Patents

Literature

101results about How to "Increase propensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

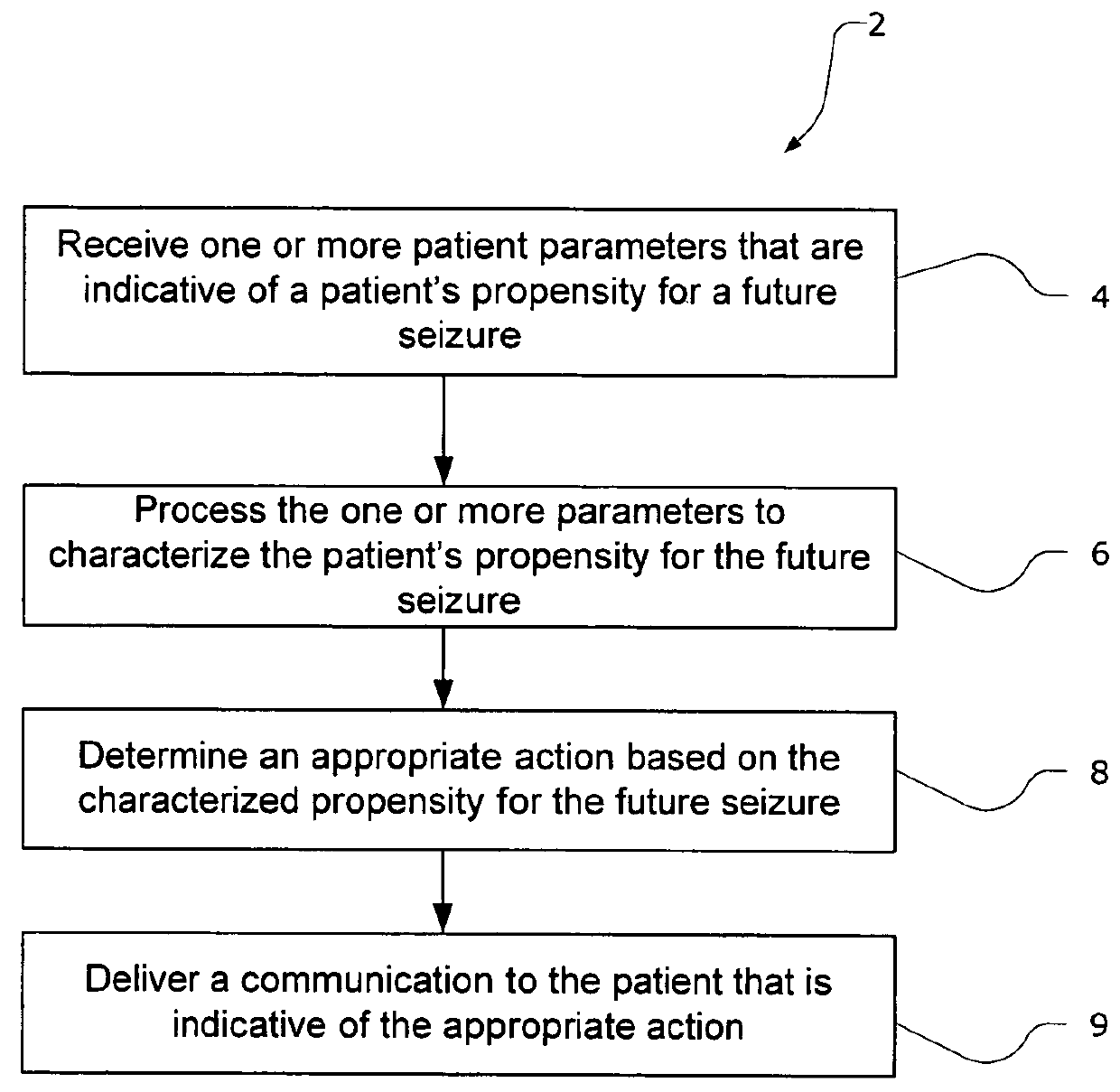

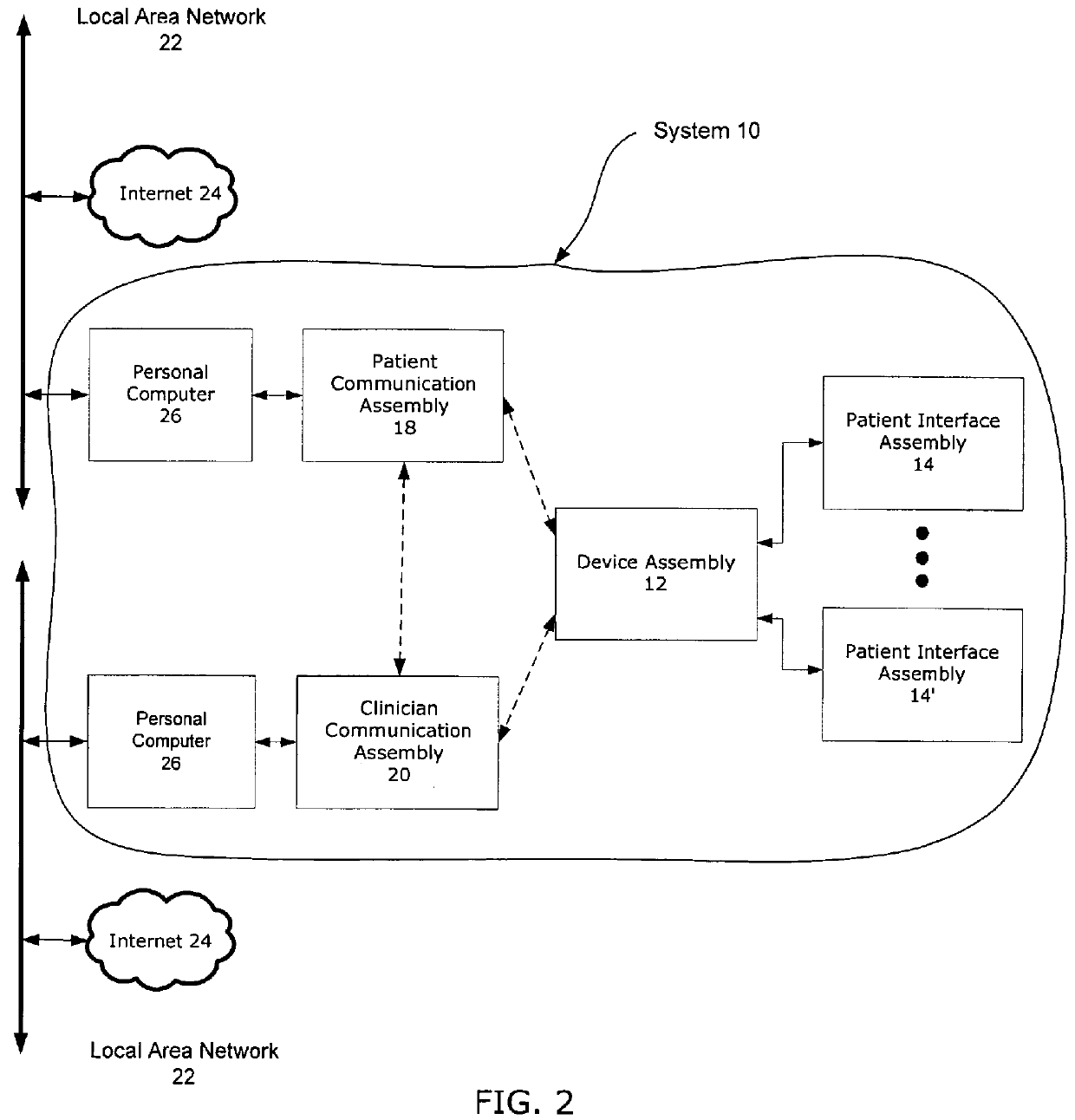

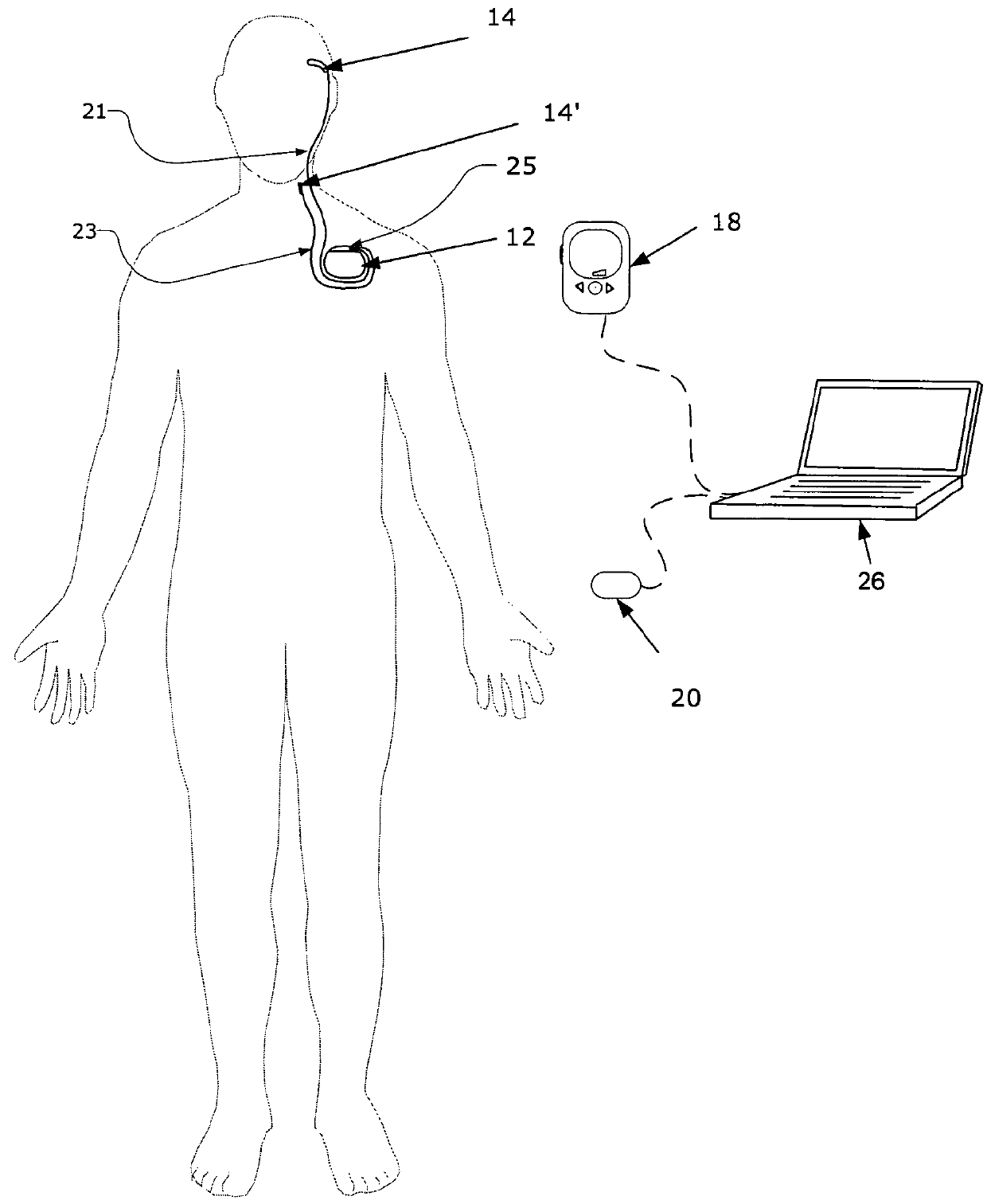

Methods and systems for recommending an appropriate action to a patient for managing epilepsy and other neurological disorders

ActiveUS20070150024A1Low profileIncrease probabilityElectroencephalographyPhysical therapies and activitiesNeurological disorderEpileptic seizure

