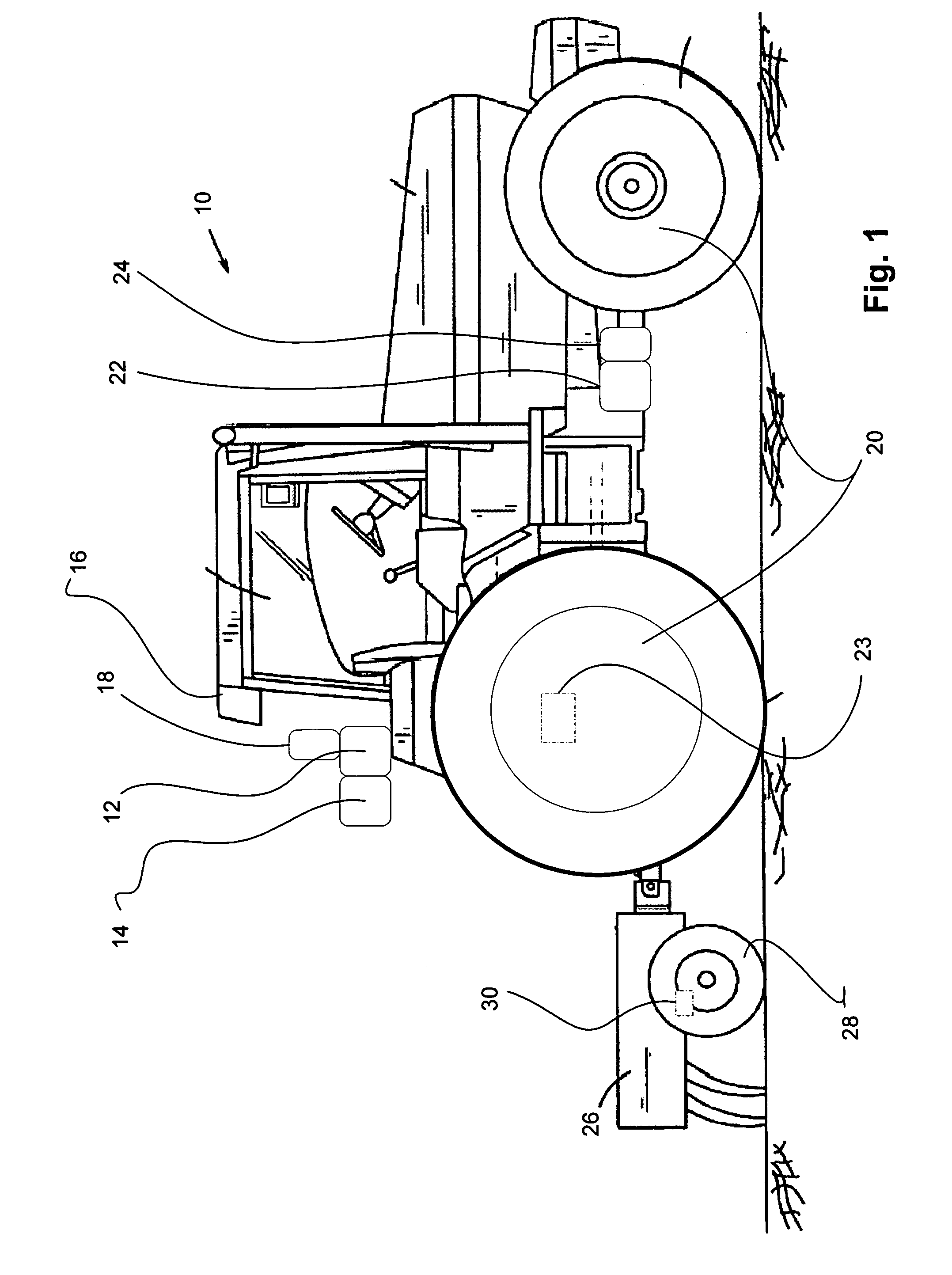

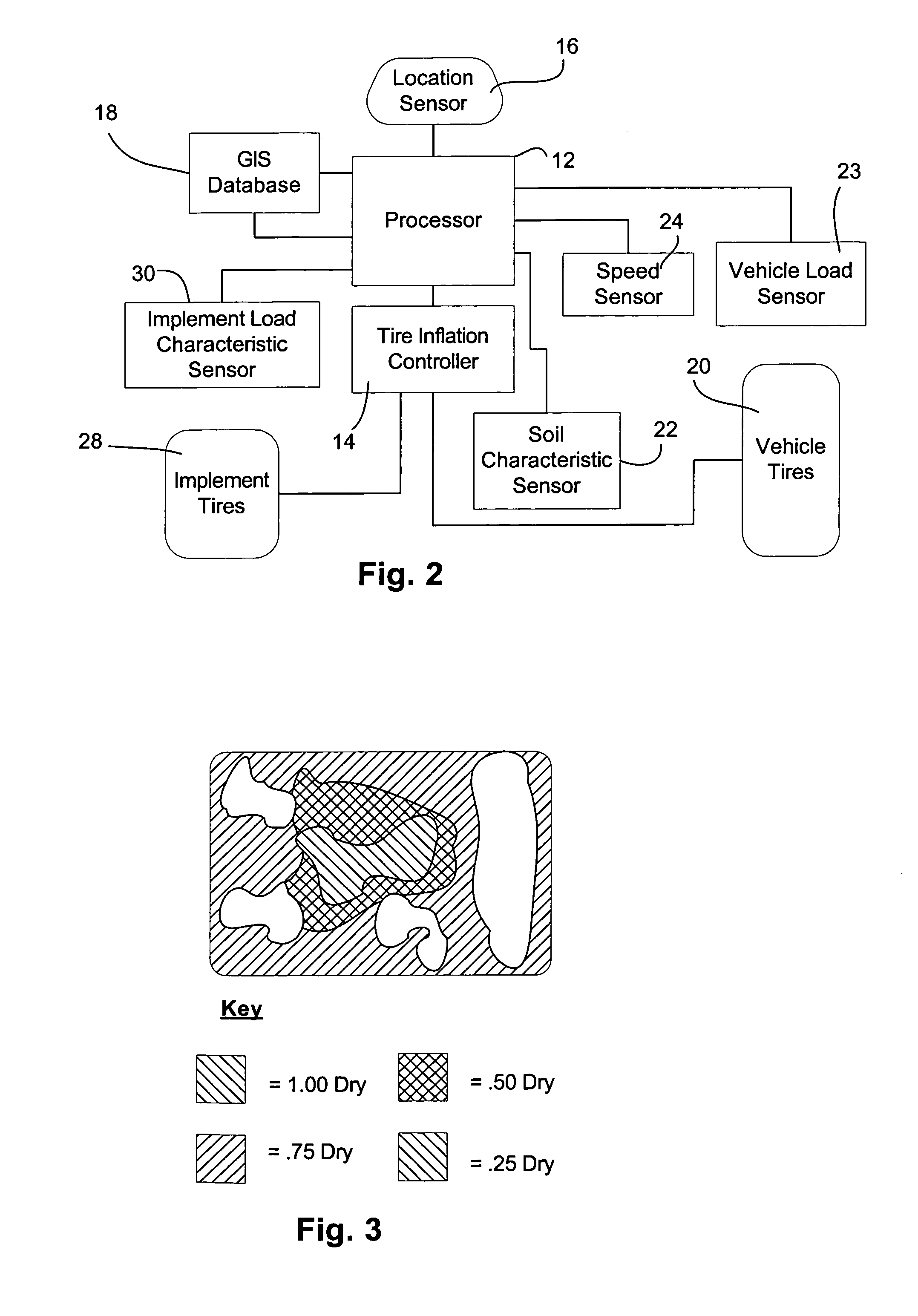

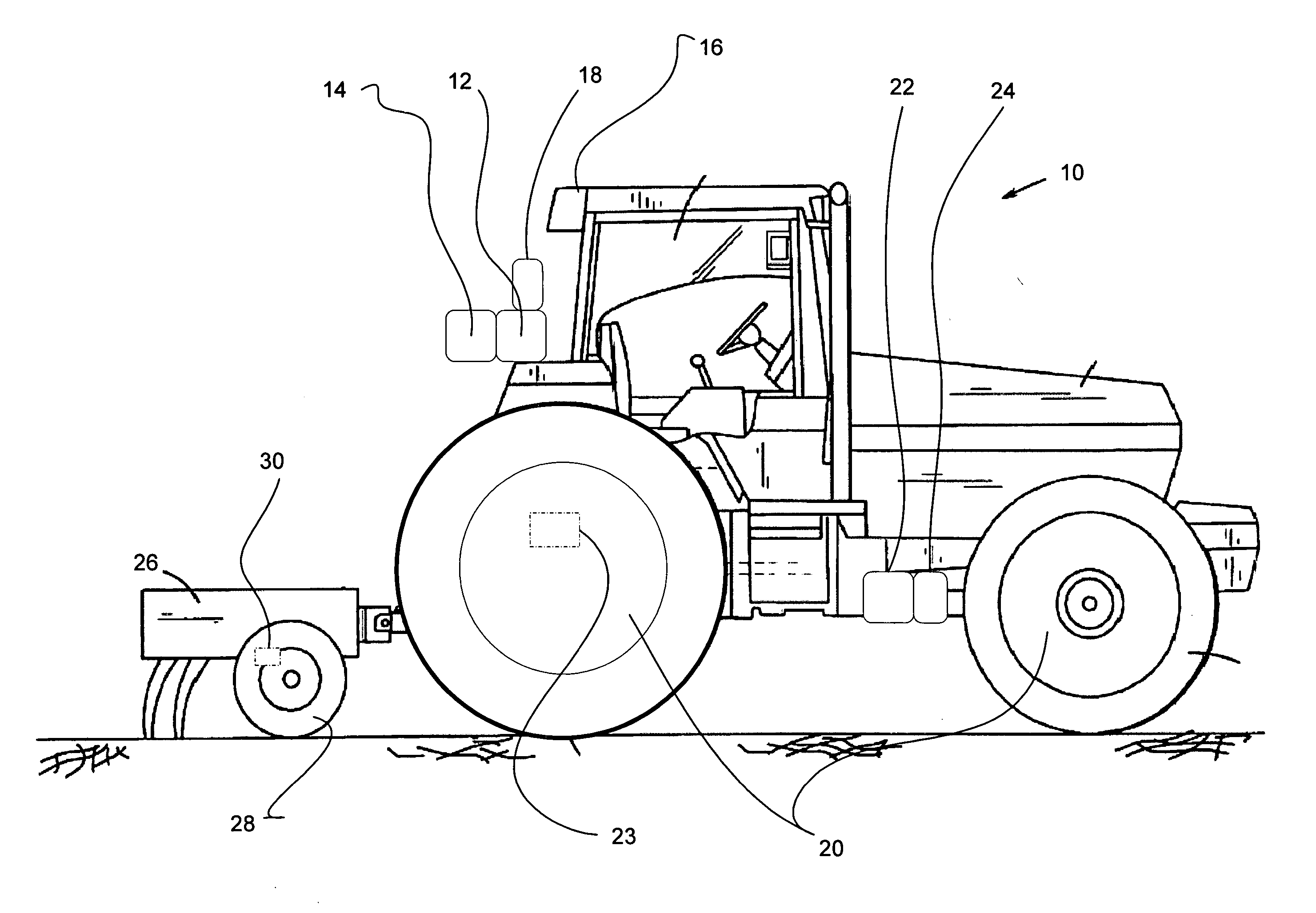

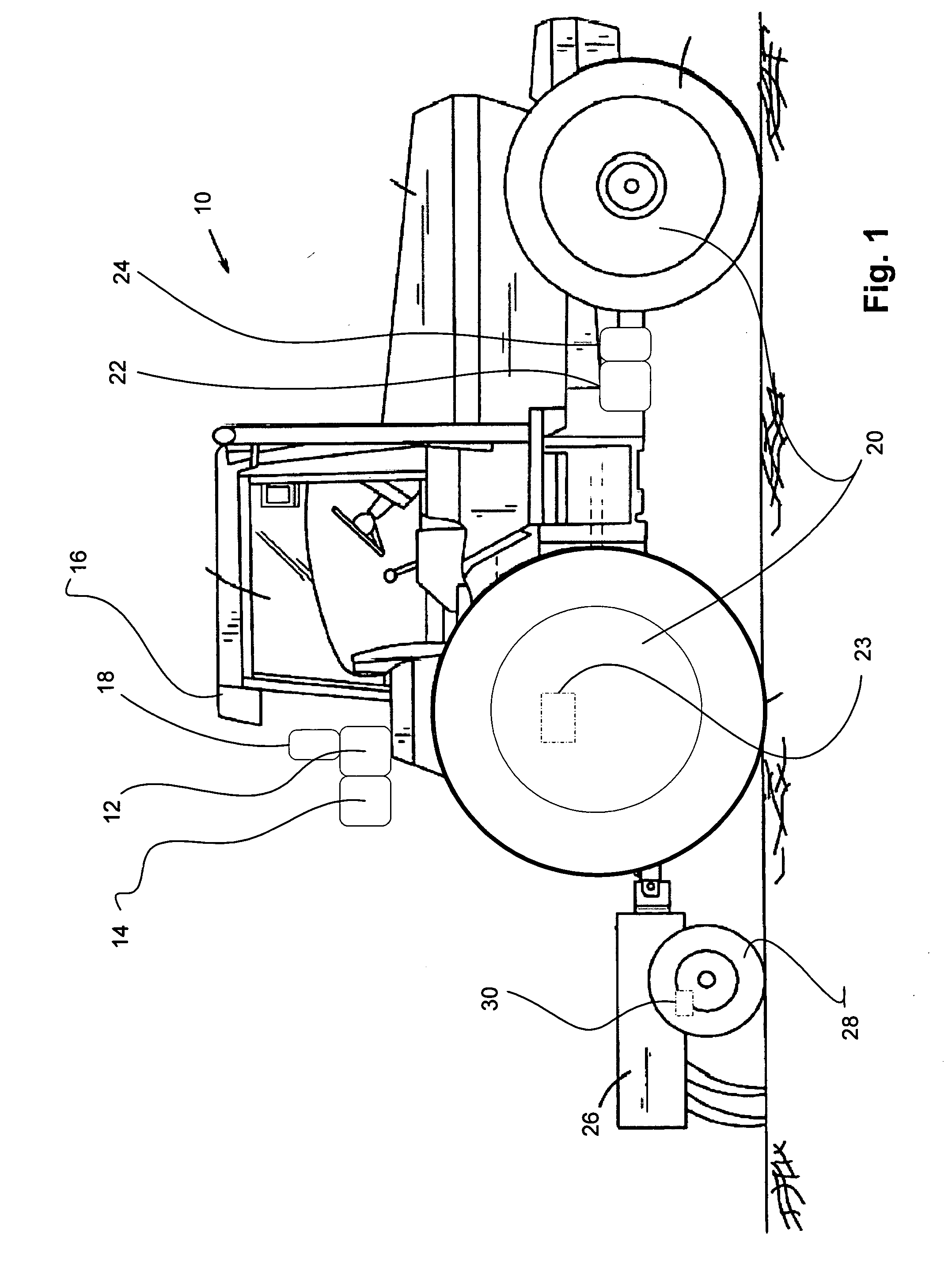

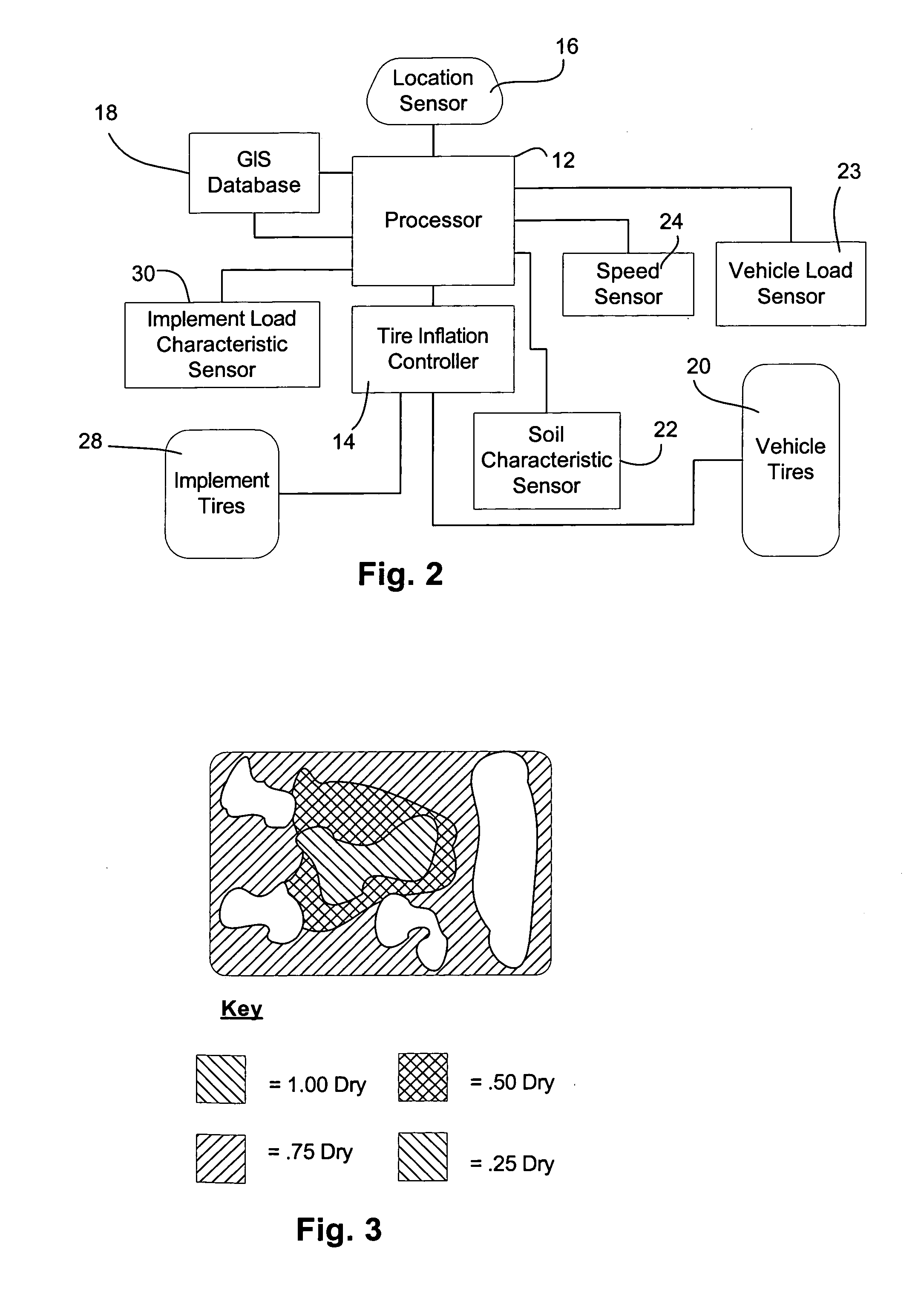

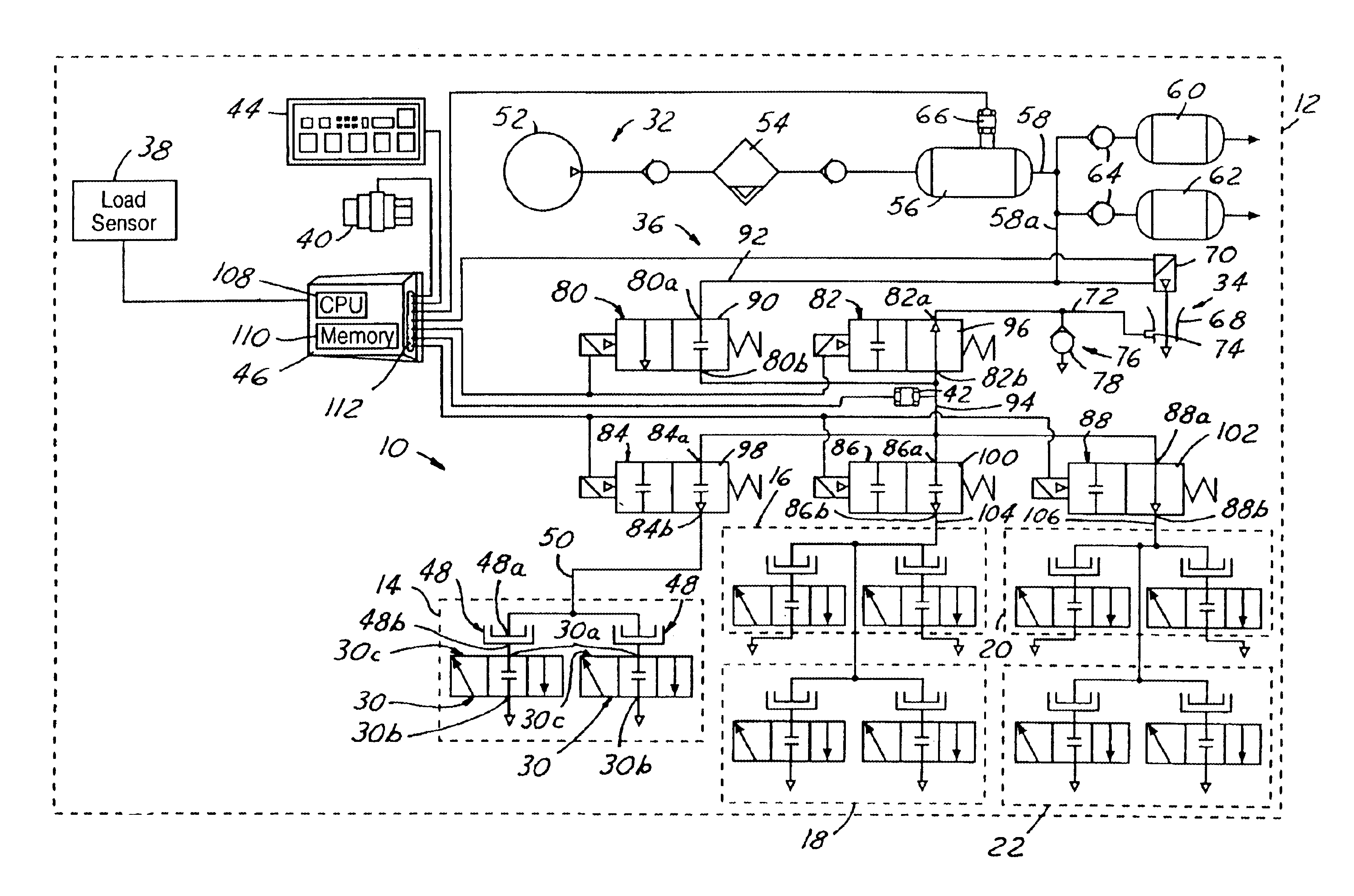

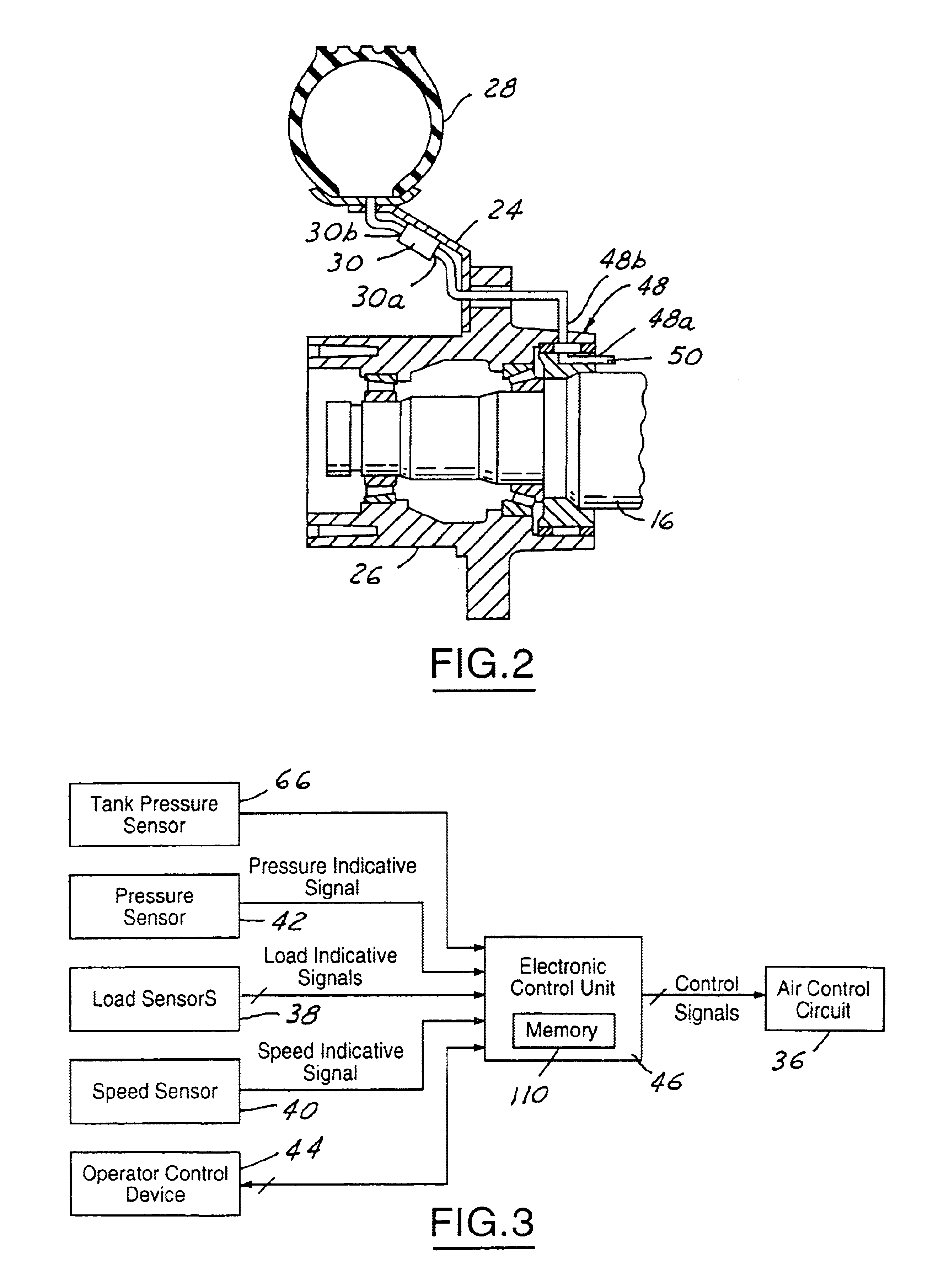

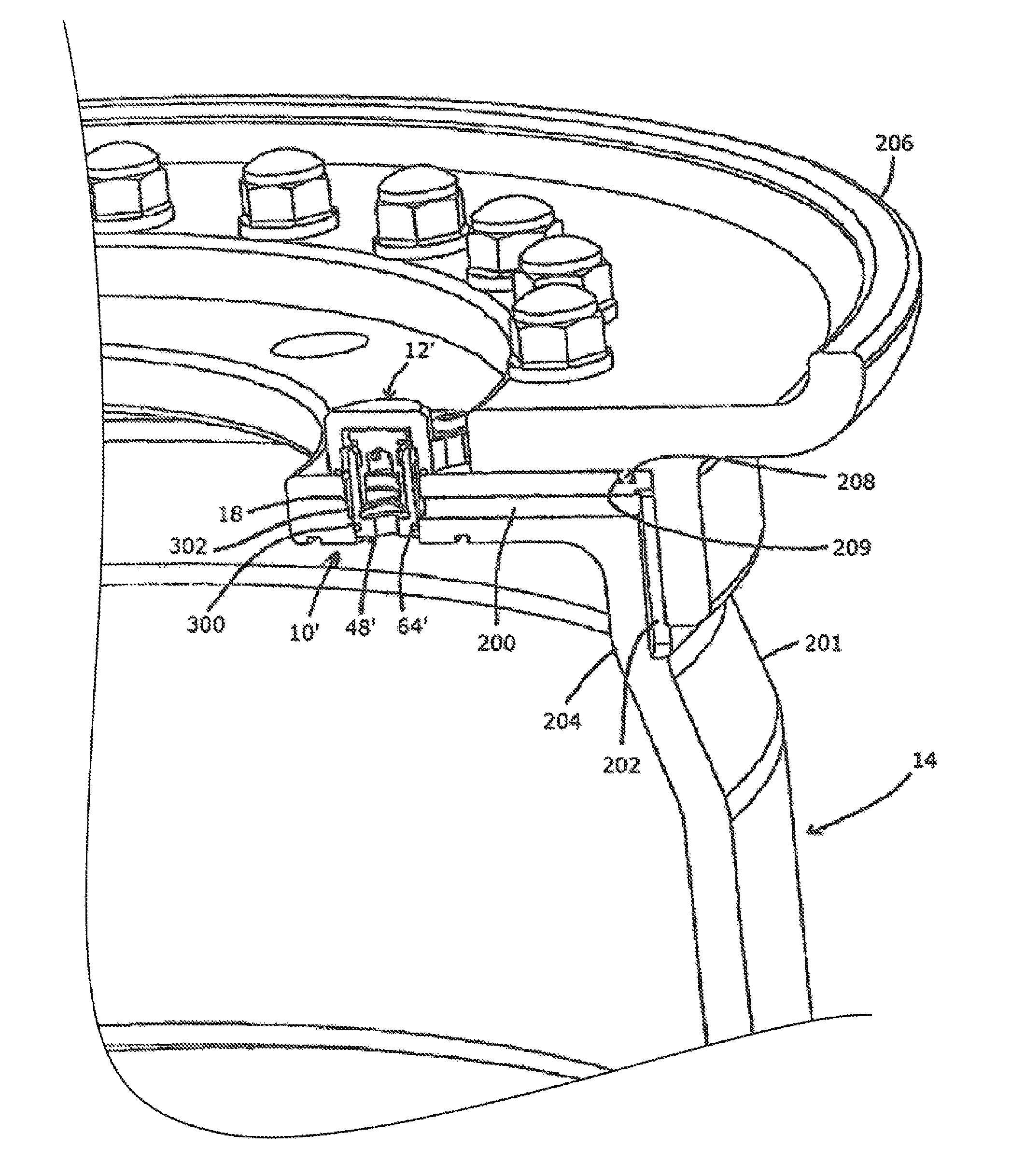

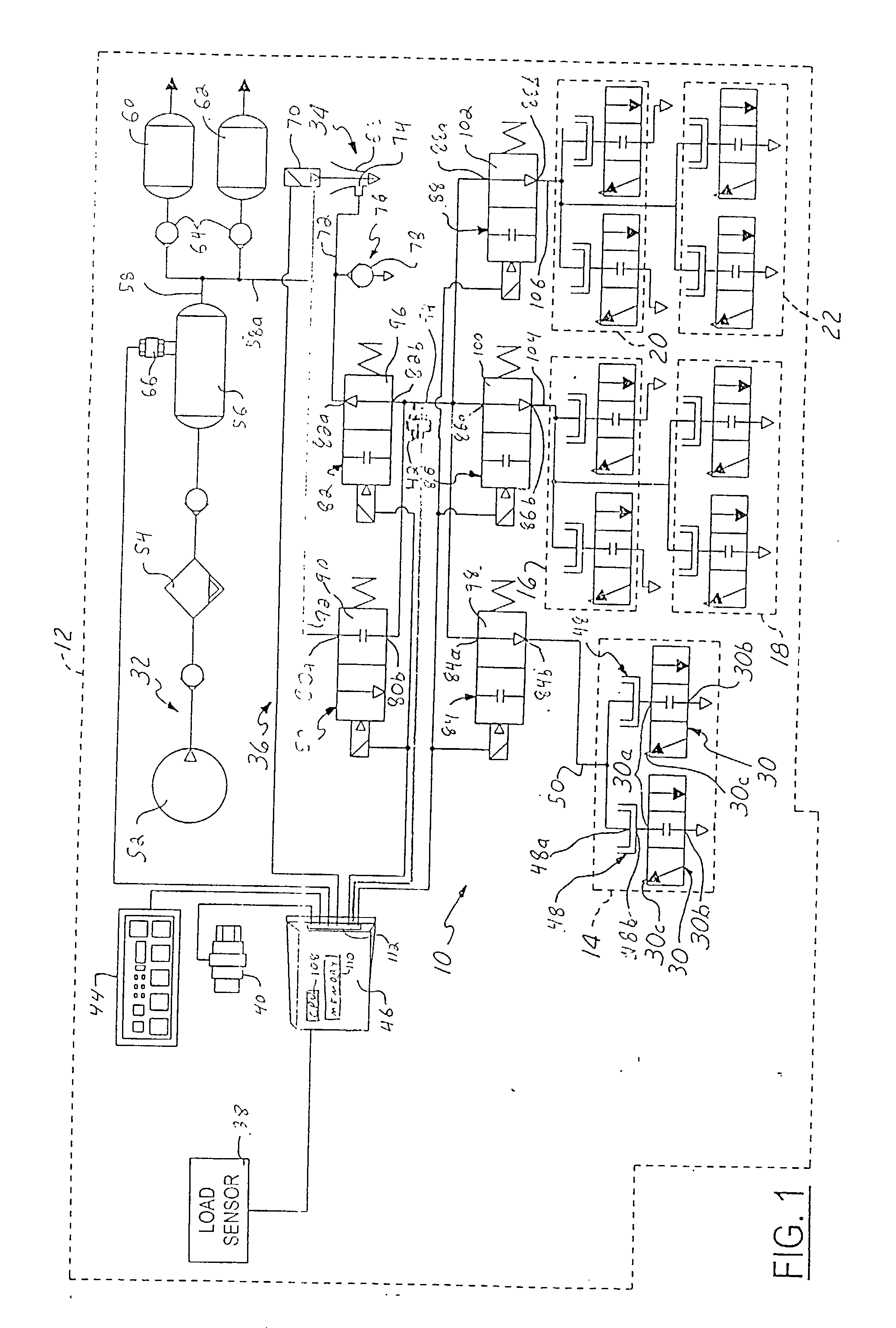

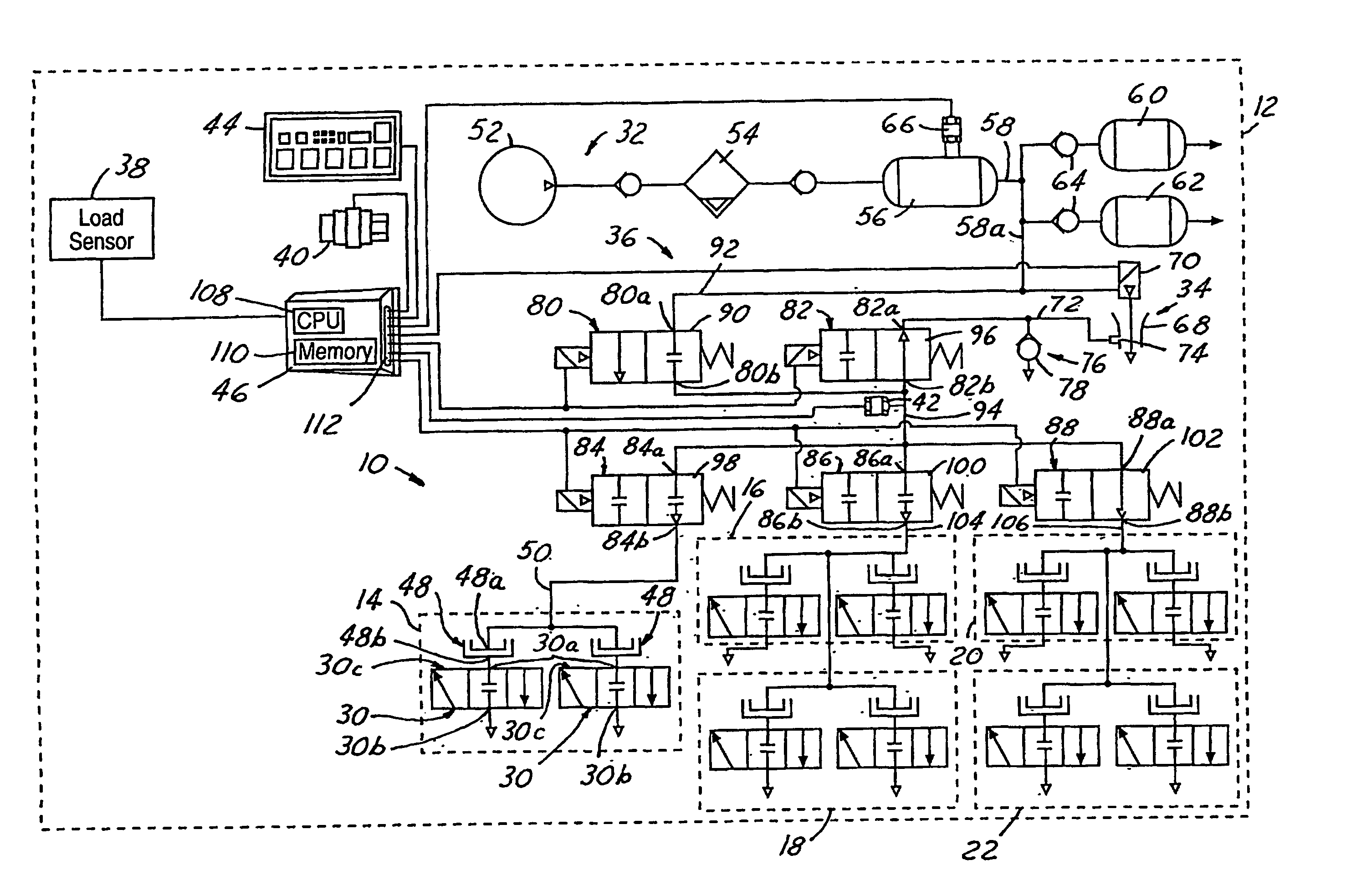

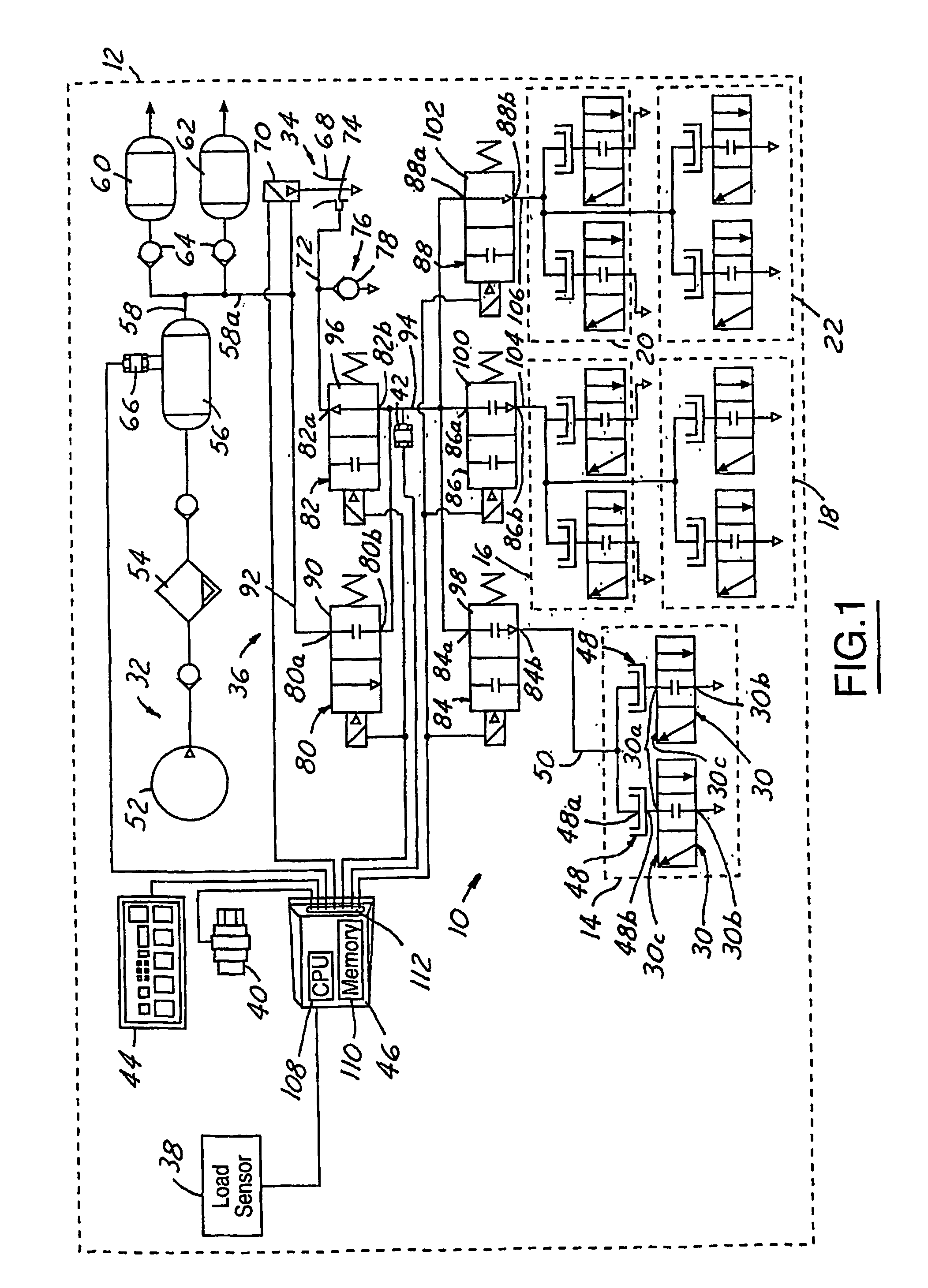

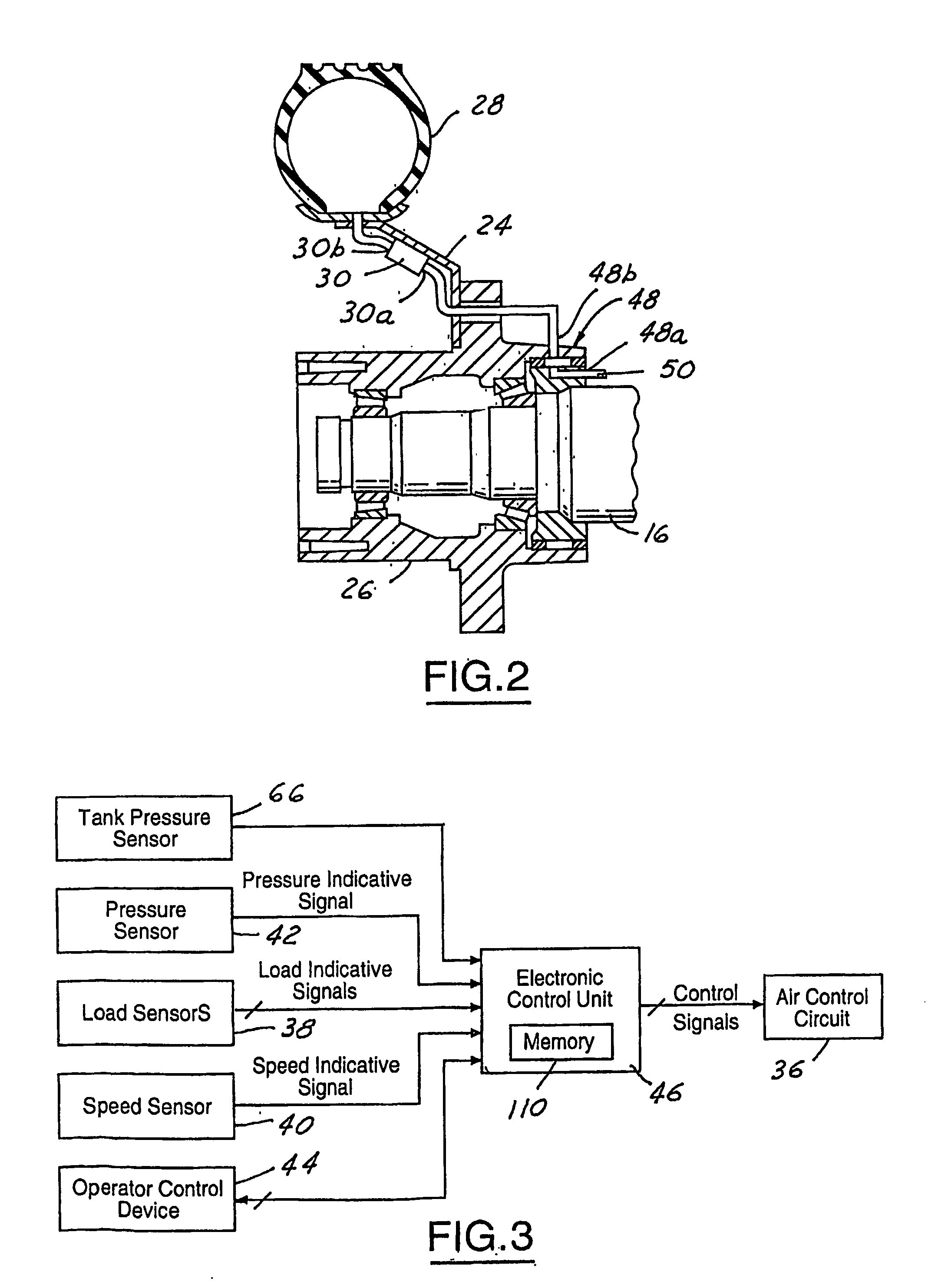

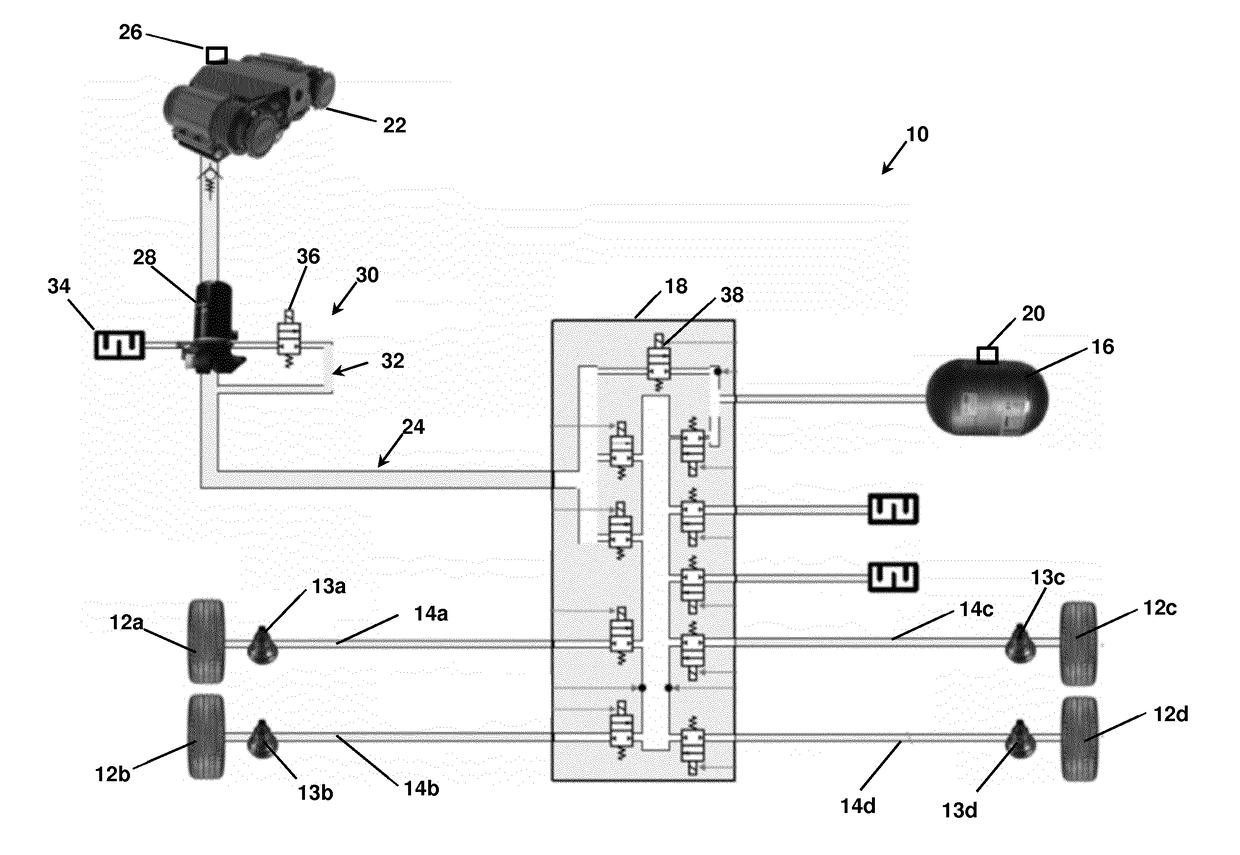

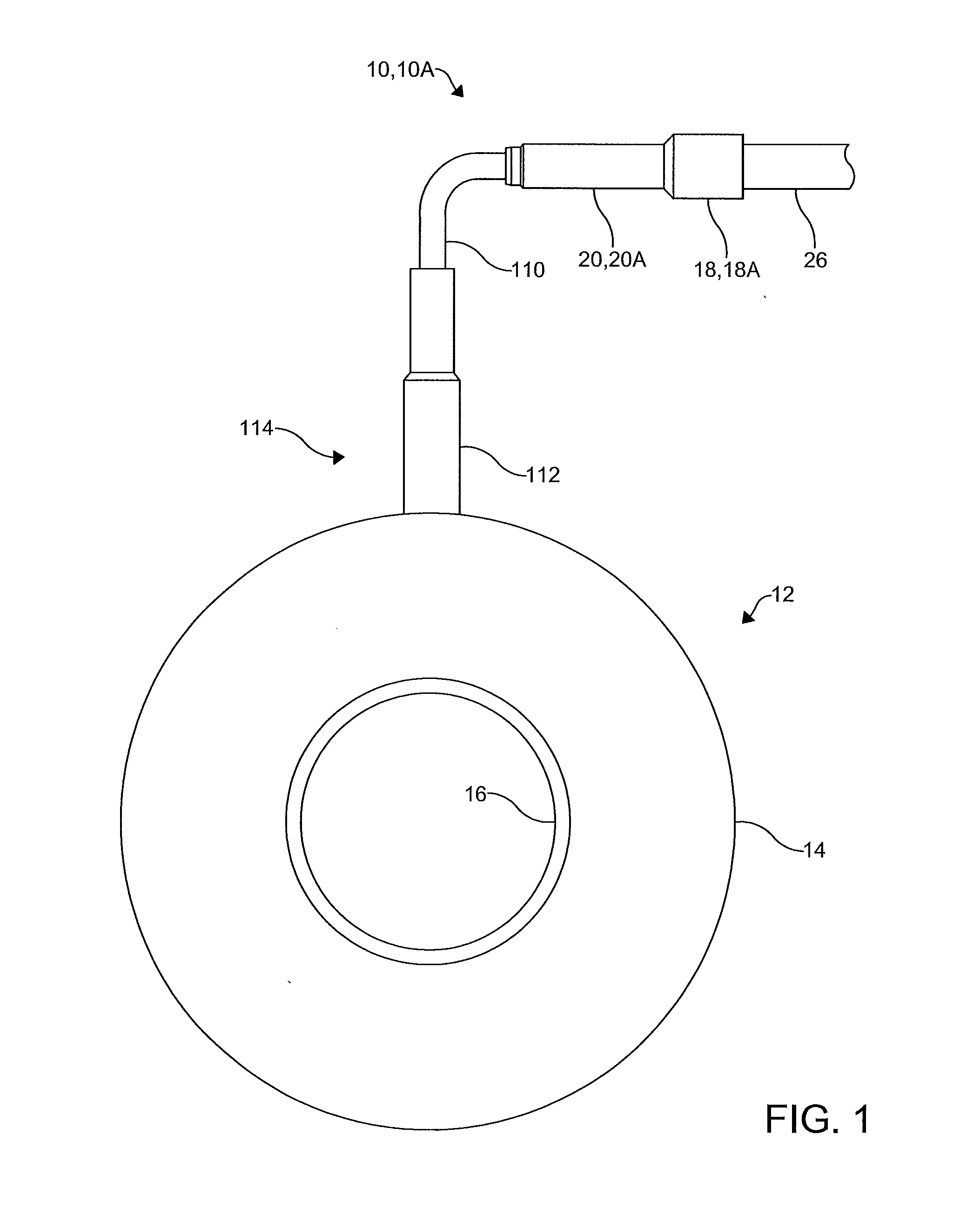

Tire inflation system for use with an agricultural implement

ActiveUS7302837B2Increase and decrease loadTyre measurementsRoads maintainenceCentral tire inflation systemLocation determination

Owner:BLUE LEAF I P INC

Tire inflation system for use with an agricultural implement

ActiveUS20070068238A1Increase and decrease loadTyre measurementsRoads maintainenceCentral tire inflation systemLocation determination

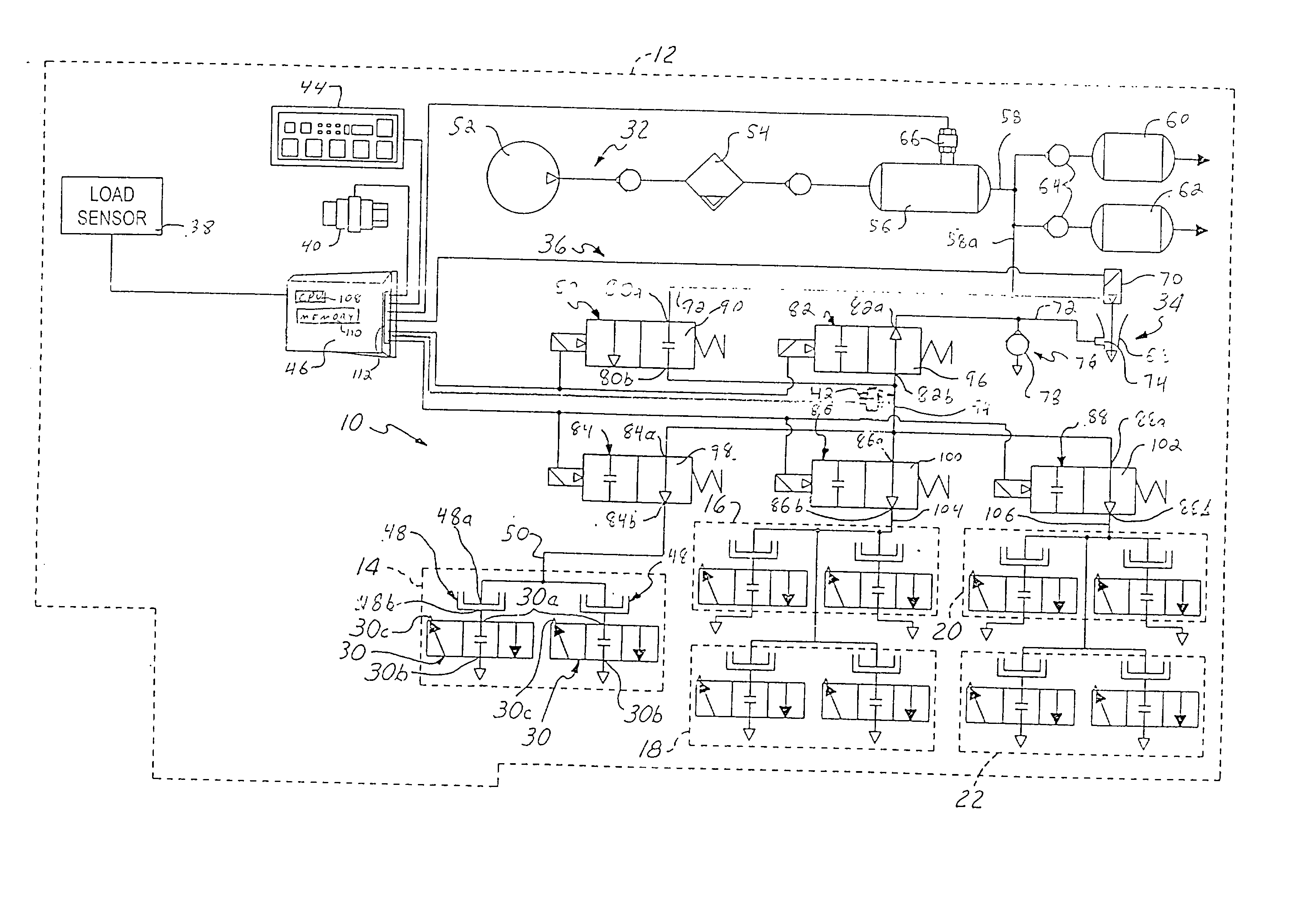

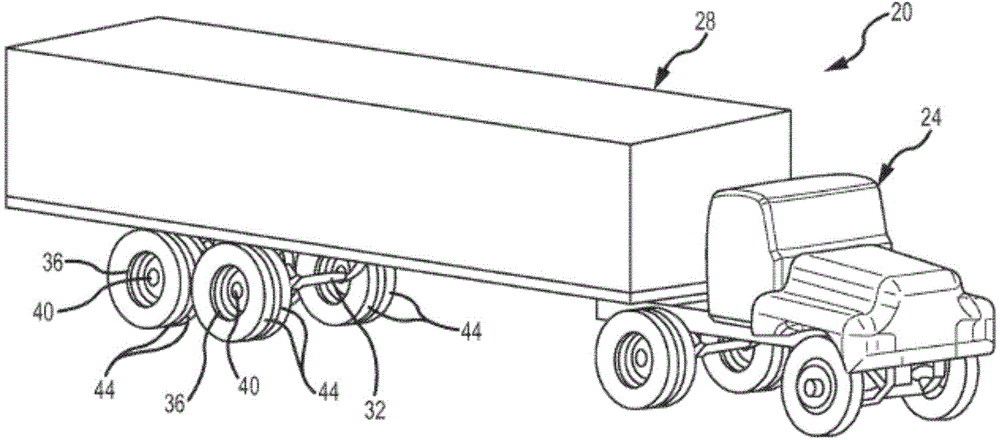

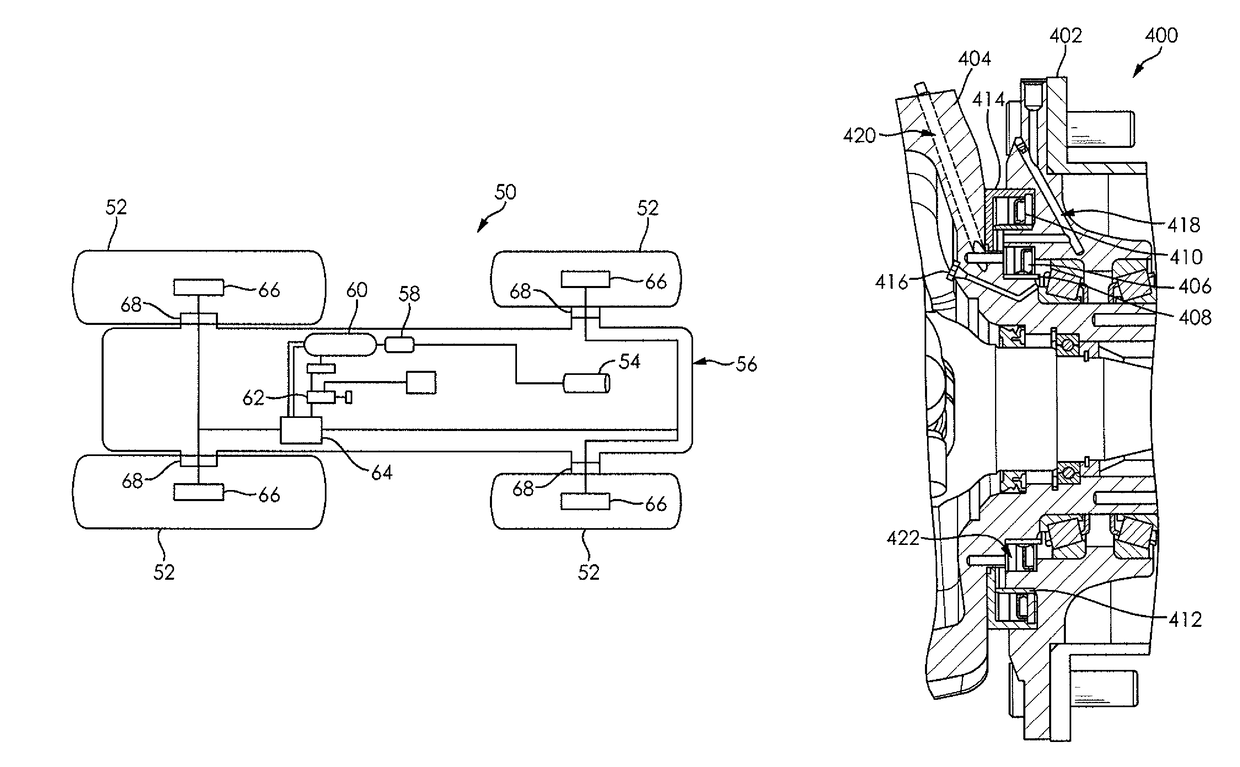

A central tire inflation system for an agricultural implement that is linked to a work vehicle for movement in a field. The central tire inflation system includes a database of soil conditions corresponding to location, an implement load sensor, a location determiner, a processor, and tire inflation controller. The processor determines the proper inflation of implement tires based on factors including the soil conditions and implement load.