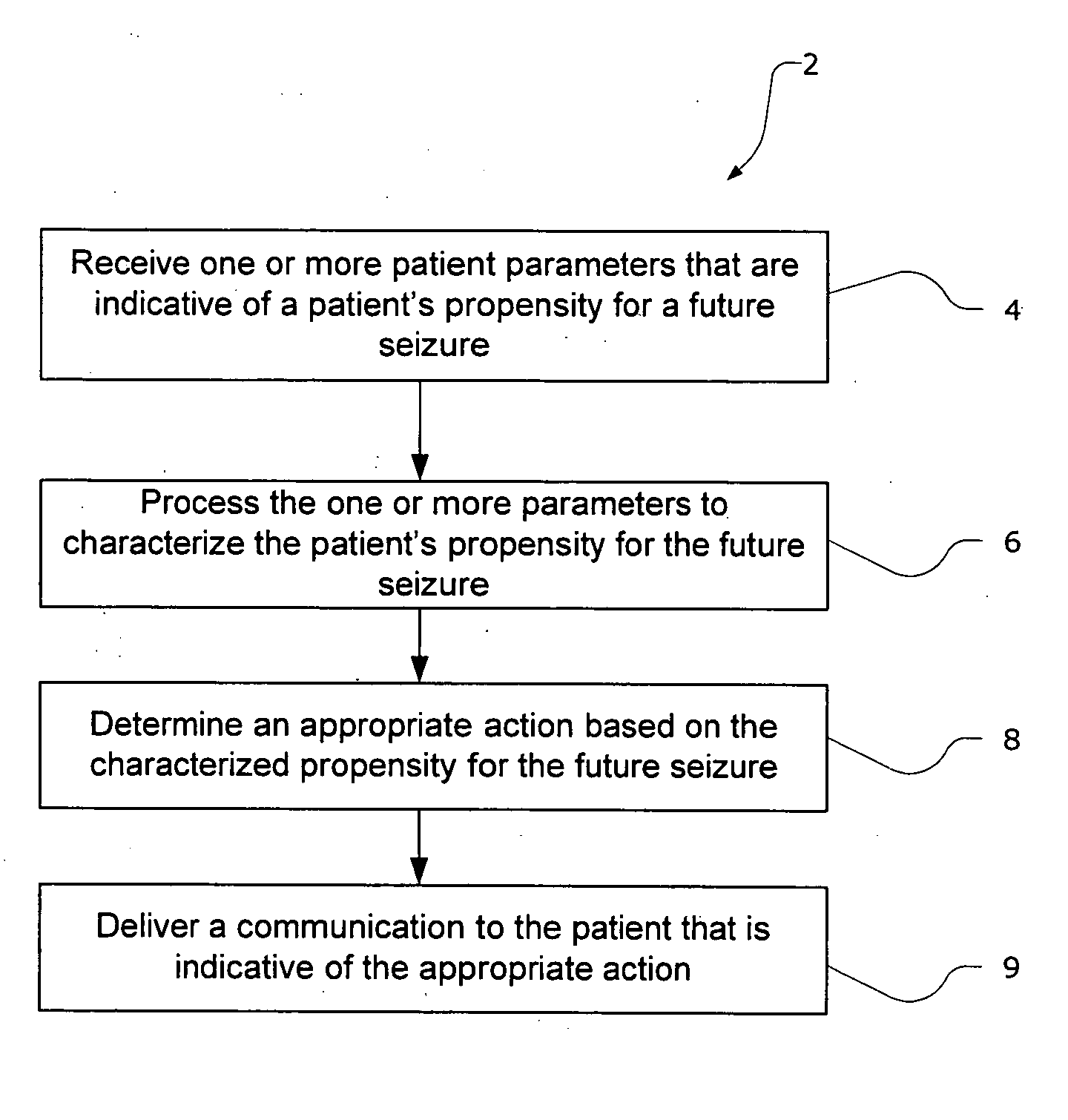

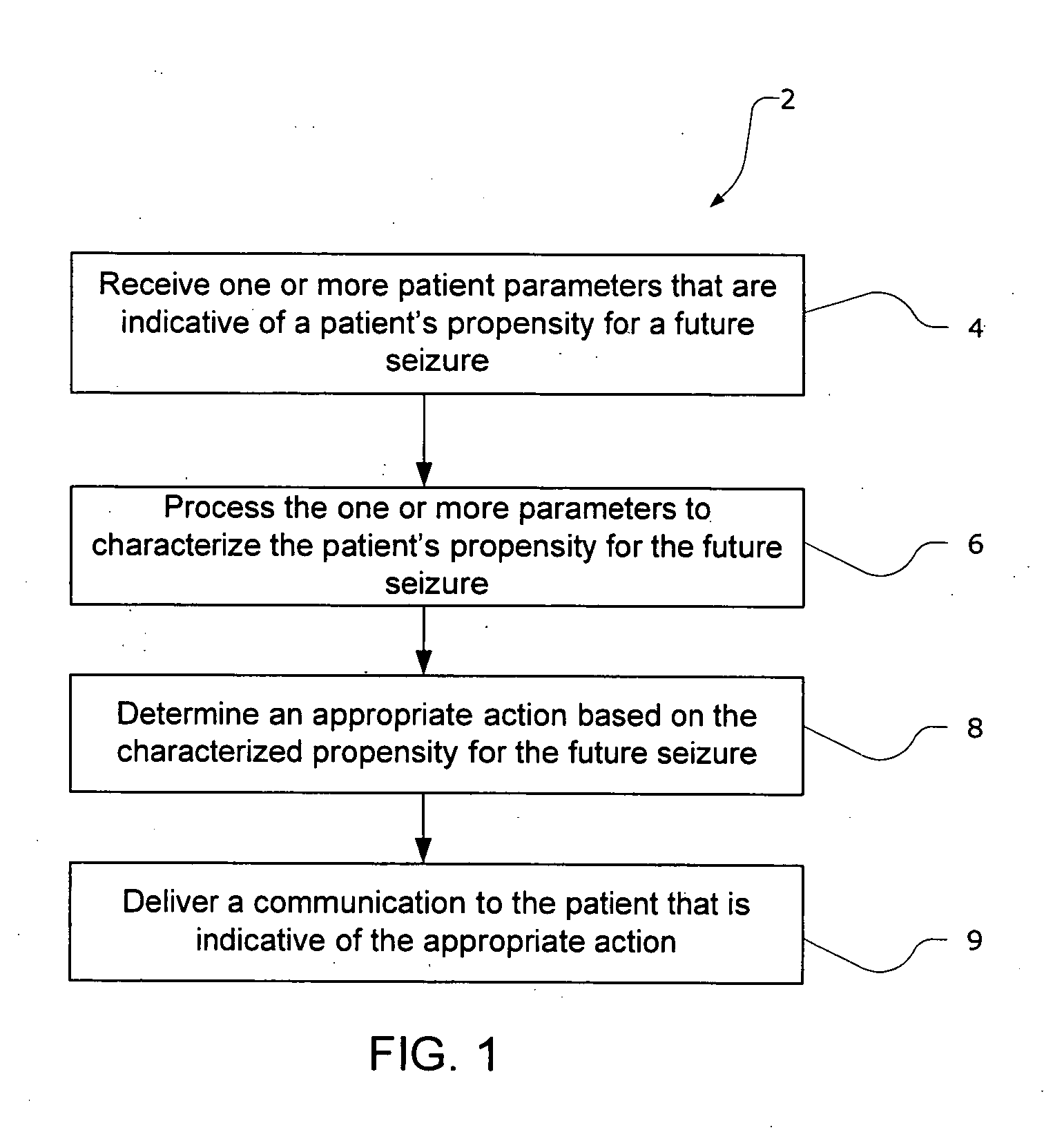

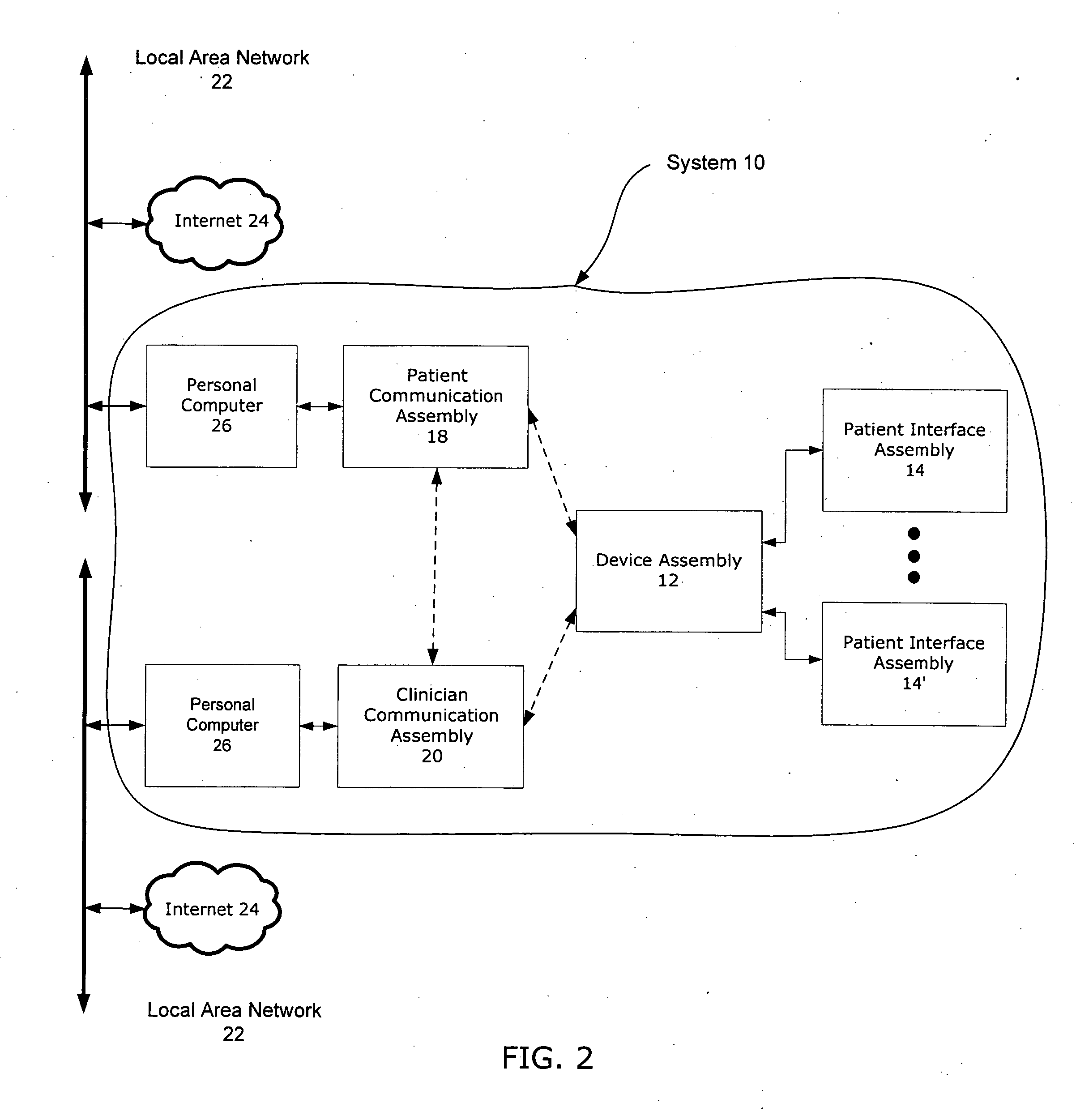

The present invention provides methods and system for managing neurological disorders such as epilepsy. In one embodiment, the method comprises measuring one or more signals from a patient and processing the one or more signals to characterize a patient's propensity for a future seizure. The characterized propensity for the seizure is thereafter used to determine an appropriate action for managing or treating the predicted seizure; and a recommendation is communicated to the patient that is indicative of the appropriate action.

Owner:CYBERONICS INC

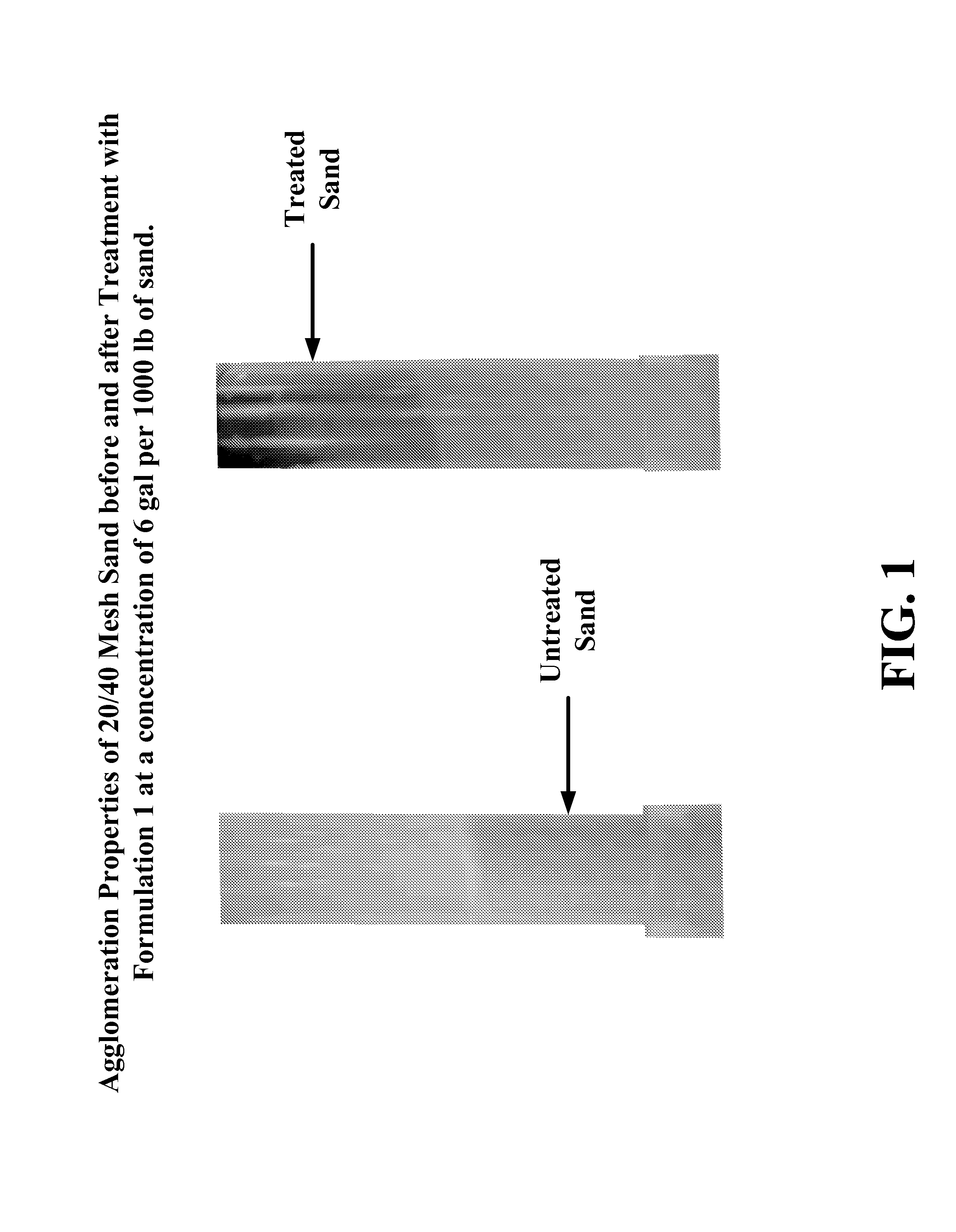

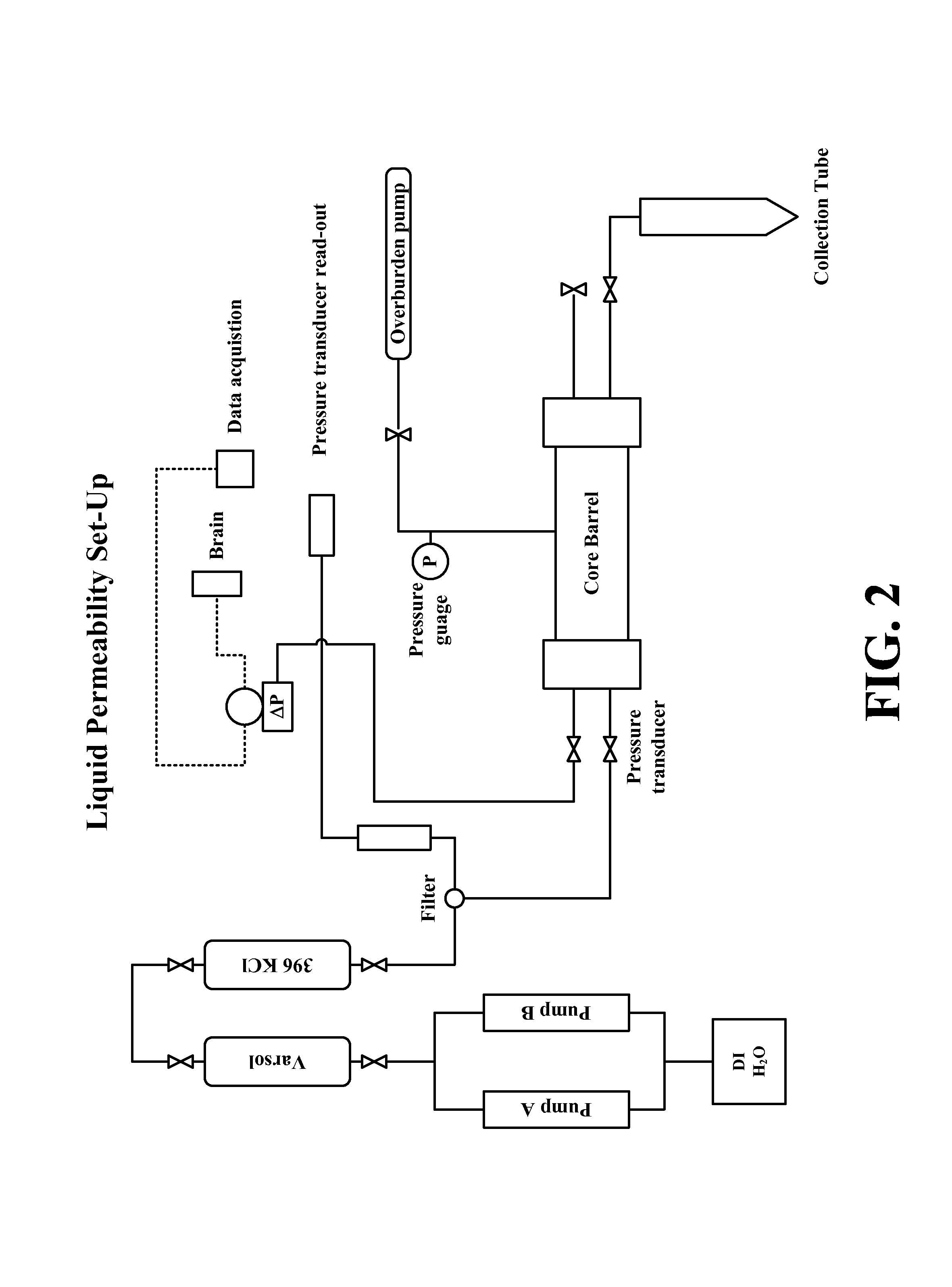

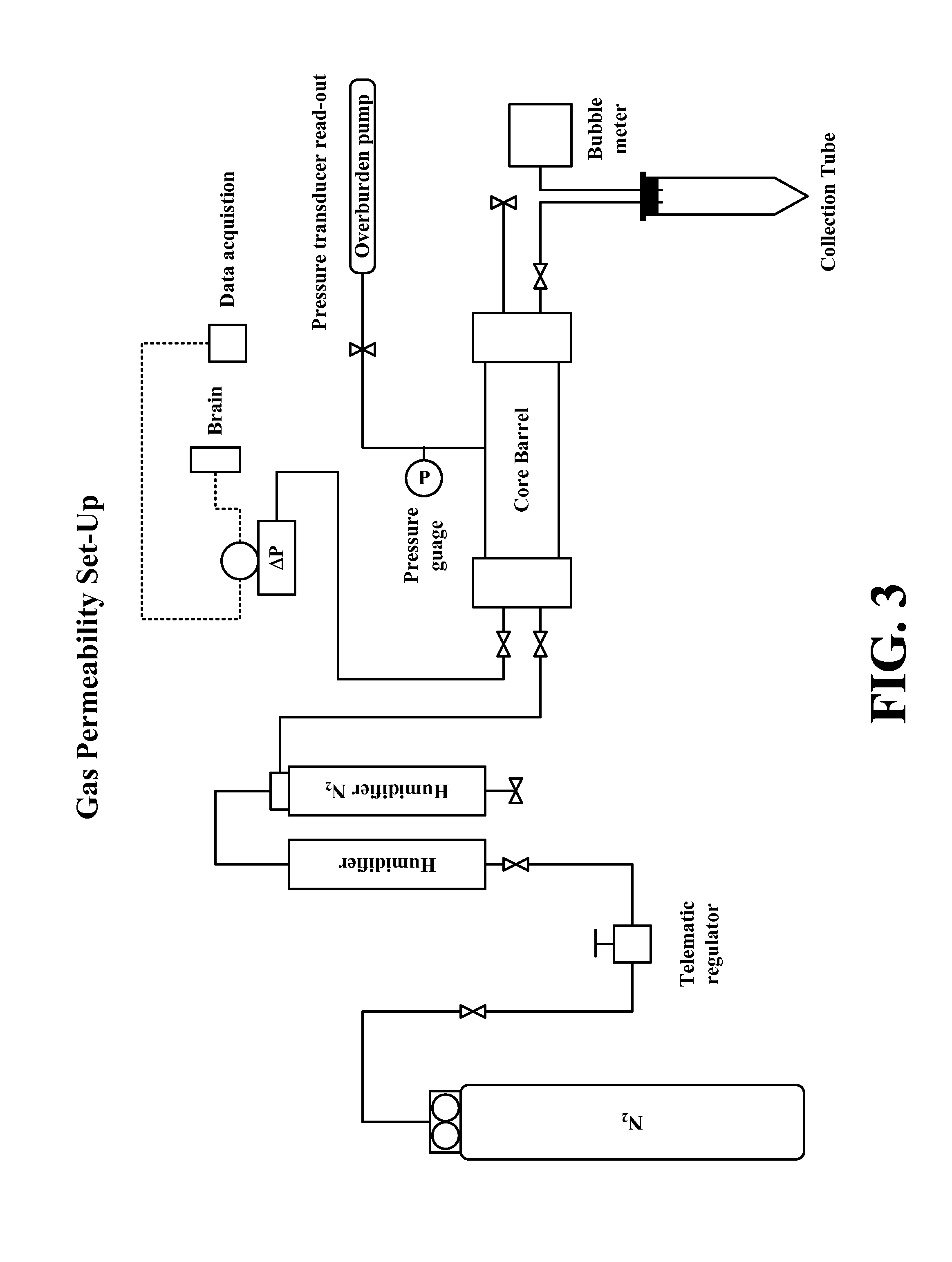

Aggregating reagents, modified particulate metal-oxides, and methods for making and using same

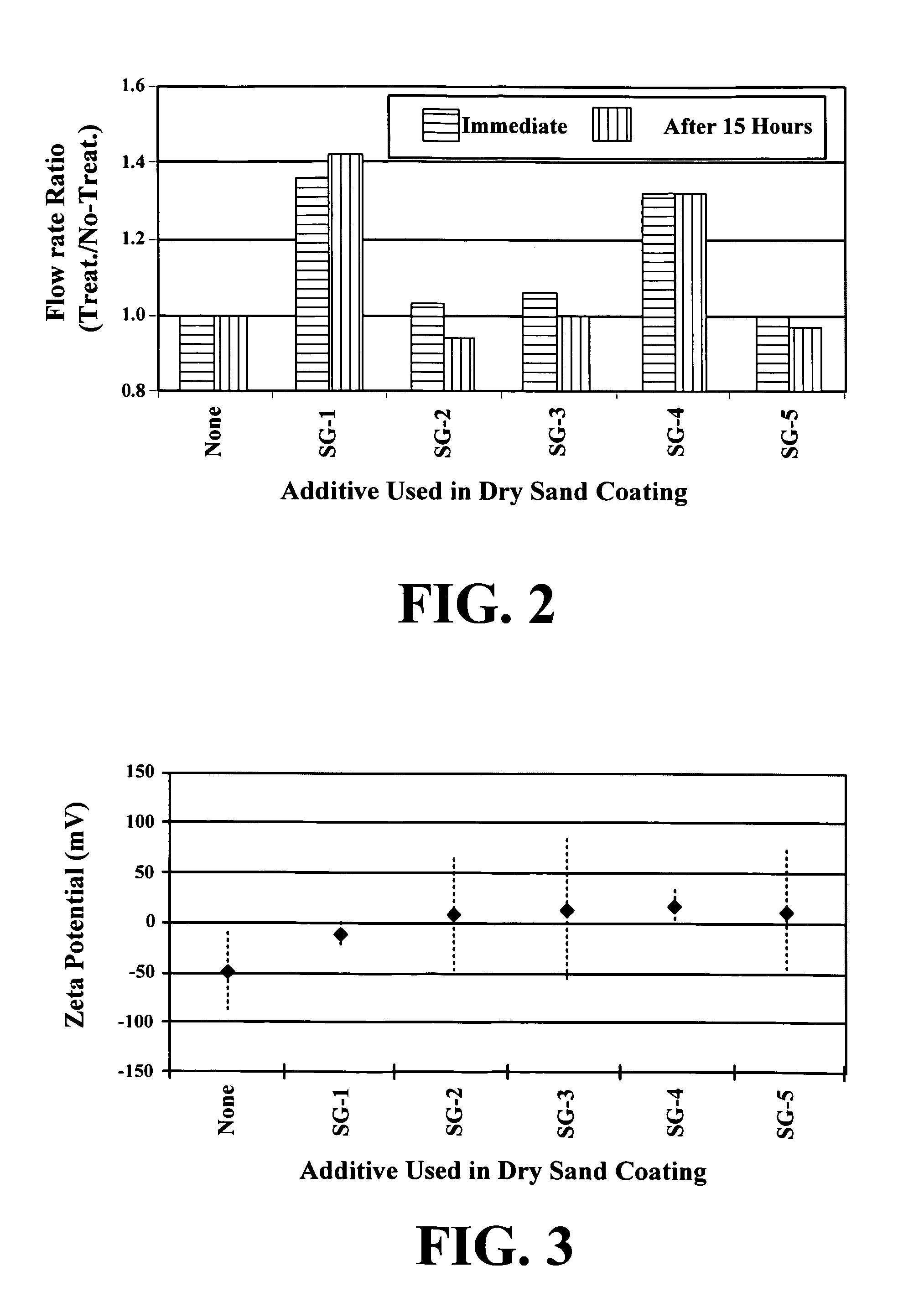

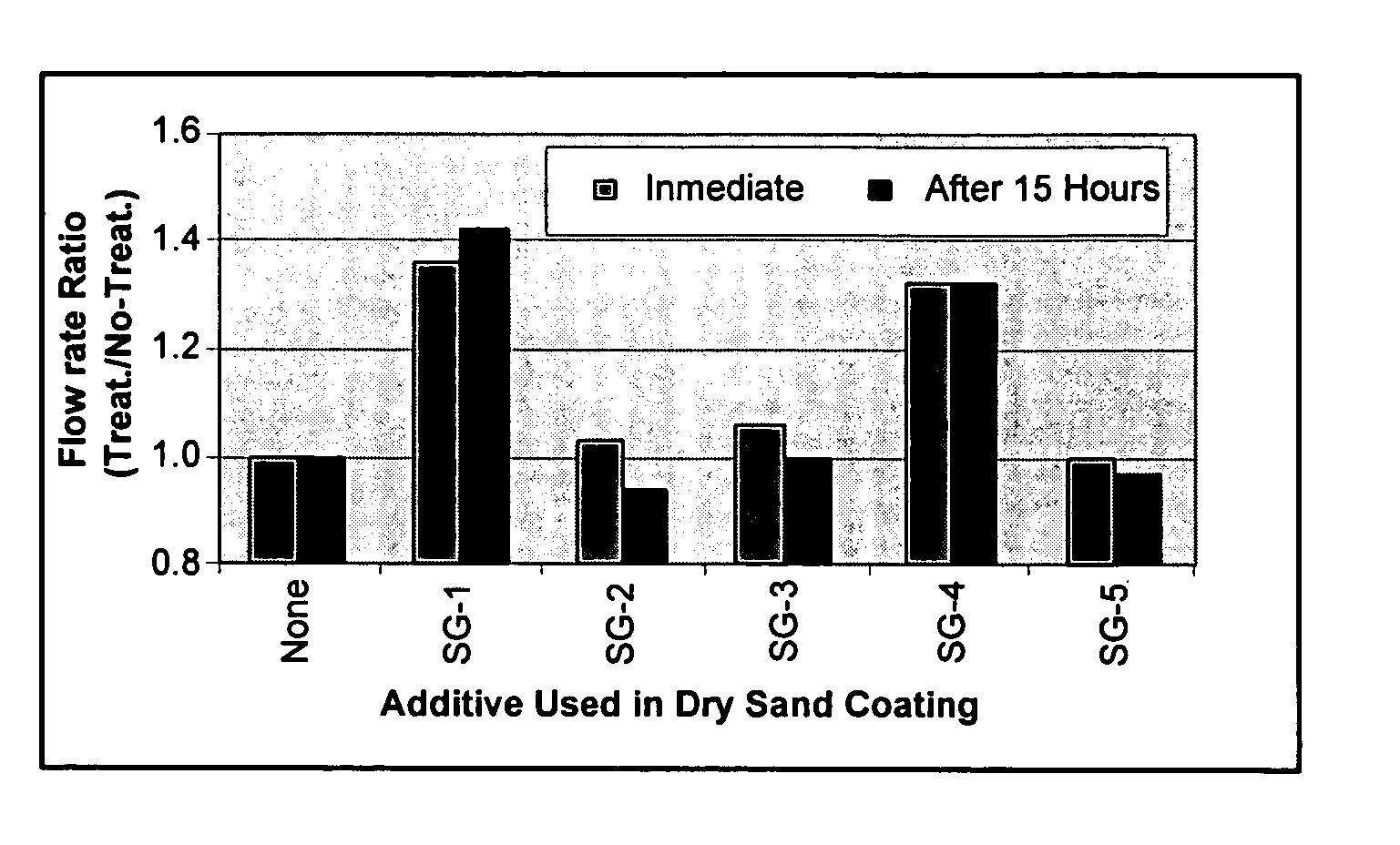

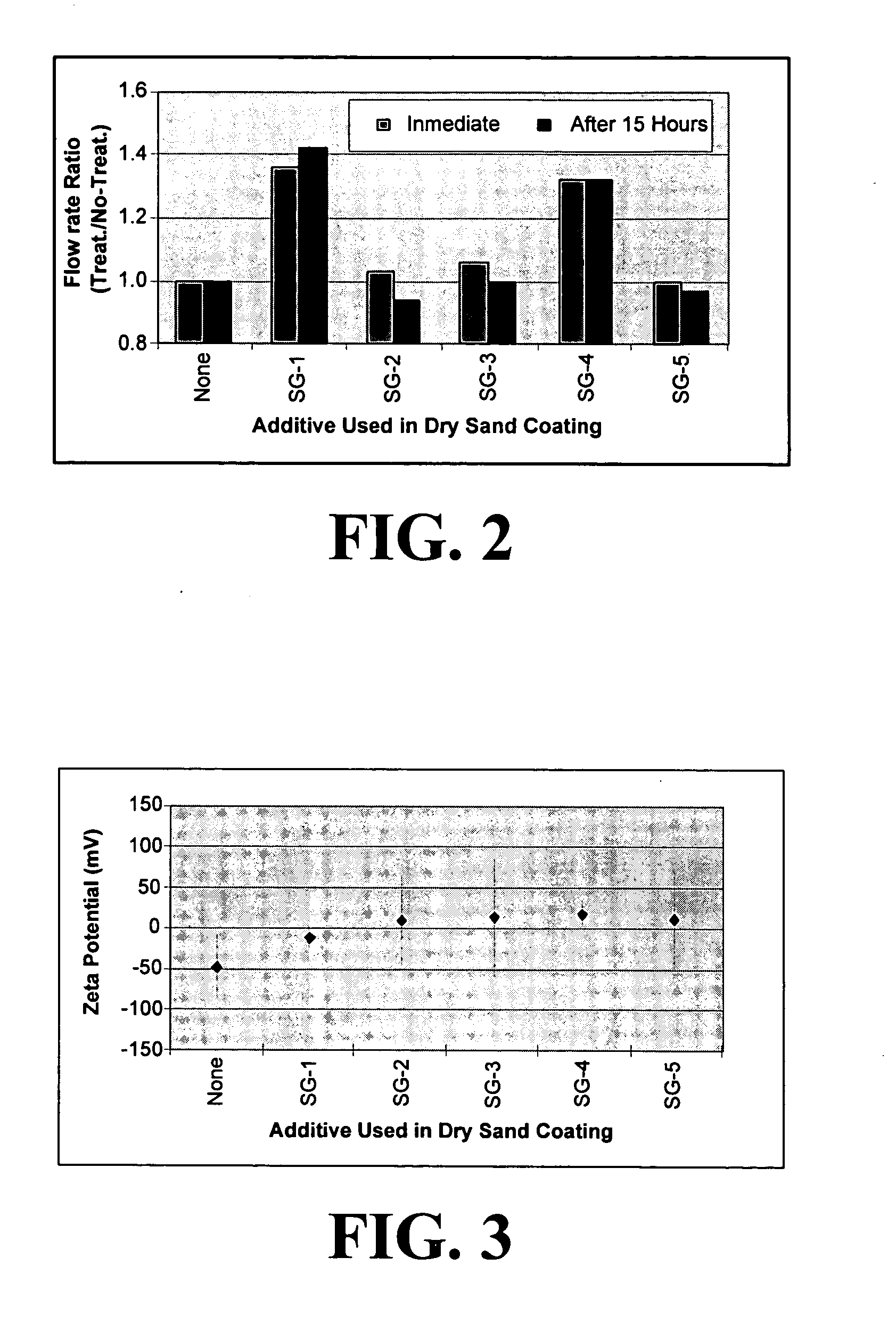

ActiveUS7392847B2Improved self-aggregating propertyIncrease propensityBiocideLiquid/gas jet drillingParticulate metalMaterials science

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

Aggregating reagents, modified particulate metal-oxides, and methods for making and using same

ActiveUS20070131425A1Improved self-aggregating propertyIncrease propensityBiocideLiquid/gas jet drillingParticulate metalMaterials science