Owner:BLUE LEAF I P INC

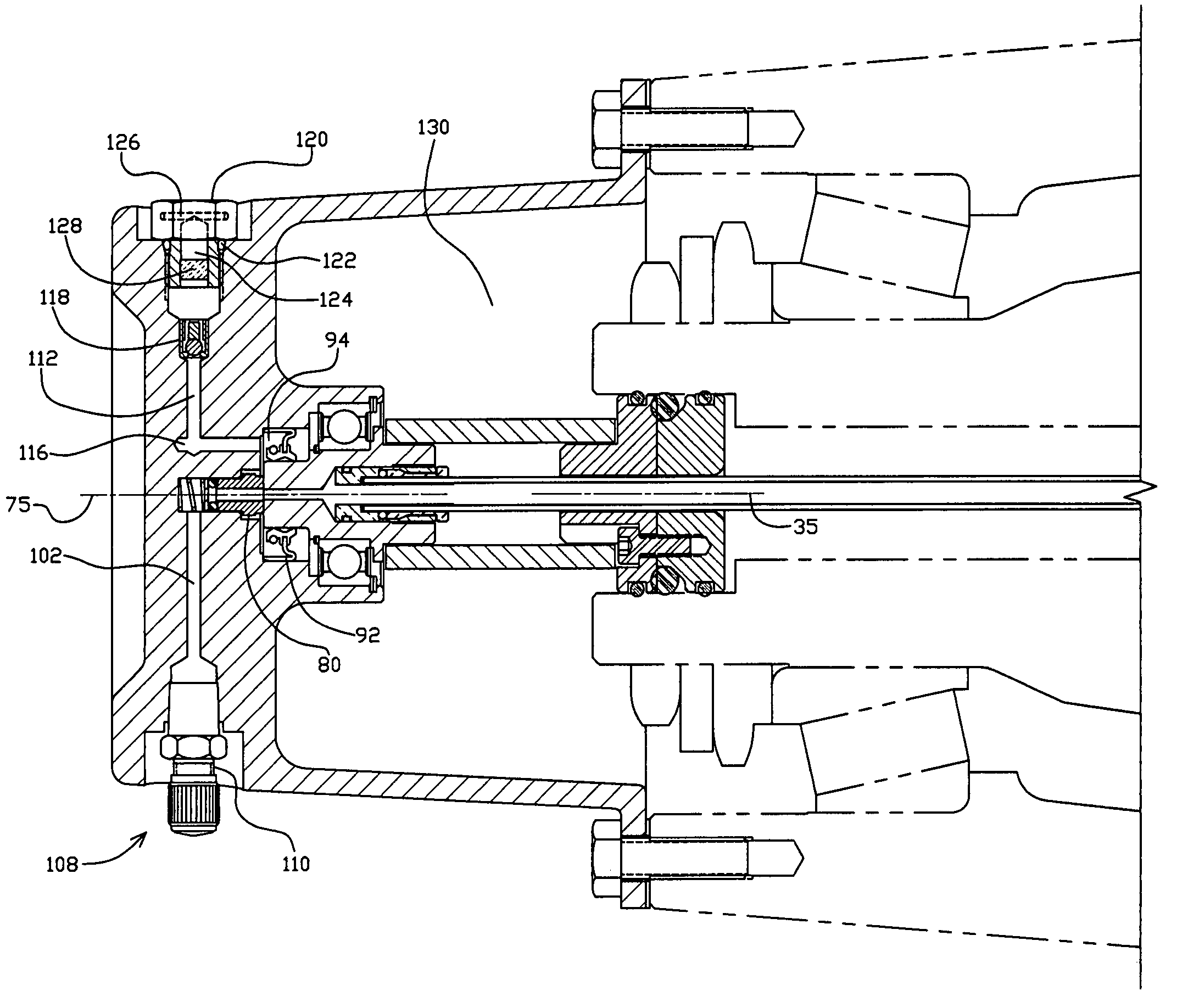

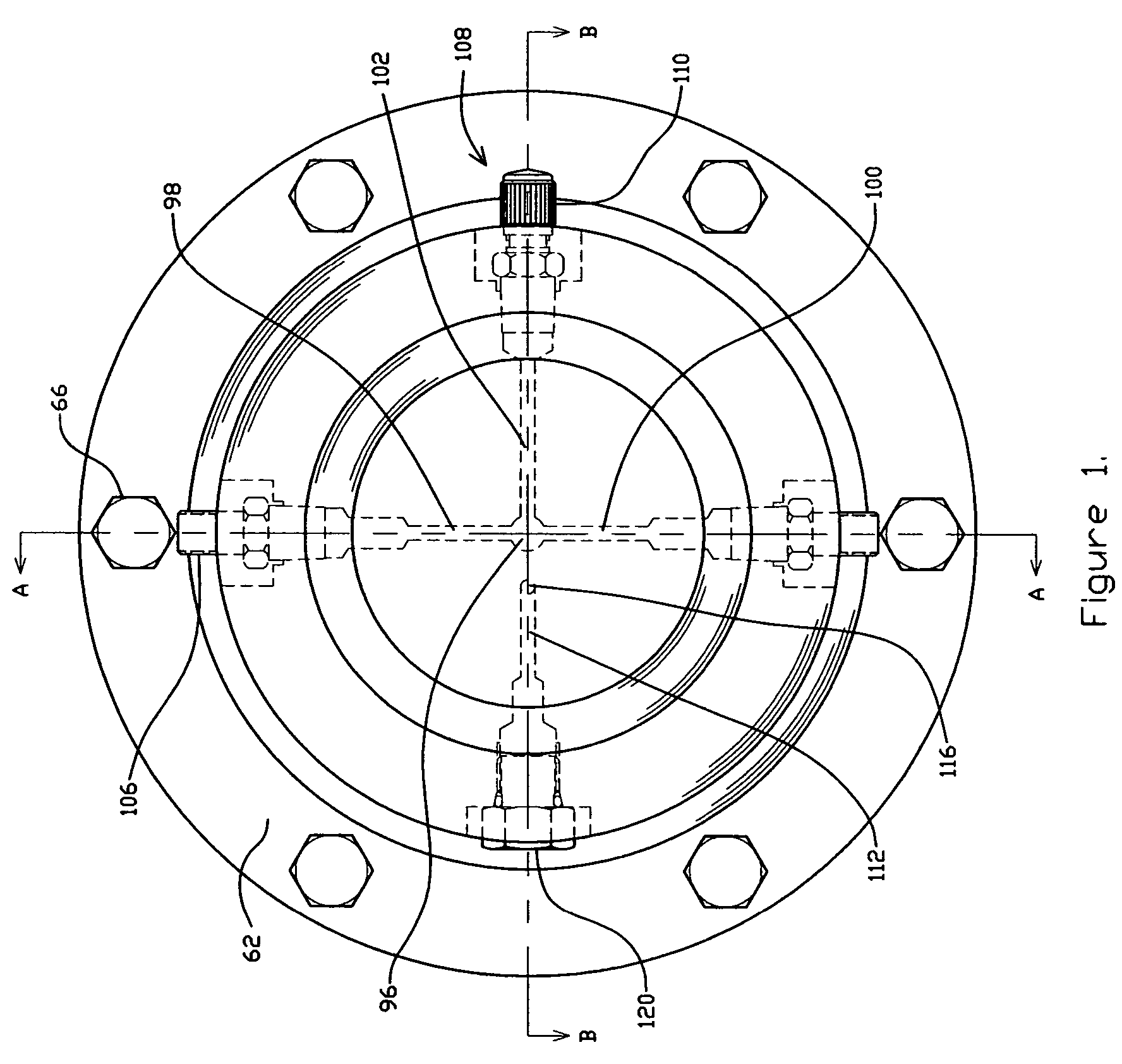

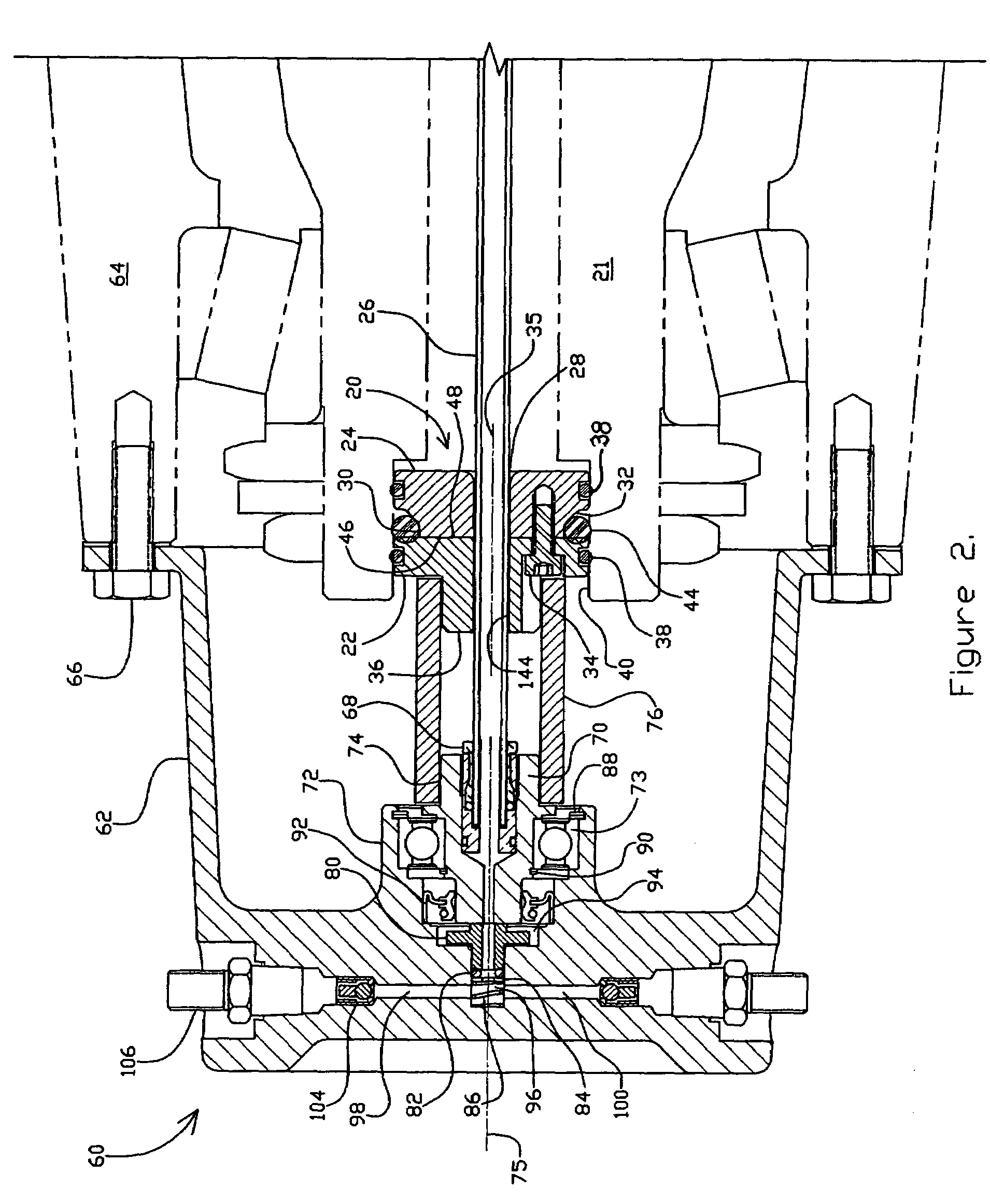

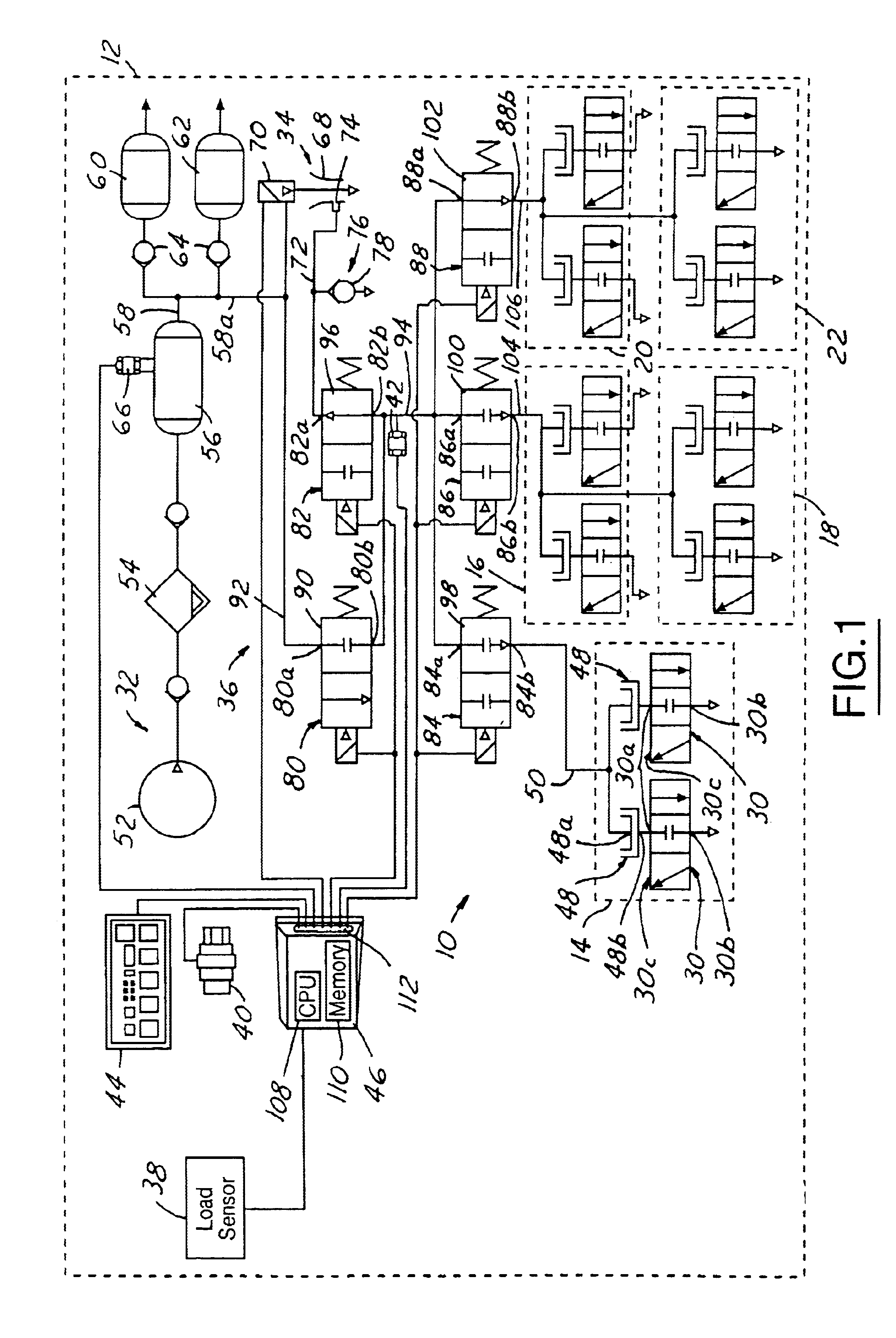

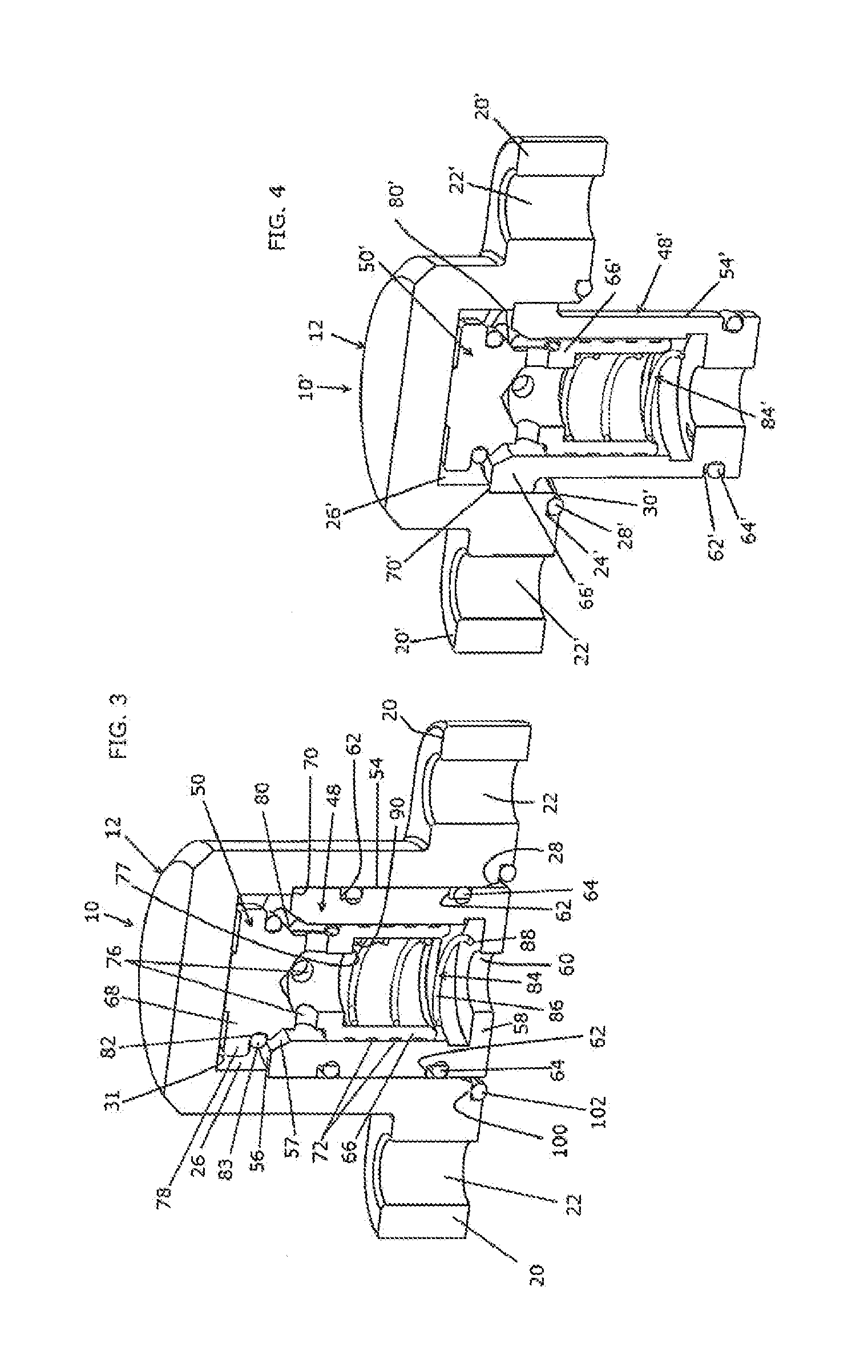

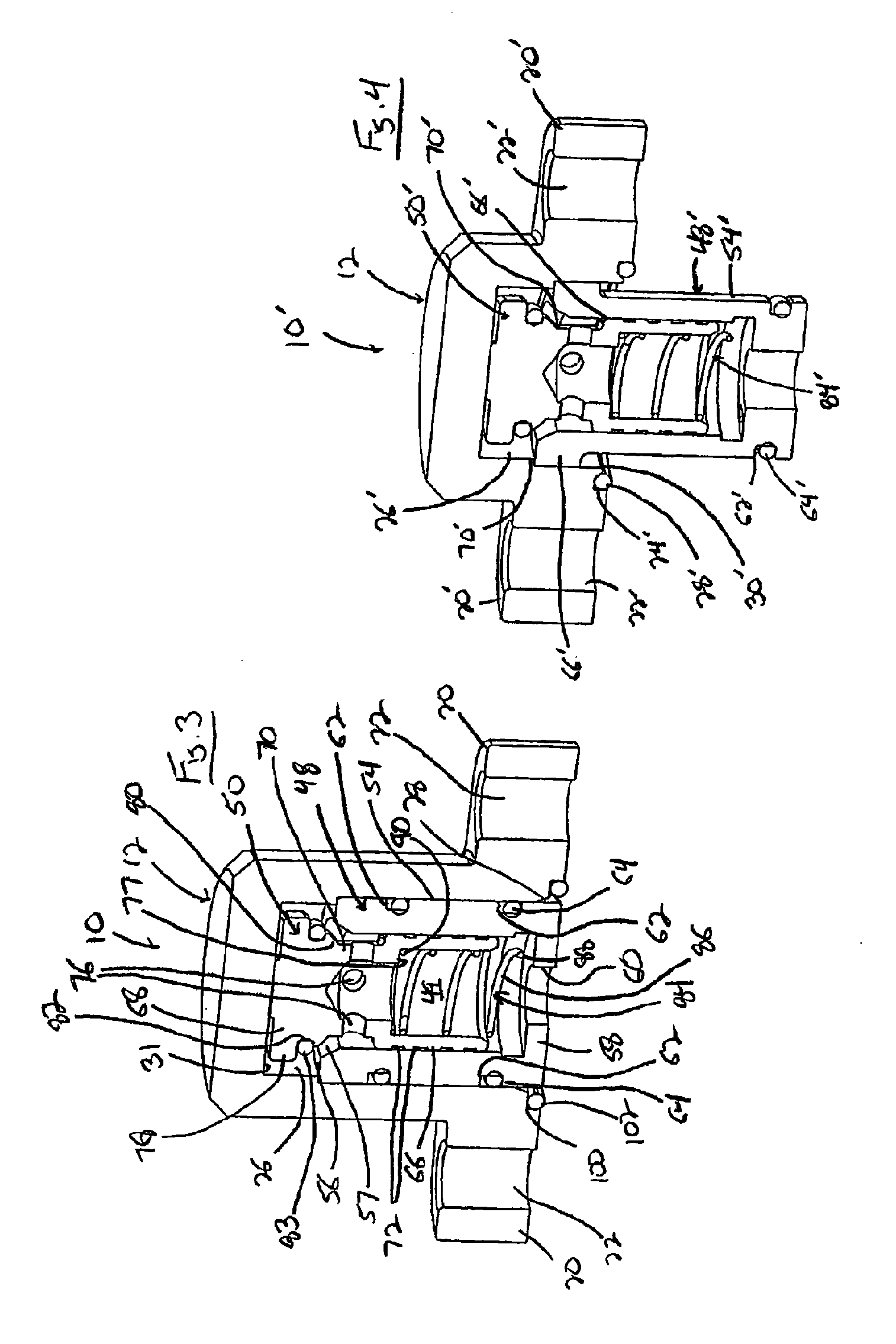

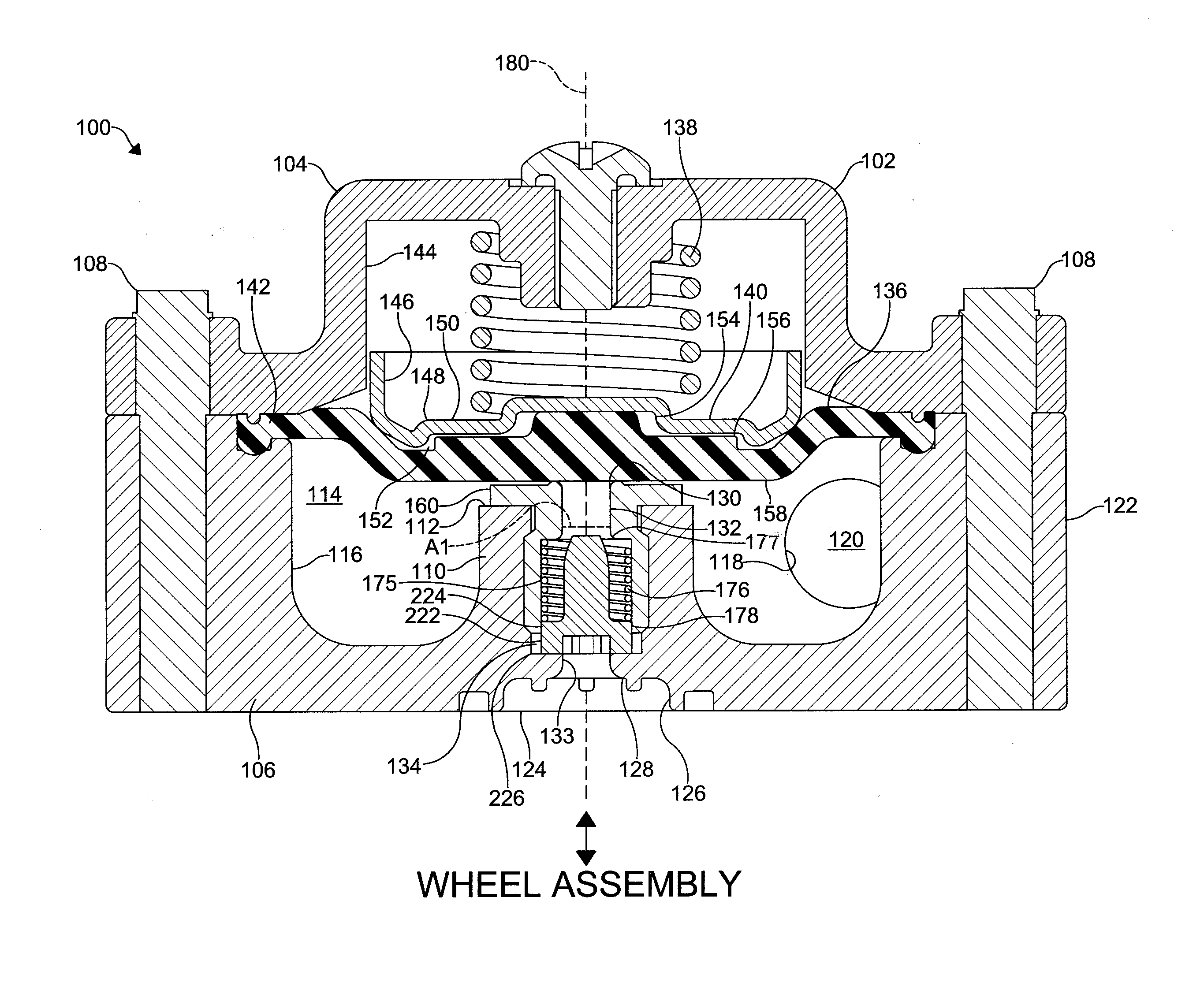

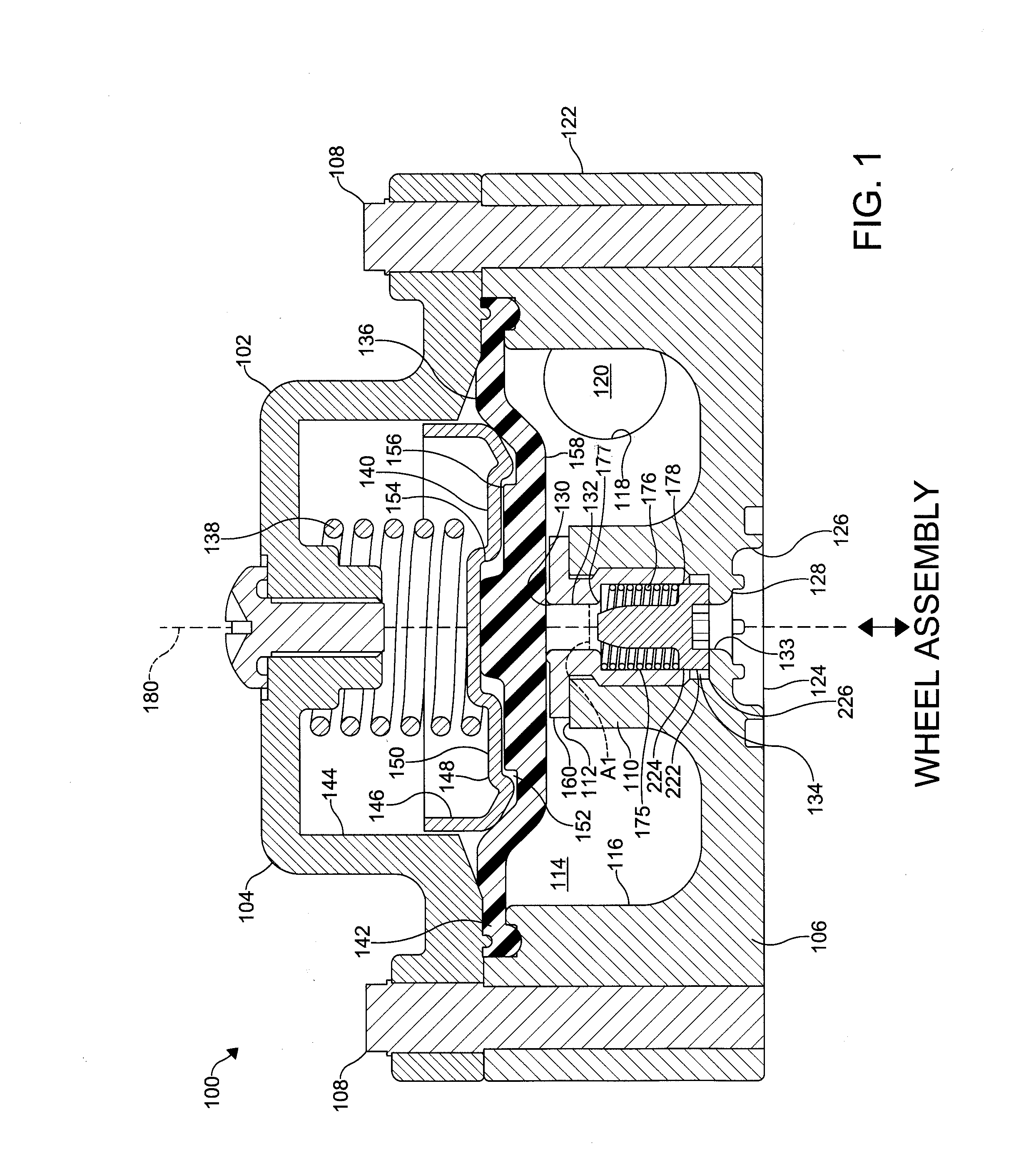

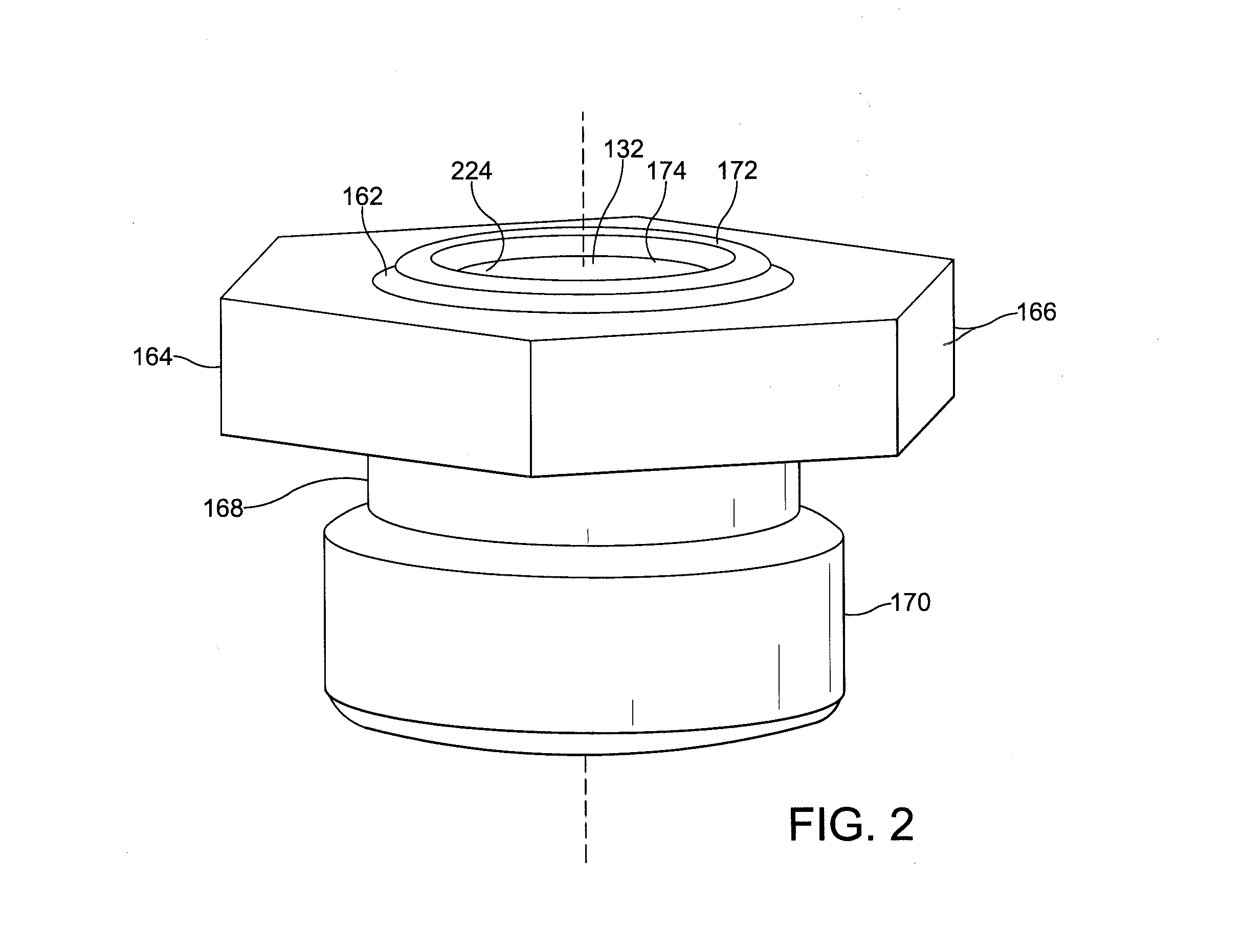

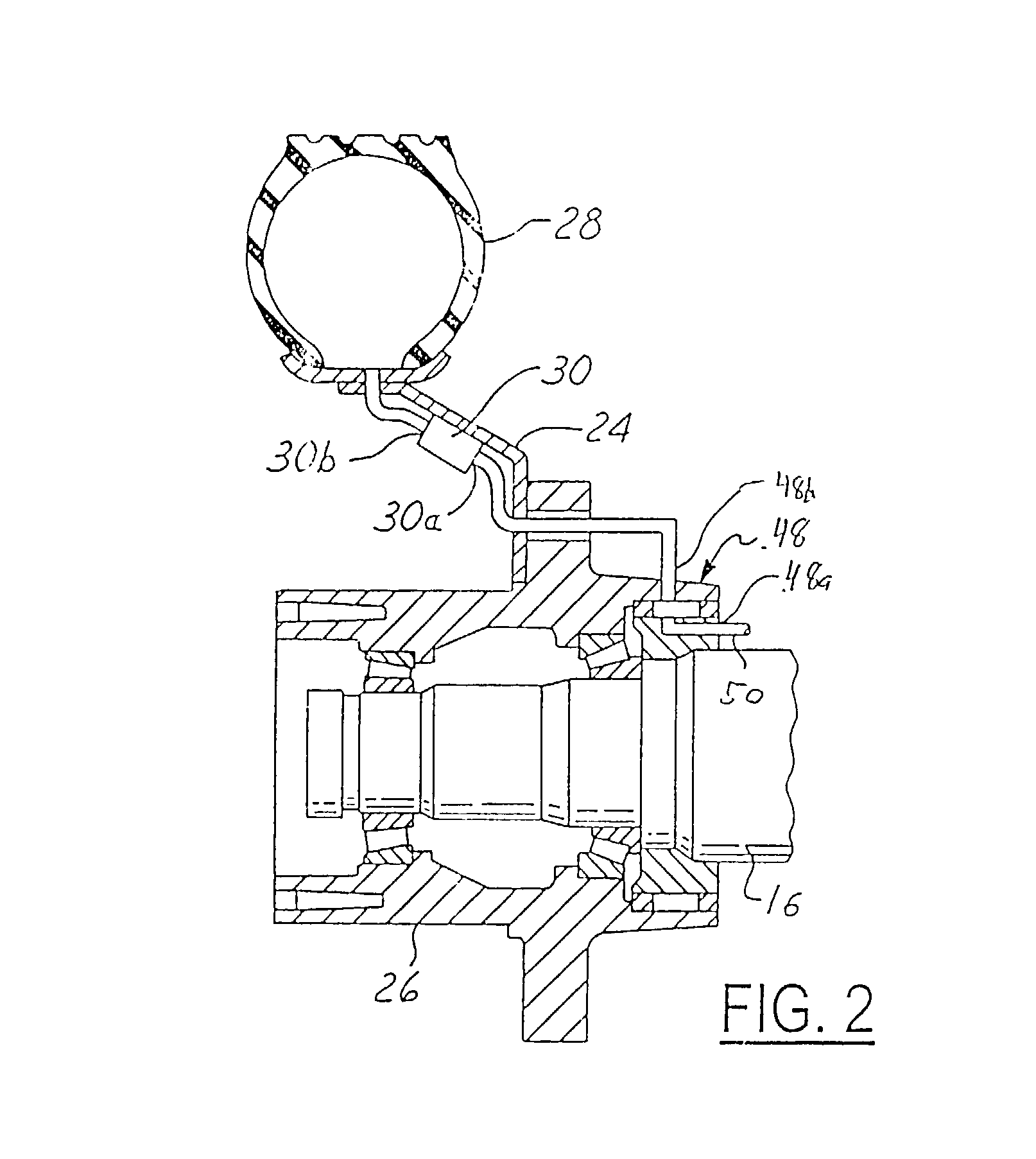

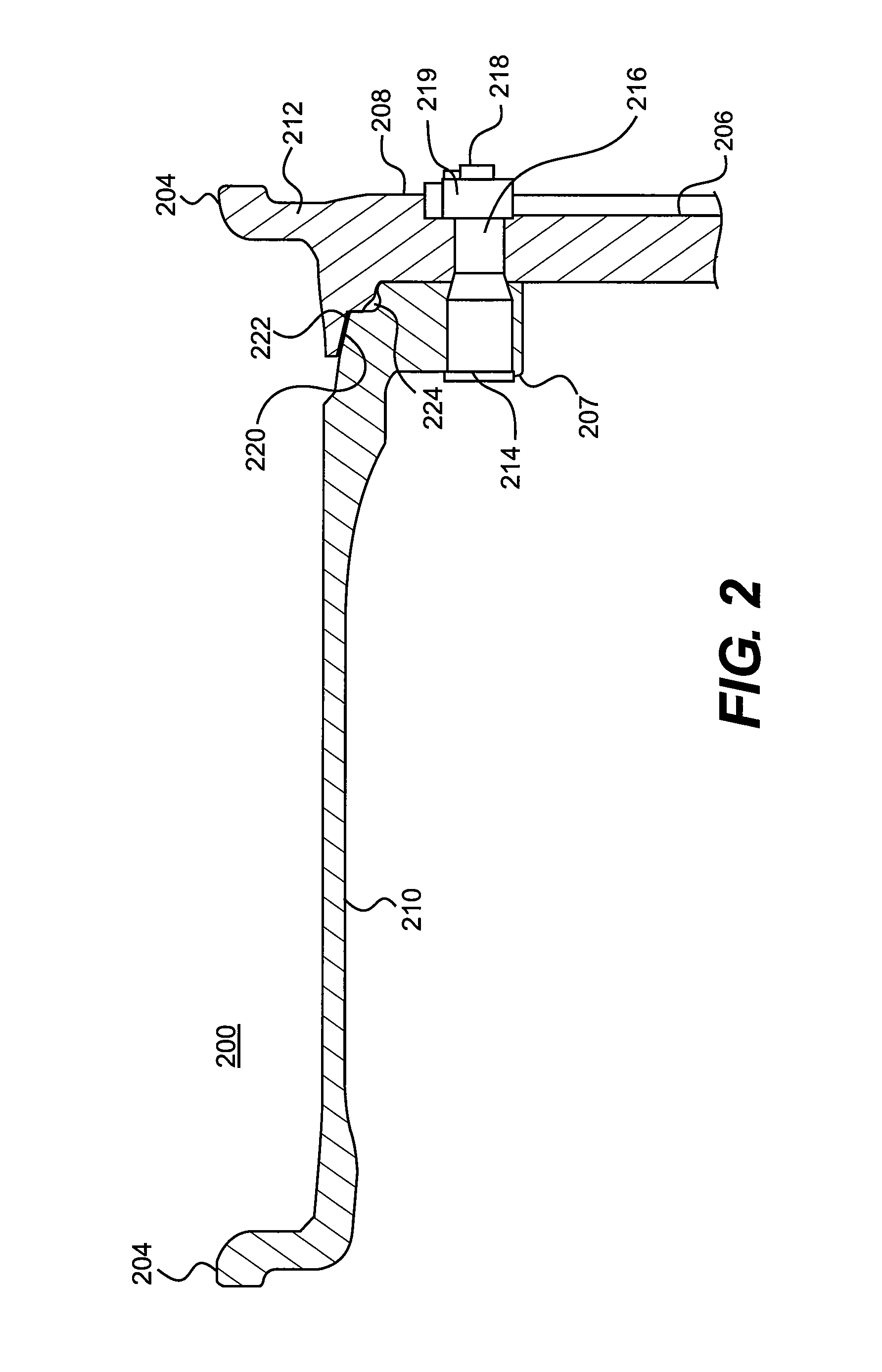

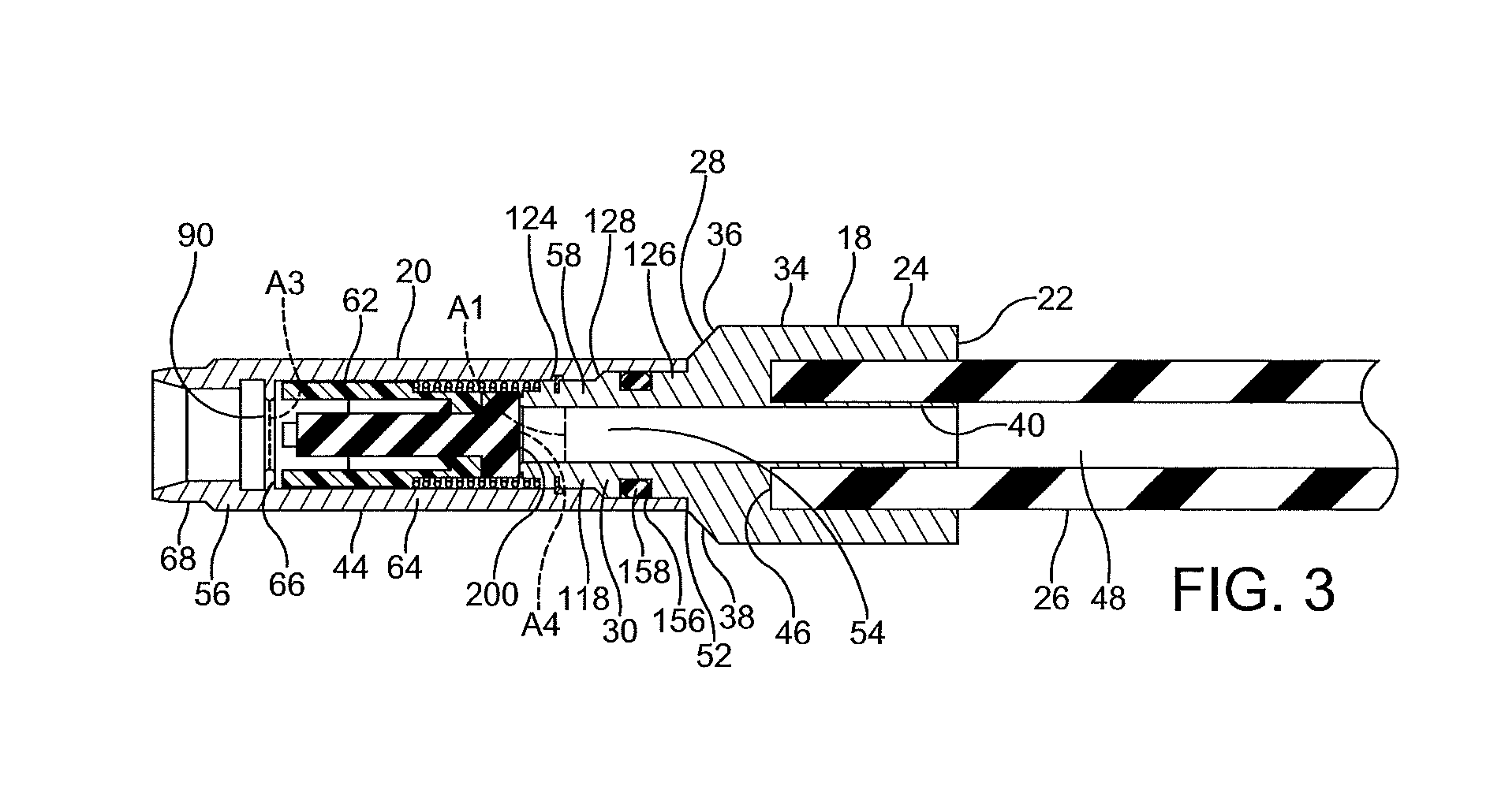

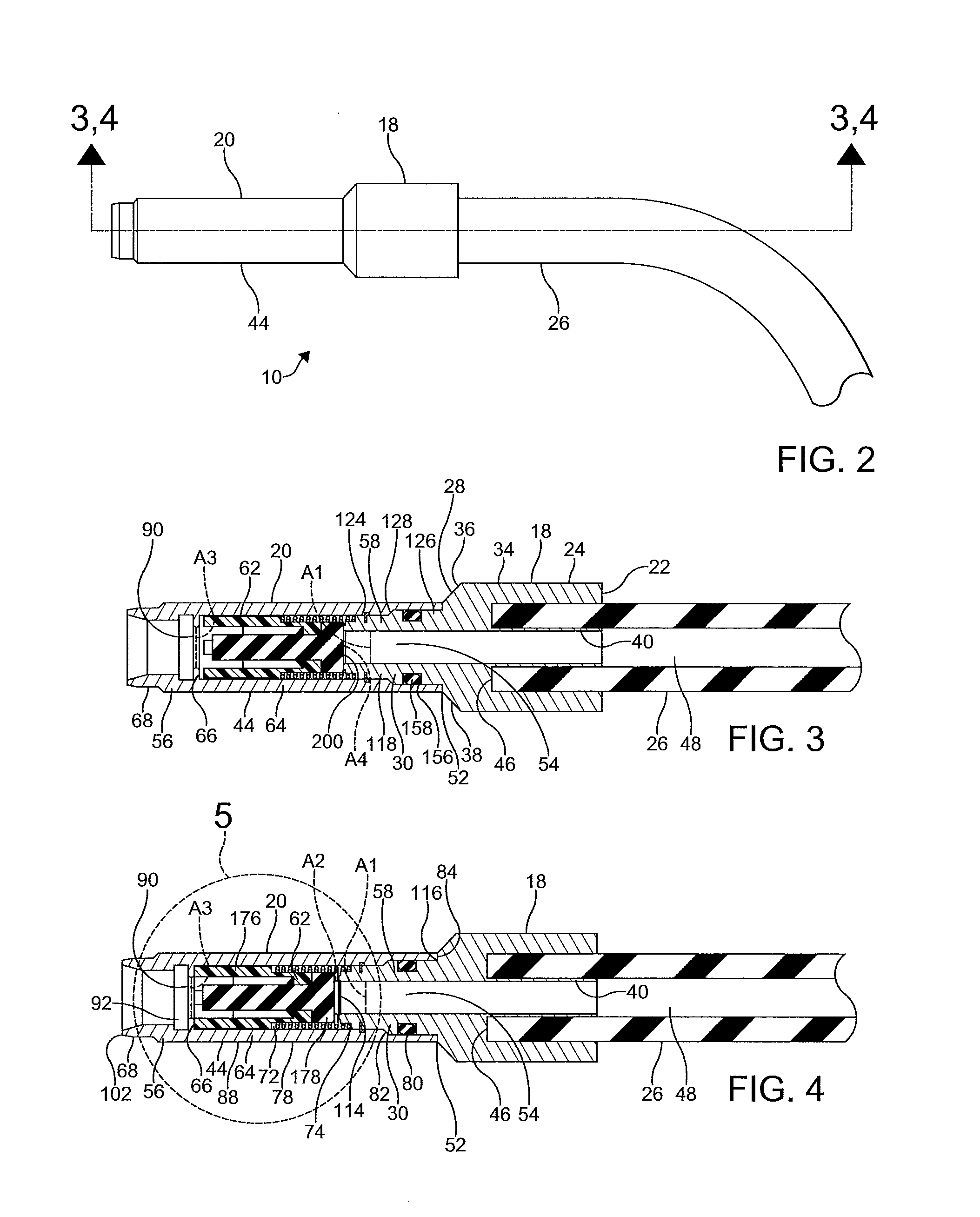

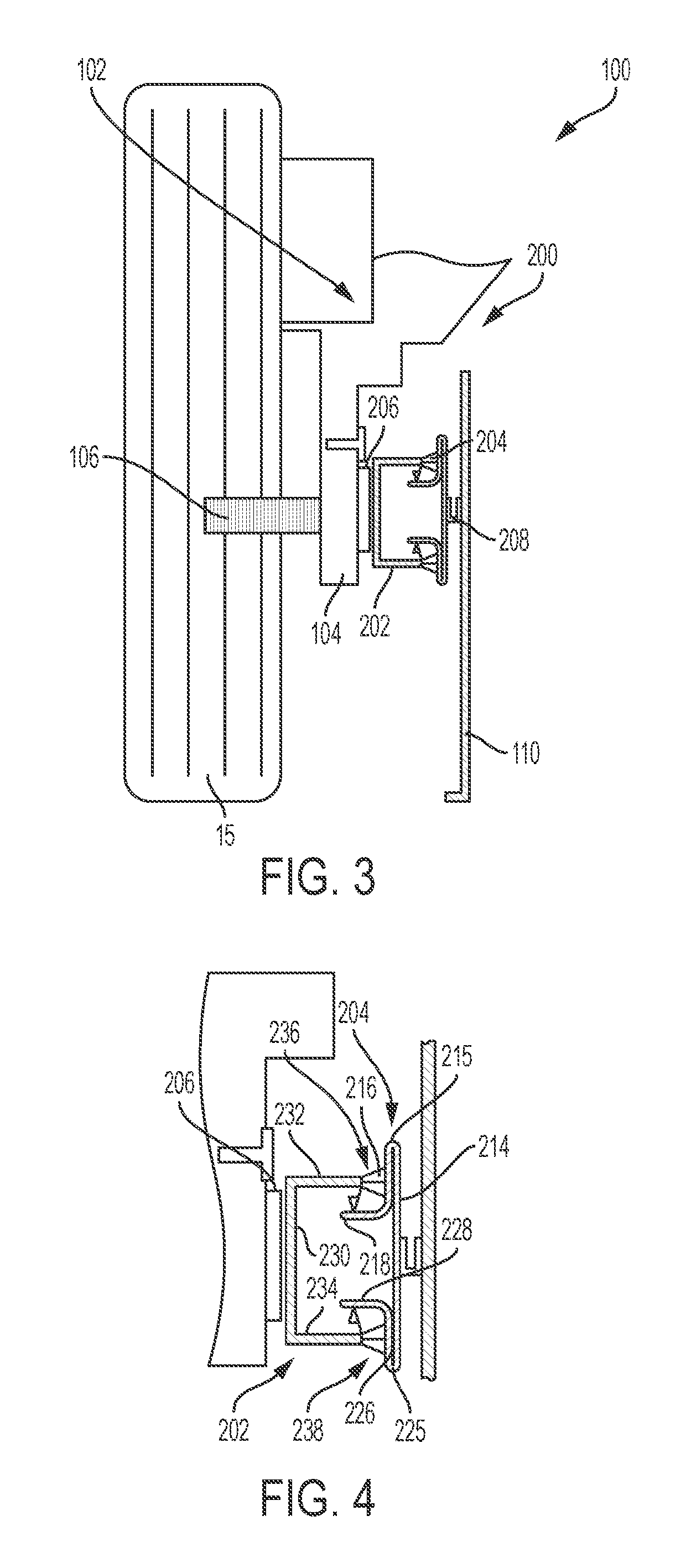

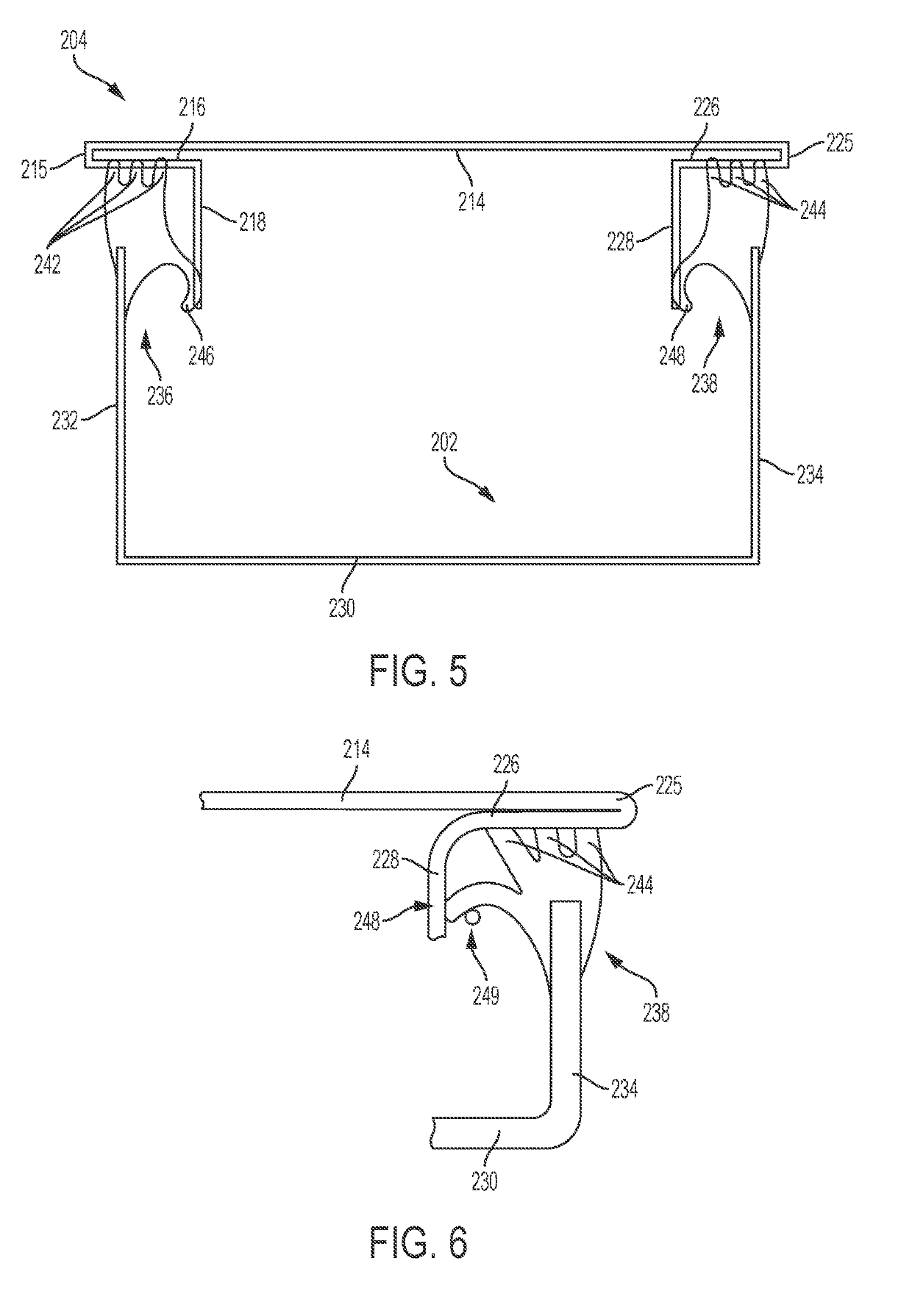

Central tire inflation system rotary air union

ActiveUS7207365B2Tyre measurementsTyre-inflating valvesCentral tire inflation systemAtmospheric pressure

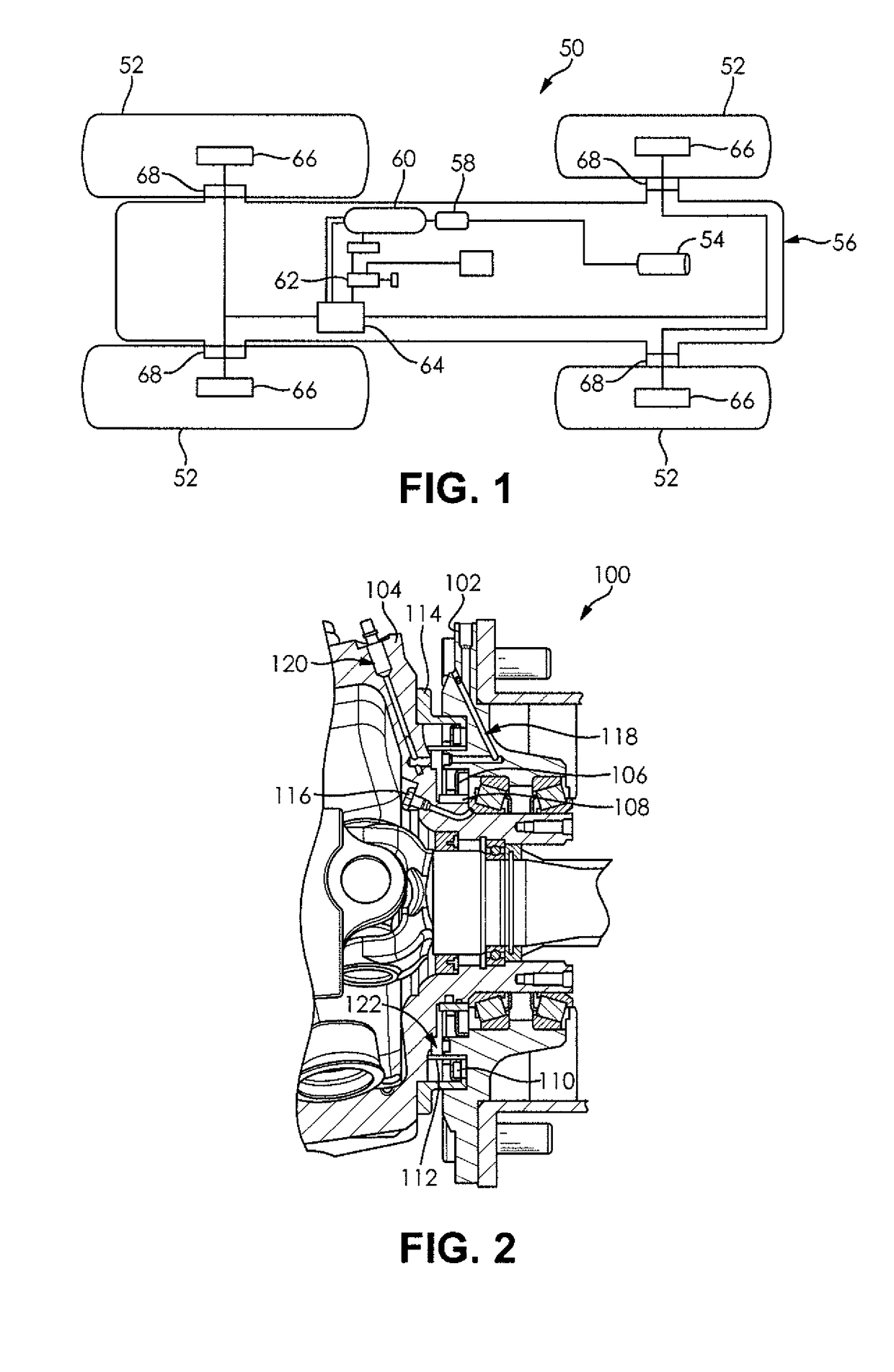

A central tire inflation system for maintaining tire inflation on a vehicle having a torque transfer sleeve connected between an axle plug assembly and a stationary shaft on the rotary union assembly. A flexible conduit extends through the axle plug to the rotary union assembly and is used to provide air pressure to tires connected to the rotary union assembly. The torque transfer sleeve limits rotational torque on the flexible conduit. Primary and secondary seals are provided on the rotary union assembly as well. A vent chamber between the primary and secondary seals allows the release of air which exits the primary seal, which prevents pressure from entering the lubrication area of the rotary union assembly.

Owner:PRESSURE SYST INT LLC

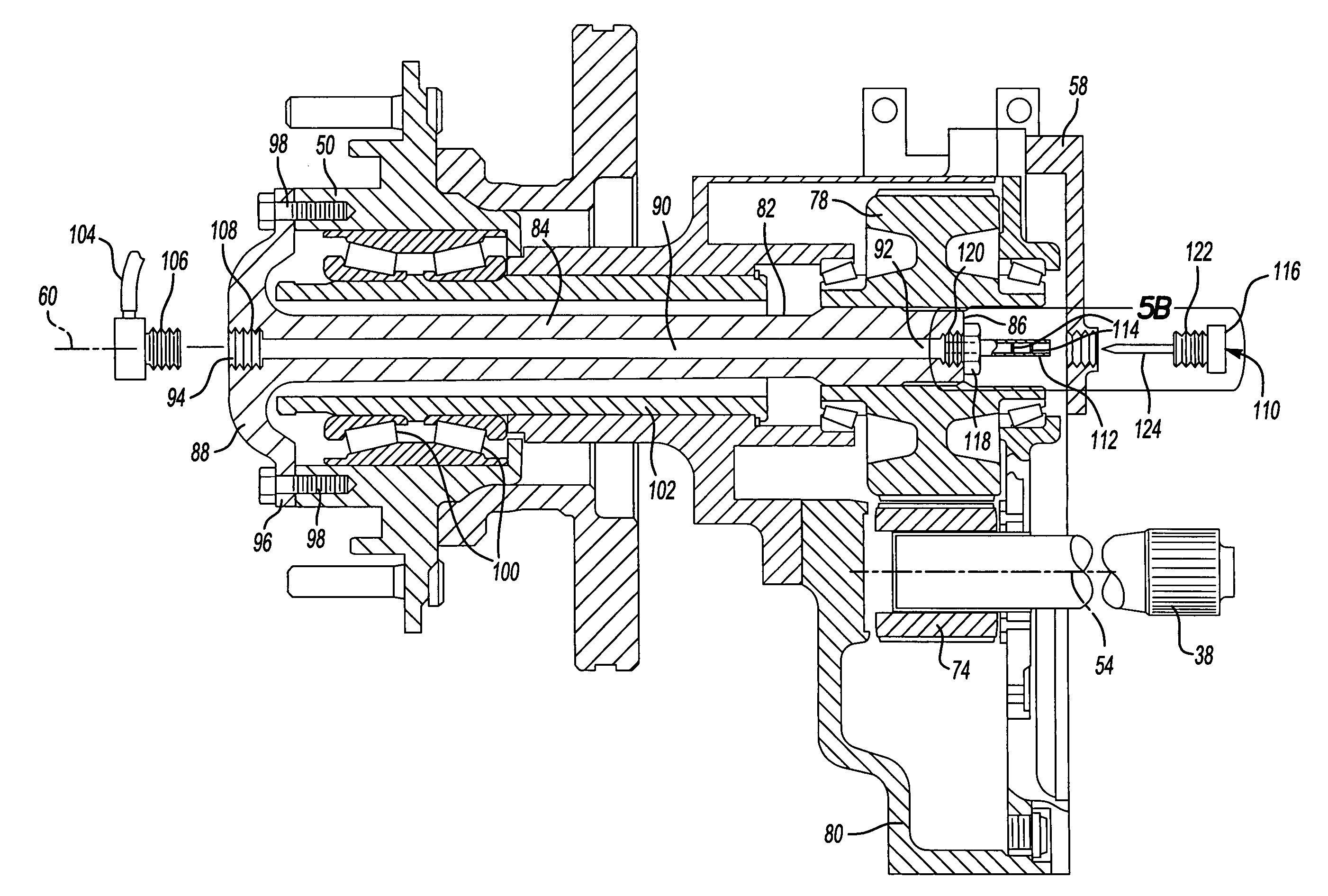

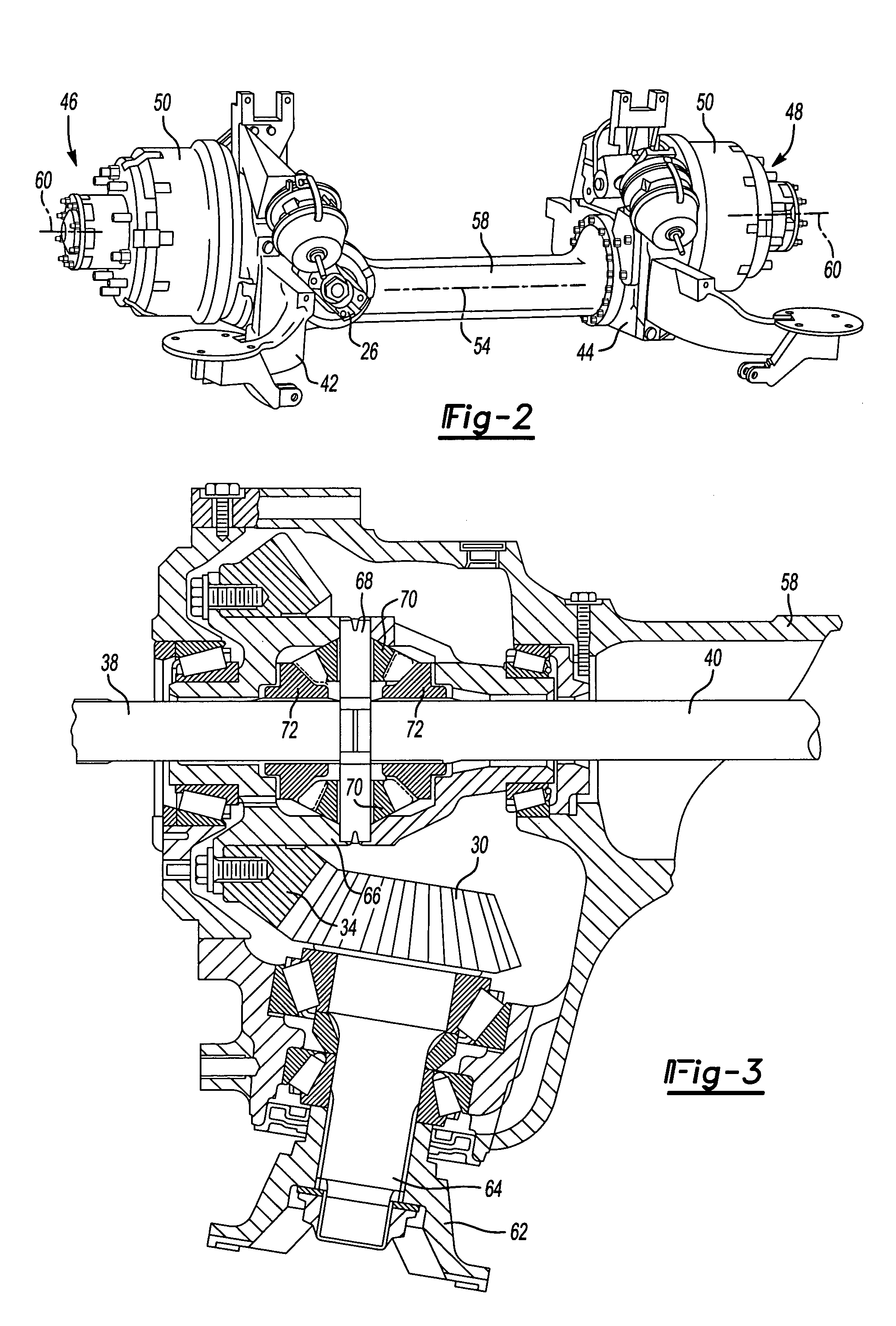

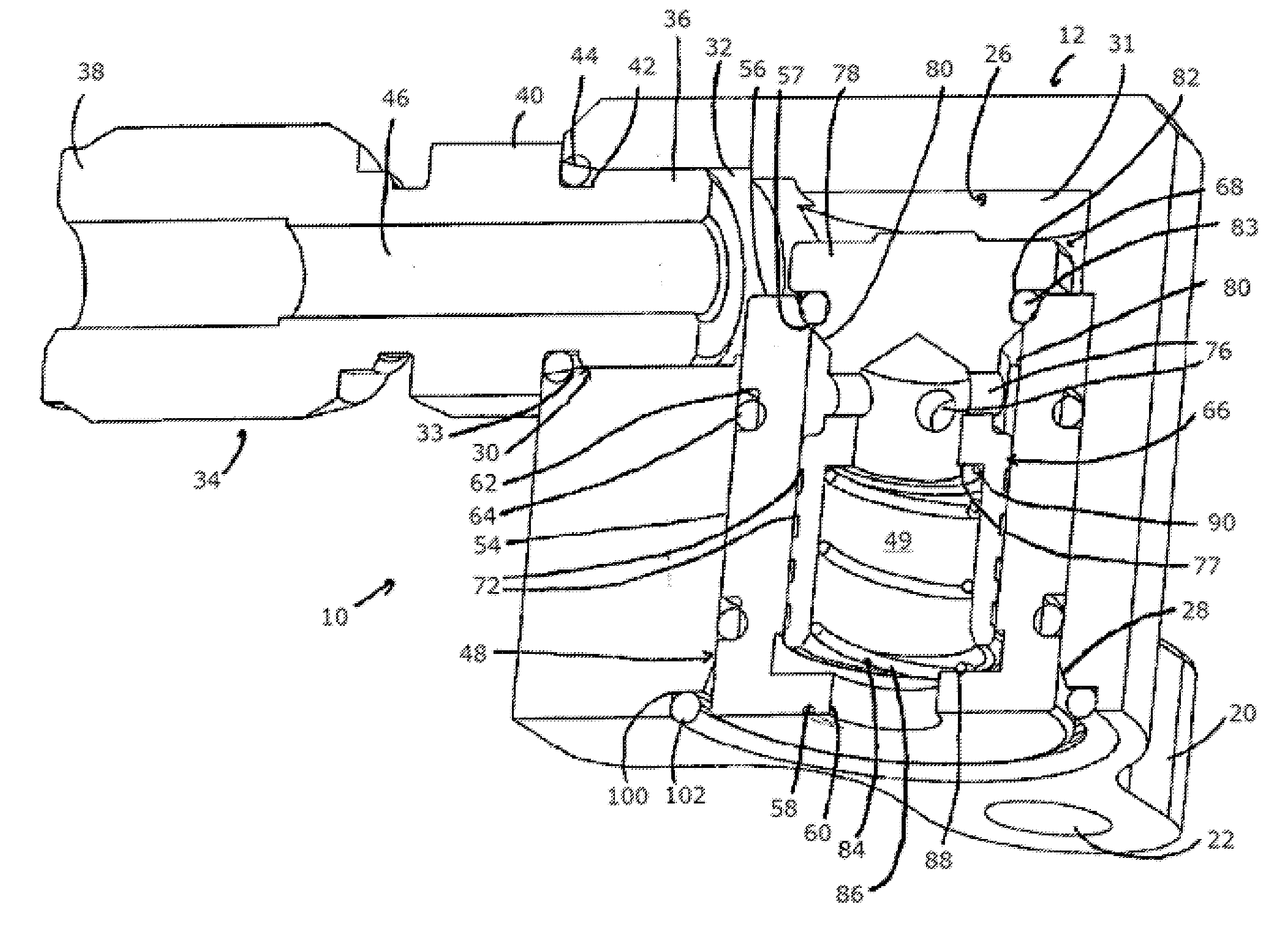

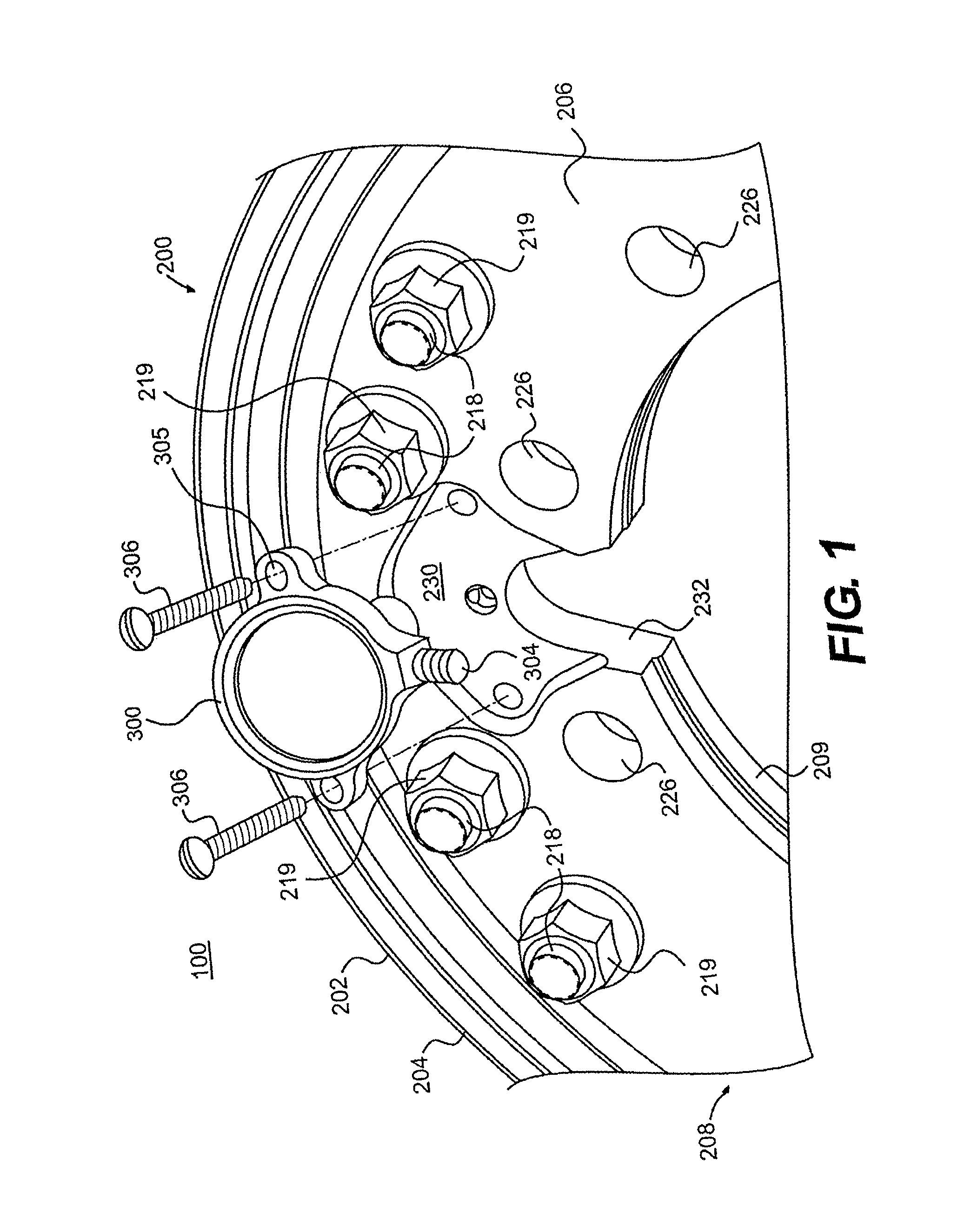

Central tire inflation system for drive axle

ActiveUS7185688B2Increase supplyEasy to installTyre measurementsTyre-inflating valvesGear wheelEngineering

A tire inflation system for a portal drive axle assembly includes fluid flow passages that are formed within rotating wheel shafts, which drive a pair of wheel end assemblies. The portal drive axle assembly includes a driving input that drives a pair of axle shafts. A wheel gear assembly operably couples each axle shaft to the respective wheel shaft. The wheel gear assemblies transfer the driving force from the axle shafts to the wheel shafts, which are positioned at different vertical location relative to the axle shafts. A first end of each wheel shaft is in fluid communication with a vehicle air supply and a second end of each wheel shaft is in fluid communication with a tire assembly. Seal assemblies are mounted for rotation with the wheel shaft at the first end of the wheel shafts. An air supply needle is mounted to a non-rotating axle structure and includes a base member that is in fluid communication with the air supply and a hollow needle body that extends from the base member through the seal assembly and into the fluid flow passage. Thus, air is selectively supplied to the tire assemblies in a sealed environment by traveling from the air supply, through the rotating wheel shafts, and into the tire assemblies.

Owner:ARVINMERITOR TECH

Active adaptation of control algorithms for a central tire inflation system

InactiveUS6758088B2Tyre measurementsPackaging under special atmospheric conditionsAir volumeLine tubing

A method for control of a tire pressure management system (or central tire inflation system) is provided which enables active adaptation of control variables in the system in response to variations in air line volume. The air line volume in a conduit between an air source and a vehicle tire is determined. Subsequently, one or more values for control variables are adjusted in response to the air line volume and various parameters associated with the system are determined in response to the adjusted values of the control variables.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