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

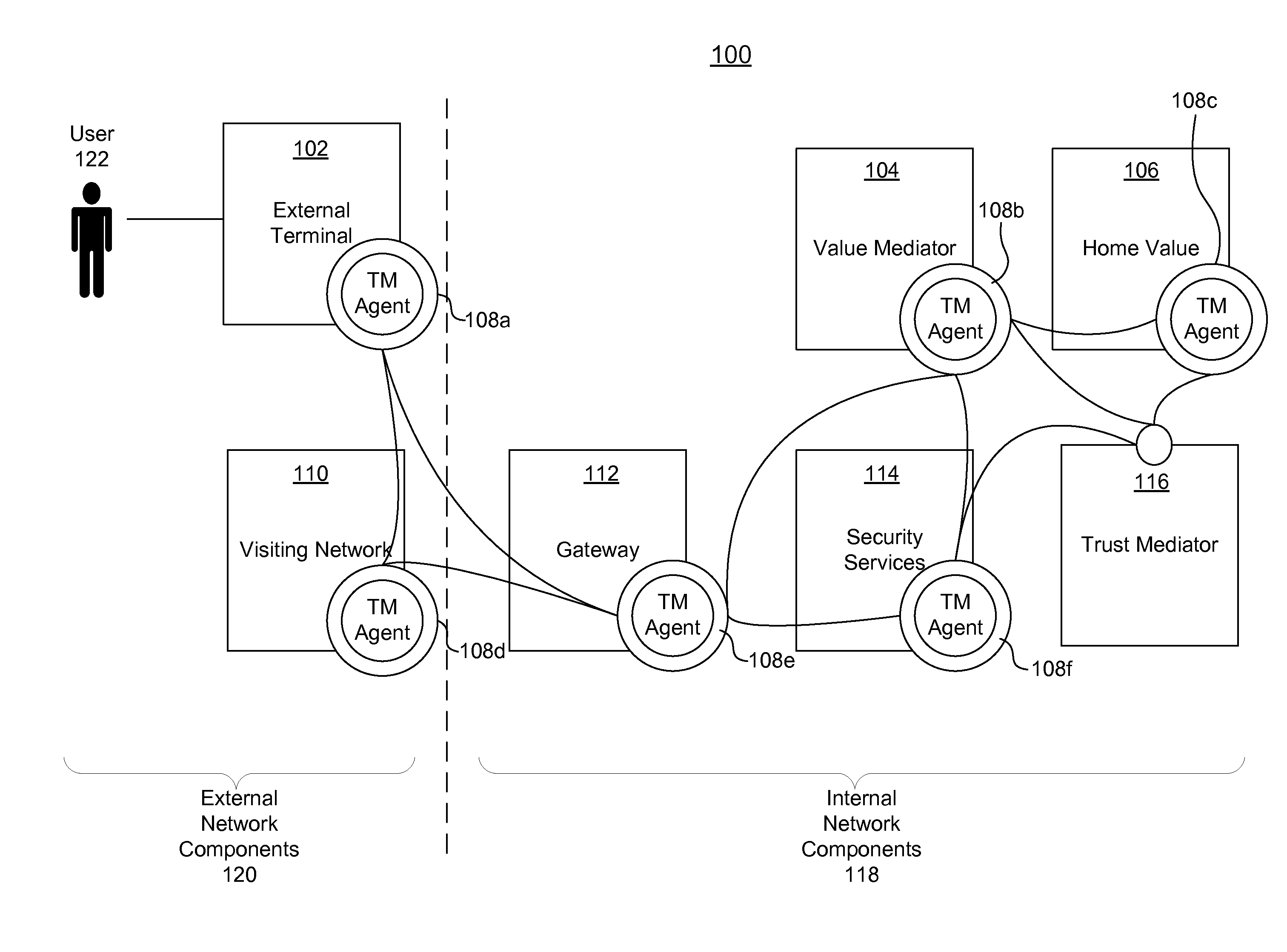

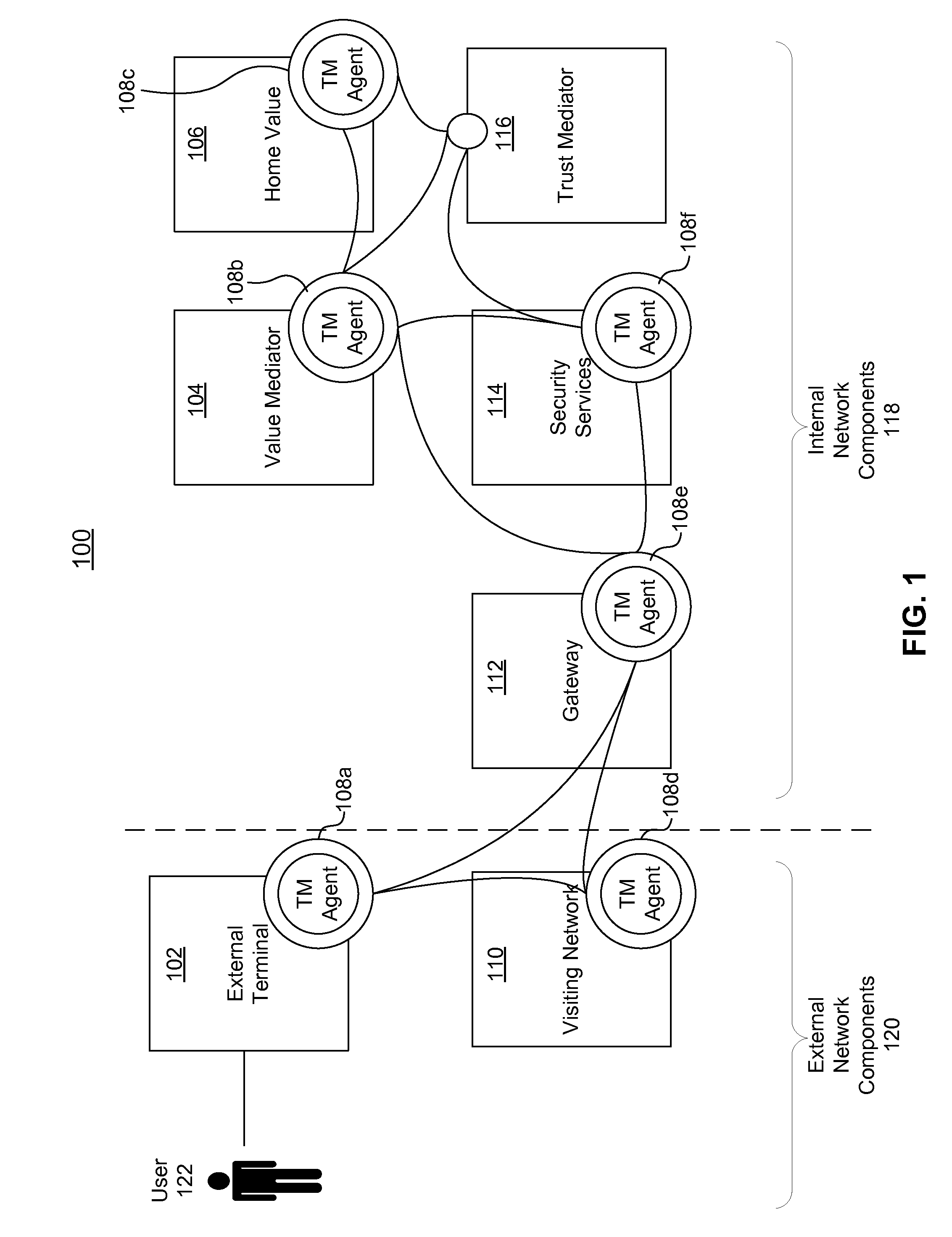

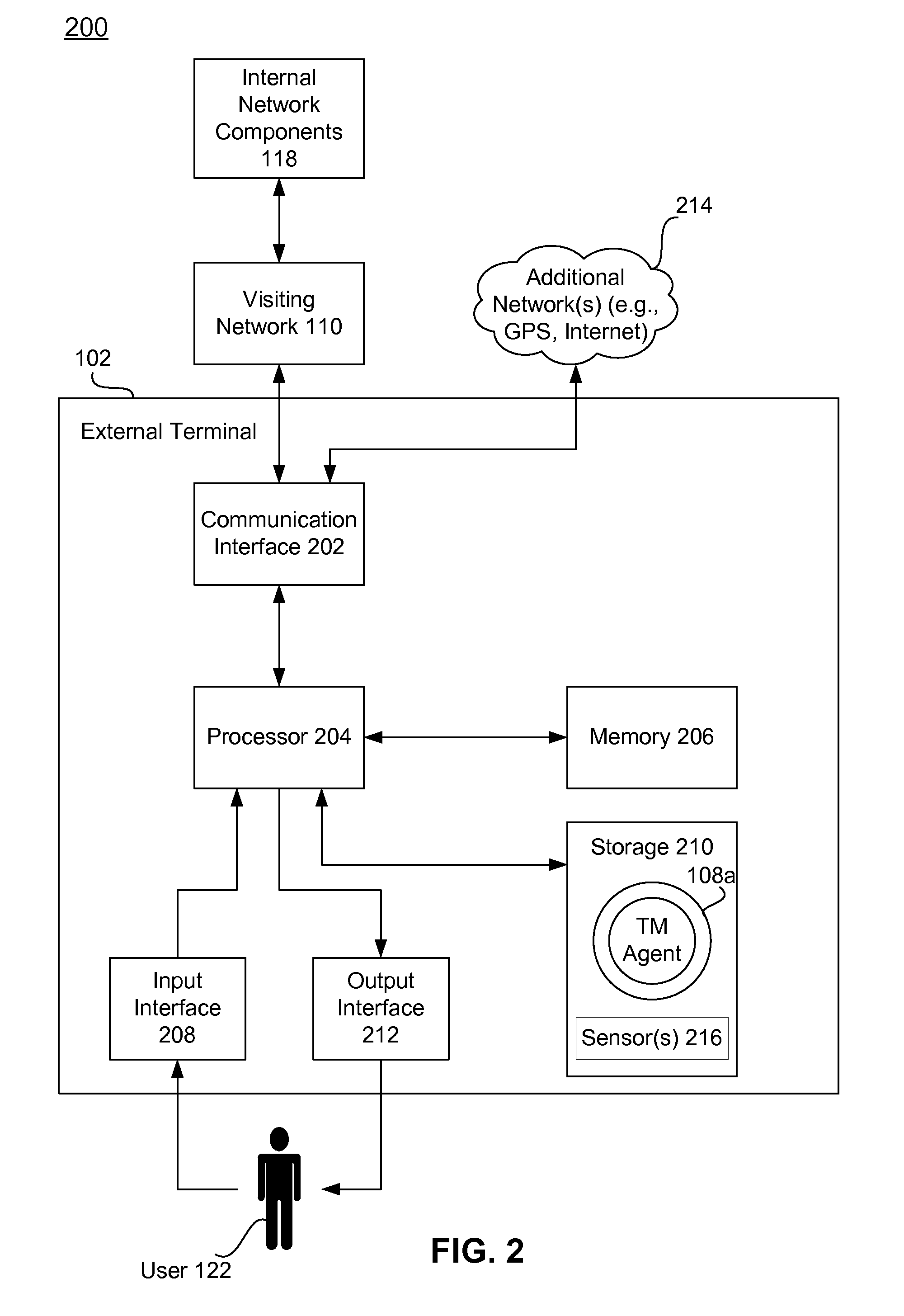

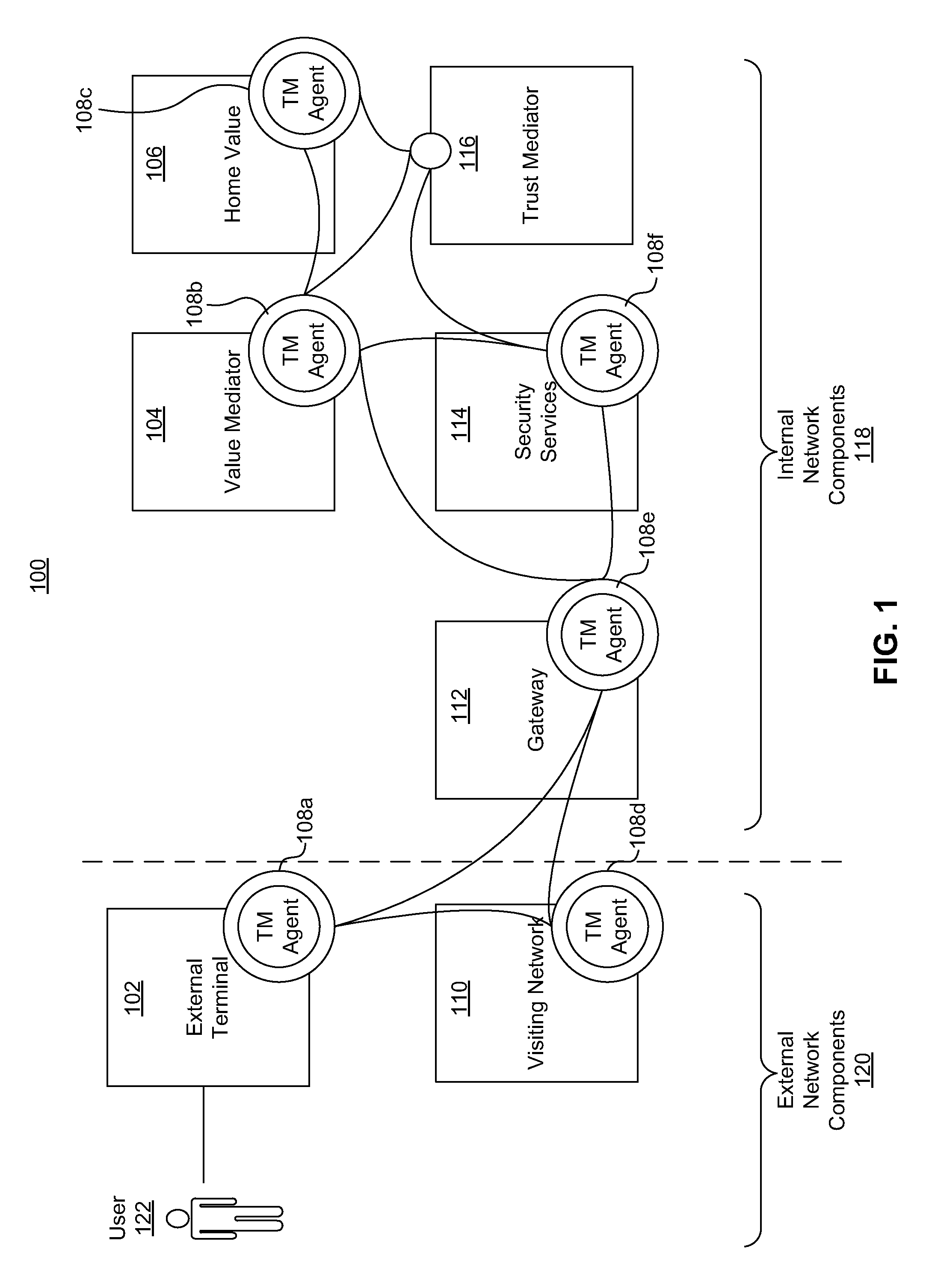

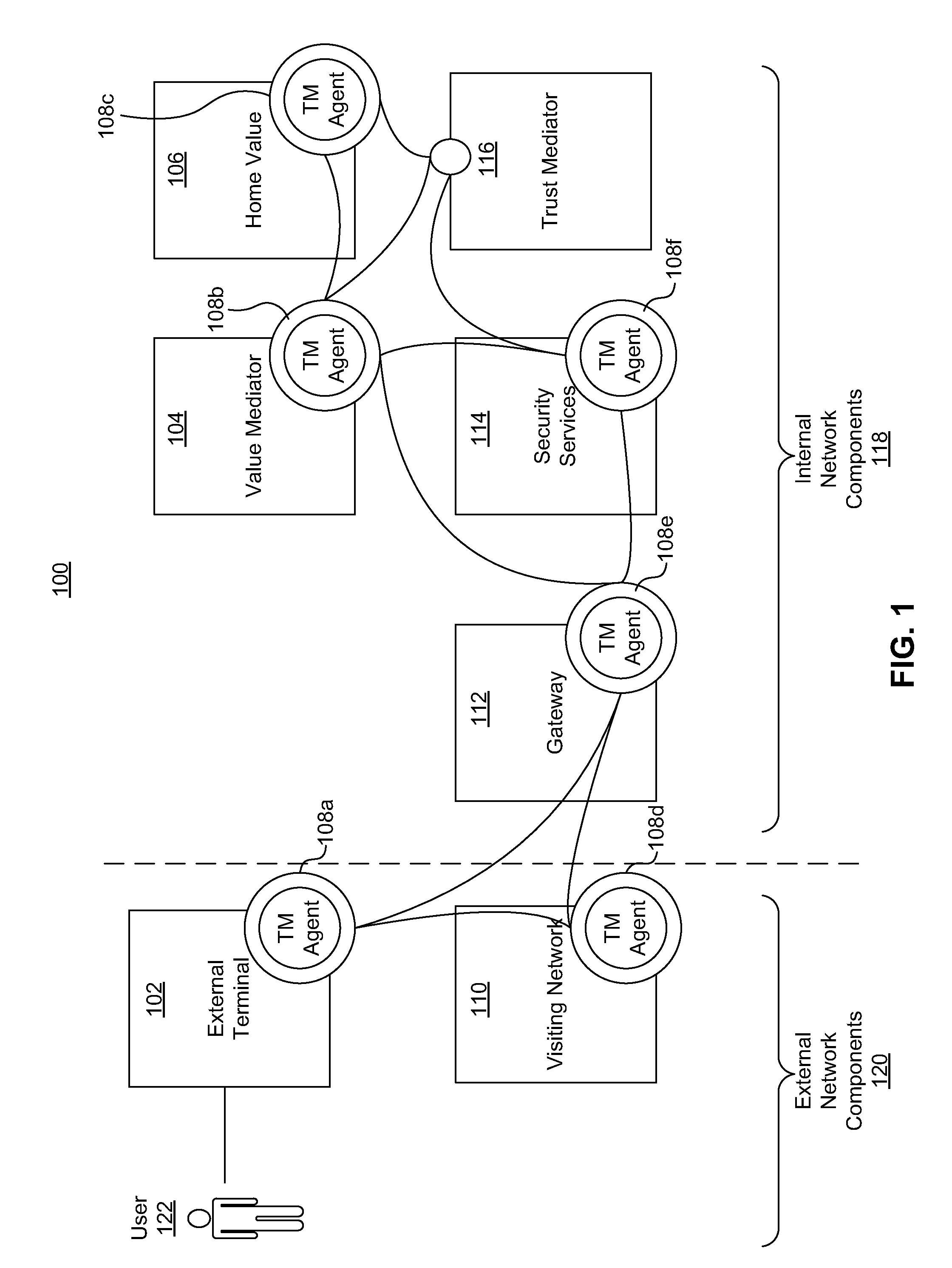

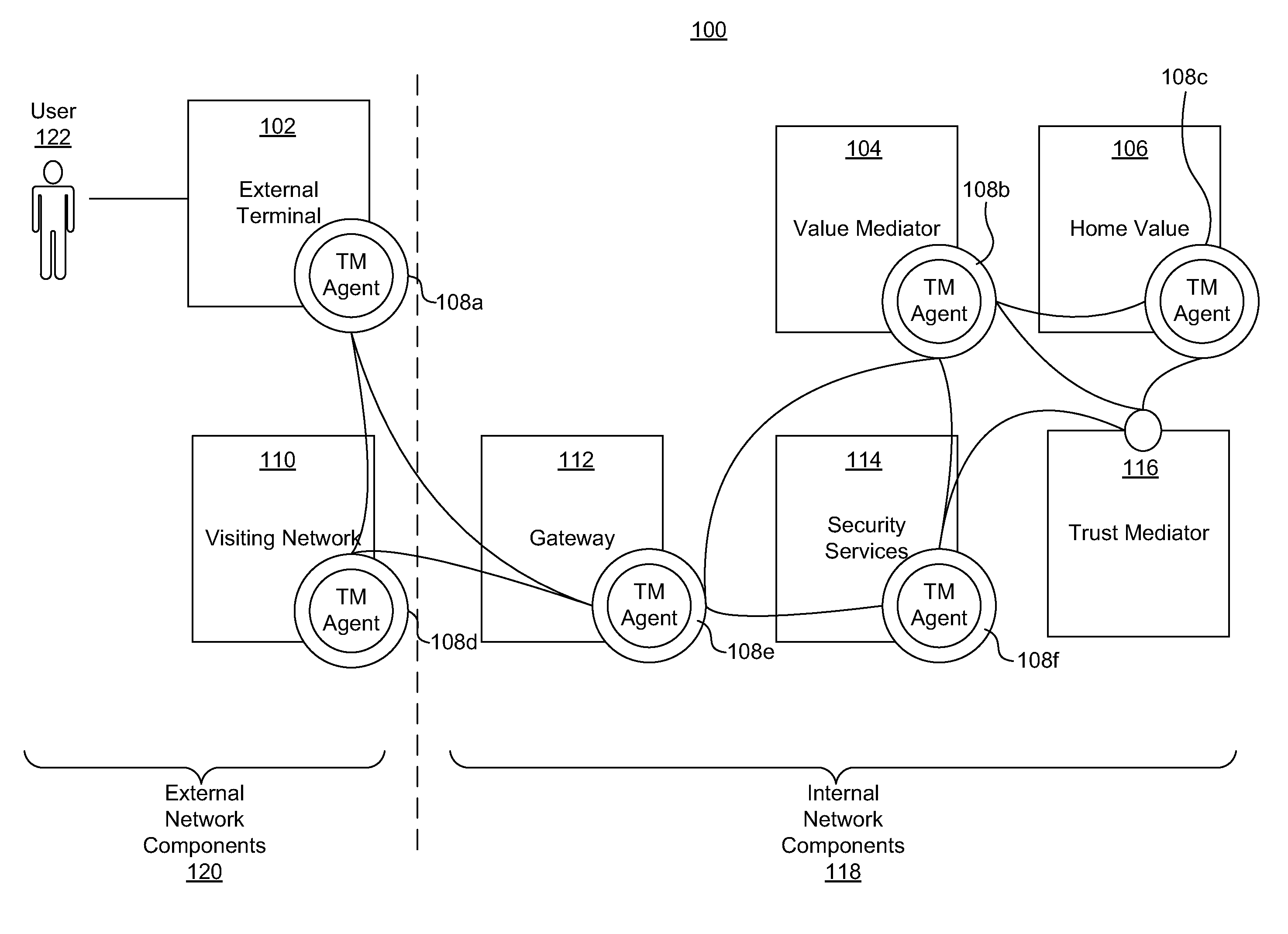

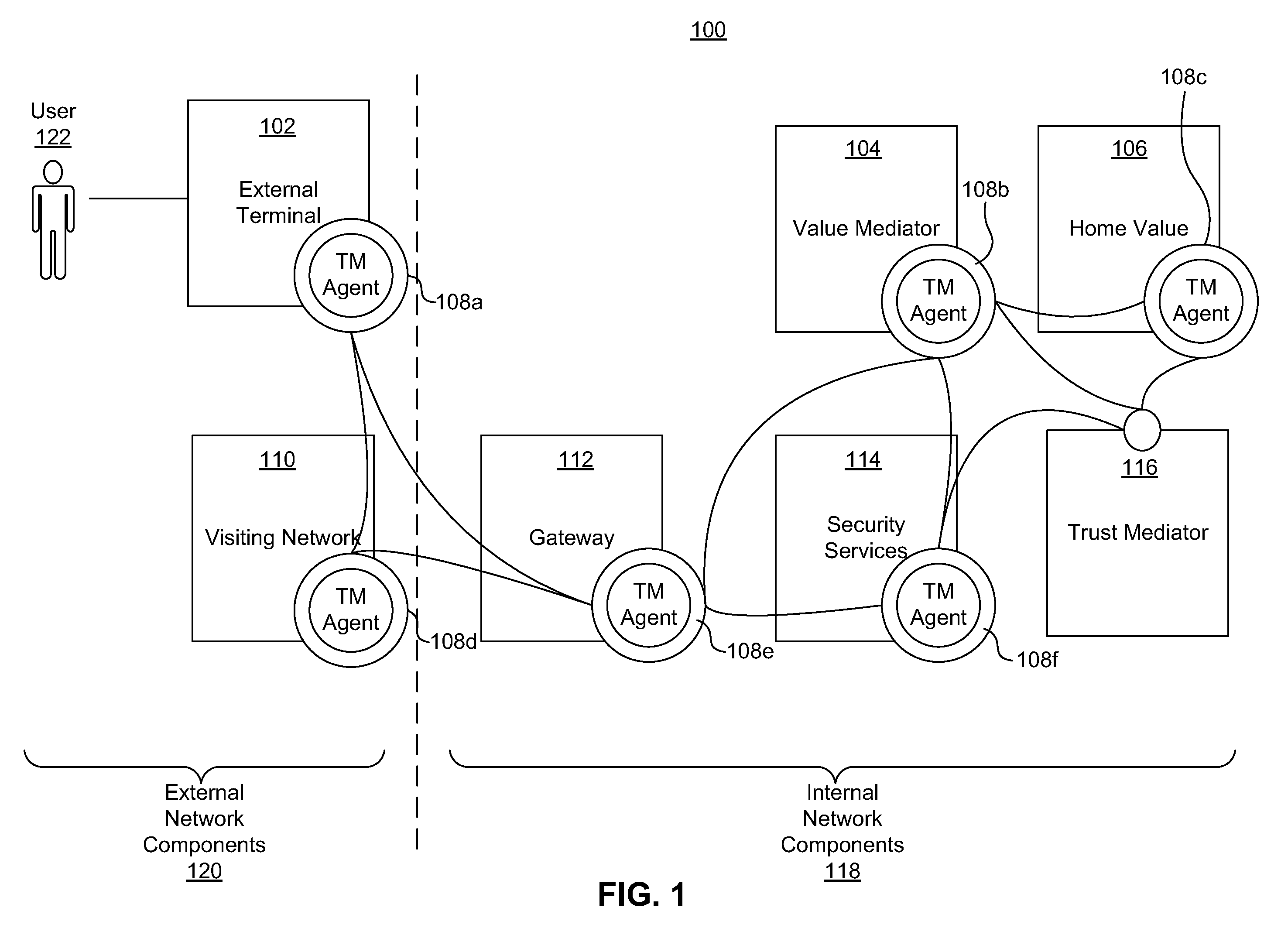

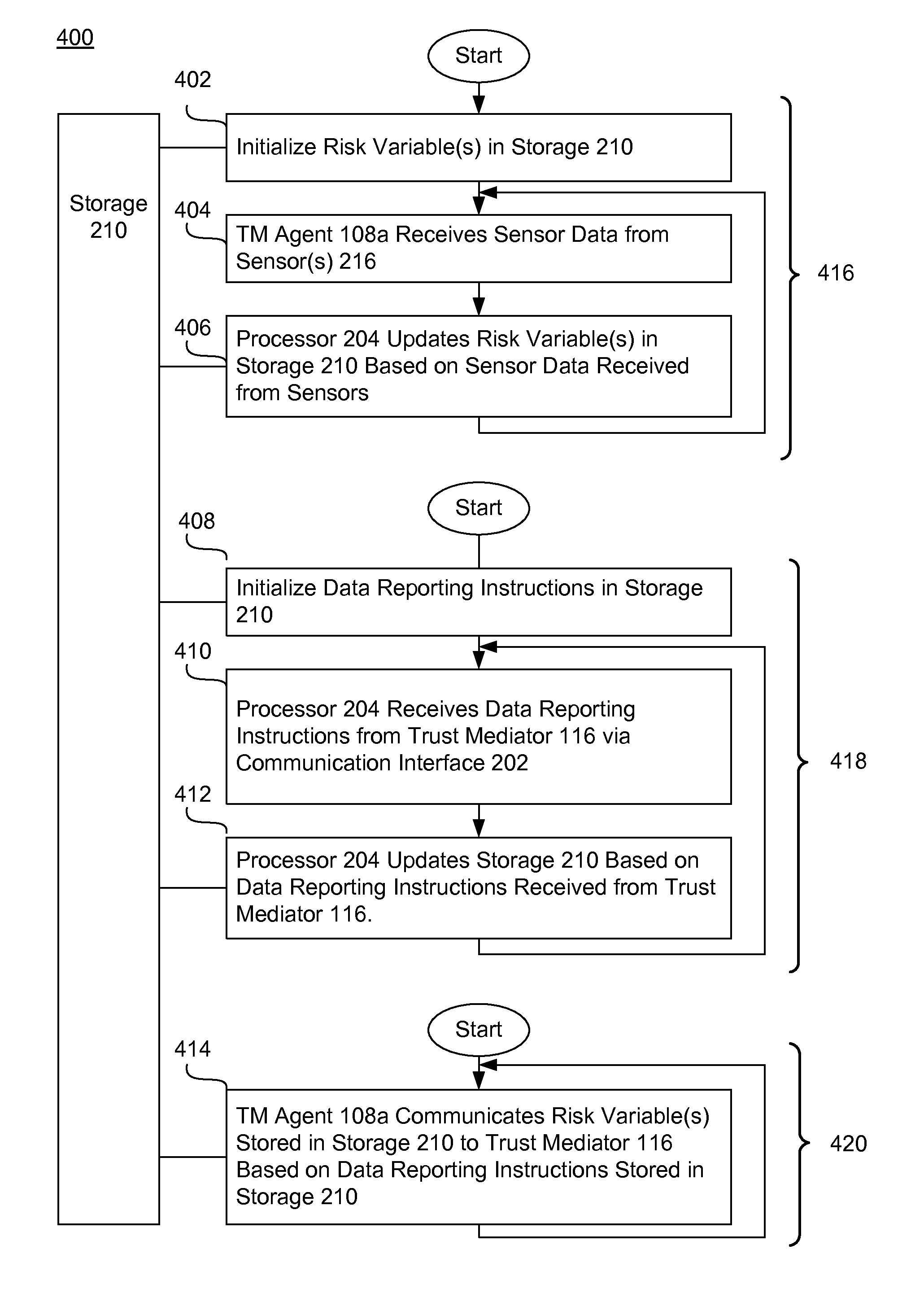

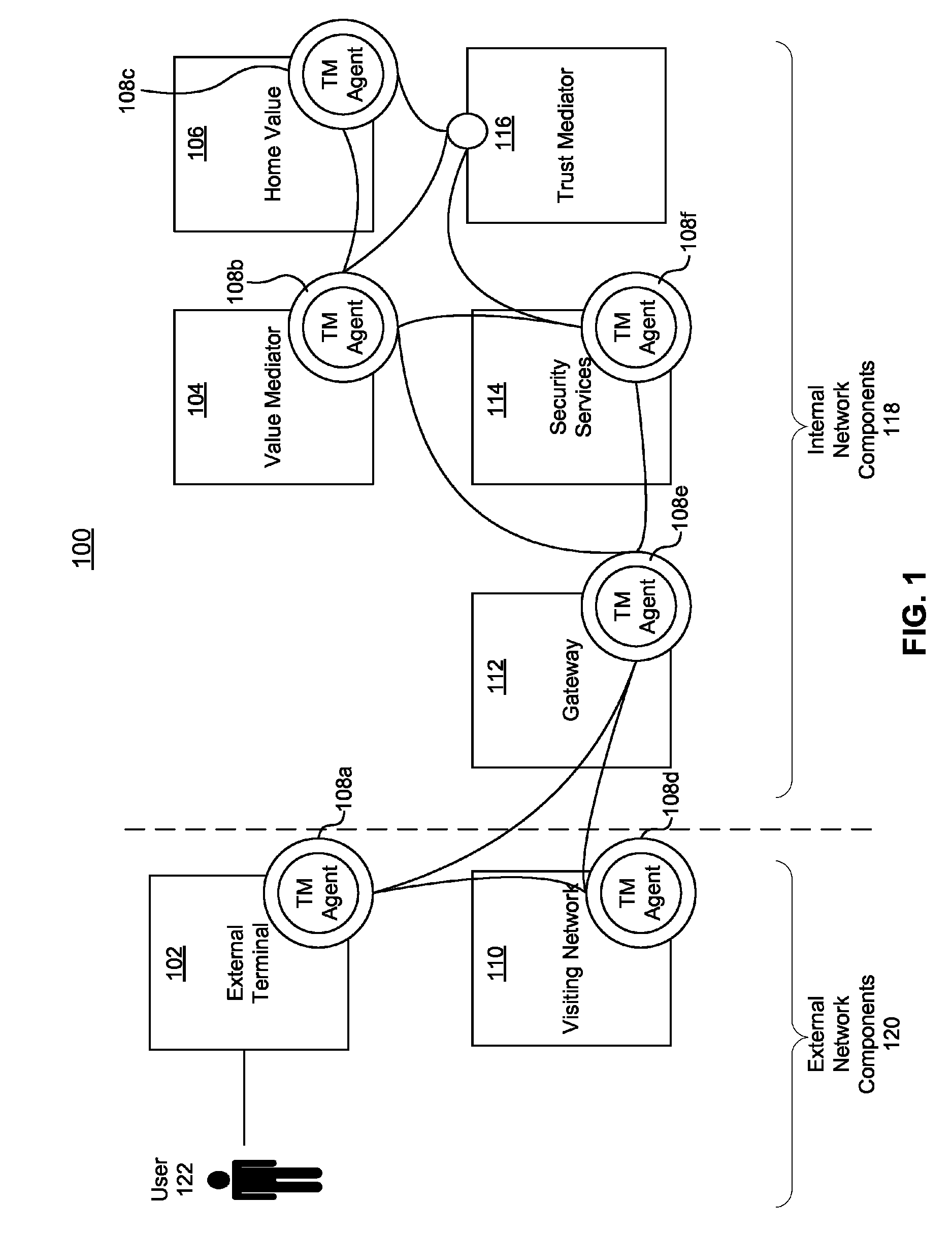

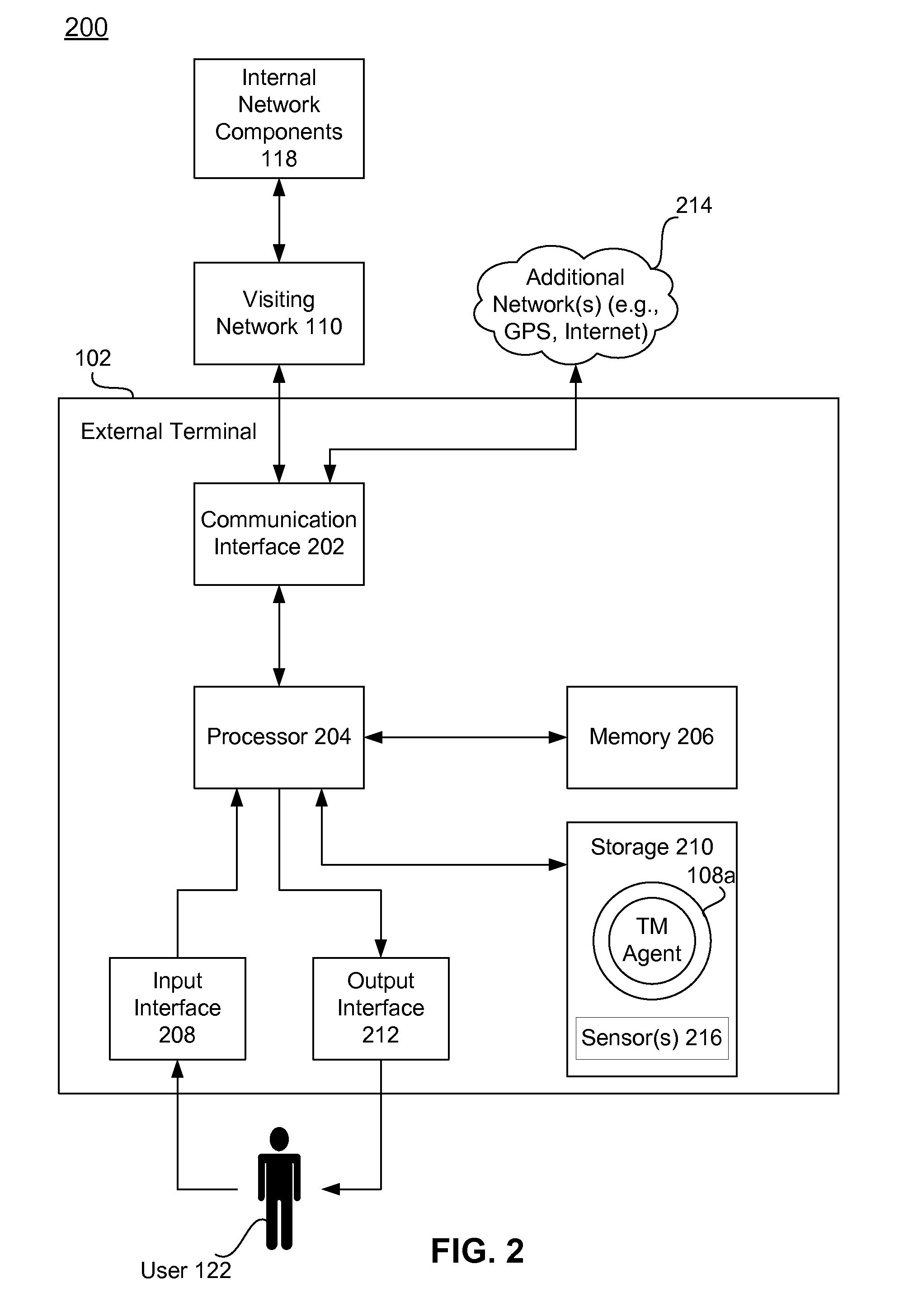

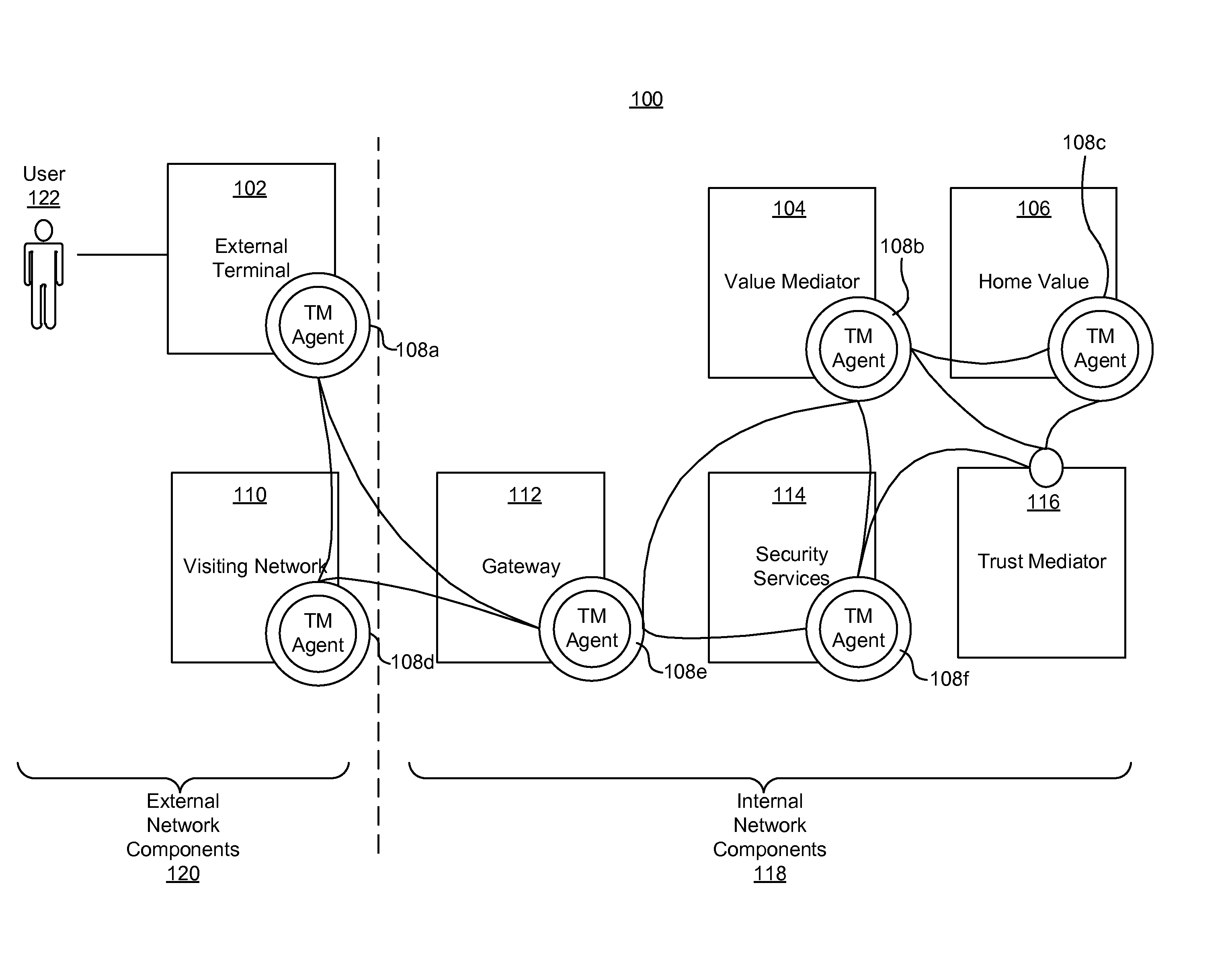

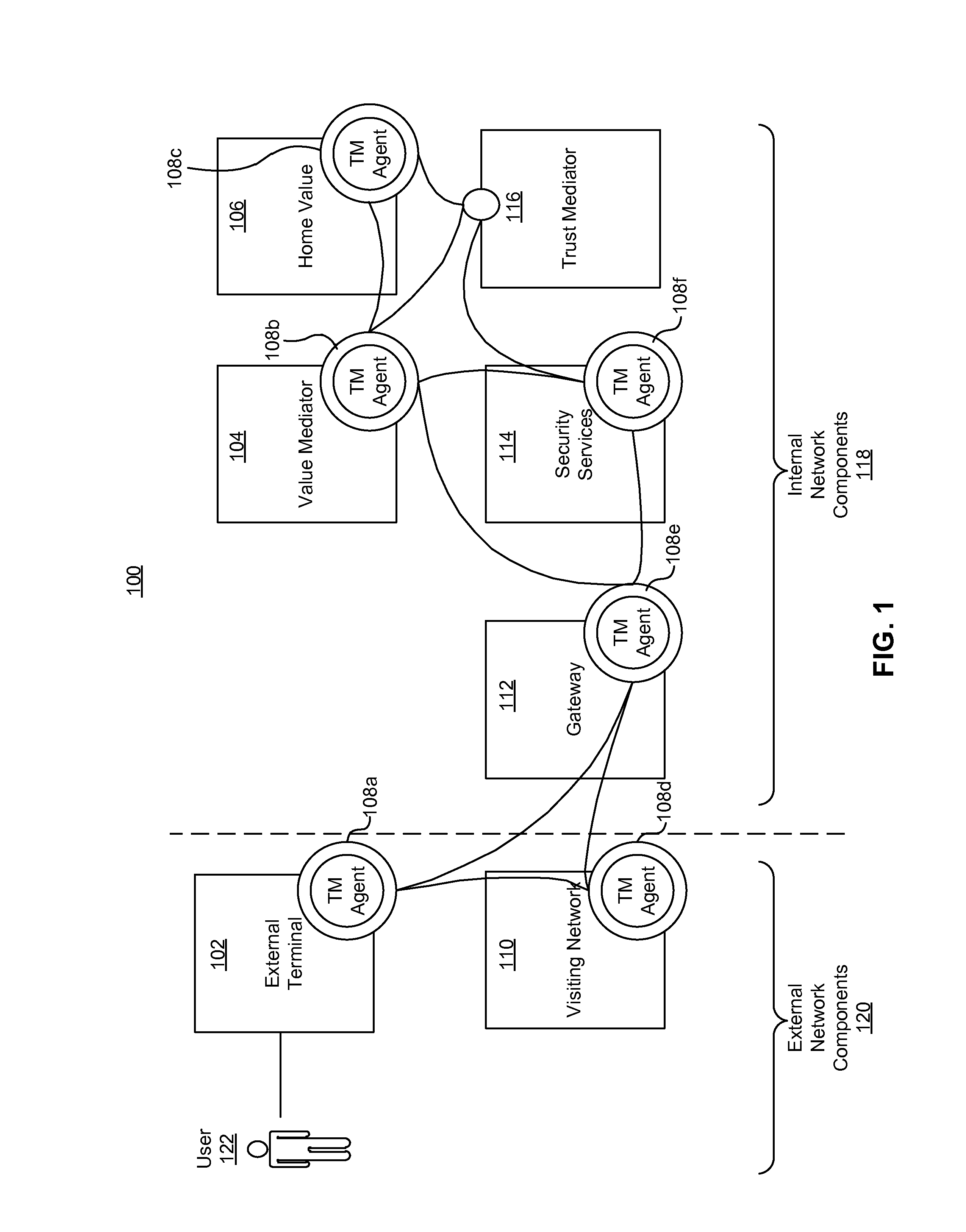

Systems, methods, and computer program products for collecting and reporting sensor data in a communication network

ActiveUS20110154497A1Shorten the time to marketIncrease propensityFinanceMemory loss protectionComputer networkEngineering

A system for collecting and reporting sensor data in a communication network includes a microprocessor coupled to a memory and an electronic storage device. The microprocessor receives sensor data from sensors, and stores the sensor data for each sensor in the electronic storage device. The microprocessor also receives, via the communication network, a data reporting instruction defining a data reporting technique corresponding to the sensor data associated with one or more of the sensors. The data reporting instruction is stored in the electronic storage device, and the microprocessor transmits, to a trust mediator over the communication network, at least a portion of the sensor data based on the data reporting instruction. The trust mediator maintains an acceptable level of security for data throughout the communication network by adjusting security safeguards based on the sensor data.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