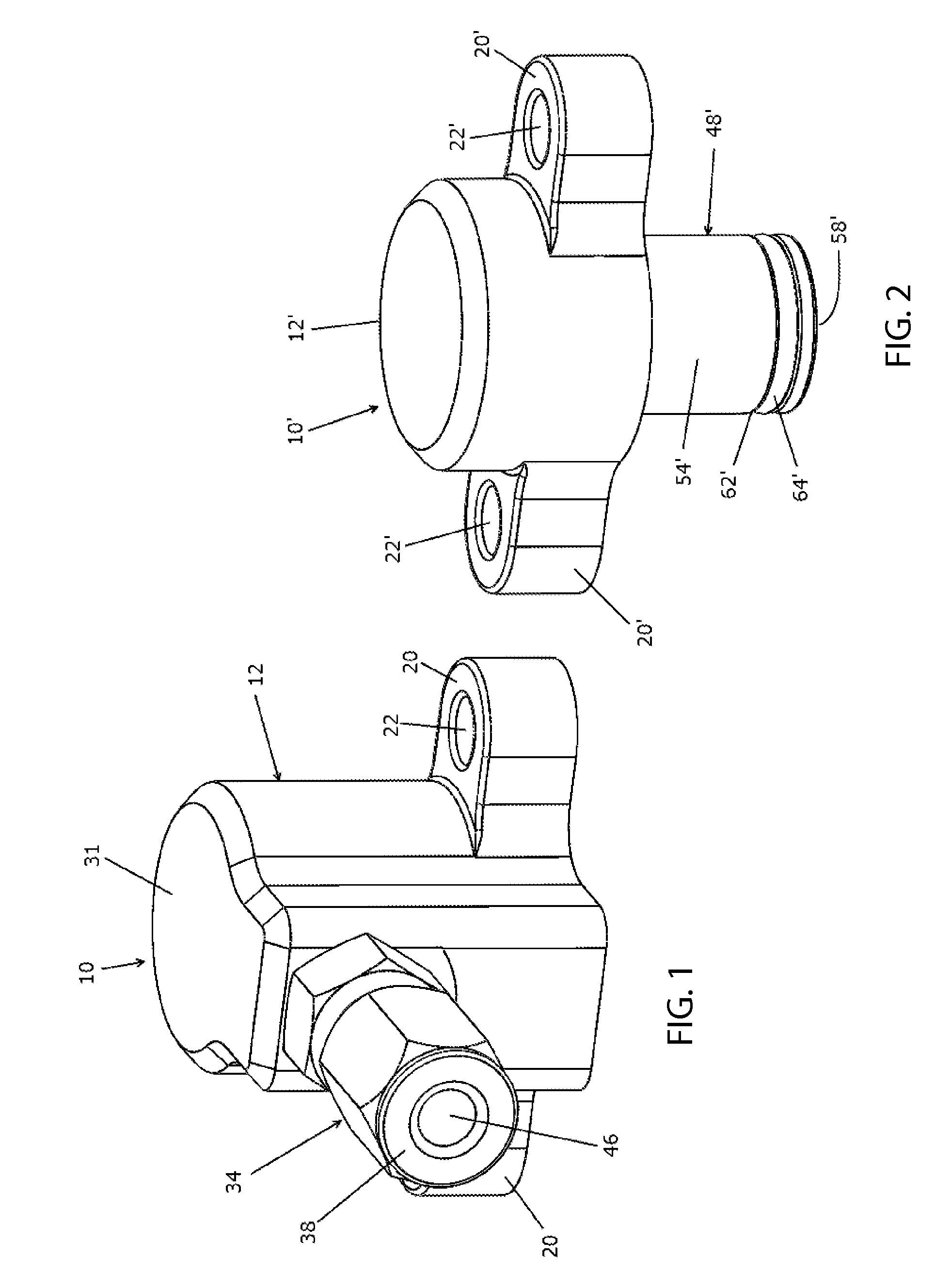

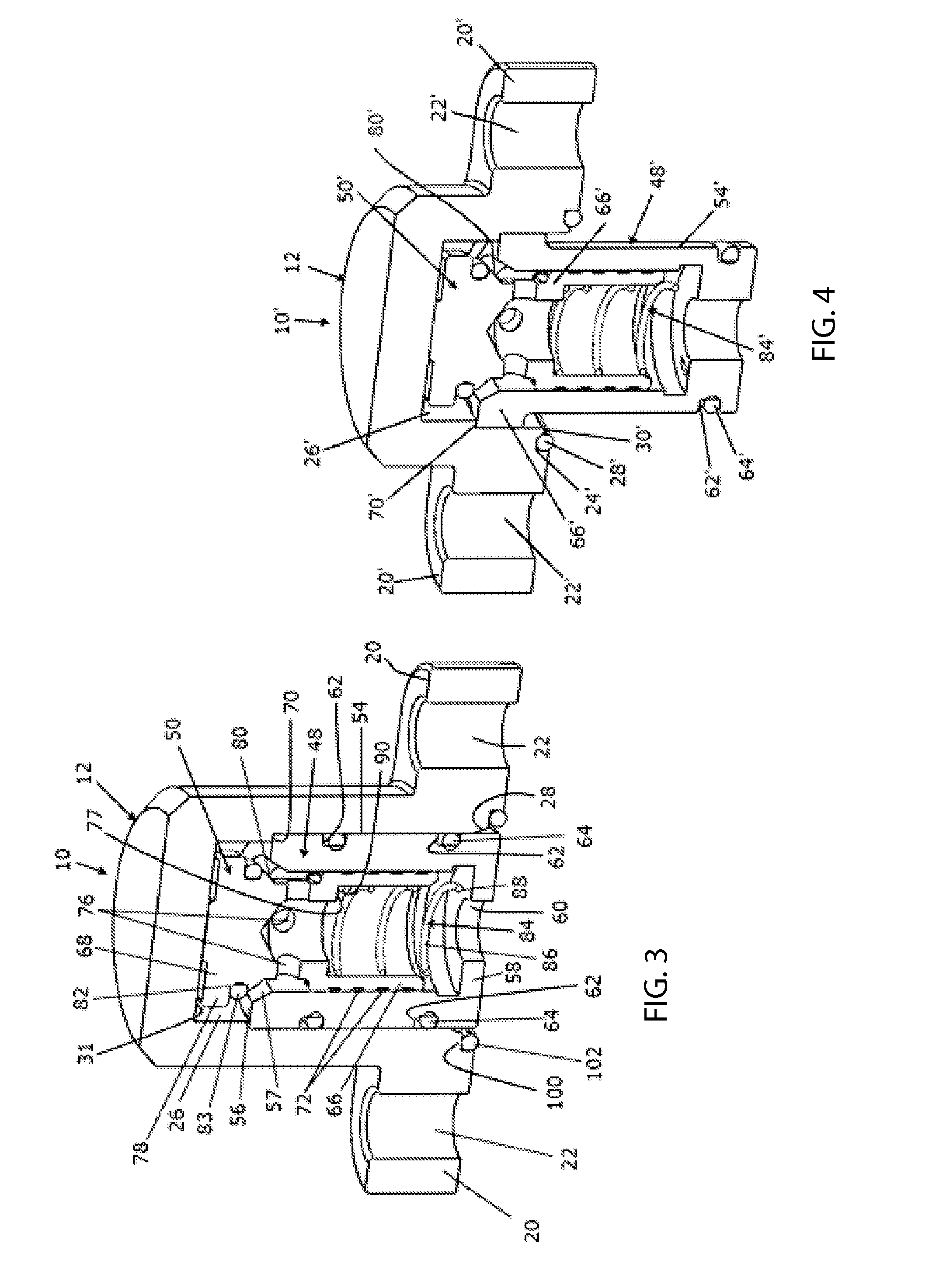

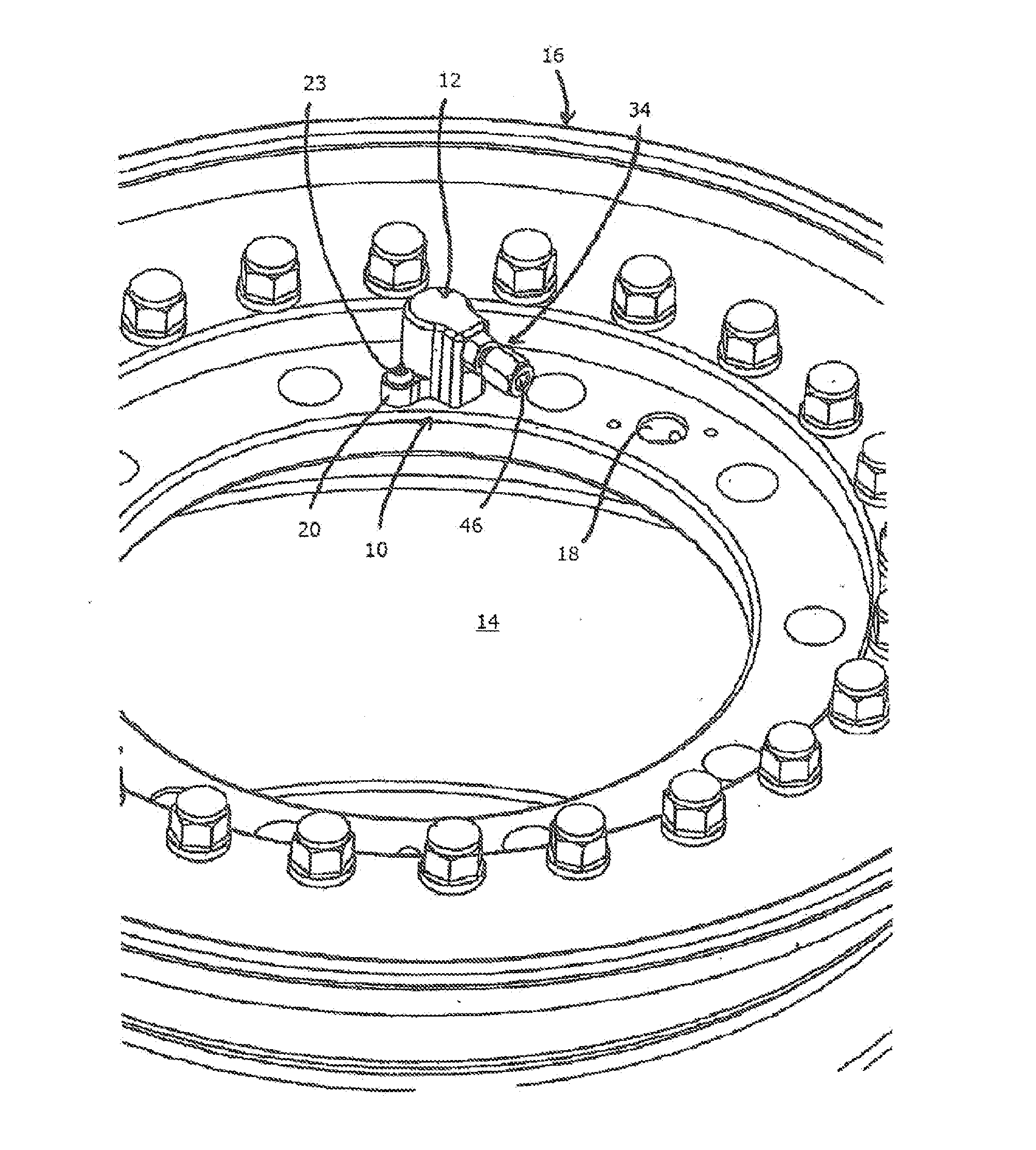

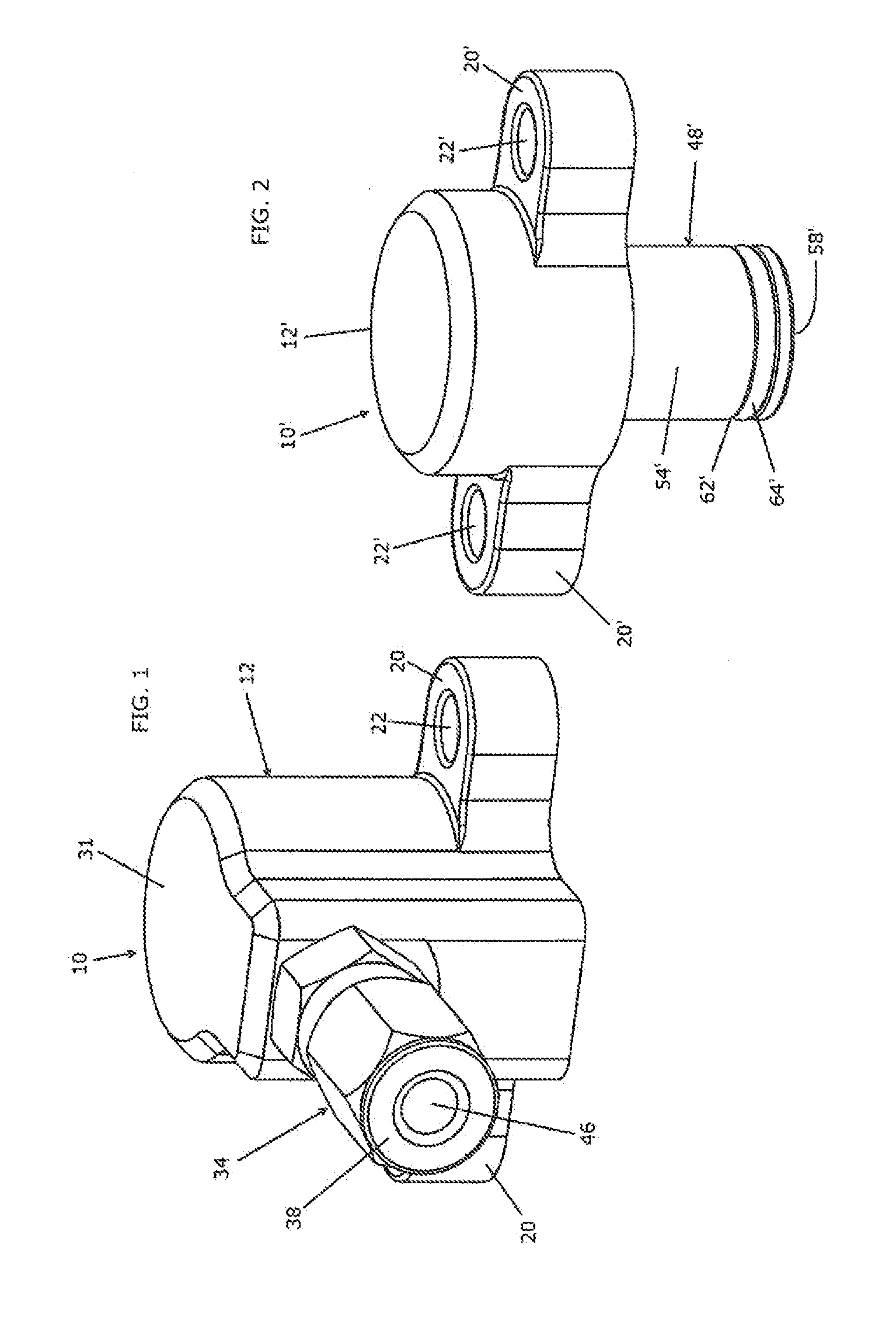

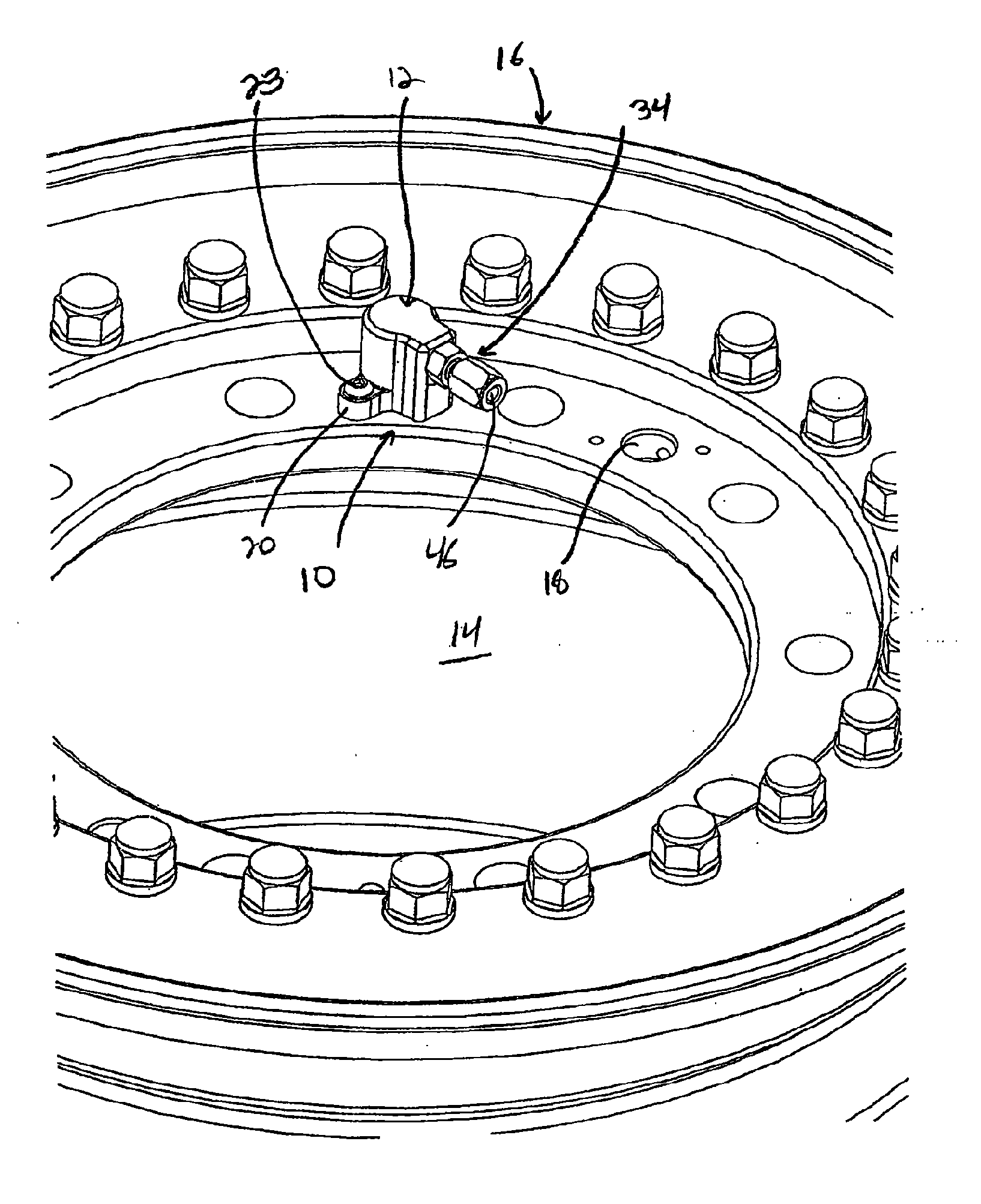

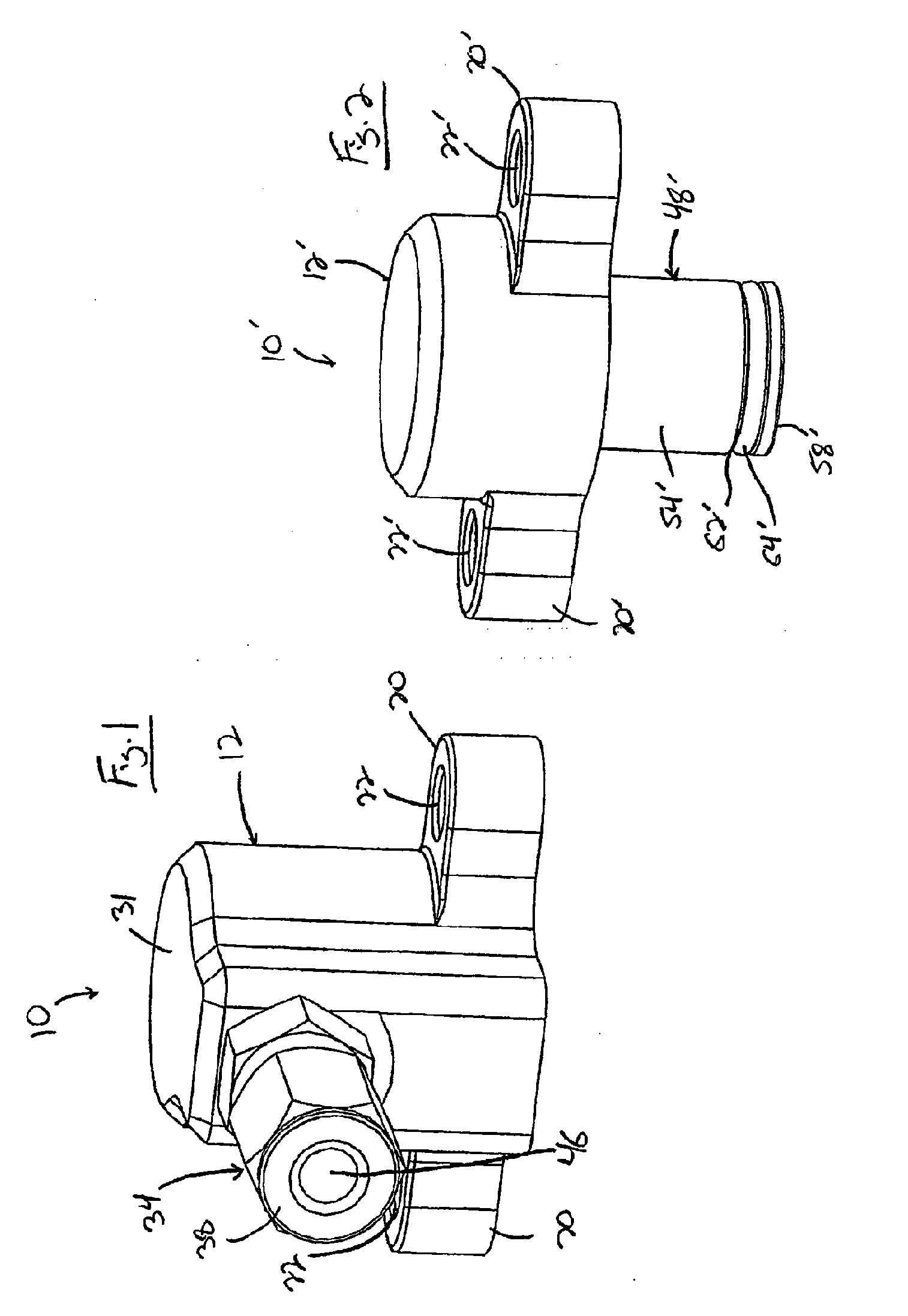

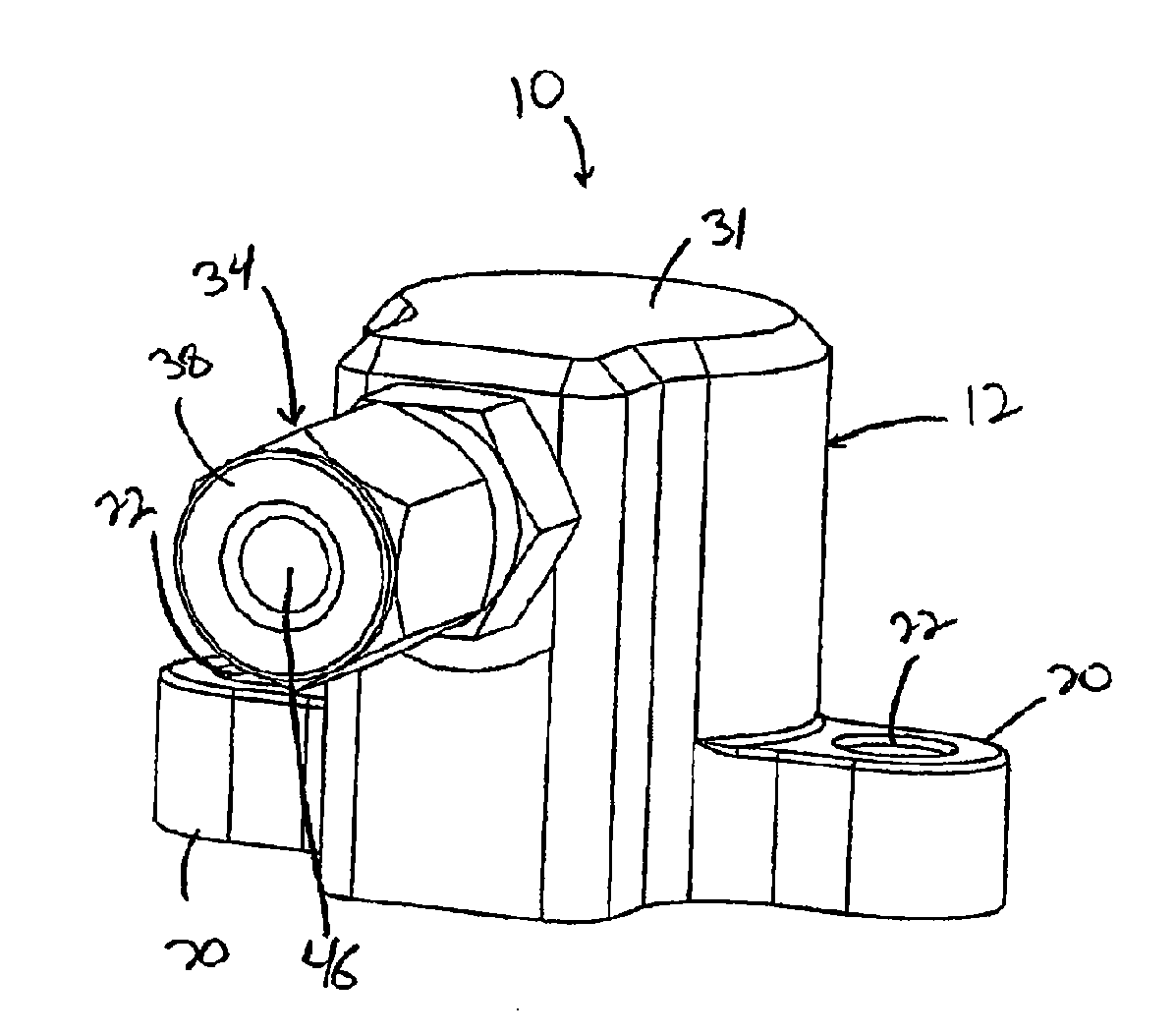

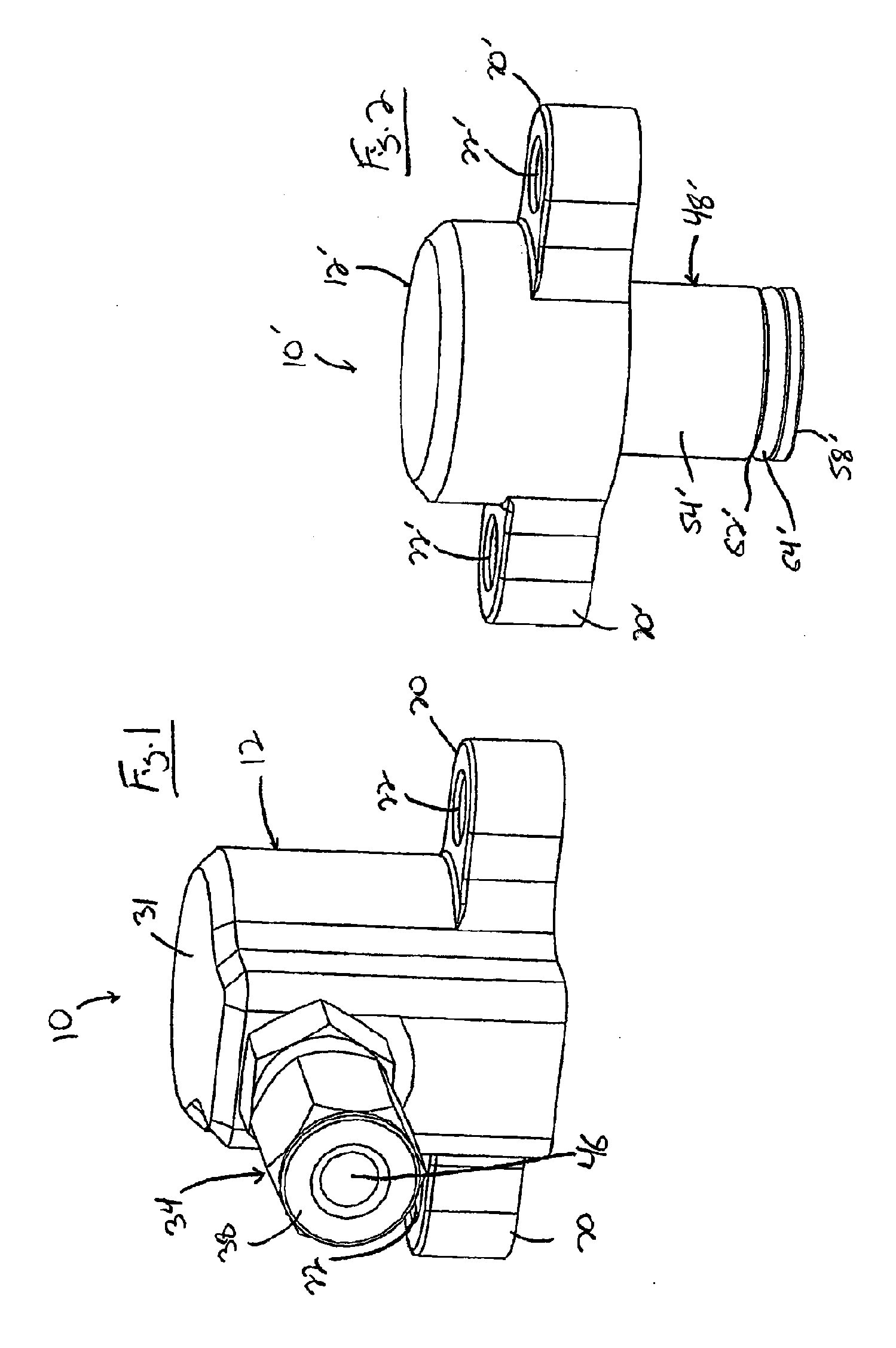

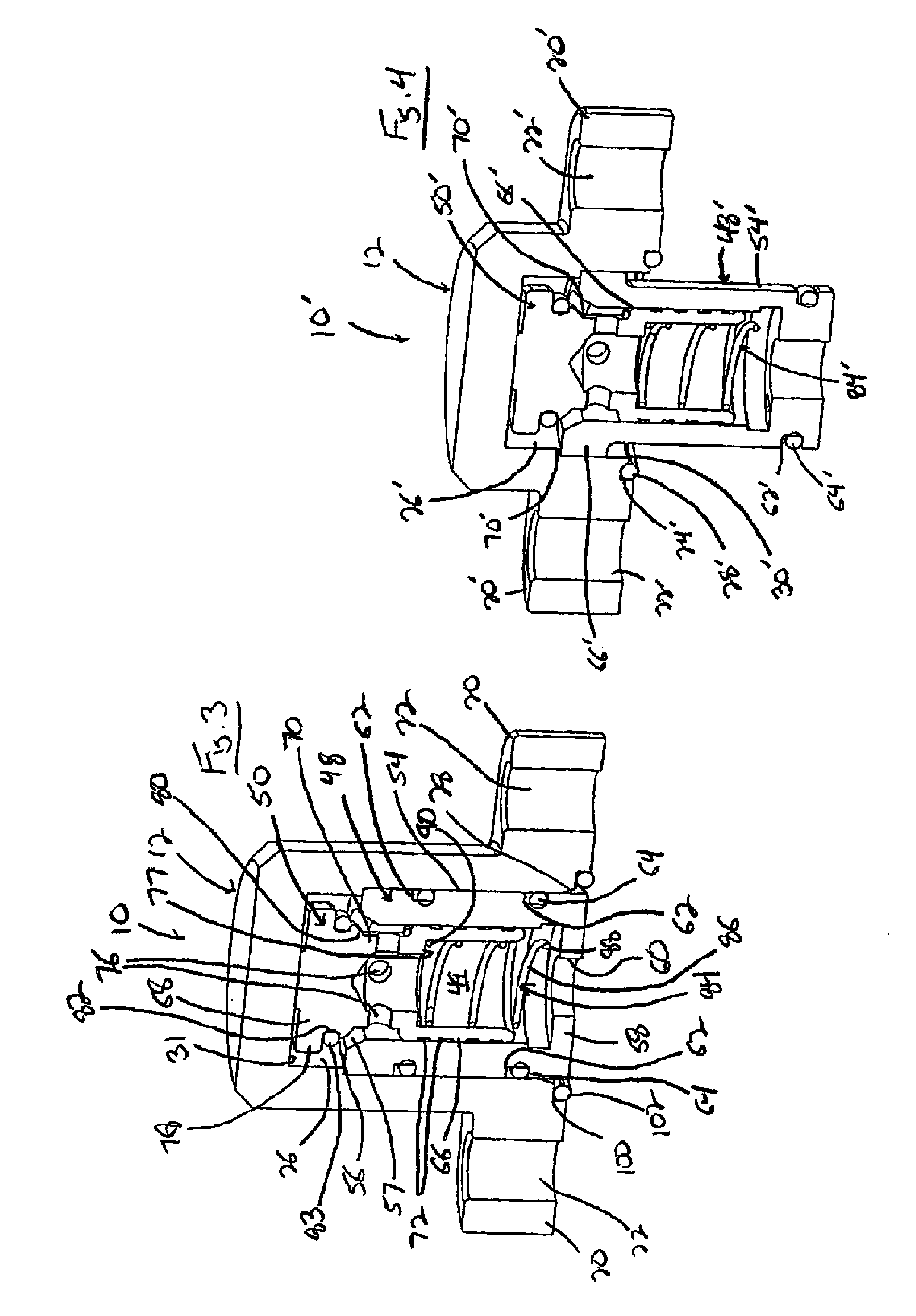

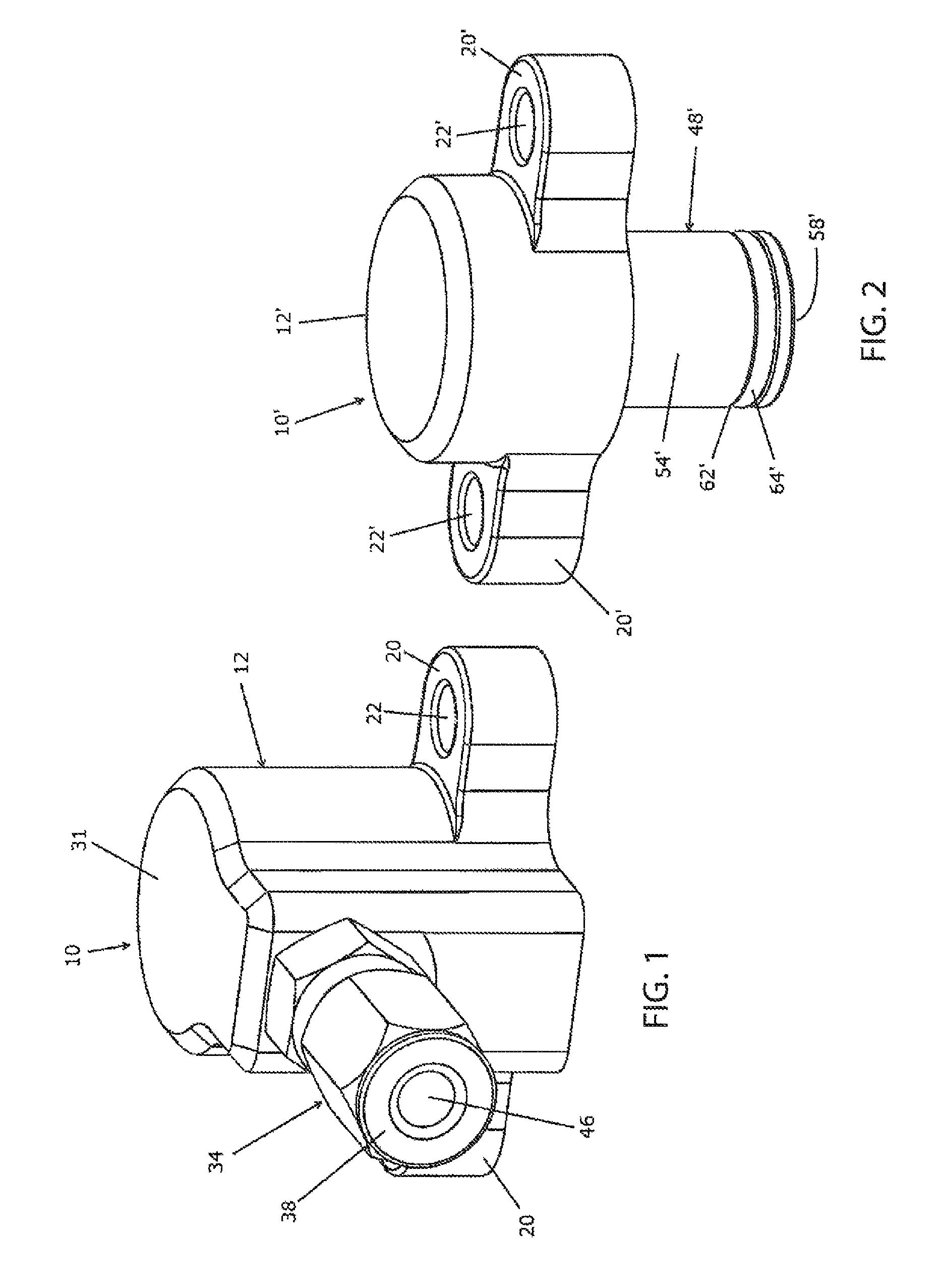

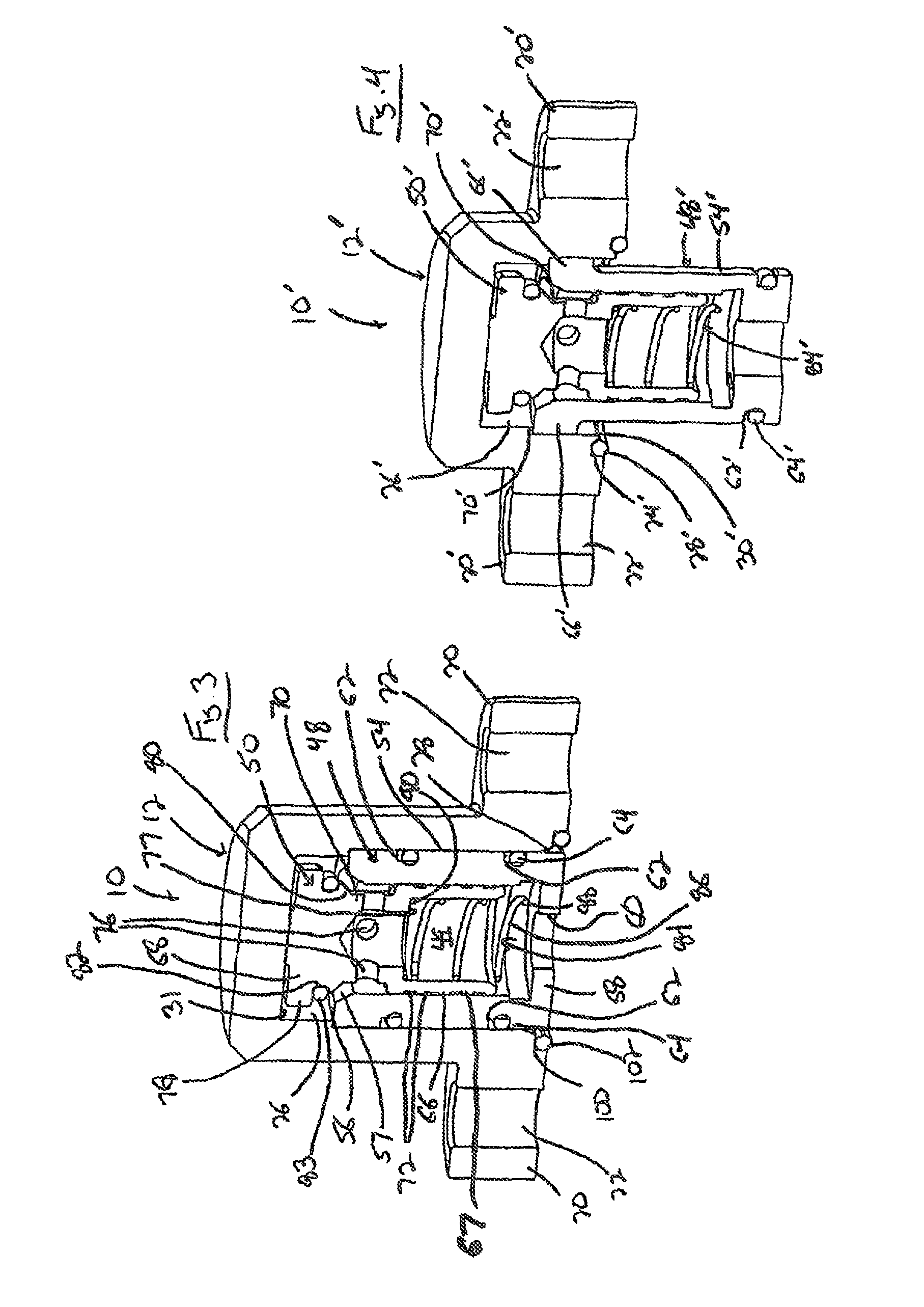

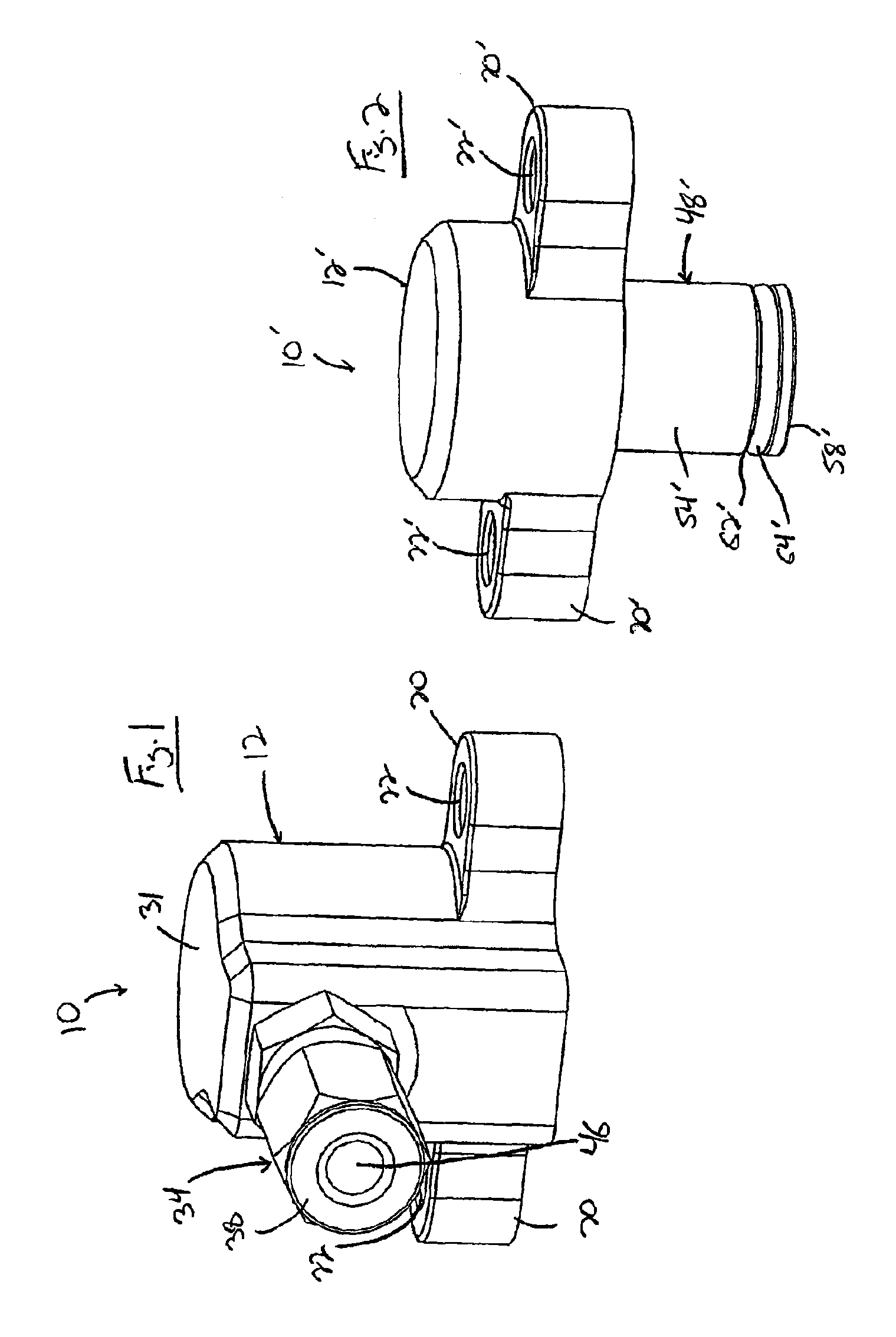

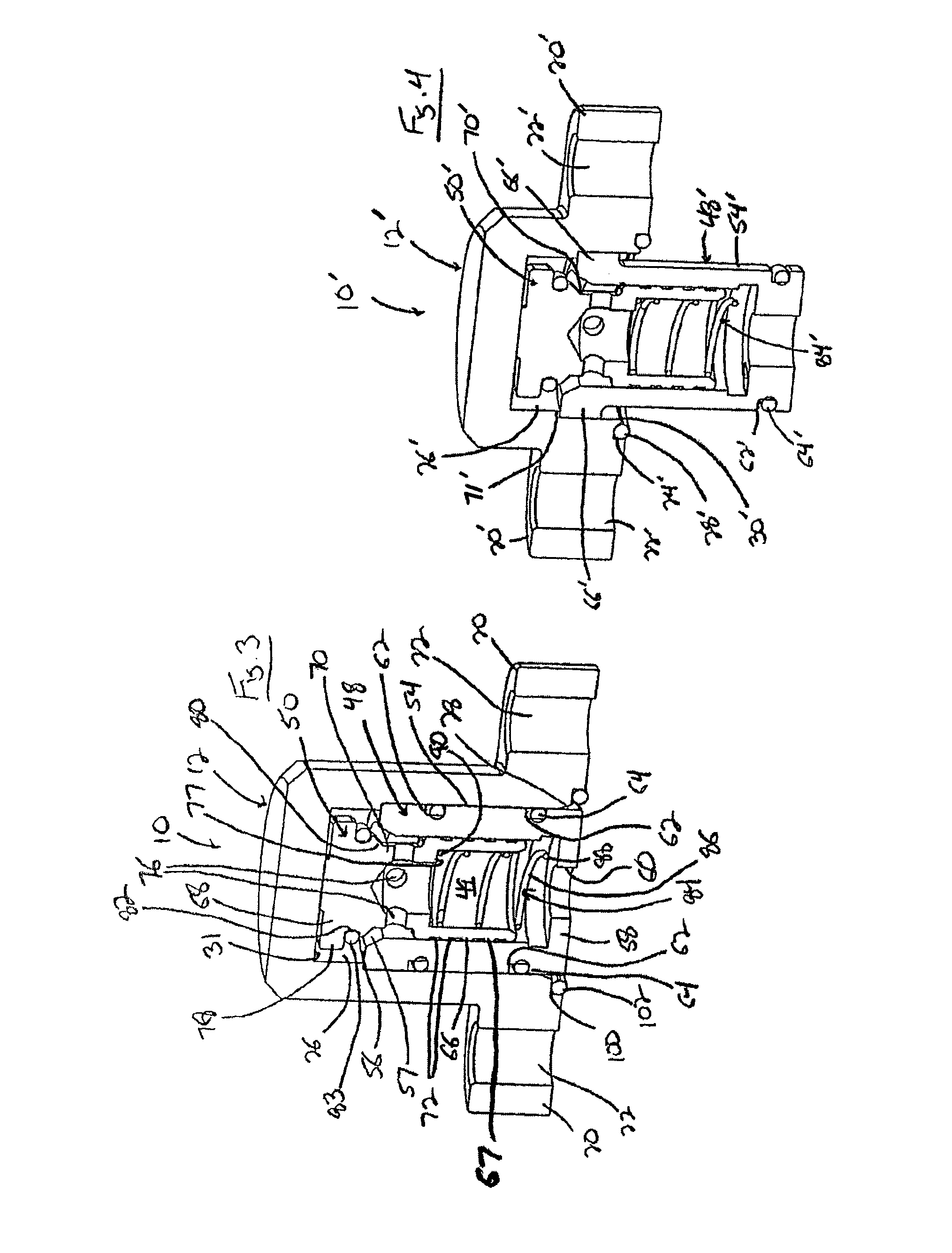

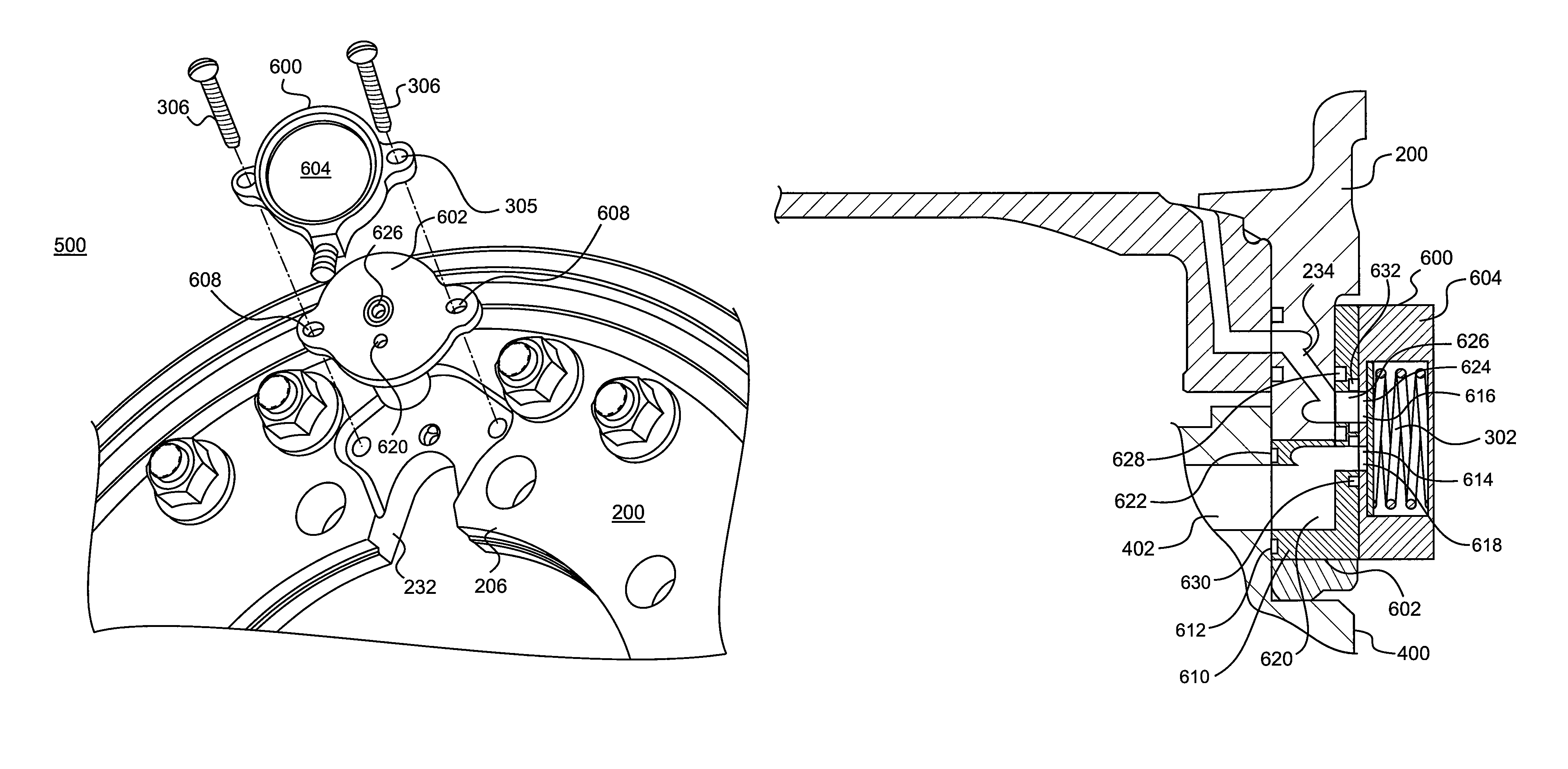

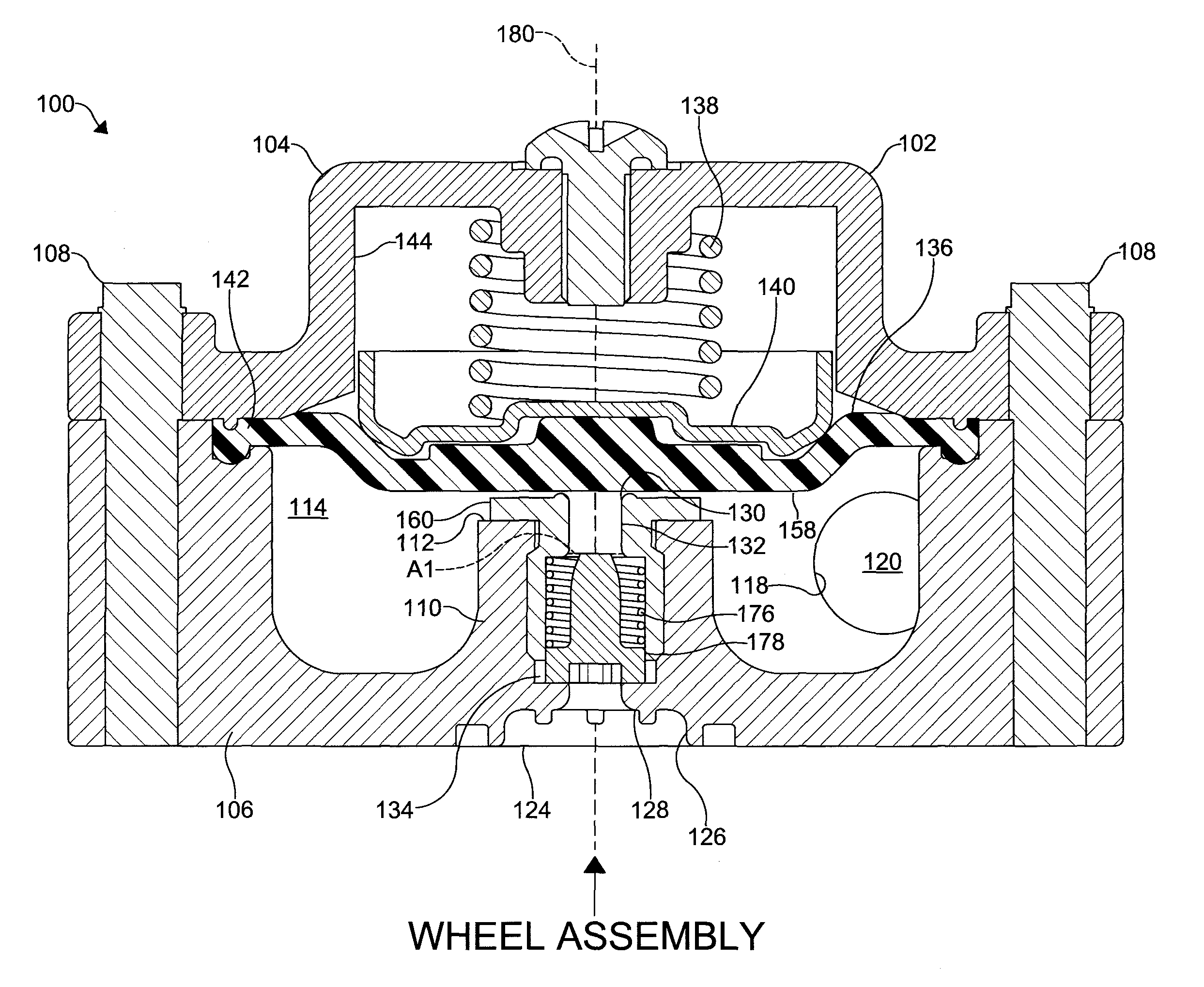

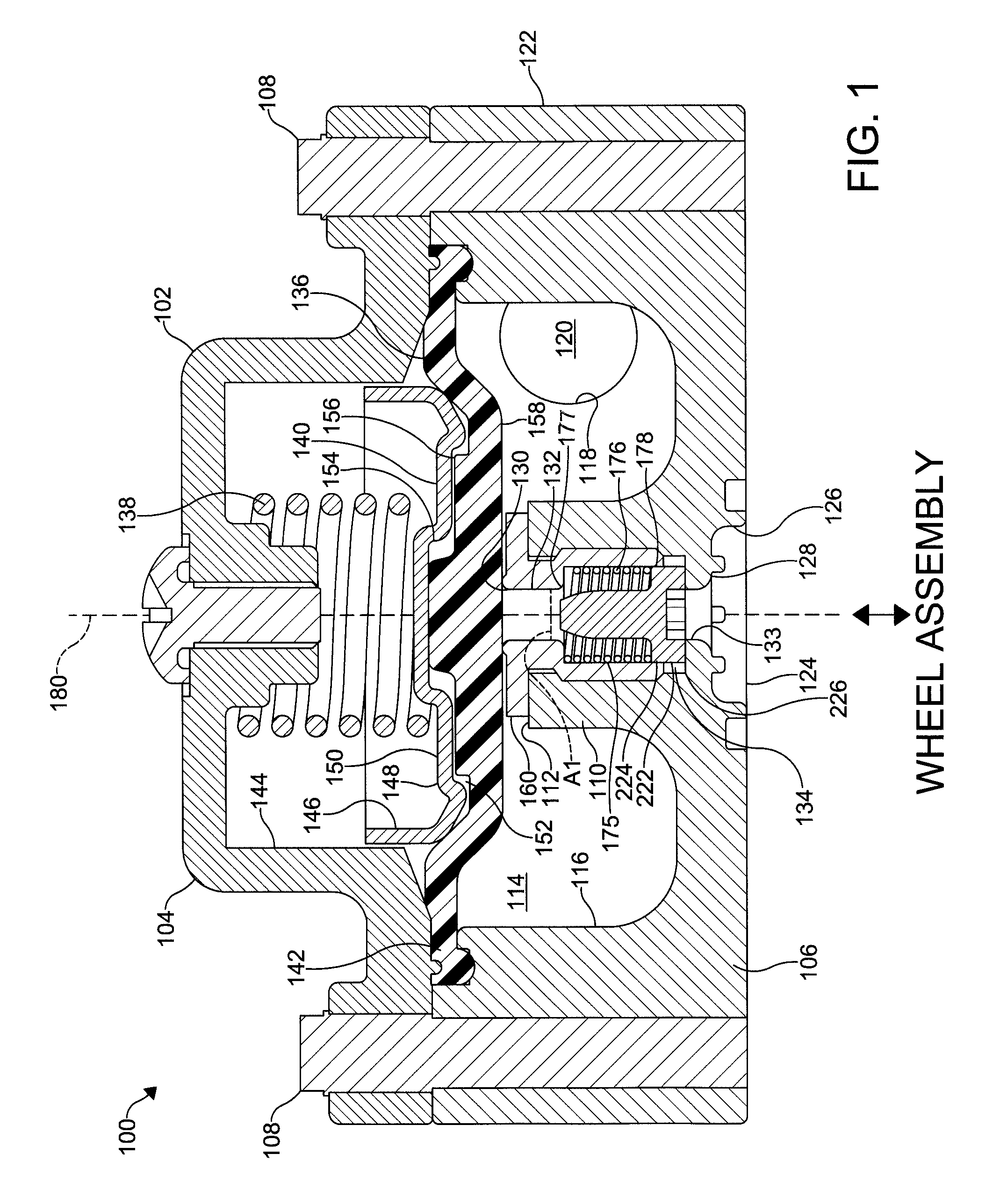

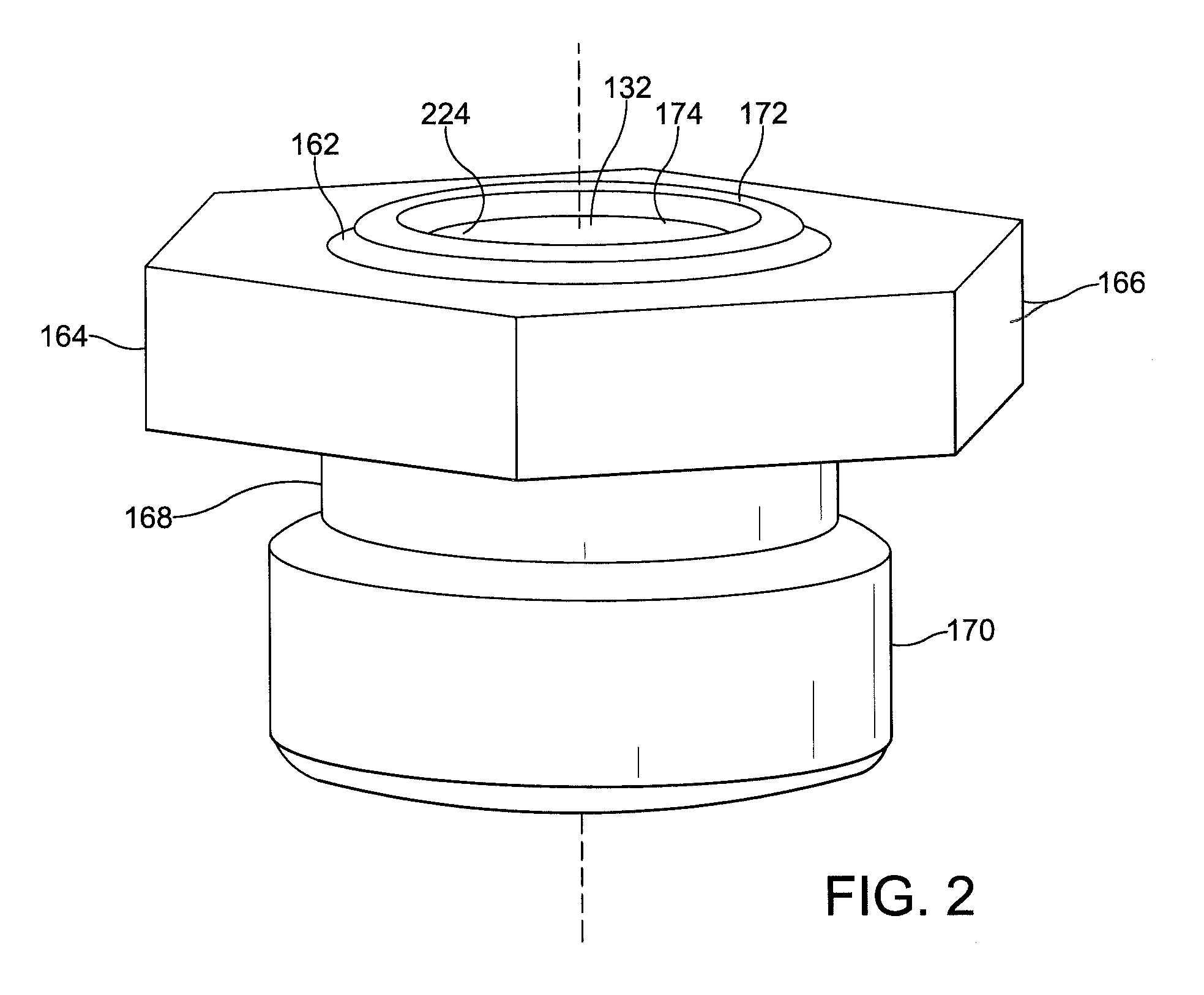

Central Tire Inflation Wheel Assembly and Valve

InactiveUS20130276902A1Easy constructionExtend your lifeCheck valvesPipeline systemsEngineeringCentral tire inflation system

The present invention is a central tire inflation system and a valve for use in the system including a casing securable to the rim of a vehicle in communication with the tire that houses a main body connectable to a pressurized fluid supply of the central tire inflation system, and a valve member moveable within the main body to control the flow of air through the valve. The valve can be mounted flush on the exterior surface of the rim or in a recessed position within the rim, and can be connected to a manifold that is able to control the flow of pressurized fluid from the central tire inflation system to each valve and tire connected to the valve. The operation of the manifold and pressurized fluid supply can be controlled utilizing a controller operably connected to the manifold and fluid supply.

Owner:MEDLEY MARTIN A +1

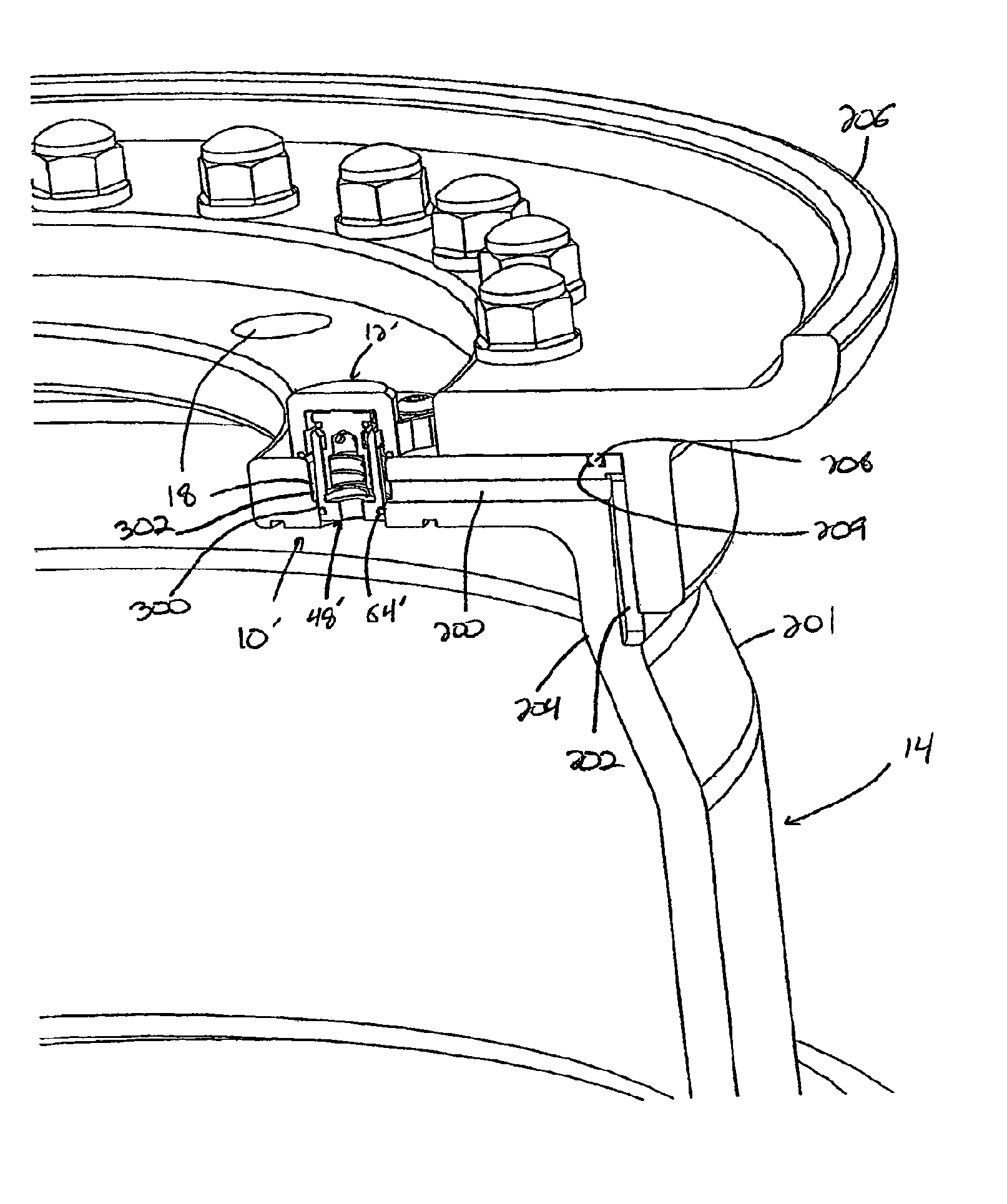

Central Tire Inflation Wheel Assembly, Valve and Central Tire Inflation System

InactiveUS20130282232A1Easy constructionExtend your lifeVehicle testingRegistering/indicating working of vehiclesCentral tire inflation systemFluid supply

The present invention is a valve for use in a central tire inflation system including a casing securable to the rim of a vehicle in communication with the tire that houses a main body connectable to a pressurized fluid supply of the central tire inflation system, and a valve member moveable within the main body to control the flow of air through the valve. The valve can be mounted flush on the exterior surface of the rim or in a recessed position within the rim, and can be connected to a manifold that is able to control the flow of pressurized fluid from the central tire inflation system to each valve and tire connected to the valve. The operation of the manifold and pressurized fluid supply can be controlled utilizing a controller operably connected to the manifold and fluid supply, and to sensing devices in the valve that supply information regarding the operational conditions of the vehicle to the controller to assist in adjusting the inflation of the tires as necessary.

Owner:MEDLEY MARTIN A +1

Central Tire Inflation Wheel Assembly, Valve and Central Tire Inflation System

ActiveUS20110175716A1Easy constructionExtend your lifeTyre measurementsThin material handlingCentral tire inflation systemOperant conditioning

The present invention is a valve for use in a central tire inflation system including a casing securable to the rim of a vehicle in communication with the tire that houses a main body connectable to a pressurized fluid supply of the central tire inflation system, and a valve member moveable within the main body to control the flow of air through the valve. The valve can be mounted flush on the exterior surface of the rim or in a recessed position within the rim, and can be connected to a manifold that is able to control the flow of pressurized fluid from the central tire inflation system to each valve and tire connected to the valve. The operation of the manifold and pressurized fluid supply can be controlled utilizing a controller operably connected to the manifold and fluid supply, and to sensing devices that supply information regarding the operational conditions of the vehicle to the controller to assist in adjusting the inflation of the tires as necessary.

Owner:GLOBAL ENG MARKETING

Central Tire Inflation Wheel Assembly and Valve

ActiveUS20100147387A1Easy constructionExtend your lifeCheck valvesPipeline systemsEngineeringCentral tire inflation system

The present invention is a valve for use in a central tire inflation system including a casing securable to the rim of a vehicle in communication with the tire that houses a main body connectable to a pressurized fluid supply of the central tire inflation system, and a valve member moveable within the main body to control the flow of air through the valve. The valve can be mounted flush on the exterior surface of the rim or in a recessed position within the rim, and can be connected to a manifold that is able to control the flow of pressurized fluid from the central tire inflation system to each valve and tire connected to the valve. The operation of the manifold and pressurized fluid supply can be controlled utilizing a controller operably connected to the manifold and fluid supply.

Owner:GLOBAL ENG MARKETING

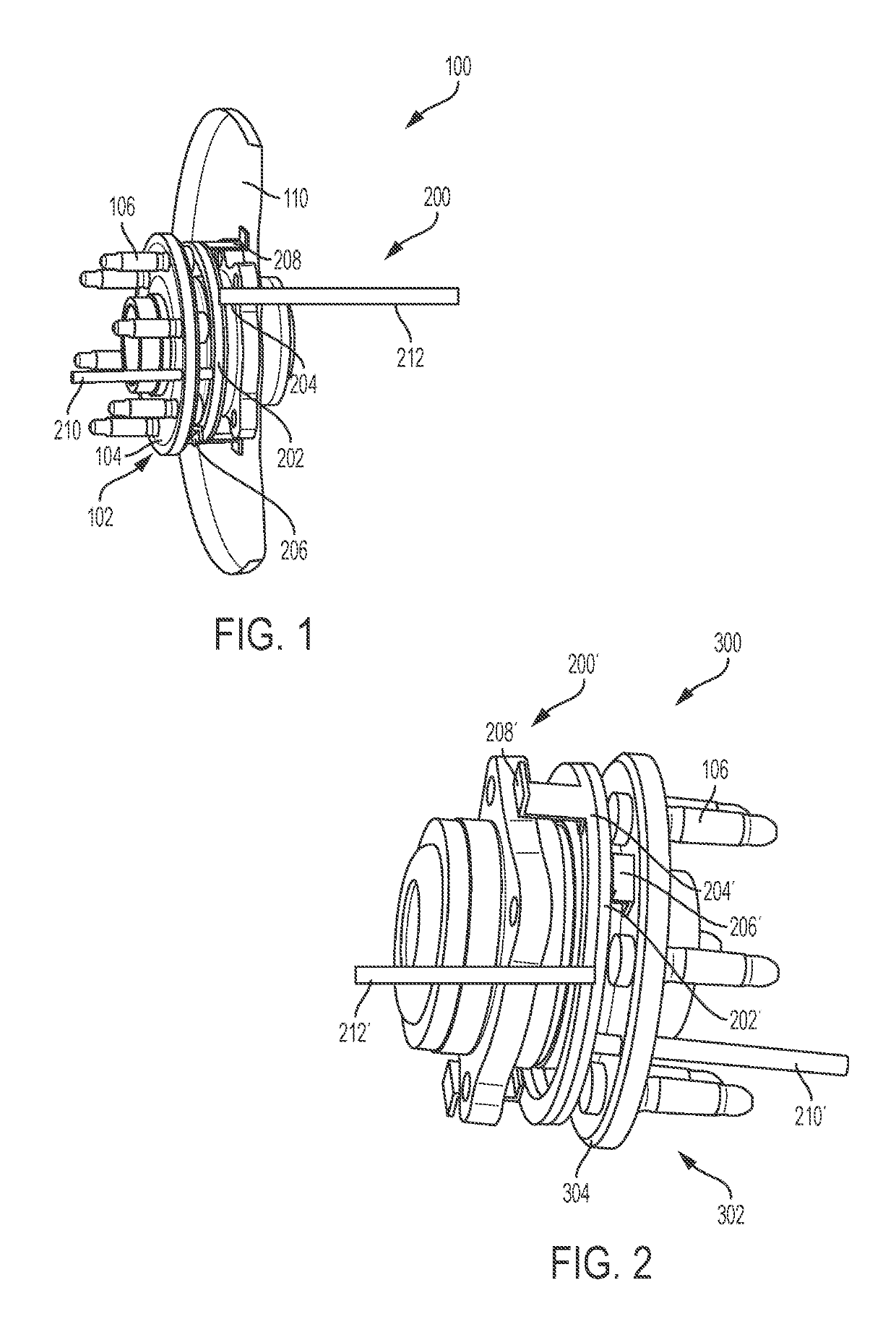

Central tire inflation wheel assembly, valve and central tire inflation system

ActiveUS8844596B2Easy constructionExtend your lifeCheck valvesTyre measurementsCentral tire inflation systemFluid supply

The present invention is a valve for use in a central tire inflation system including a casing securable to the rim of a vehicle in communication with the tire that houses a main body connectable to a pressurized fluid supply of the central tire inflation system, and a valve member moveable within the main body to control the flow of air through the valve. The valve can be mounted flush on the exterior surface of the rim or in a recessed position within the rim, and can be connected to a manifold that is able to control the flow of pressurized fluid from the central tire inflation system to each valve and tire connected to the valve. The operation of the manifold and pressurized fluid supply can be controlled utilizing a controller operably connected to the manifold and fluid supply, and to sensing devices that supply information regarding the operational conditions of the vehicle to the controller to assist in adjusting the inflation of the tires as necessary.

Owner:GLOBAL ENG MARKETING

Central tire inflation wheel assembly and valve

ActiveUS8307868B2Easy constructionExtend your lifeCheck valvesPipeline systemsEngineeringCentral tire inflation system

The present invention is a valve for use in a central tire inflation system including a casing securable to the rim of a vehicle in communication with the tire that houses a main body connectable to a pressurized fluid supply of the central tire inflation system, and a valve member moveable within the main body to control the flow of air through the valve. The valve can be mounted flush on the exterior surface of the rim or in a recessed position within the rim, and can be connected to a manifold that is able to control the flow of pressurized fluid from the central tire inflation system to each valve and tire connected to the valve. The operation of the manifold and pressurized fluid supply can be controlled utilizing a controller operably connected to the manifold and fluid supply.