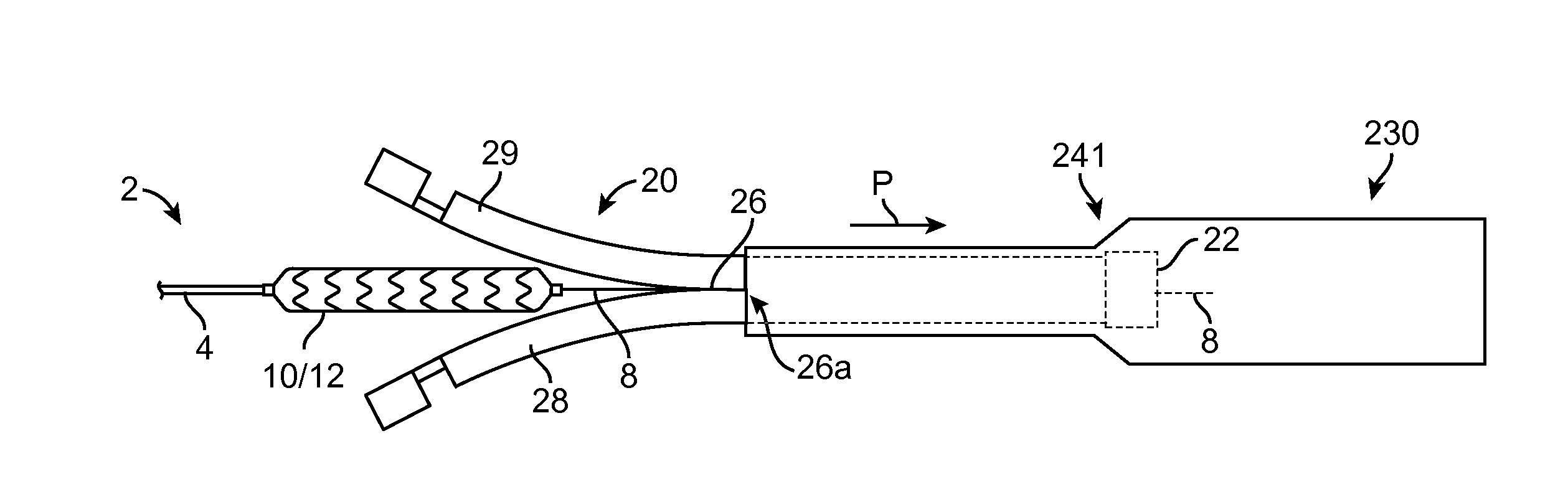

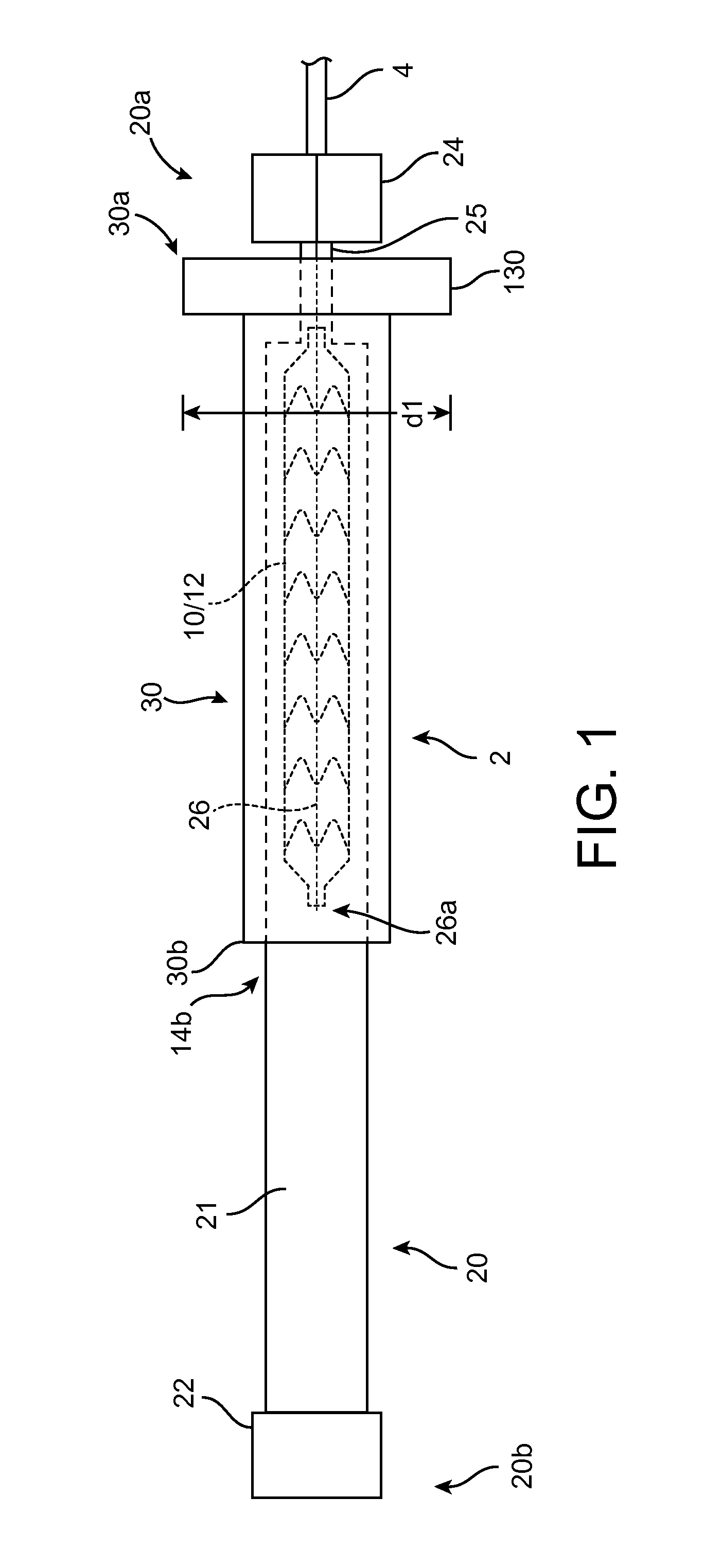

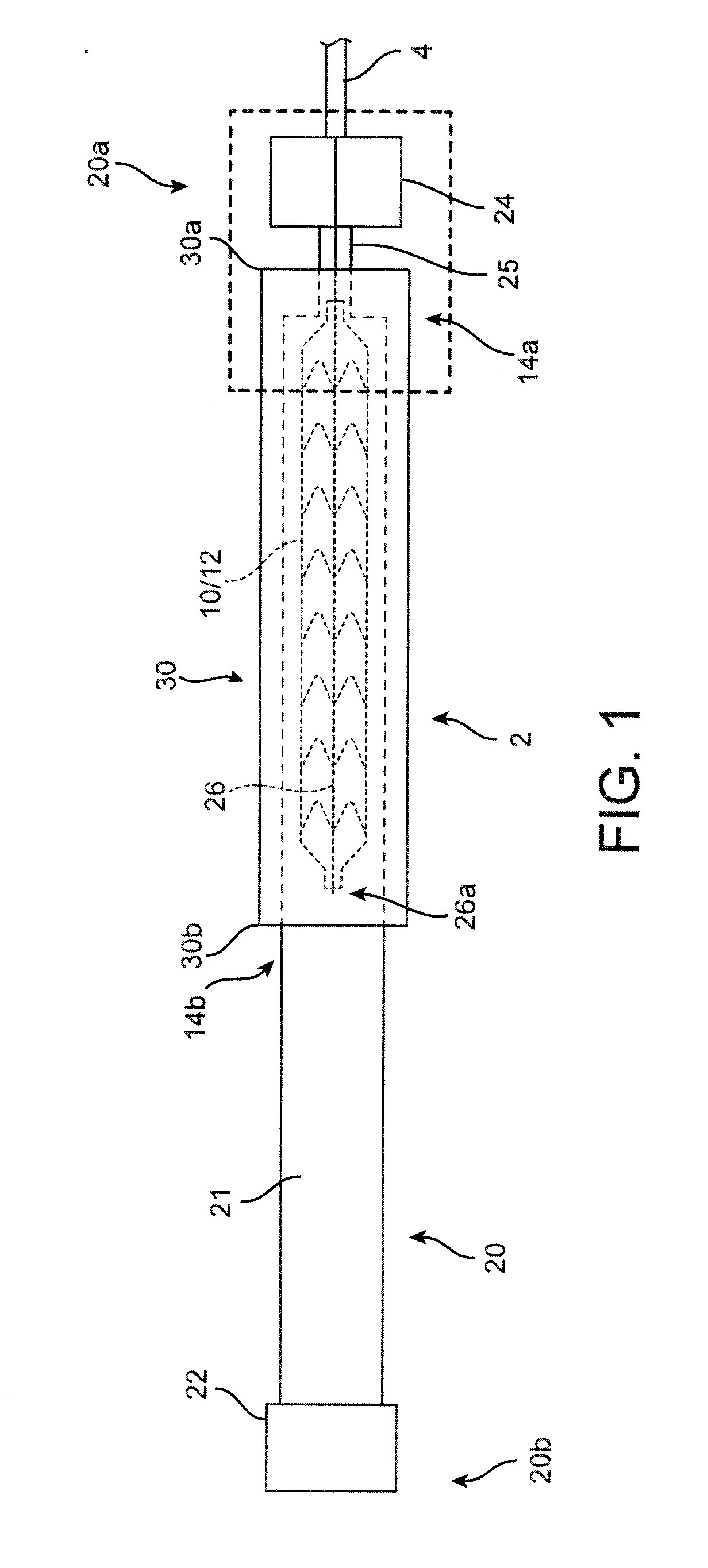

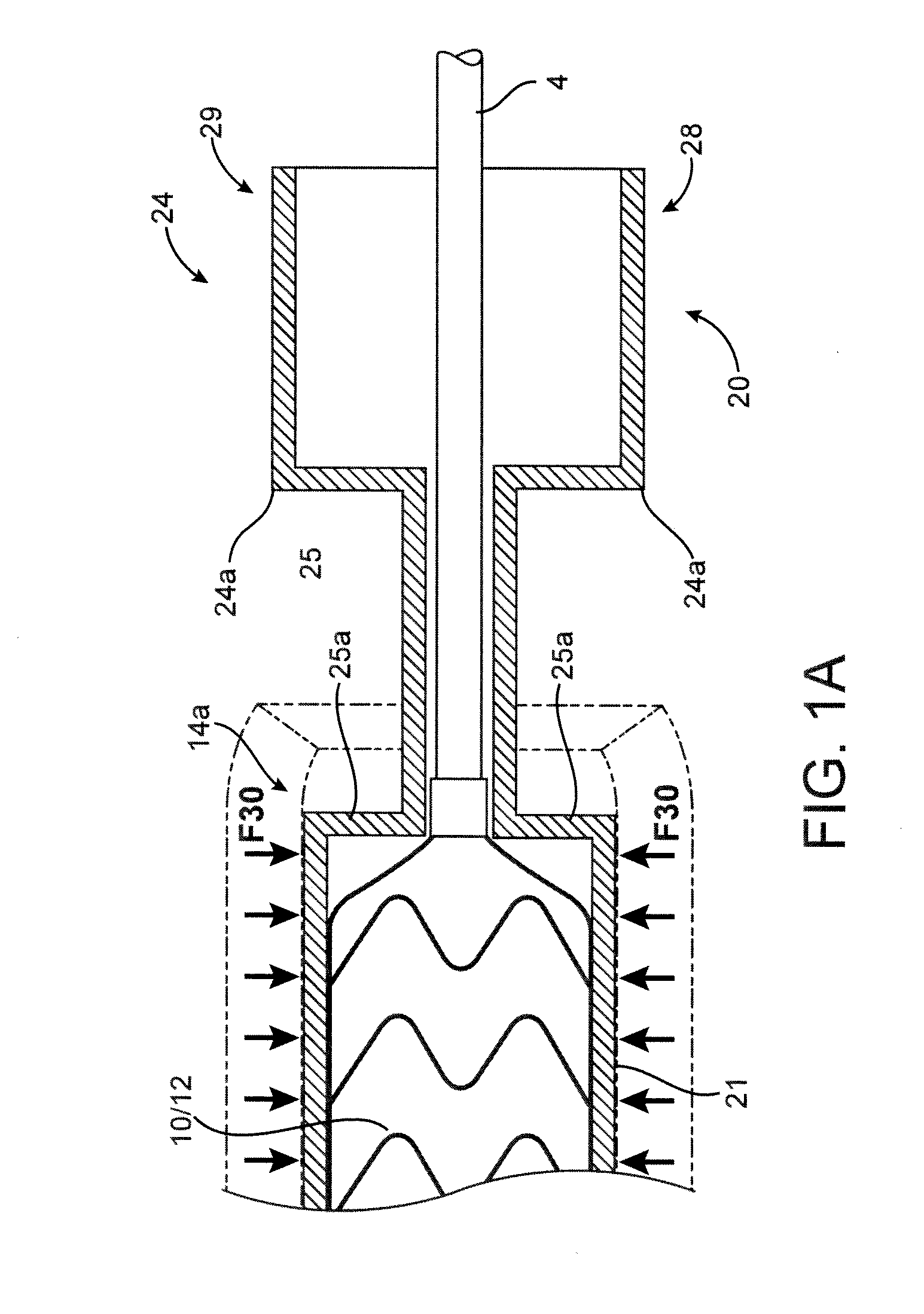

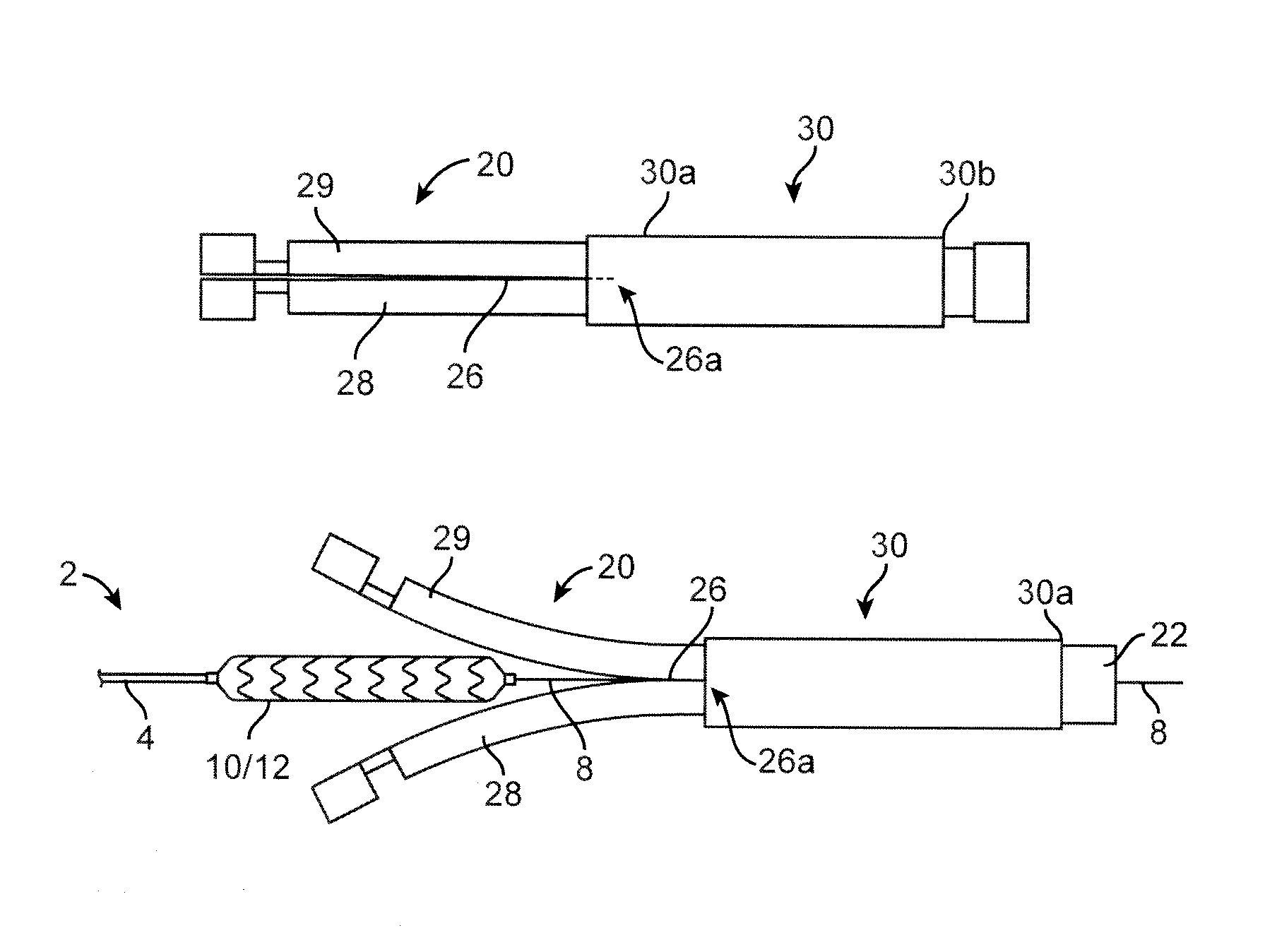

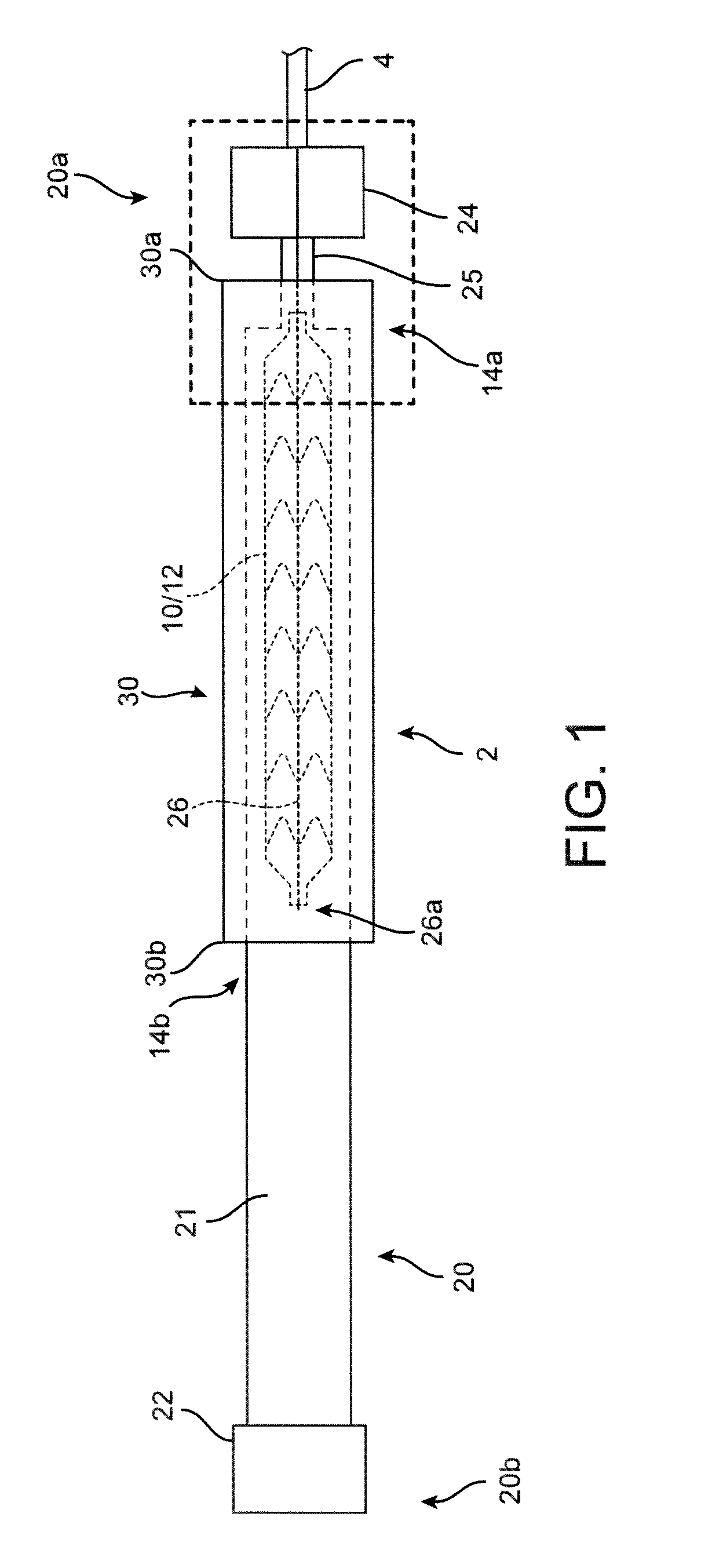

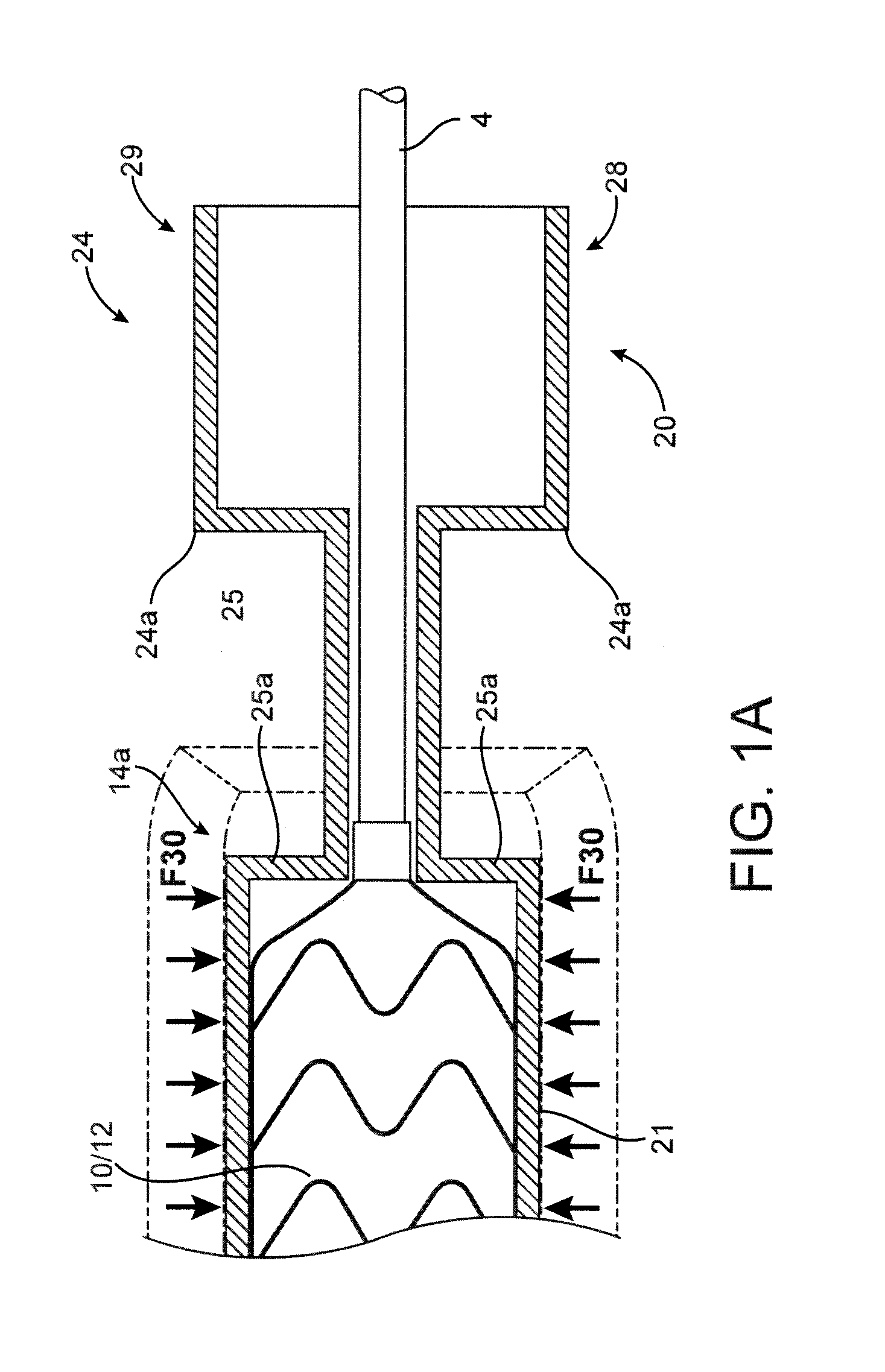

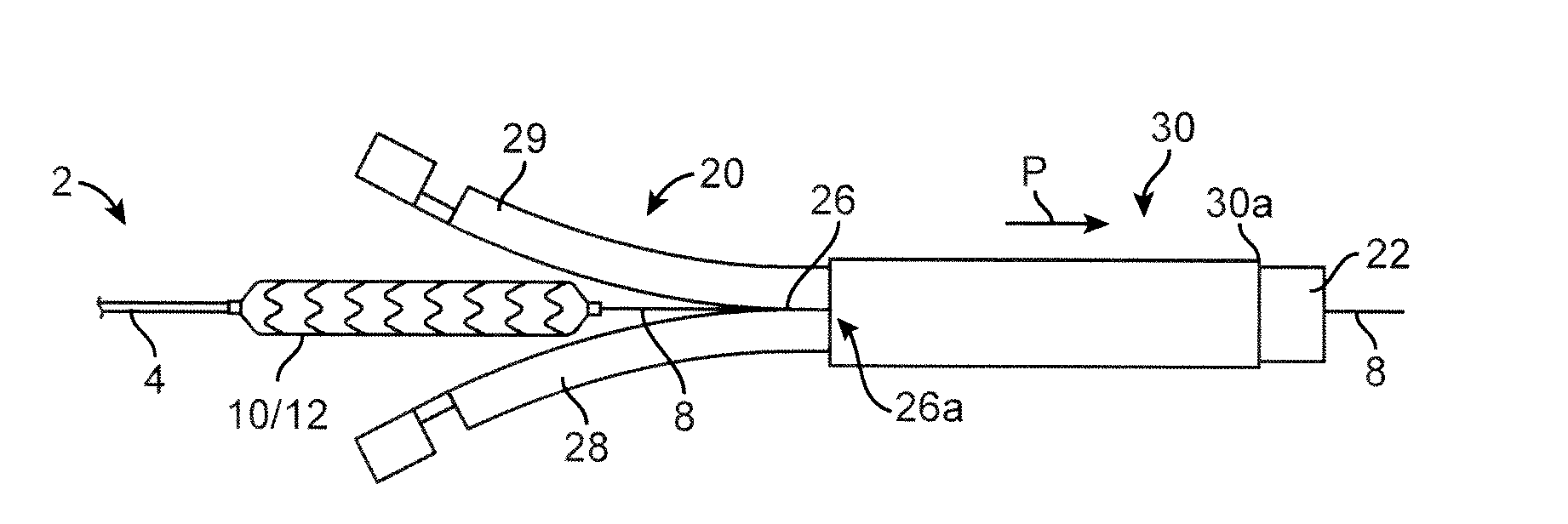

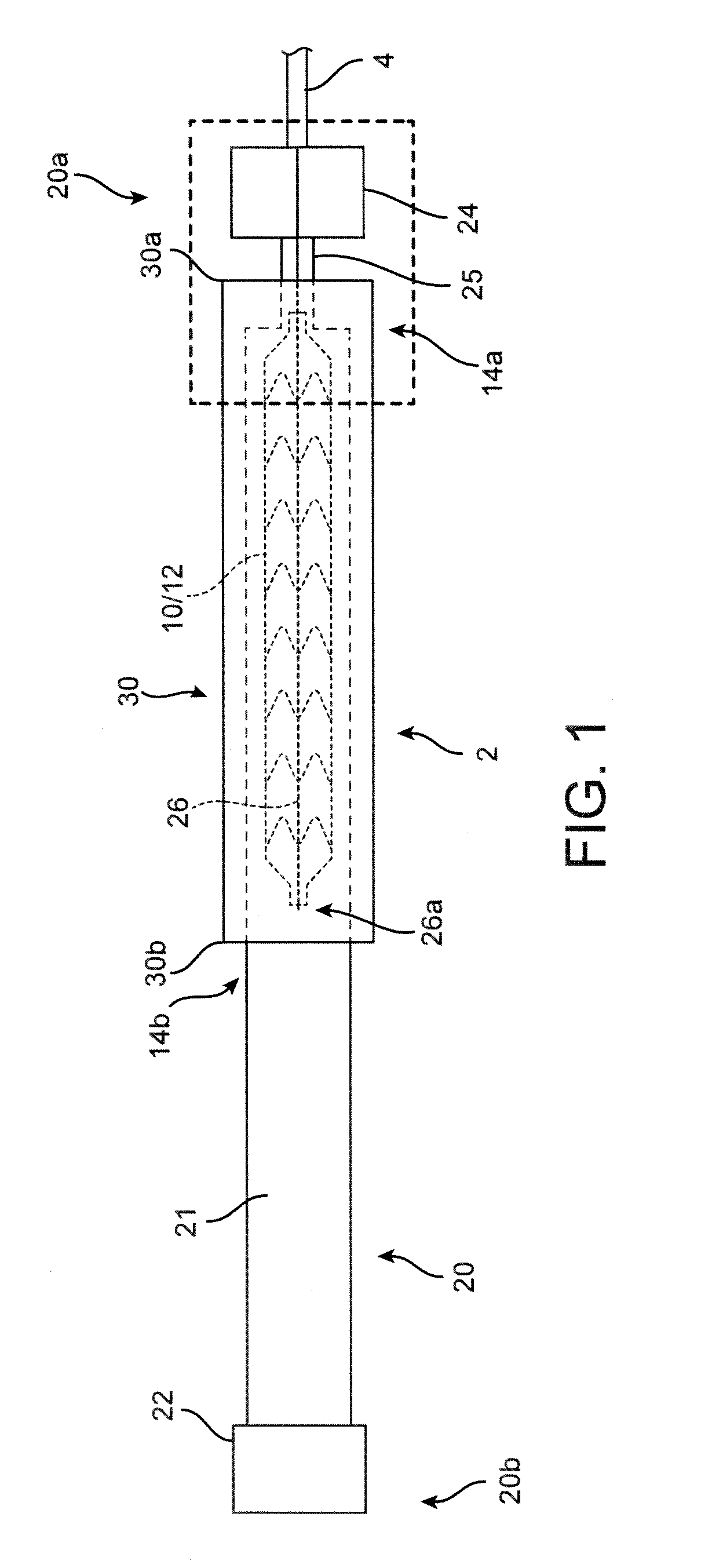

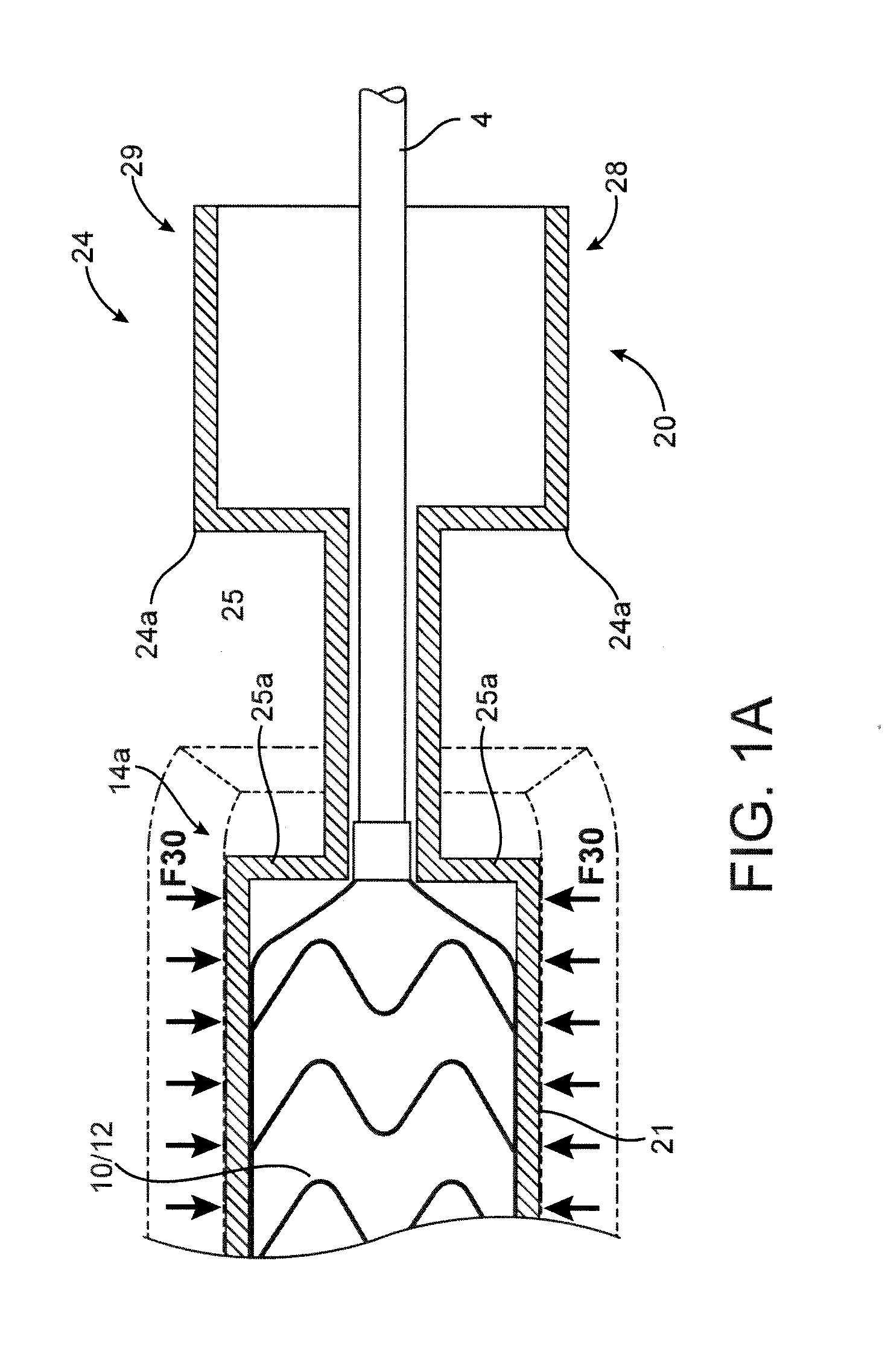