Owner:GLOBAL ENG MARKETING

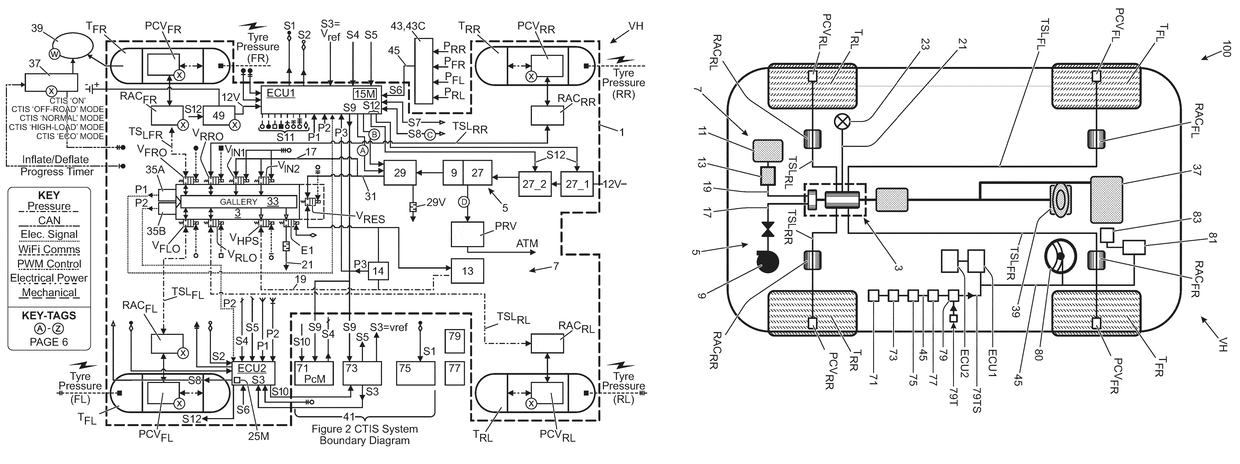

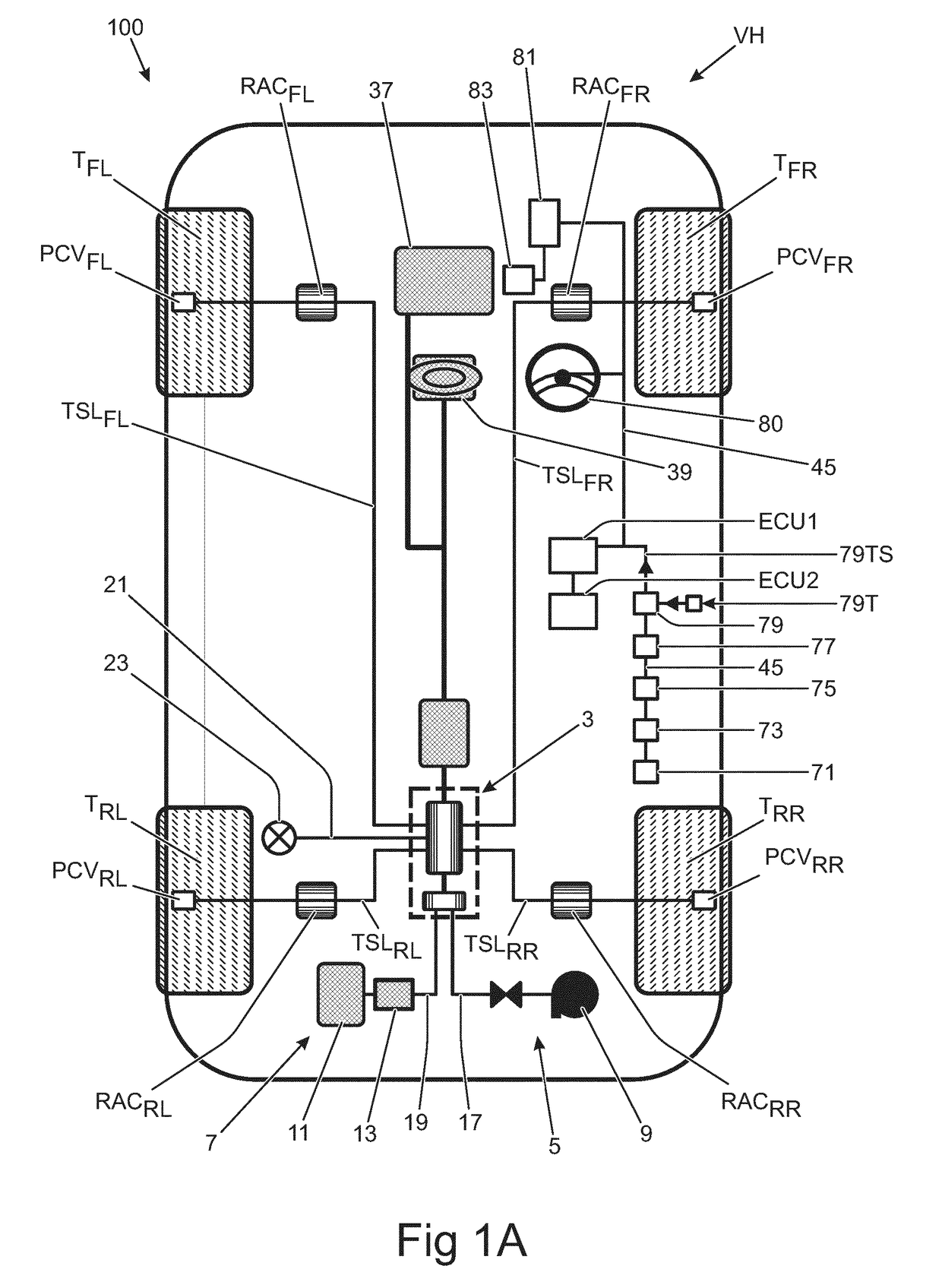

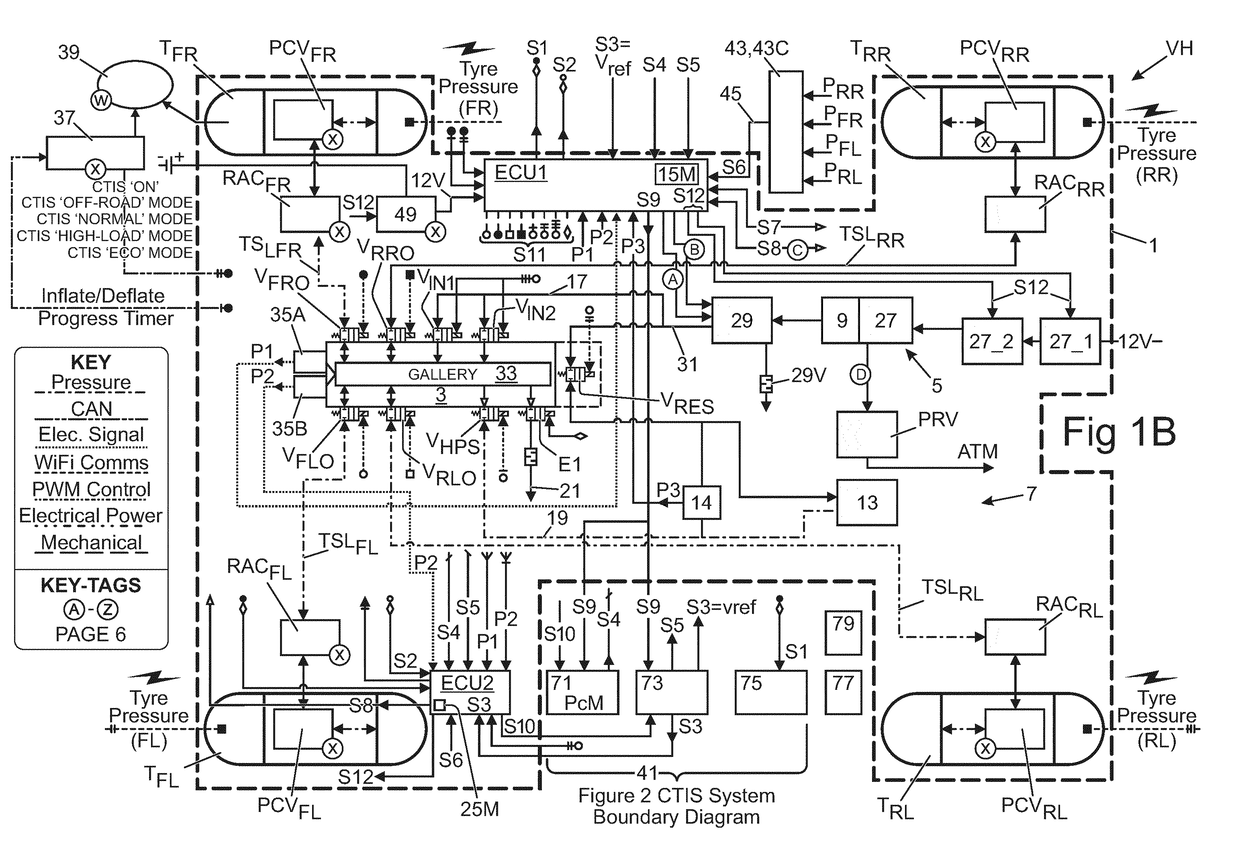

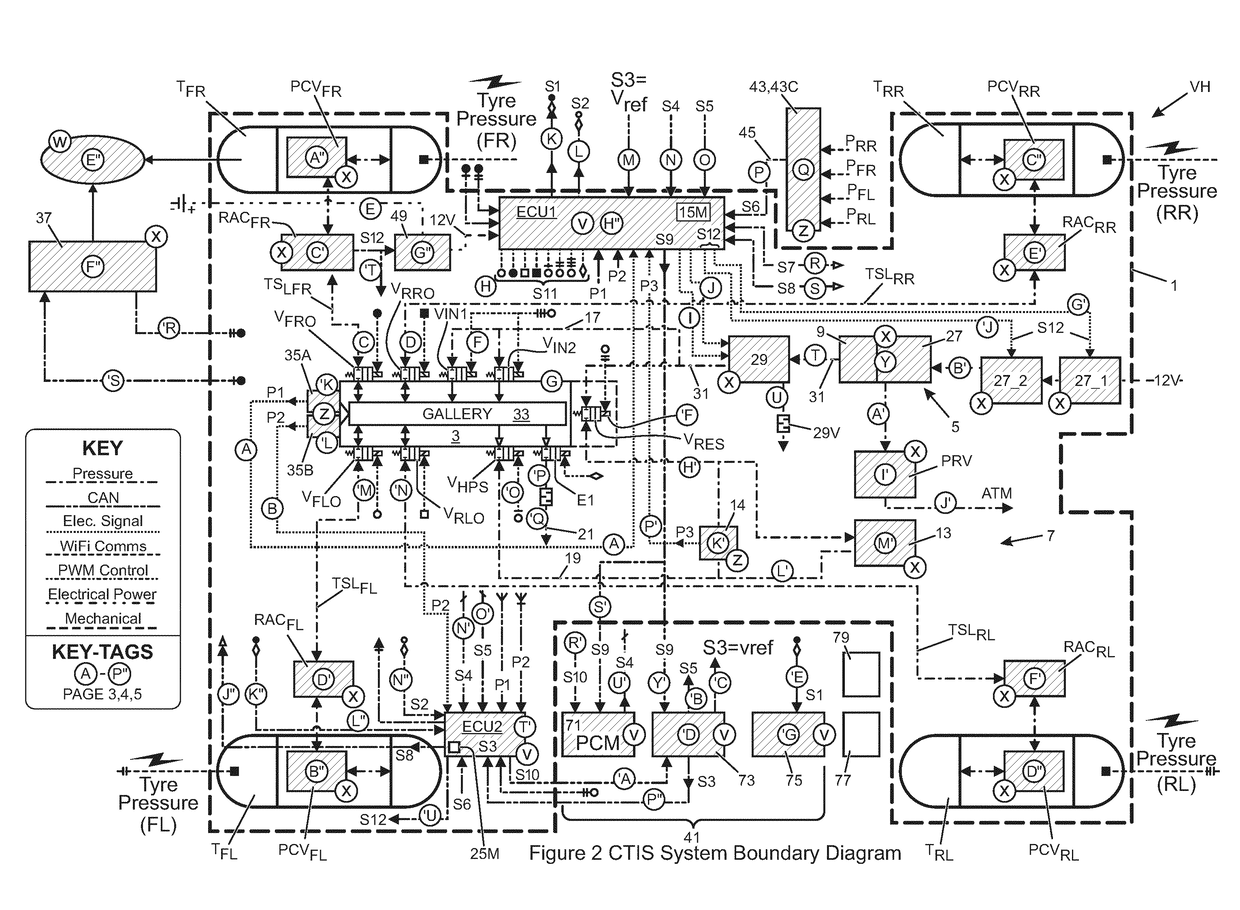

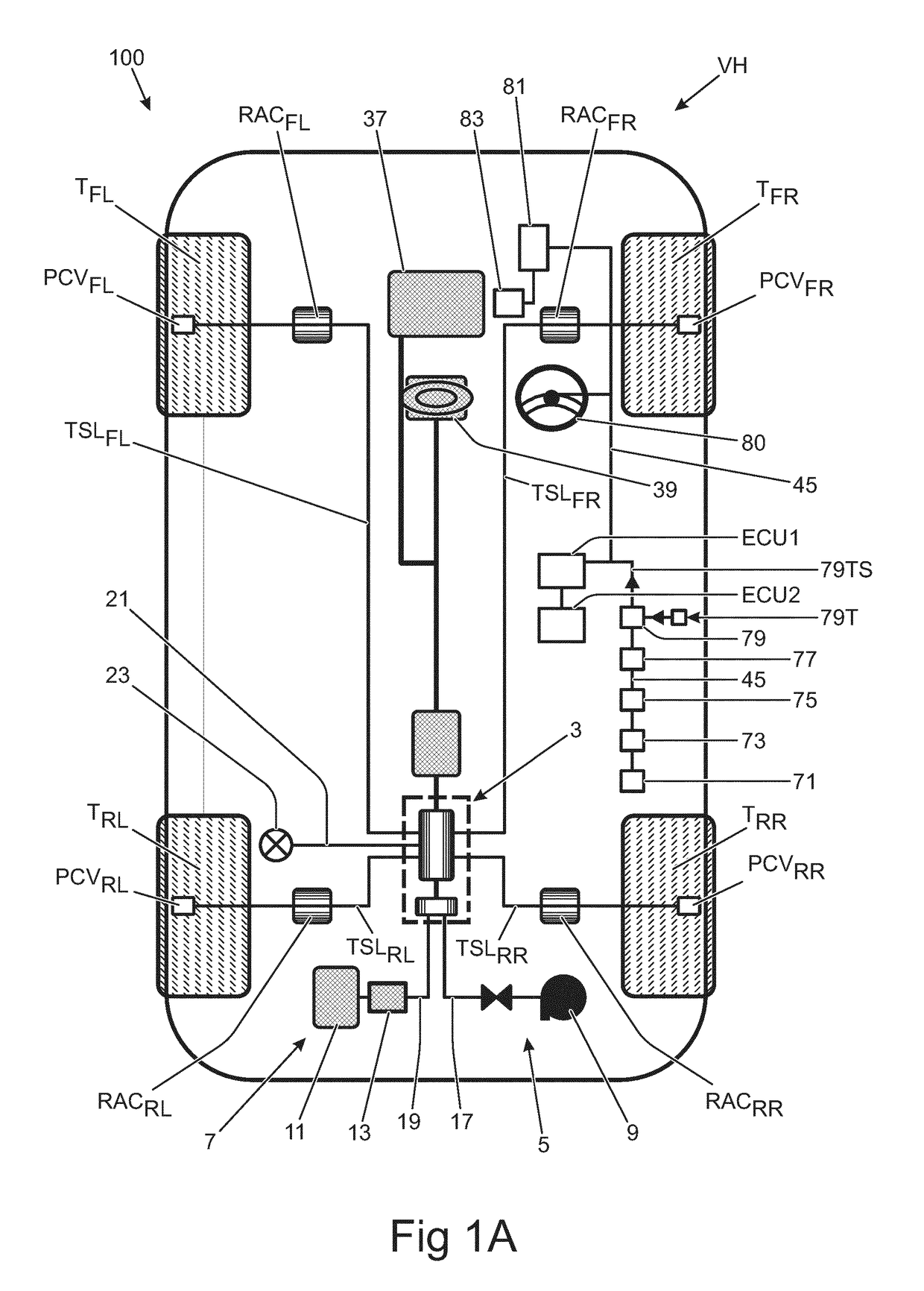

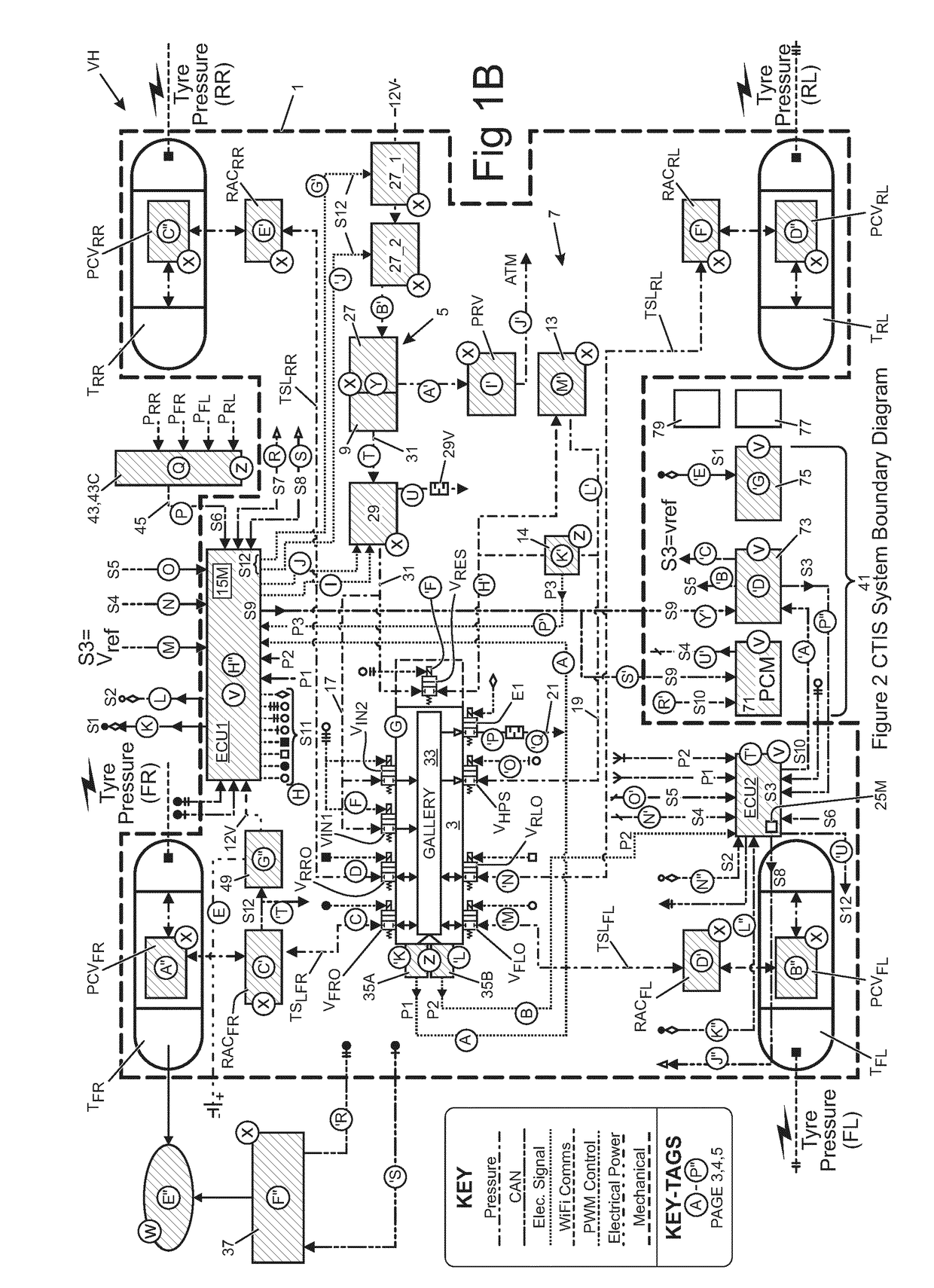

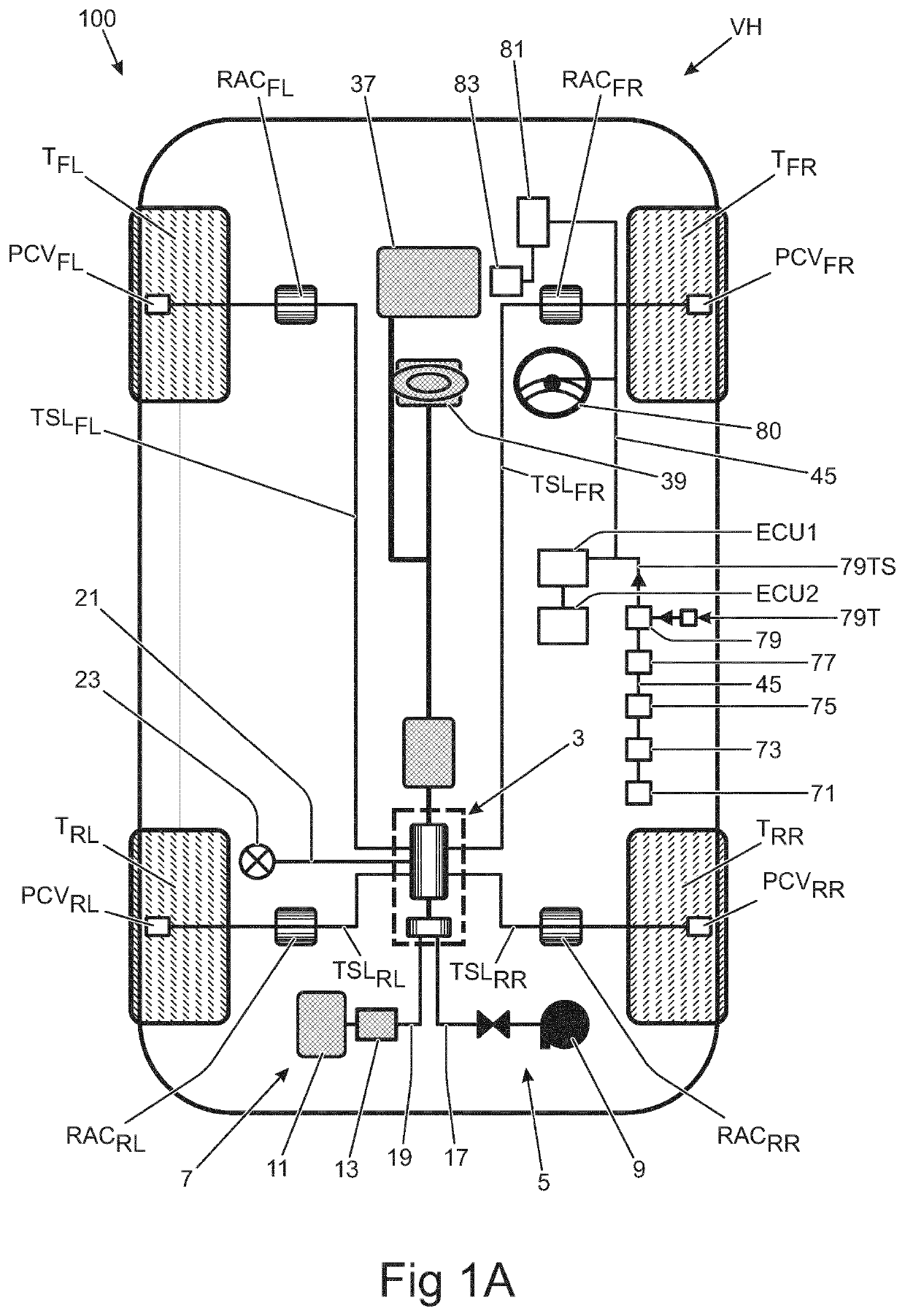

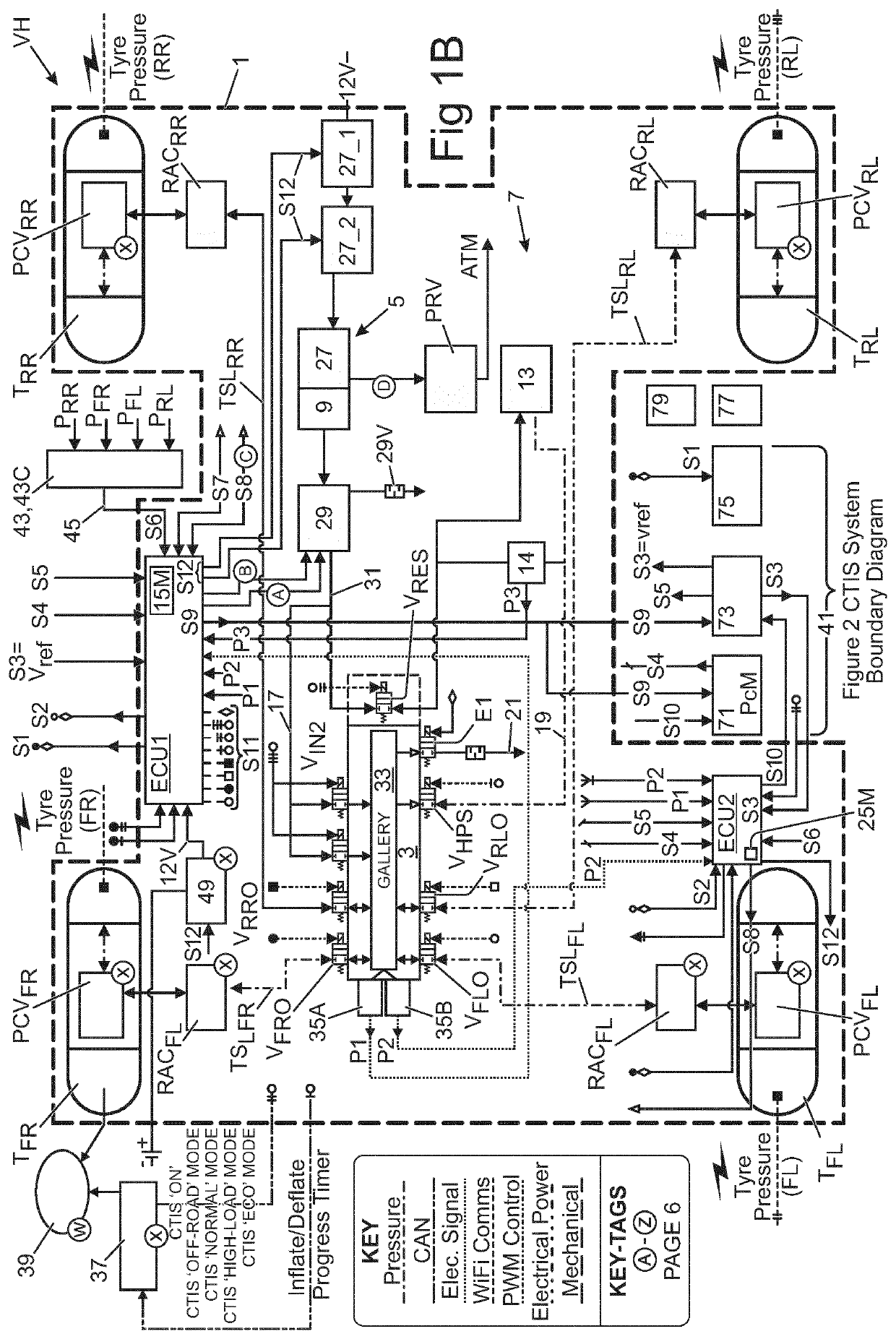

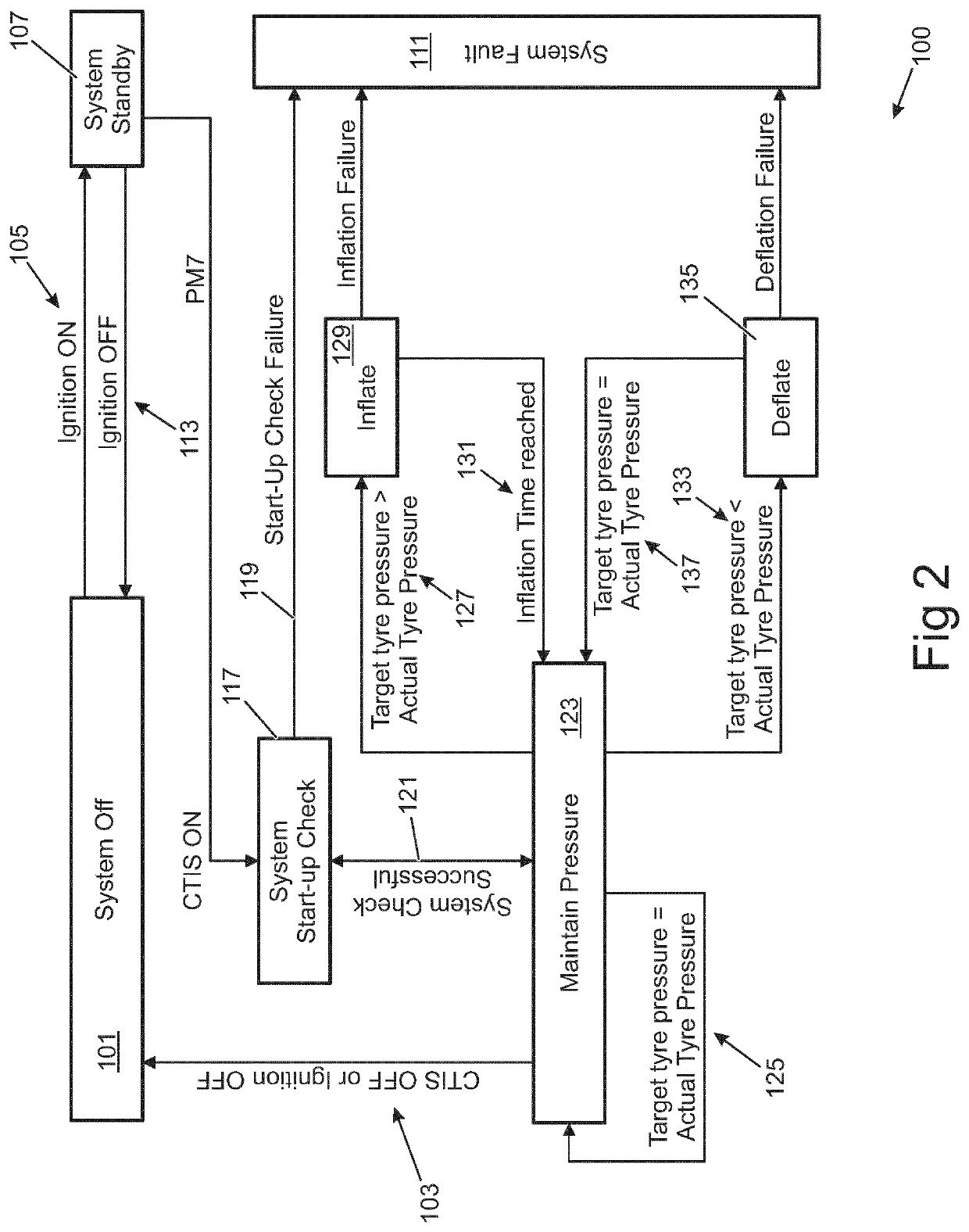

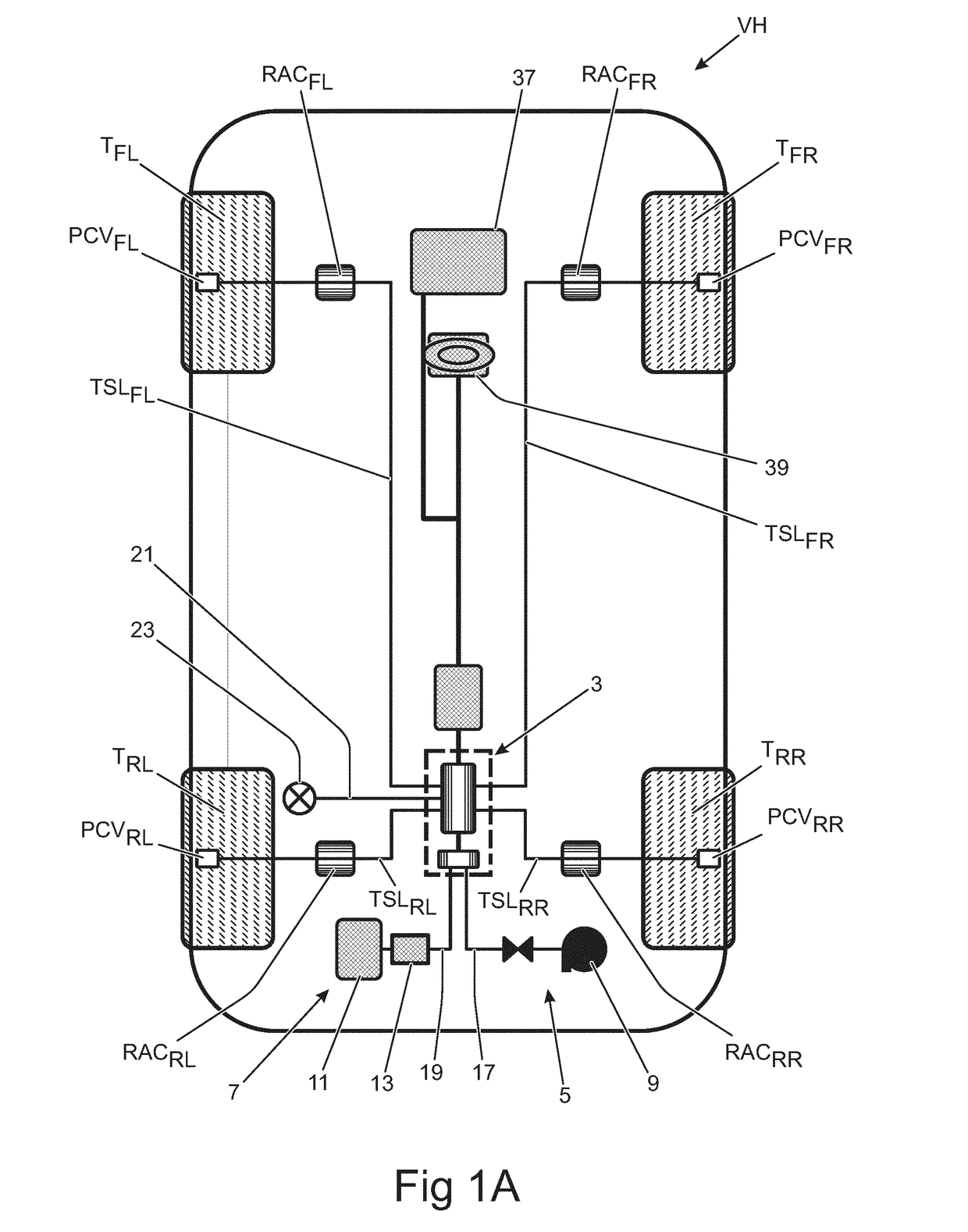

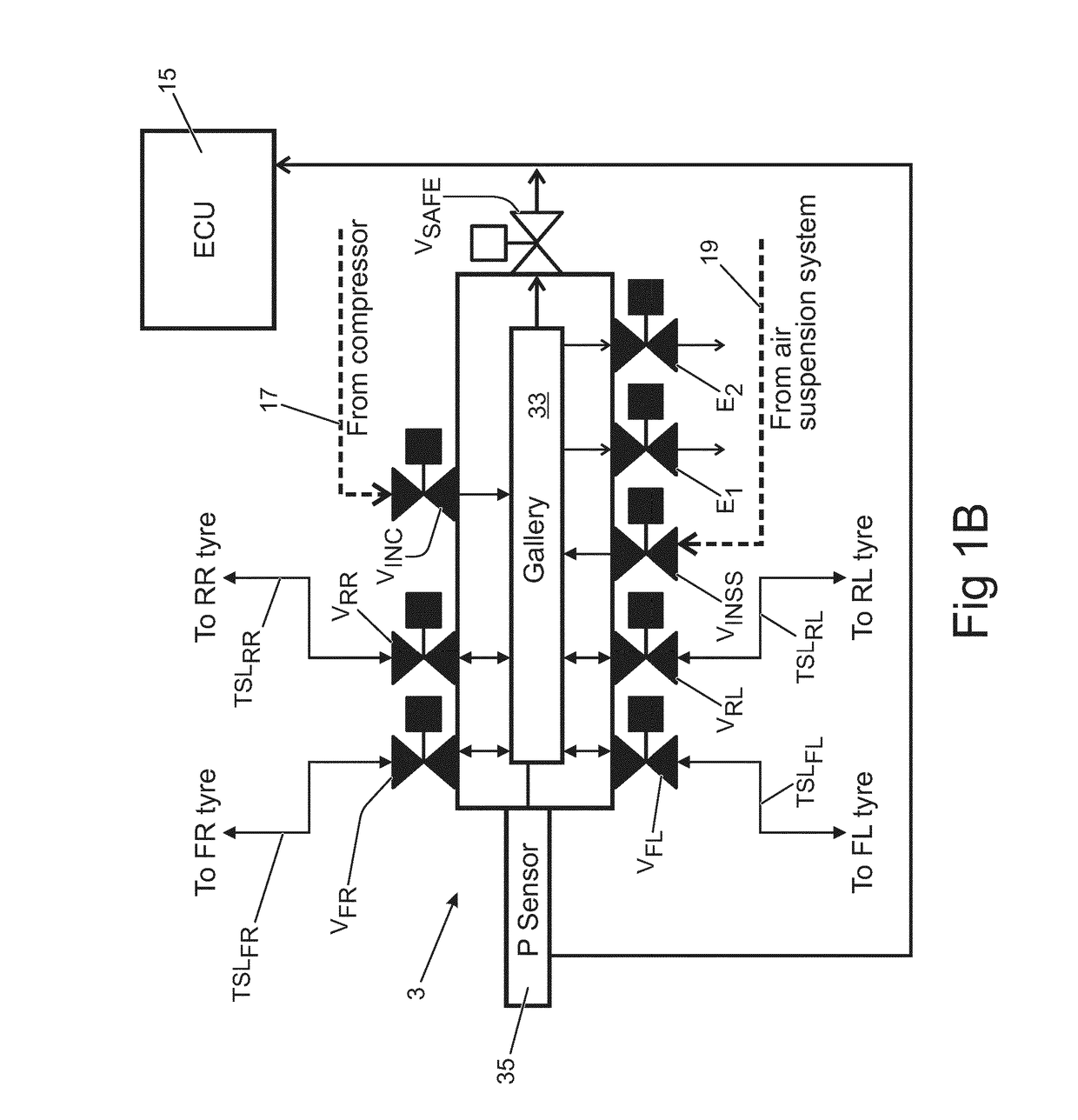

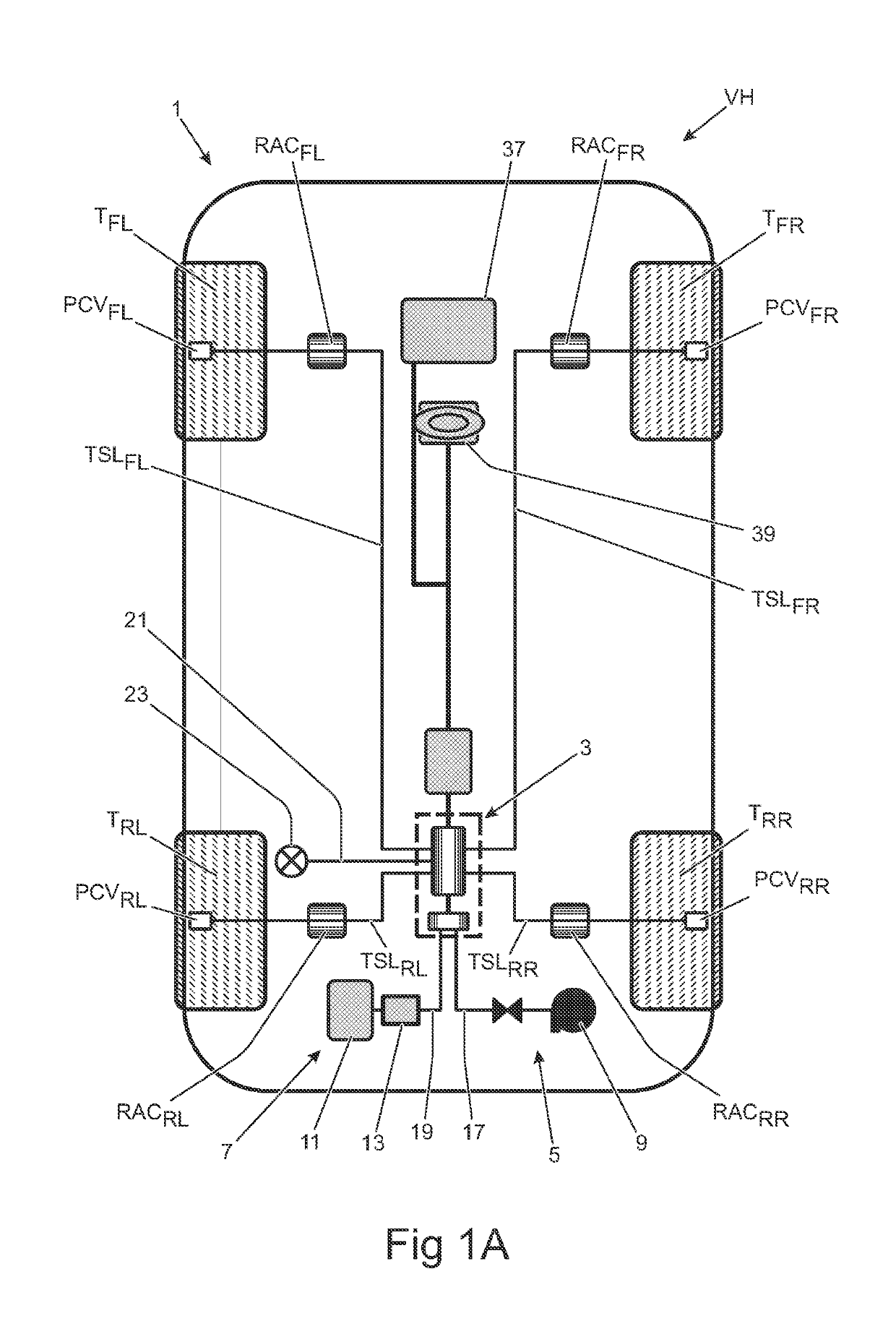

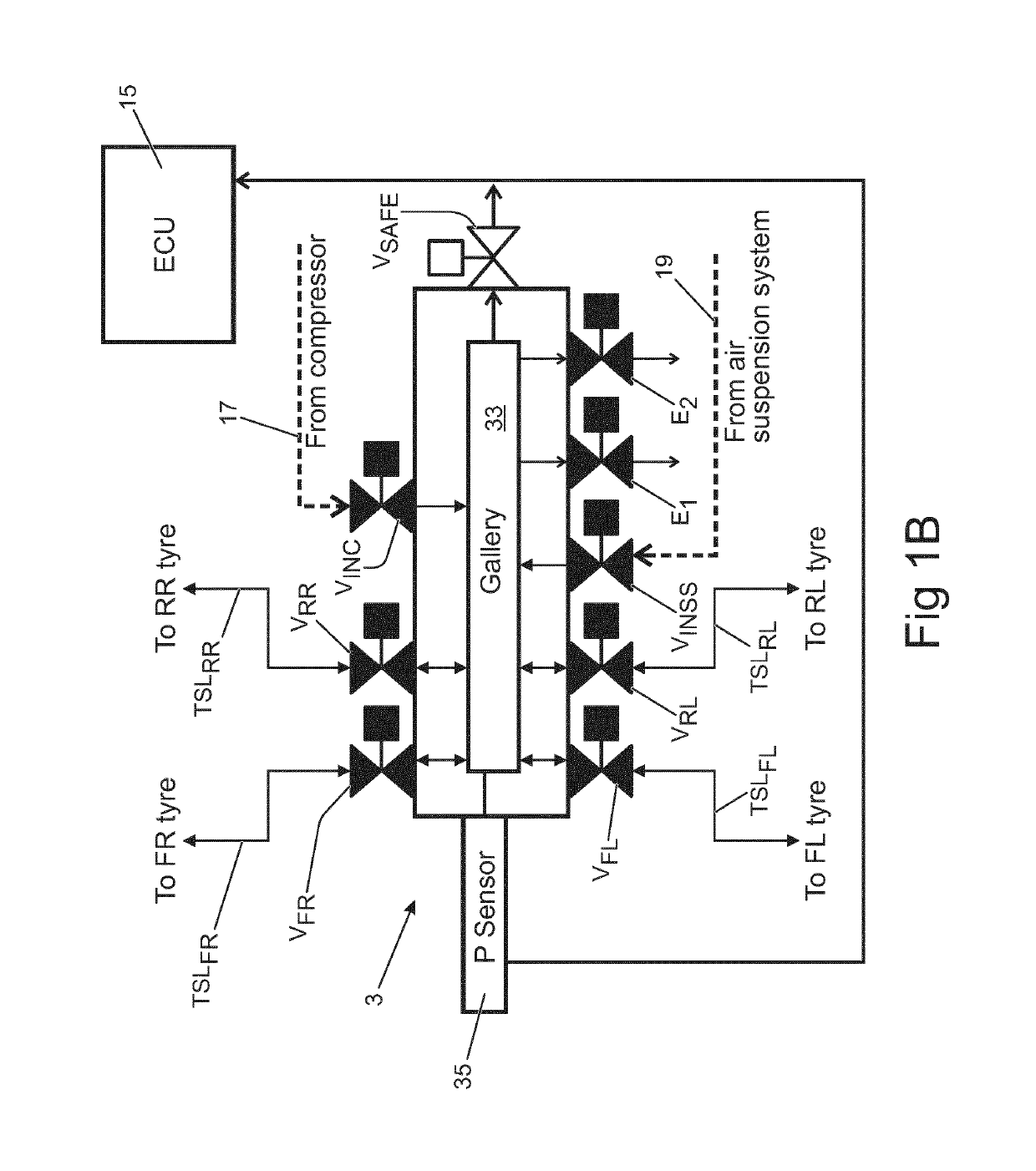

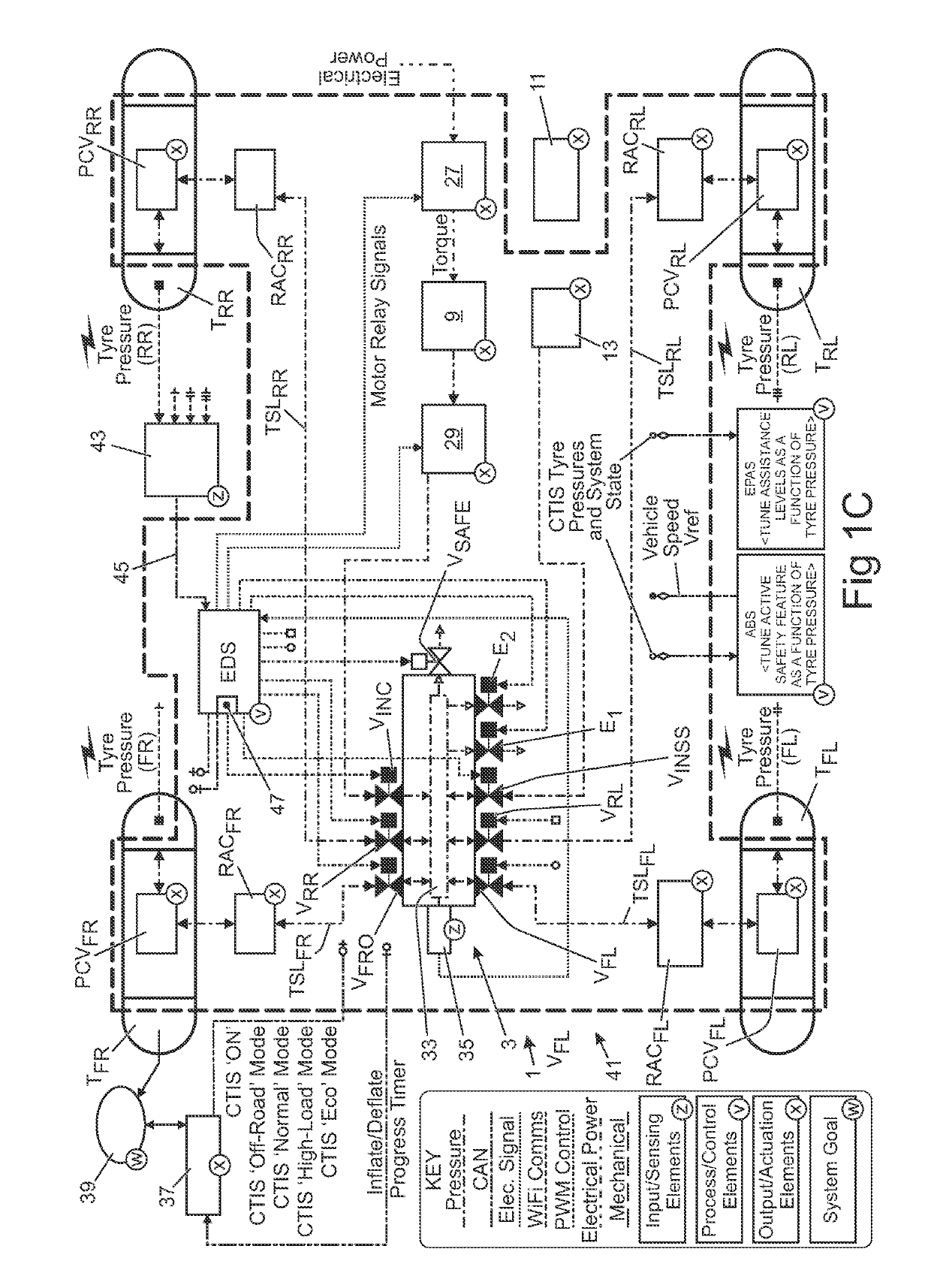

Control system, vehicle and method

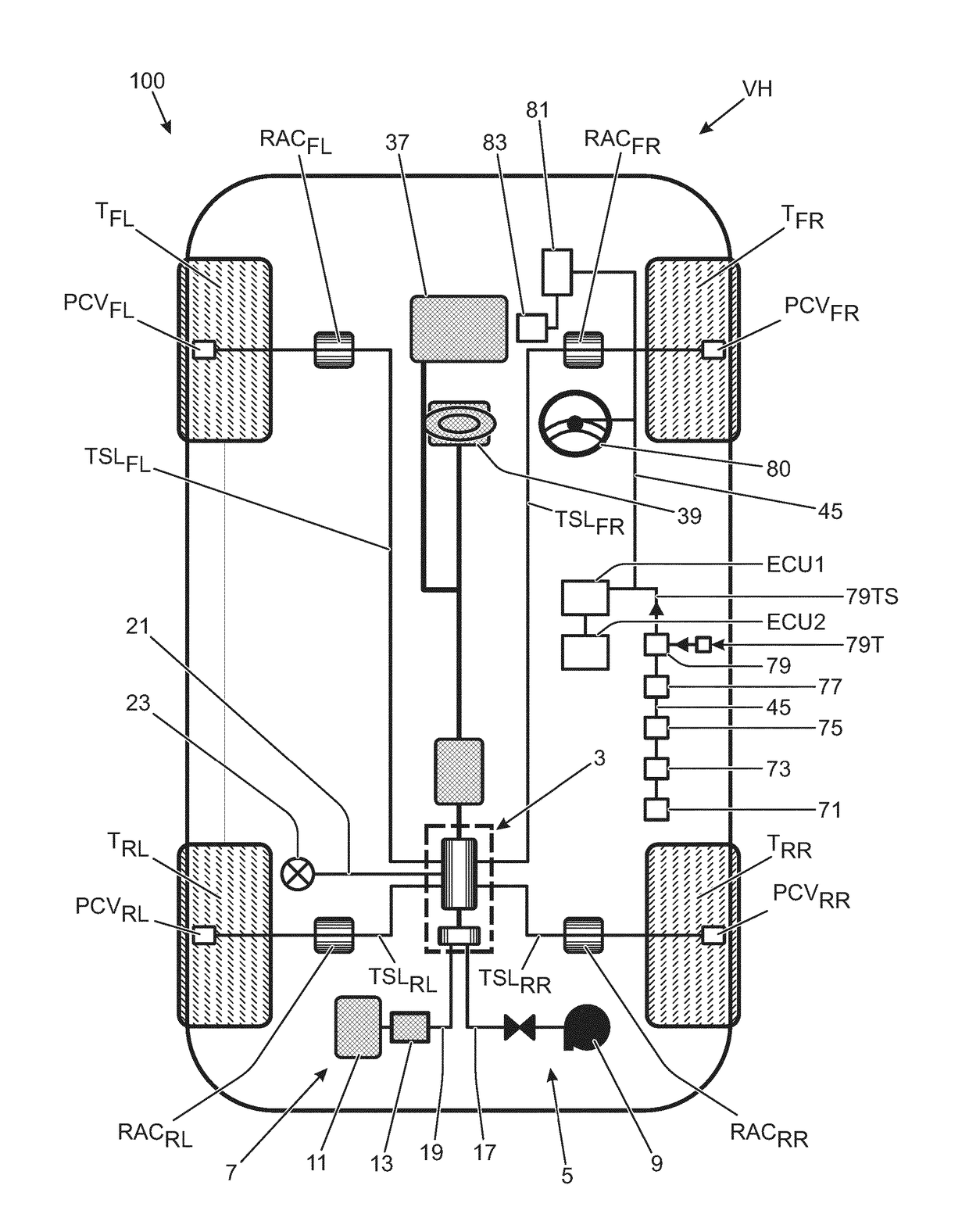

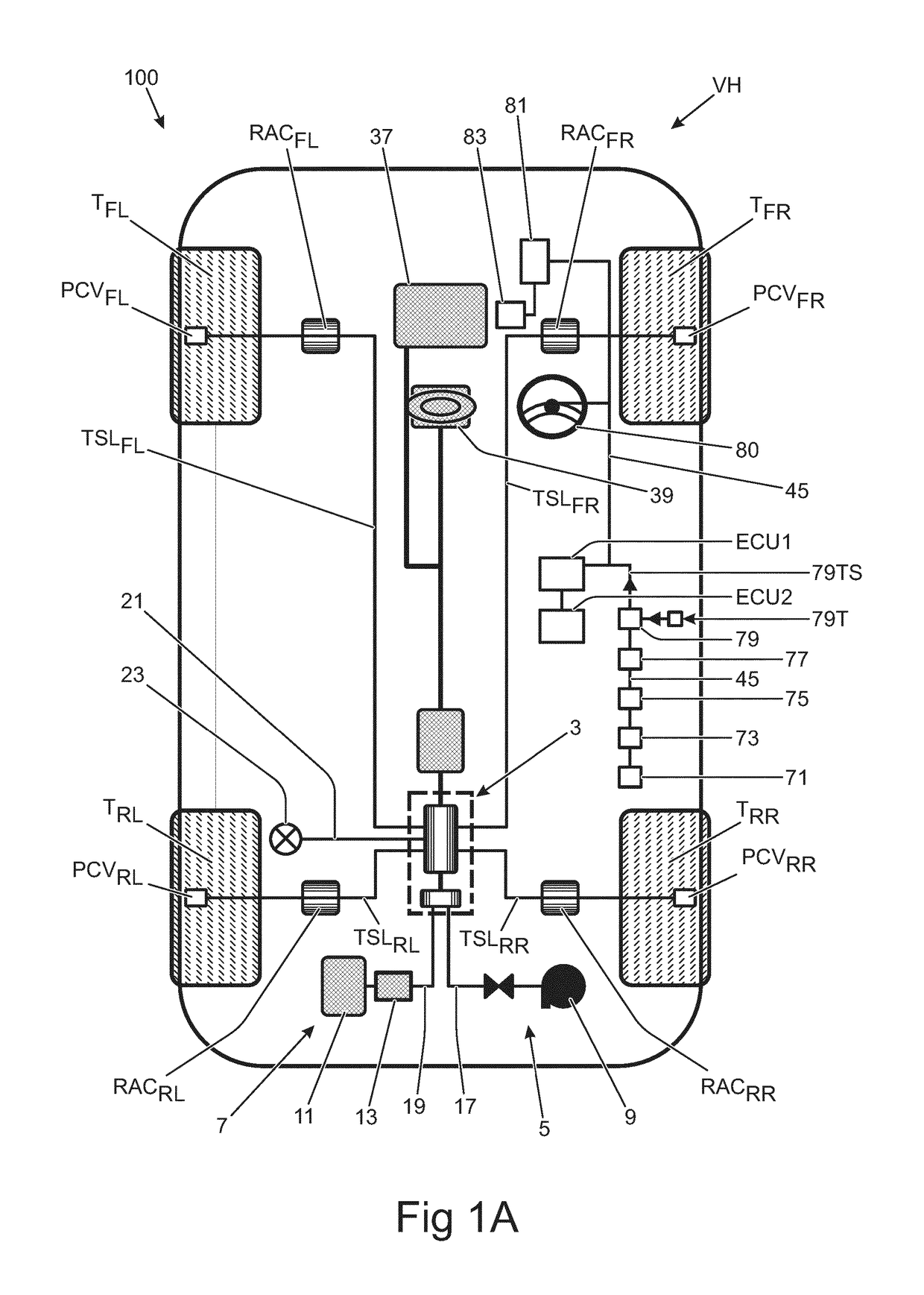

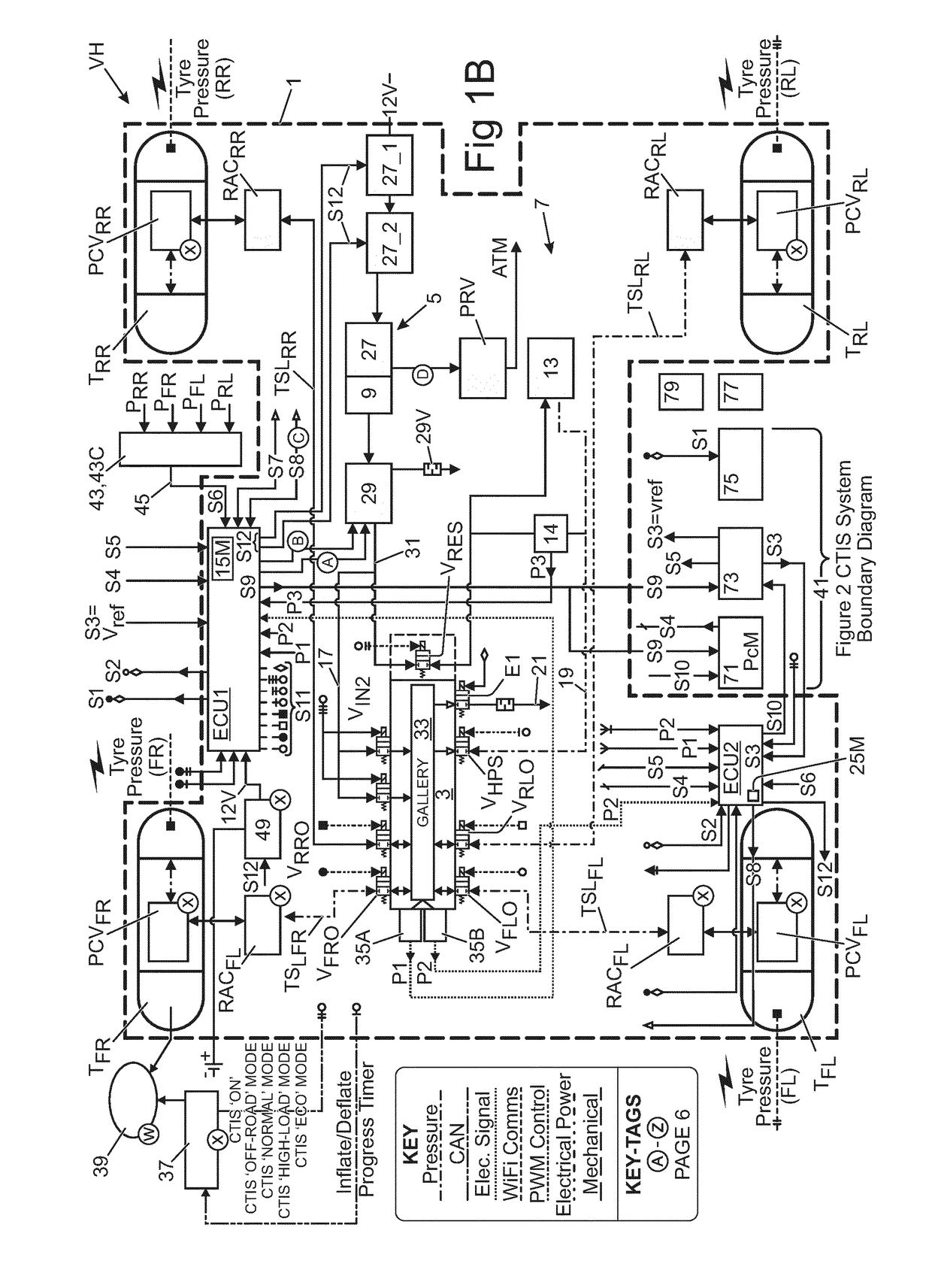

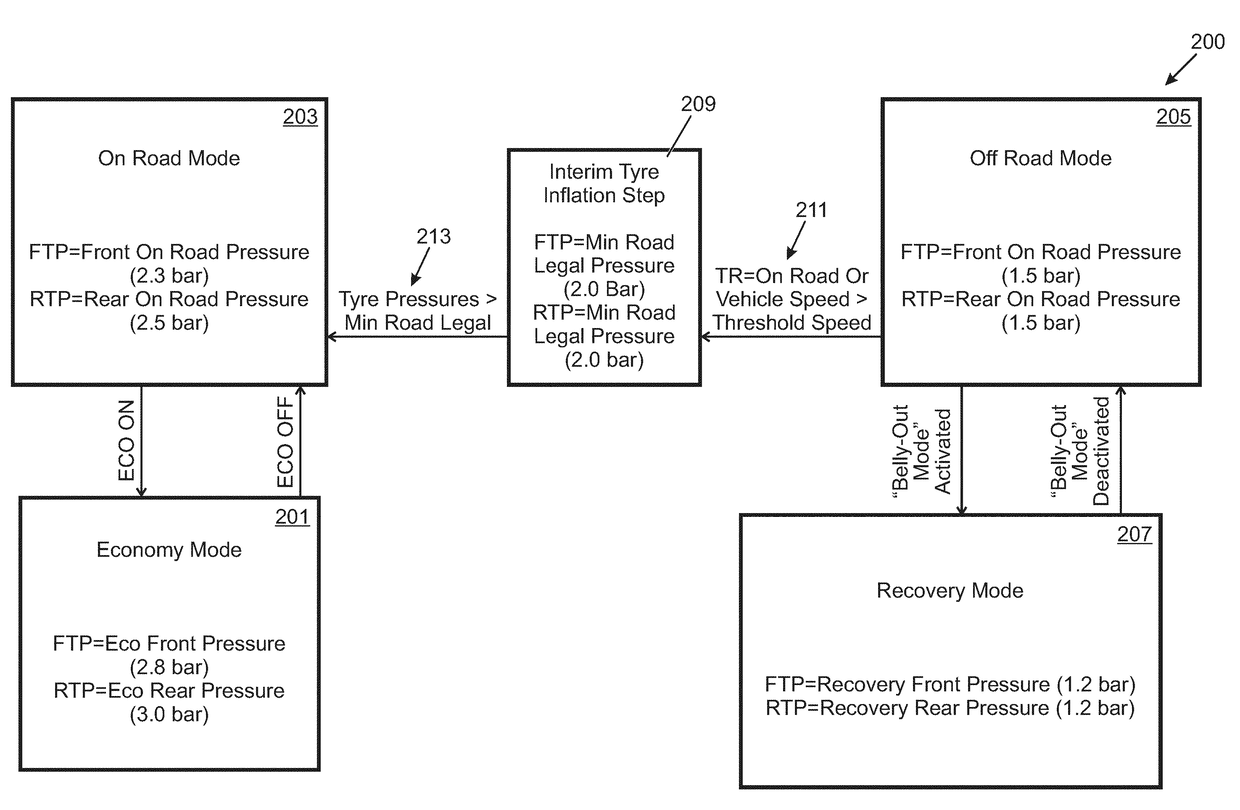

A controller for a central tire inflation system, the controller being configured to control the system to cause inflation and deflation of one or more tires, the controller being operational in a first one of a plurality of operational states in which the controller permits operation of the CTIS in any one of a plurality of operating modes in each of which the CTIS is configured to set one or more tire pressures to a predetermined tire pressure value, the controller being configured to assume operation in another operational state in which the controller prevents operation of the CTIS in a predetermined one or more of the plurality of operating modes in dependence on a determination that one or more fault conditions exist, the determination that one or more fault conditions exist being made in dependence on at least one signal indicative of a fault condition received by the controller.

Owner:JAGUAR LAND ROVER LTD

Valve assembly for a central tire inflation system

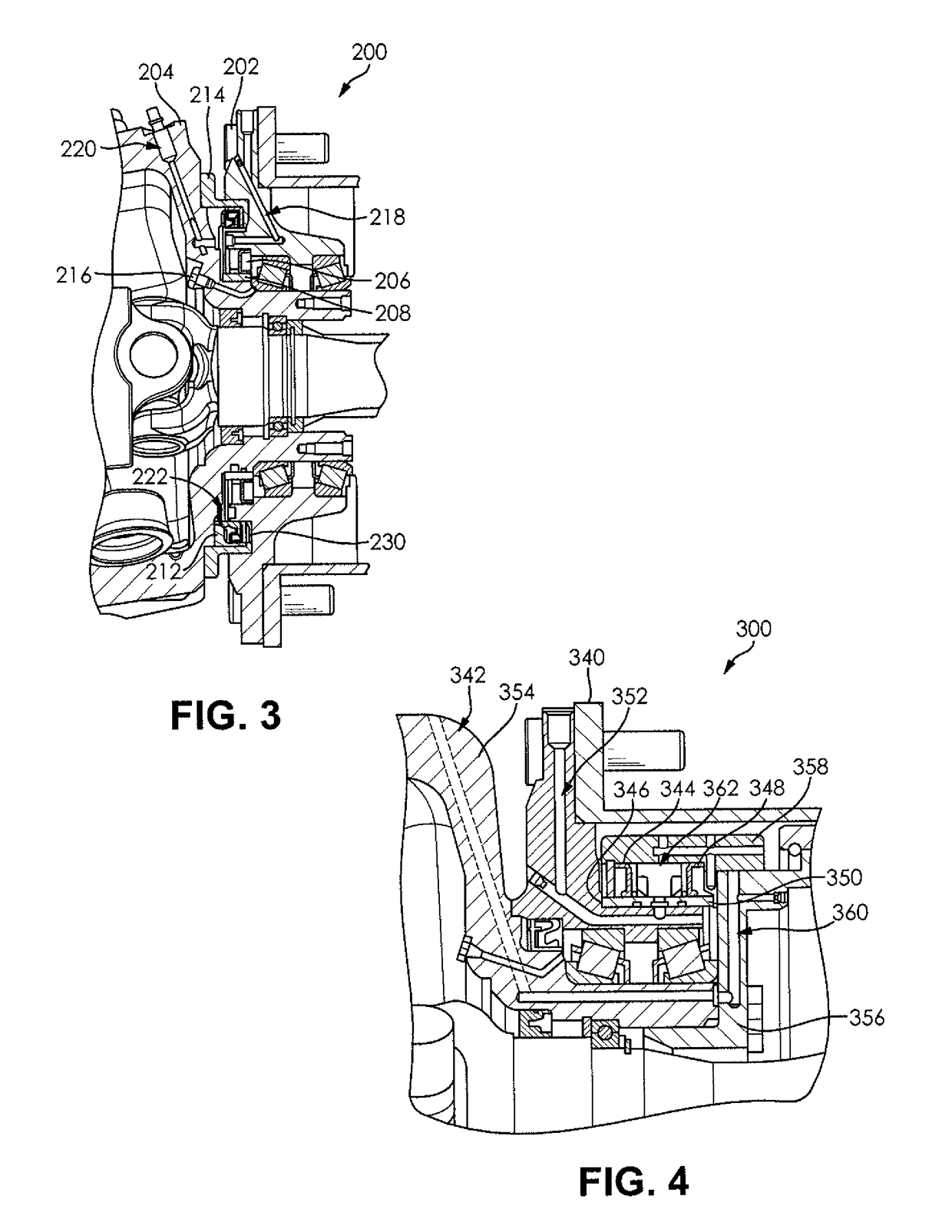

ActiveUS20140224352A1Reduce the overall diameterCheck valvesTyre measurementsCentral tire inflation systemMaterial Perforation

A valve assembly for a central tire inflation system is provided. The valve assembly includes a first housing having a first port connected to a second port via a cavity. The second port is in fluid communication with a wheel assembly. A biasing member is disposed in the cavity adjacent a first perforation formed in the first housing. A valve member is contacted by the biasing member. The valve member includes a first portion having an outer surface which is unbroken adjacent an end to allow a pressurized fluid to flow around it. The first portion reduces in diameter toward the end.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Controller for a motor vehicle and method

ActiveUS20180178598A1Sufficient pressureEnough timeRegistering/indicating working of vehiclesTyre measurementsMobile vehicleOperation mode

A controller for a motor vehicle central tire inflation system. The controller causes the system to operate in a selected one of a plurality of operating modes that include a leakage assist mode in which the controller causes the system to inflate the tires to predetermined leakage assist pressure value. The controller is configured automatically to cause the system to assume the leakage assist mode in dependence at least in part on a first pressure signal indicative of the pressure of one or more tires, wherein when the system determines that a tire is suffering leakage the system is configured to establish a gas flow path between the tire and a remote pressure sensor and to measure a pressure of gas in the tire by means of the remote pressure sensor by reference to a second pressure signal indicative of a pressure measured by the remote pressure sensor.