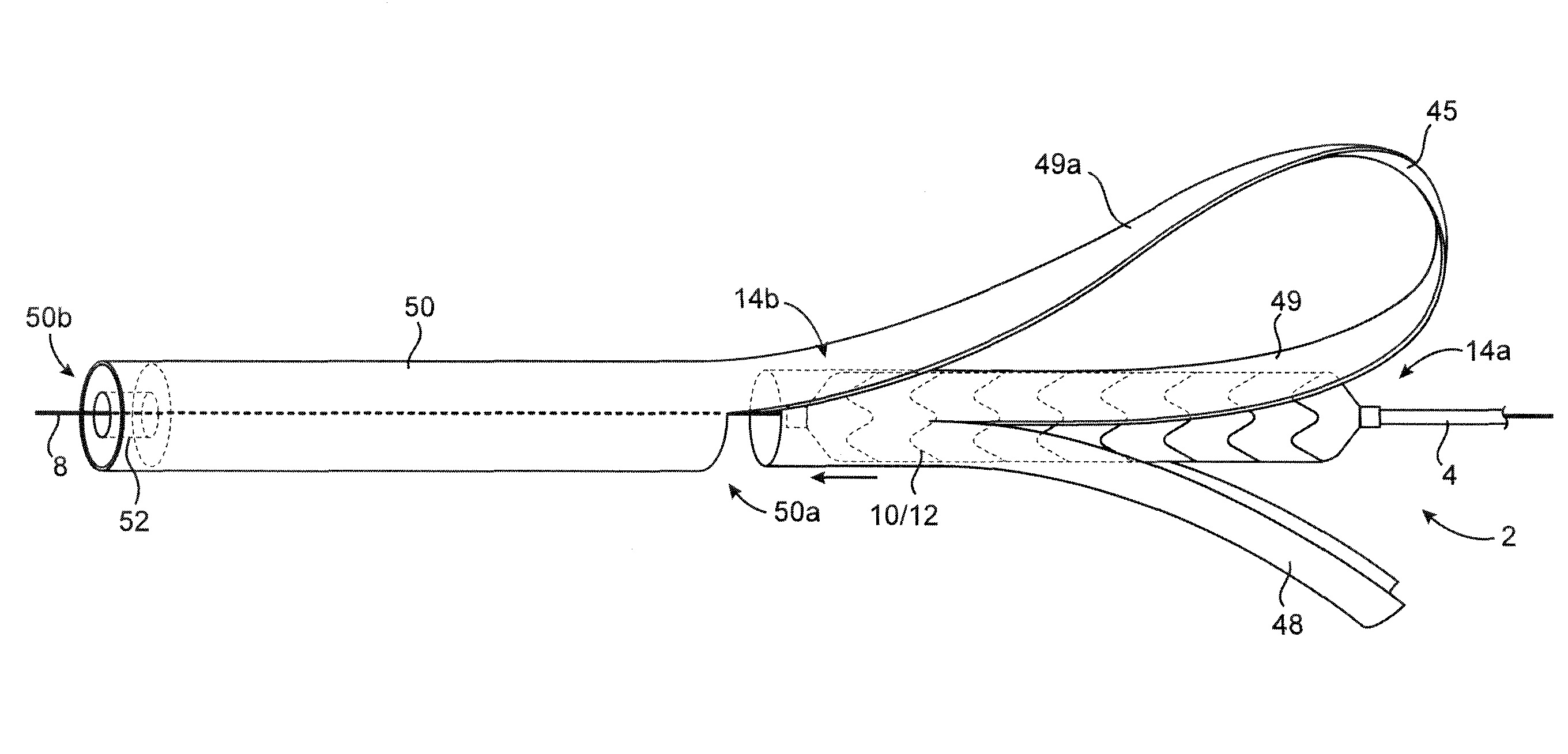

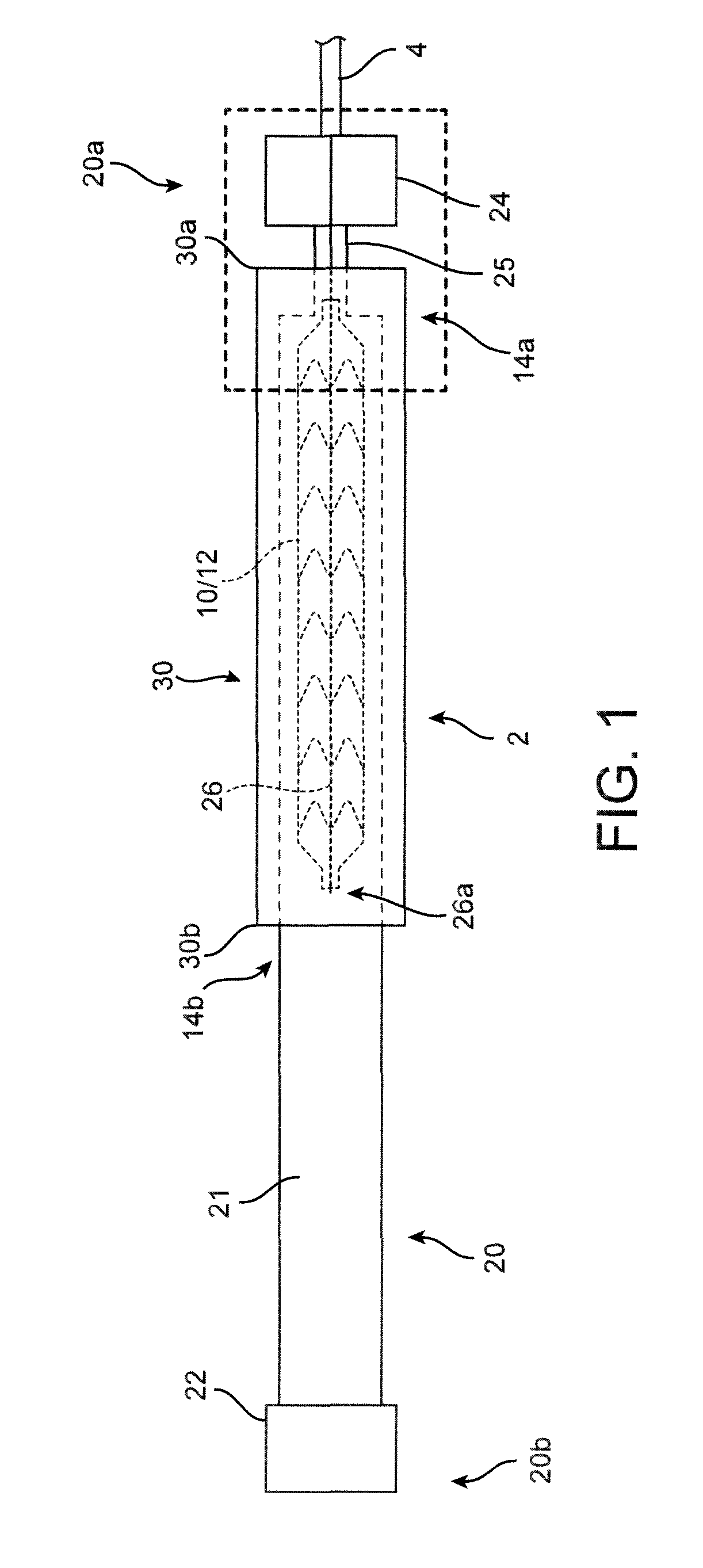

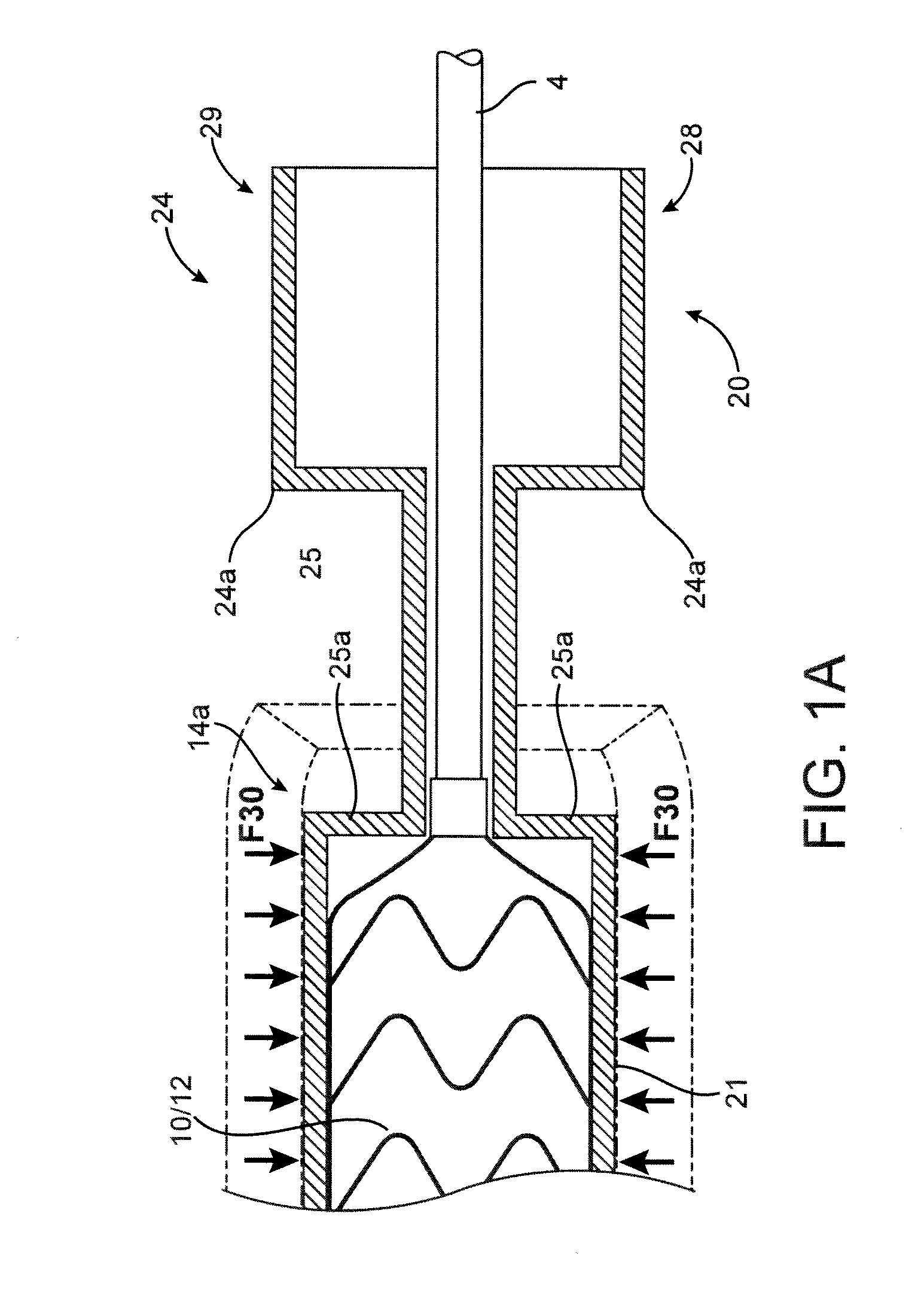

Removable sheath assembly for a polymer scaffold

ActiveUS20140379065A1Easy to disassembleMinimize damageStentsBalloon catheterHealth professionalsCatheter

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. A sheath is placed over the crimped scaffold after