Owner:JAGUAR LAND ROVER LTD

Active adaptation of control algorithms for a central tire inflation system

InactiveUS20030192372A1Tyre measurementsPackaging under special atmospheric conditionsAir volumeLine tubing

A method for control of a tire pressure management system (or central tire inflation system) is provided which enables active adaptation of control variables in the system in response to variations in air line volume. The air line volume in a conduit between an air source and a vehicle tire is determined. Subsequently, one or more values for control variables are adjusted in response to the air line volume and various parameters associated with the system are determined in response to the adjusted values of the control variables.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Vehicle wheel assemblies and valves for use with a central tire inflation system

Wheel assemblies and valves for use with central tire inflation systems are provided. A wheel assembly may include a wheel having a rim and a wall extending radially inwardly from the rim. The wall may include an inboard side and an outboard side, and a central opening therethrough. The wheel may include a wheel duct for communicating pressurized fluid to a tire. A valve may be secured to the wheel wall. The valve may include an inboard side and an outboard side. The valve may include a hub interface adapted to extend from its inboard side. The hub interface may be adapted to extend around the wheel wall. The valve may include an inlet duct opening on the hub interface to communicate with a duct in a wheel hub on which the wheel is mounted. The valve may also include an outlet duct configured to communicate with the wheel duct.

Owner:ROYAL BANK OF CANADA

Active adaptation of control algorithms for a central tire inflation system

A method for control of a tire pressure management system (or central tire inflation system) is provided which enables active adaptation of control variables in the system in response to variations in air line volume. The air line volume in a conduit between an air source and a vehicle tire is determined. Subsequently, one or more values for control variables are adjusted in response to the air line volume and various parameters associated with the system are determined in response to the adjusted values of the control variables.

Owner:DANA CORP

Control system, vehicle and method

InactiveUS20180312017A1Tyre measurementsTyre tread bands/patternsMobile vehicleElectronic controller

A control system for a motor vehicle includes a central tire inflation system (CTIS) electronic controller, the CTIS controller being configured to control the CTIS to cause inflation and deflation of one or more tires, the CTIS controller being configured to receive electronic signals indicative of current vehicle speed and tire pressure, and to generate a cumulative tire wear indicator value indicative of a cumulative amount of wear suffered by a tire at a given moment in time, the CTIS controller being configured to automatically set the cumulative tire wear indicator value to a predetermined datum value in dependence at least in part on a determination by the CTIS controller that a tire has been changed.

Owner:JAGUAR LAND ROVER LTD

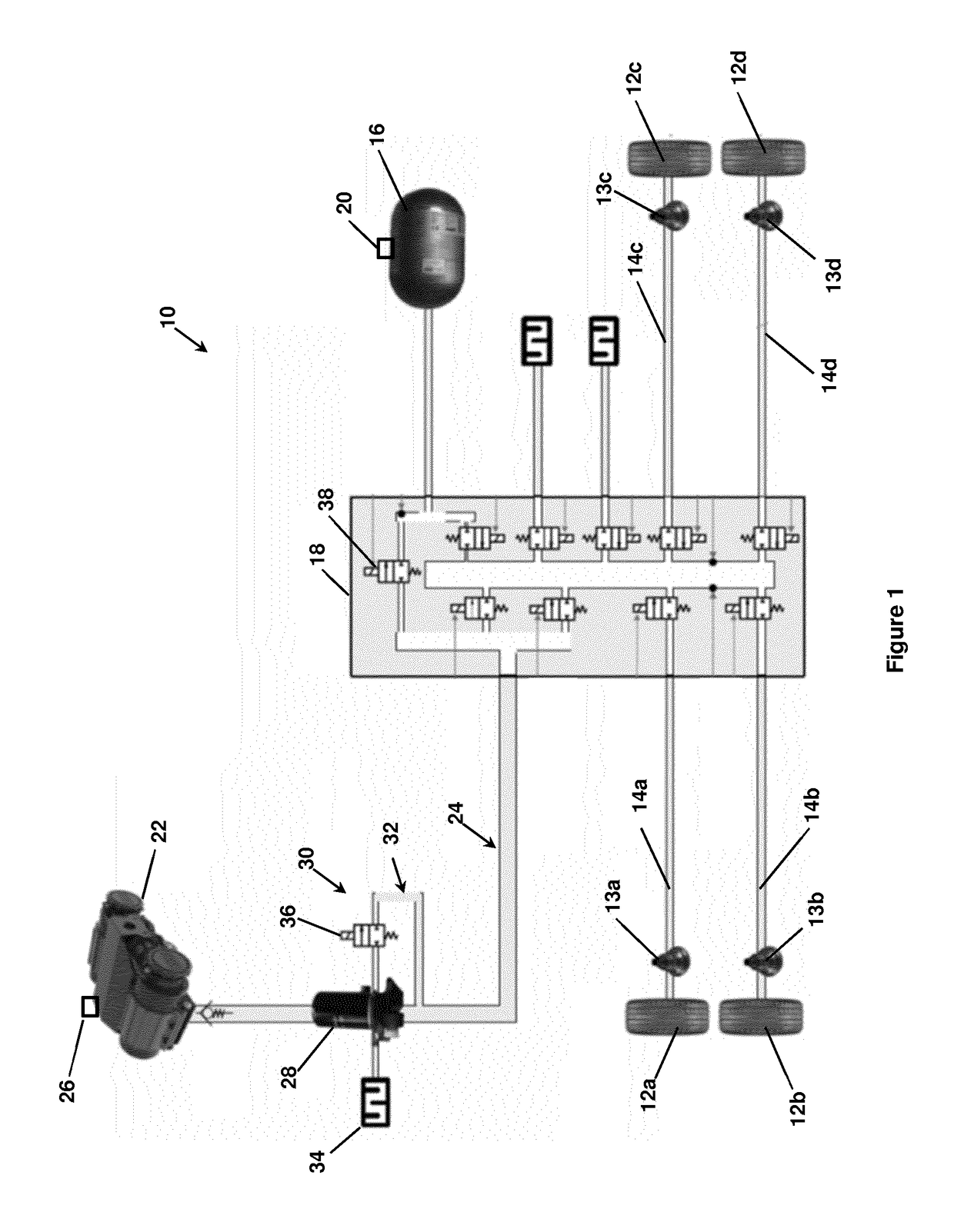

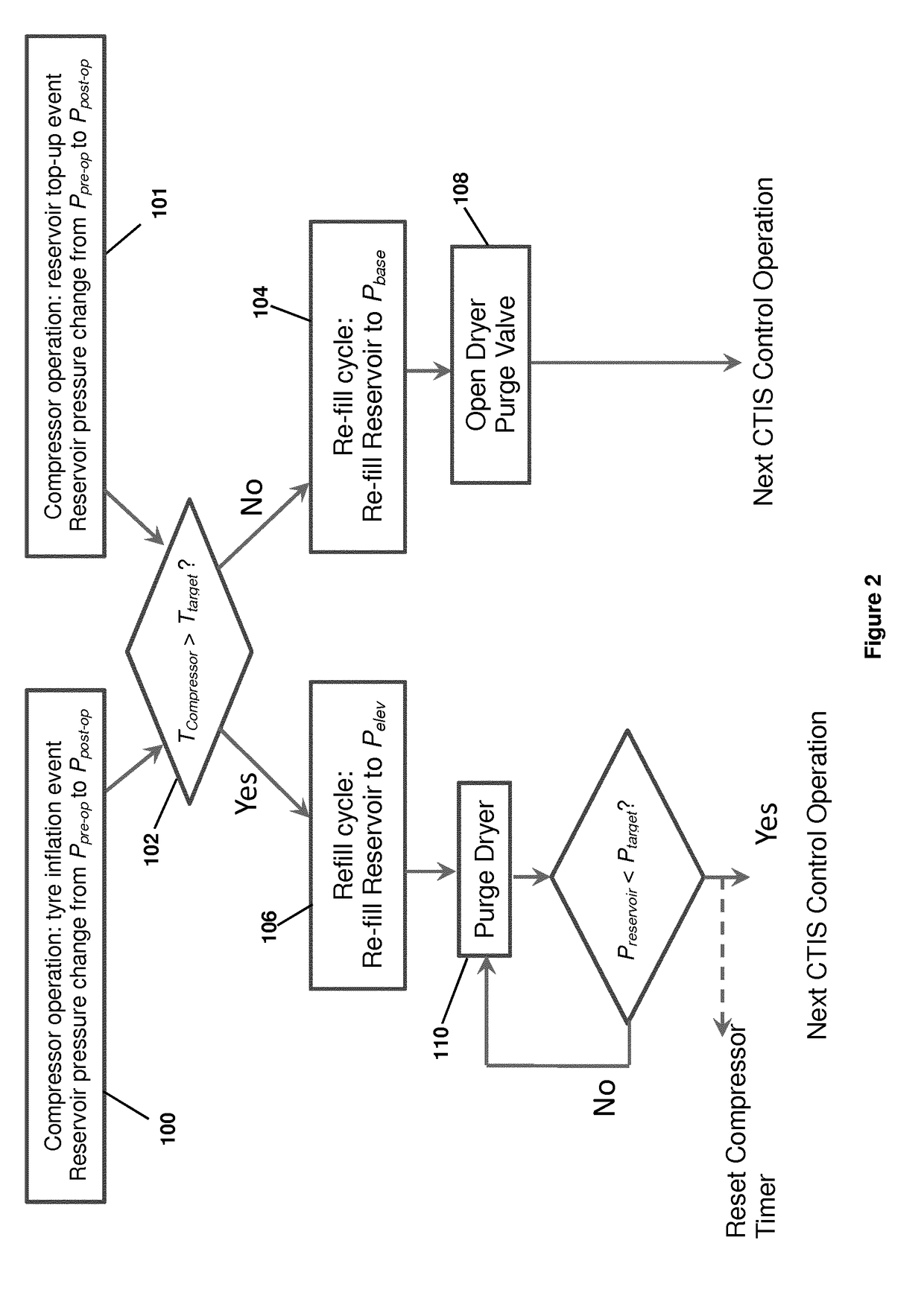

Central tyre inflation system and method

ActiveUS20180207575A1Sufficient pressureDeactivation minimizedGas treatmentDispersed particle separationStart up timeFuel tank

A central tire inflation system (CTIS) for a vehicle includes a reservoir for supplying air to the vehicle tires, a pressure sensor for monitoring air pressure in the reservoir, a compressor for supplying compressed air along a first flow path to the reservoir, a compressor timer for monitoring the run-time of the compressor, a dryer disposed on the first flow path for drying air supplied by the compressor, a purging system for routing air through the dryer along a second flow path to purge liquid from the dryer, and a controller for controlling the flow of air in the CTIS. The controller is configured: to activate the compressor in response to a request for a compressor operation, after which operation the air in the reservoir is at a post-operation pressure; when the compressor operation is complete, to determine a compressor activation period, and to determine if the compressor activation period is greater than or equal to a target period; and if the compressor activation period is less than the target period, to keep the compressor activated until pressure in the reservoir increases to a base target pressure greater than the post-operation pressure; and if the compressor activation period is greater than or equal to the target period, to keep the compressor activated until pressure in the reservoir increases to an elevated target pressure higher than the base target pressure and to activate the purging system to route air from the reservoir to purge the dryer of liquid.

Owner:JAGUAR LAND ROVER LTD

Control system, vehicle and method

InactiveUS20200031334A1Reduce scrollingIncrease propensityBrake system interactionsTyre measurementsControl systemControl engineering

A control system for a motor vehicle includes a central tire inflation system (CTIS) controller and at least one other vehicle system controller arranged to control a system associated with the at least one other vehicle system controller. The CTIS controller controls the CTIS to cause inflation and deflation of one or more tires and is configured to cause the CTIS to operate in a selected one of a plurality of operating modes in each of which the system is configured to set a pressure of one or more tires. The CTIS controller is configured to generate and output a first signal indicative of pressure of the one or more tires, the at least one other system controller being configured to receive the first signal and to control operation of the system associated with the at least one other vehicle system controller in dependence on the first signal.

Owner:JAGUAR LAND ROVER LTD

Valve assembly for a central tire inflation system

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Control system, vehicle and method

ActiveUS20180297422A1Avoid choiceSelective operationOff-road vehicle tyresTyre measurementsElectronic controllerControl system

A control system for a motor vehicle includes a central tire inflation system (CTIS) electronic controller, the CTIS controller being configured to control the CTIS to cause inflation and deflation of one or more tires, the CTIS controller being configured to cause the CTIS to operate in a selected one of a plurality of operating modes in each of which the system is configured to set a pressure of one or more tires of the vehicle to a predetermined tire pressure value, the CTIS controller being configured to receive data indicative of a type of tire fitted to the vehicle, the controller being configured to prevent operation in a predetermined at least one of the plurality of operating modes in dependence on the data indicative of tire type.

Owner:JAGUAR LAND ROVER LTD

Central tire inflation system

ActiveUS20170113498A1Inhibition of activationEliminate needTyre measurementsEngineeringCentral tire inflation system

A processor for controlling operation of a central tire inflation system (CTIS) to change a tire pressure of a tire of a vehicle is configured to control the CTIS to inflate or deflate the tire to a predetermined tire pressure which is above a target tire pressure for the tire. The processor then controls the CTIS to deflate the tire until the target tire pressure is reached. In this manner, a second tire inflation operation to achieve the target tire pressure in the tire can be avoided.

Owner:JAGUAR LAND ROVER LTD

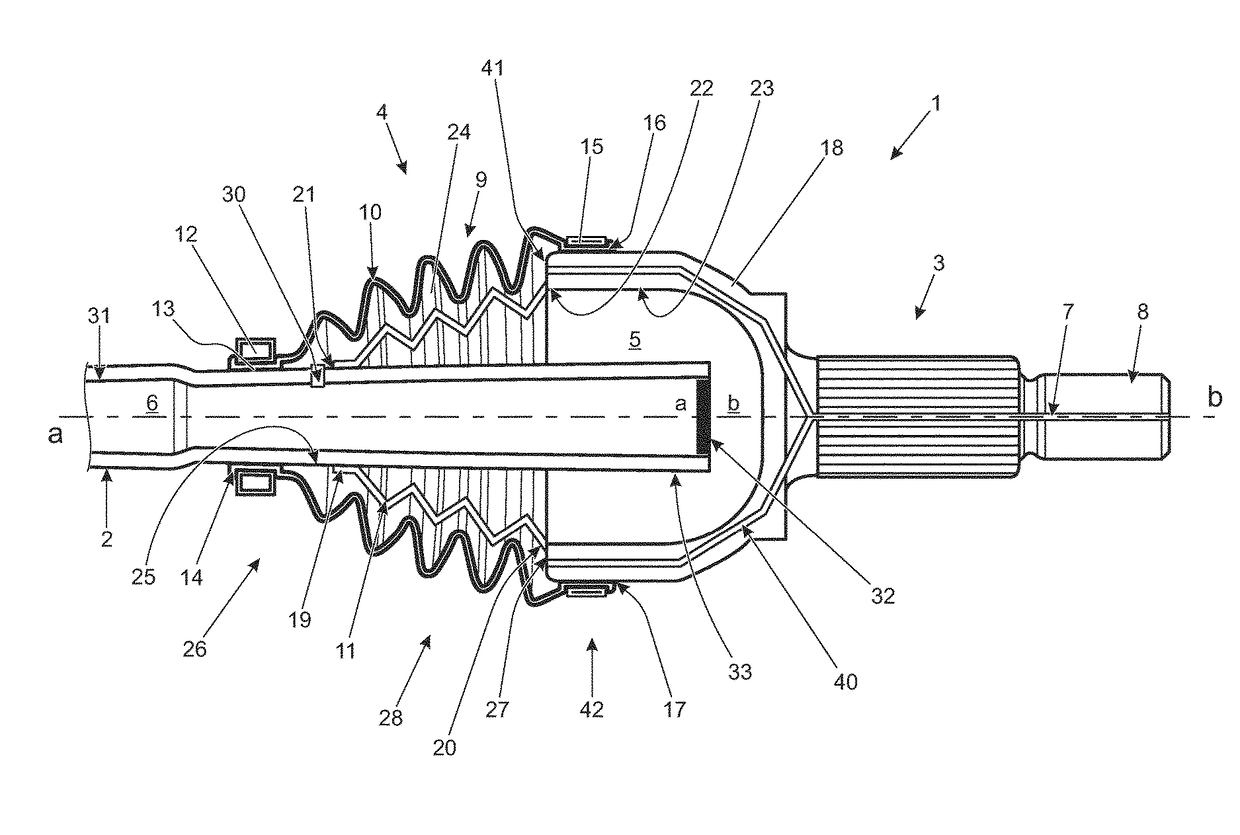

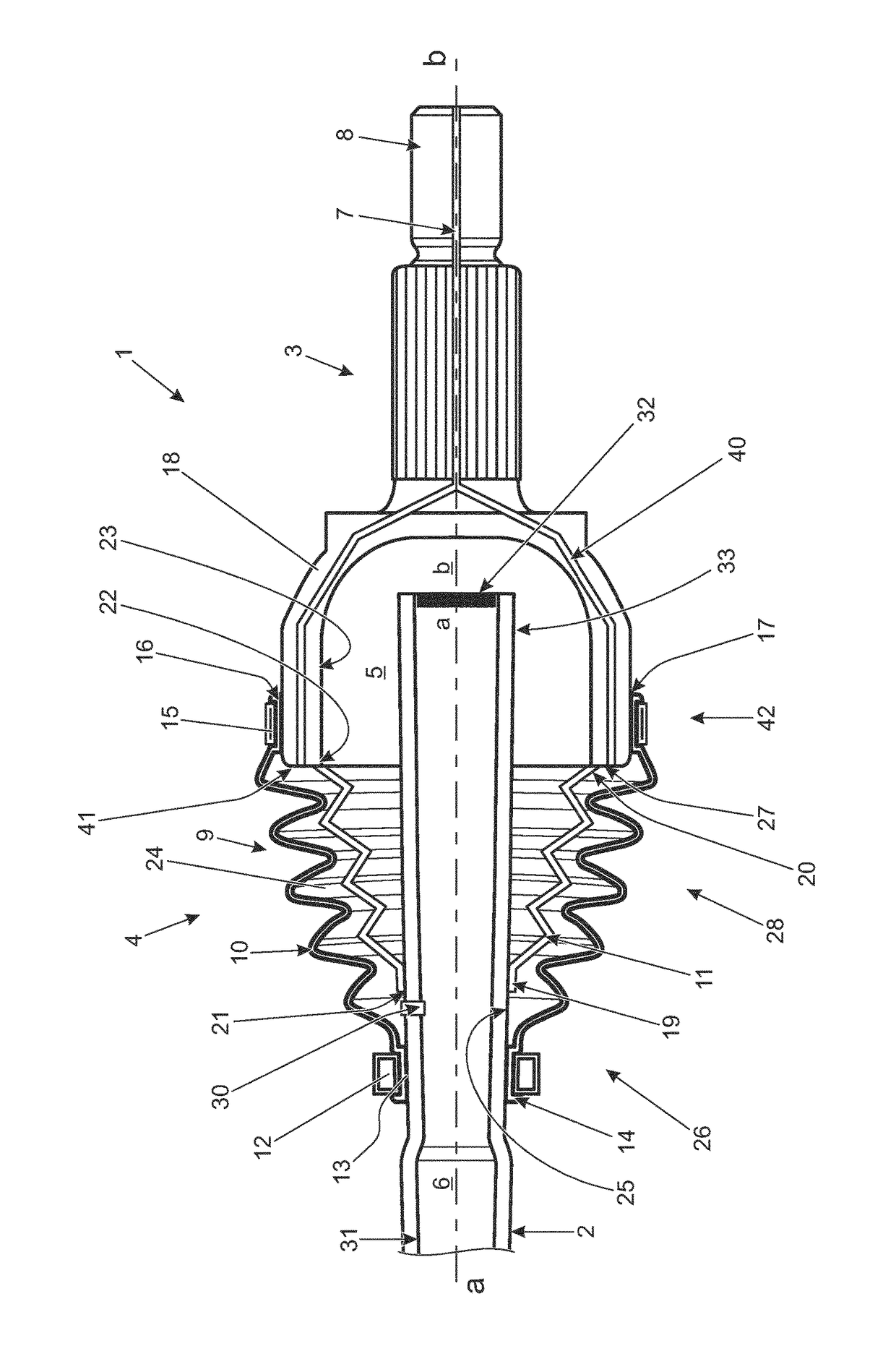

Gaiter

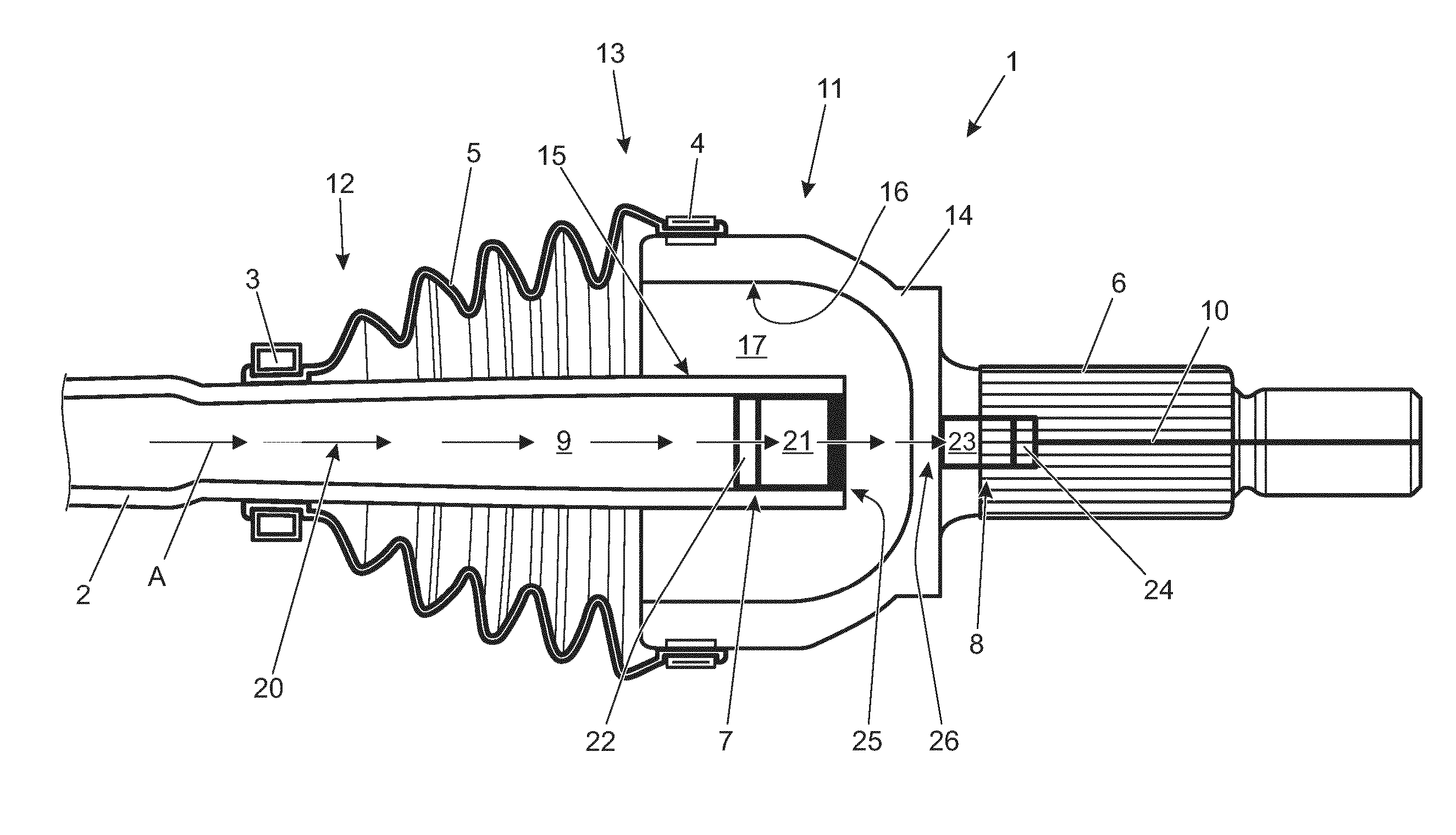

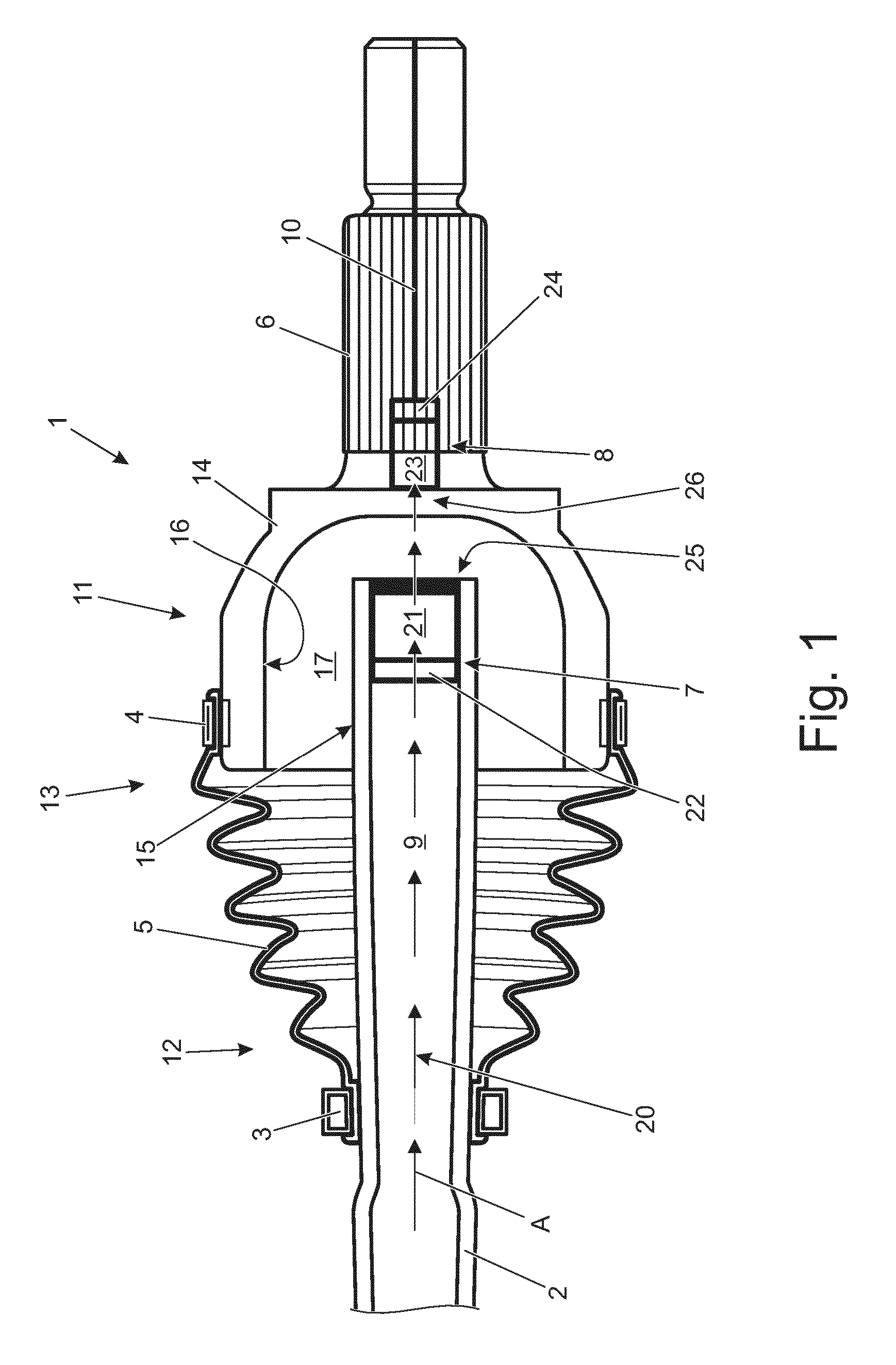

A gaiter (4) for a lubricated joint (1) comprises a sidewall structure (9) defining an enclosure (5) for receiving a lubricant and a passageway (24) for conveying a gas. In use, the passageway (12) conveys gas in isolation from said enclosure (5). Gaiters (4) in accordance with the invention find application in vehicle central tire inflation systems (CTIS).

Owner:JAGUAR LAND ROVER LTD

Filter device

ActiveUS20160199768A1Combination devicesSemi-permeable membranesEngineeringCentral tire inflation system

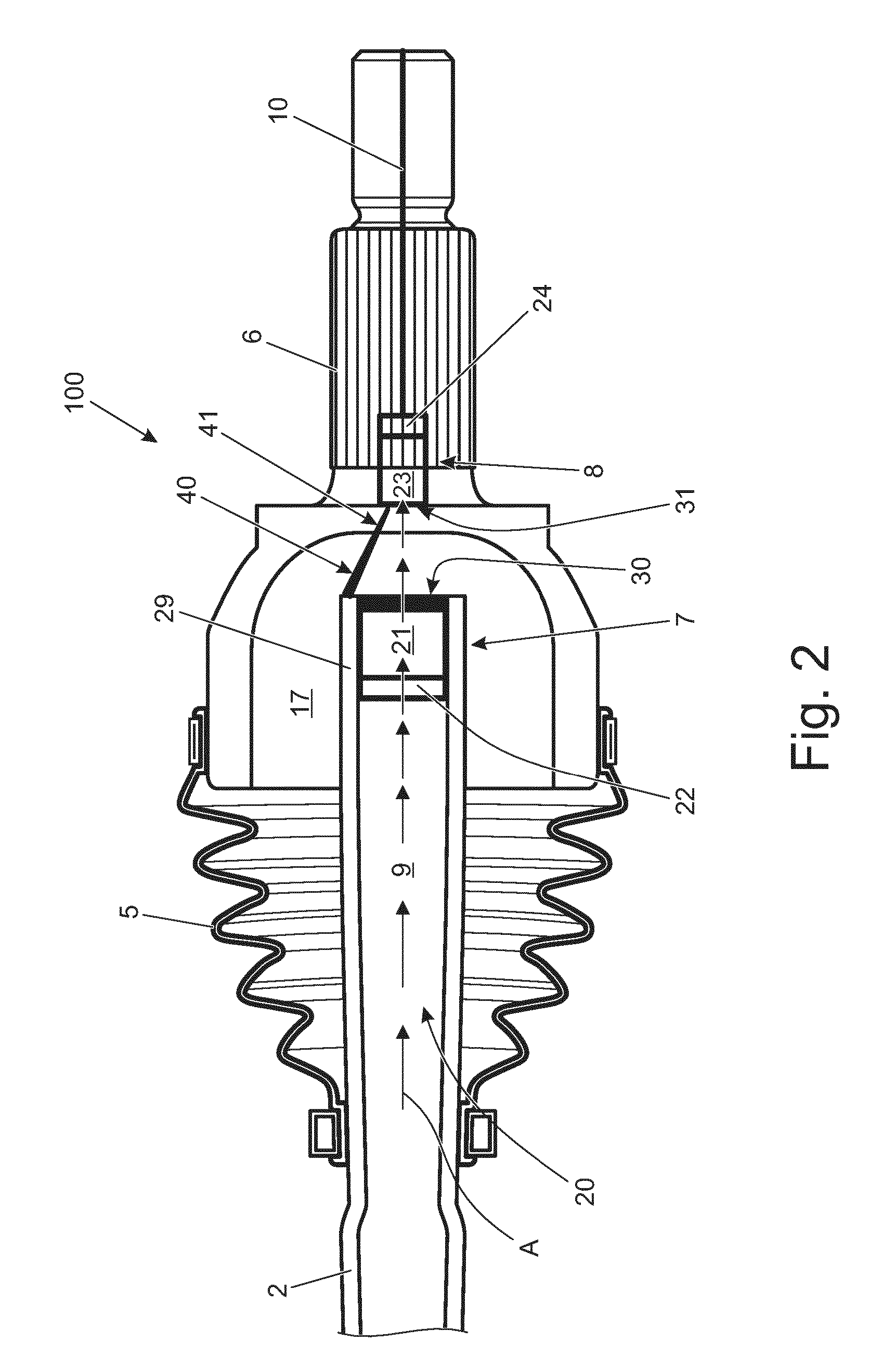

A filter device (7, 8) for a conduit (9, 10) comprises a gas-permeable pre-filter element (21, 23) and a gas-permeable, liquid-impermeable filter element (22, 24). The filter device (7, 8) is configured to be fluidly coupled to a conduit (9, 10) such that a gas can be caused to flow, in sequence, through the pre-filter element (21, 23), the filter element (22, 24) and then the conduit (9, 10). Such a filter device (7, 8) can for example be used in each of a vehicle hollow driveshaft (2) and a hollow wheel stub axle (6) forming a CV joint (11) having a compressed air supply line which passes therethrough, as is the case in some central tyre inflation systems (CTISs). Thus, compressed air can be supplied via said air supply line without the need for an additional fluid transfer device fluidly connecting the driveshaft and the stub axle's conduits (9, 10).

Owner:JAGUAR LAND ROVER LTD

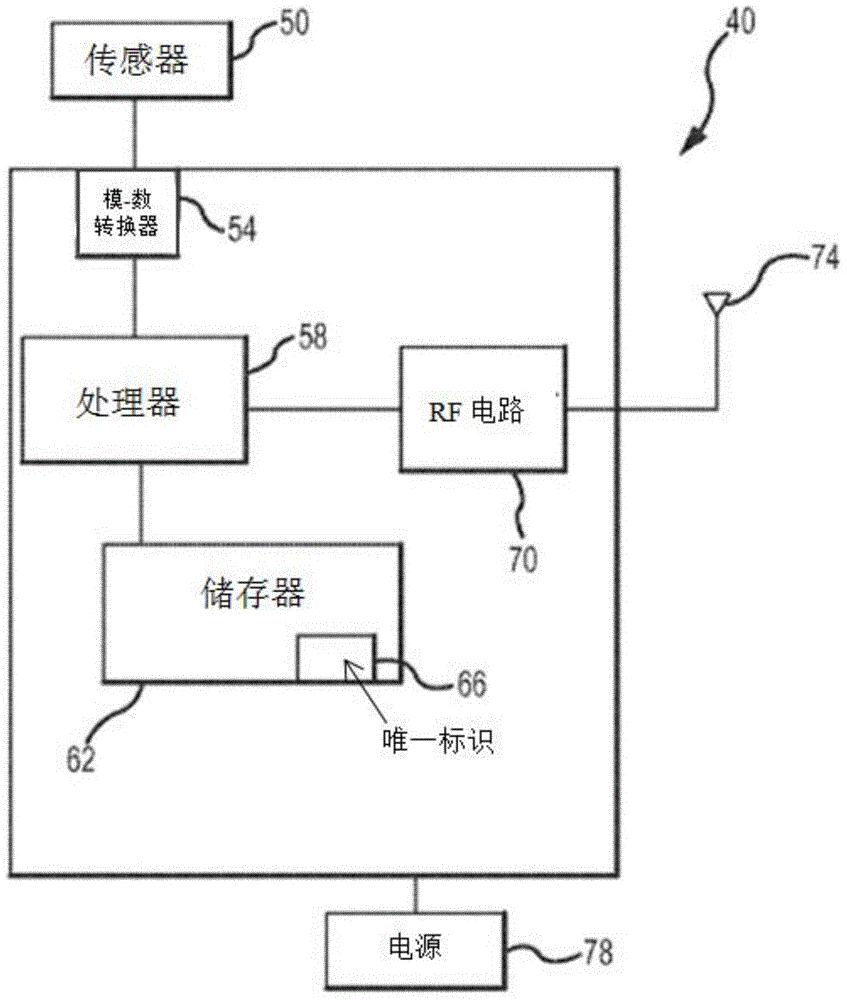

Wireless proportional flow indication for a tire inflation system

A flow indication system for a central tire inflation system is provided. The flow indication system provides a venturi in fluid communication with the conduit providing air to a tire. A pressure reading is taken at the inlet and throat of the venturi and the air flowing through the venturi is calculated based on the pressure differential. According to some embodiments, the pressure readings are provided to a microcontroller that uses a table and interpolation algorithms to calculate the flow of the air flowing through the venturi, such as the mass of air in a given unit of time (grams / second for example). In one embodiment, two separate pressure sensors are coupled to different ends of a narrowed orifice that causes a pressure change in the flow as flow rate increases in the throat of the sensor. This pressure change is then used to calculate a proportional flow that can then be broadcast to various parties instead of an on / off reading.

Owner:压力系统国际公司

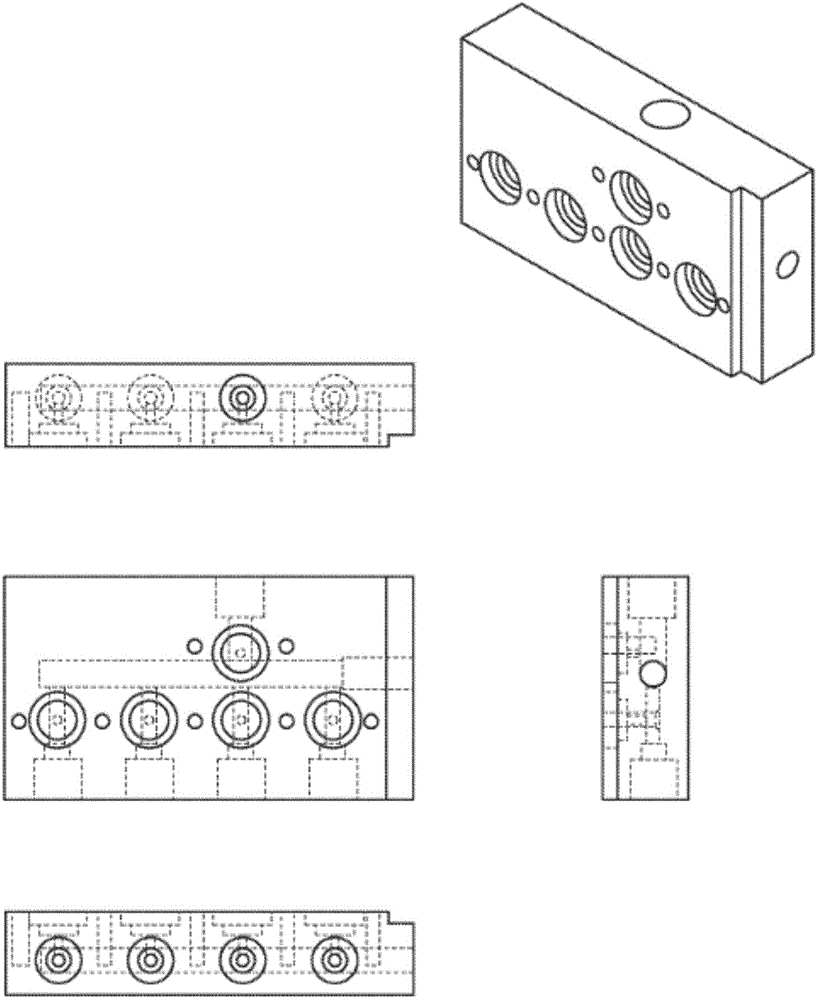

Assembly for a central tire inflation system

An assembly for a central tire inflation system includes a first housing having a first end and a hose member provided in the first end. A valve assembly is in fluid communication with the hose member via the first housing. The valve assembly includes a second housing and a valve positioned within the second housing. The second housing includes a base portion which comprises a lower wall portion. The valve is biased towards the lower wall portion by a biasing member to open the valve assembly.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Central tire inflation system

ActiveUS10399392B2Inhibition of activationEliminate needTyre measurementsTweelCentral tire inflation system

A processor for controlling operation of a central tire inflation system (CTIS) to change a tire pressure of a tire of a vehicle is configured to control the CTIS to inflate or deflate the tire to a predetermined tire pressure which is above a target tire pressure for the tire. The processor then controls the CTIS to deflate the tire until the target tire pressure is reached. In this manner, a second tire inflation operation to achieve the target tire pressure in the tire can be avoided.

Owner:JAGUAR LAND ROVER LTD

Rotary seal for a central tire inflation system

ActiveUS10011150B2Facilitate communicationEngine sealsAdjustable jointsEngineeringCentral tire inflation system

A rotary seal arrangement for use with a central tire inflation system is provided. The rotary seal arrangement comprises a stationary portion, a rotating portion, a first sealing ring, a second sealing ring, and a first bushing portion. The stationary portion defines a first air passage therethrough and the rotating portion defines a second air passage therethrough. The first sealing ring and the second sealing ring are each disposed on one of the rotating portion and the stationary portion. The first bushing is disposed on one of the rotating portion and the stationary portion. The first bushing is in dynamic sealing engagement with the first sealing ring. The stationary portion, the rotating portion, the first sealing ring, and the second sealing ring form a sealed cavity that facilitates fluid communication between the first air passage and the second air passage.

Owner:DANA ITAL SPA

Central tire inflation system

An exemplary system for controlling air pressure in a tire of a vehicle includes an air transfer ring assembly including a reservoir member, a cover member, a first air transfer member, a second air transfer member, and a sealing member configured to seal the reservoir member against the cover member and defining a pressured reserve air chamber. The reservoir member is coupled to a hub assembly of the vehicle and the cover member is coupled to a brake assembly of the vehicle to facilitate the transfer of air to and from a rotating vehicle component and a stationary vehicle component.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com