crimping to reduce recoil of the crimped polymer scaffold and maintain scaffold-balloon engagement relied on to hold the scaffold to the balloon when the scaffold is being delivered to a target in a body. The sheath is removed by a health professional either by removing the sheath directly or using a tube containing the catheter.

Owner:ABBOTT CARDIOVASCULAR

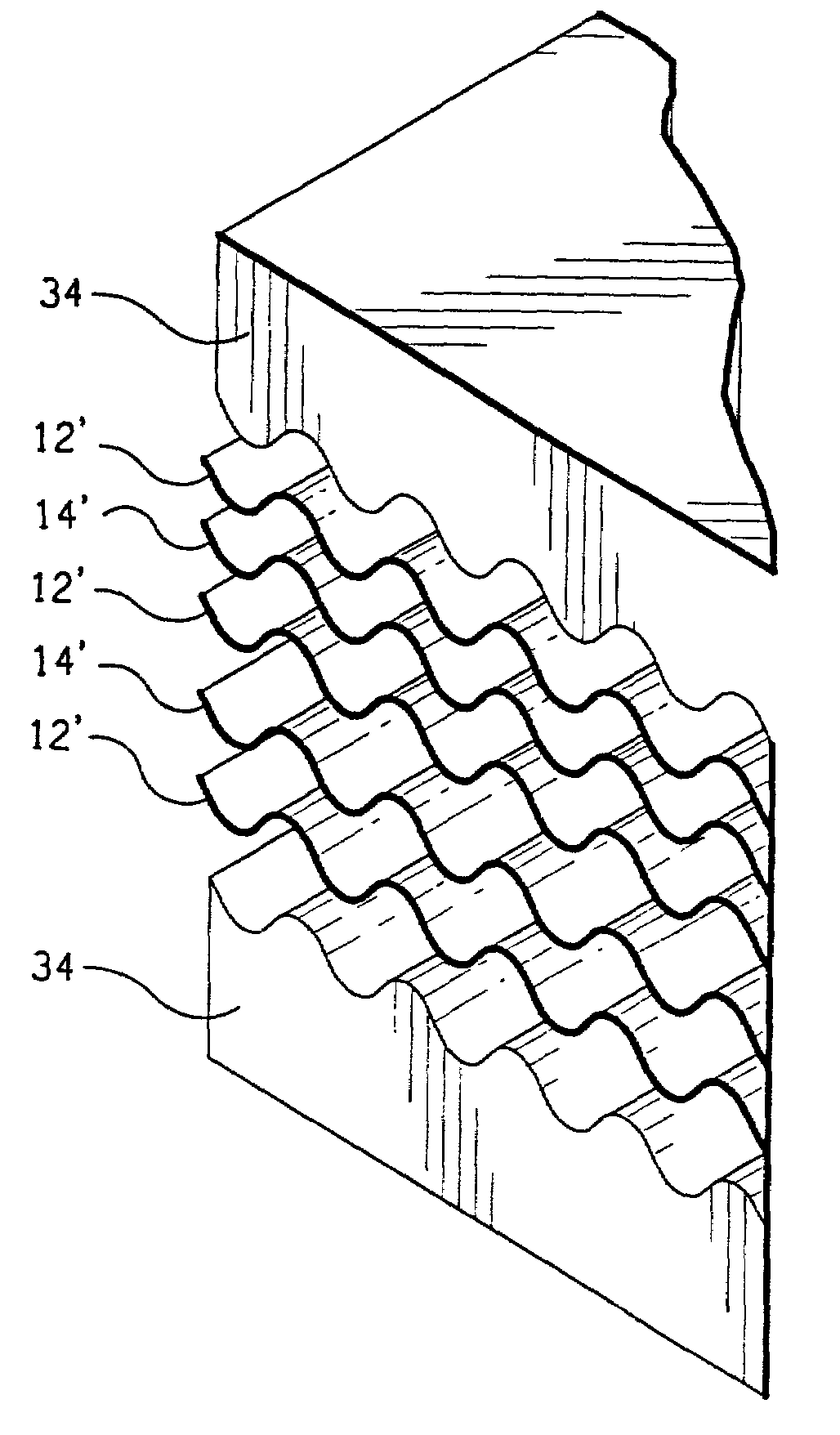

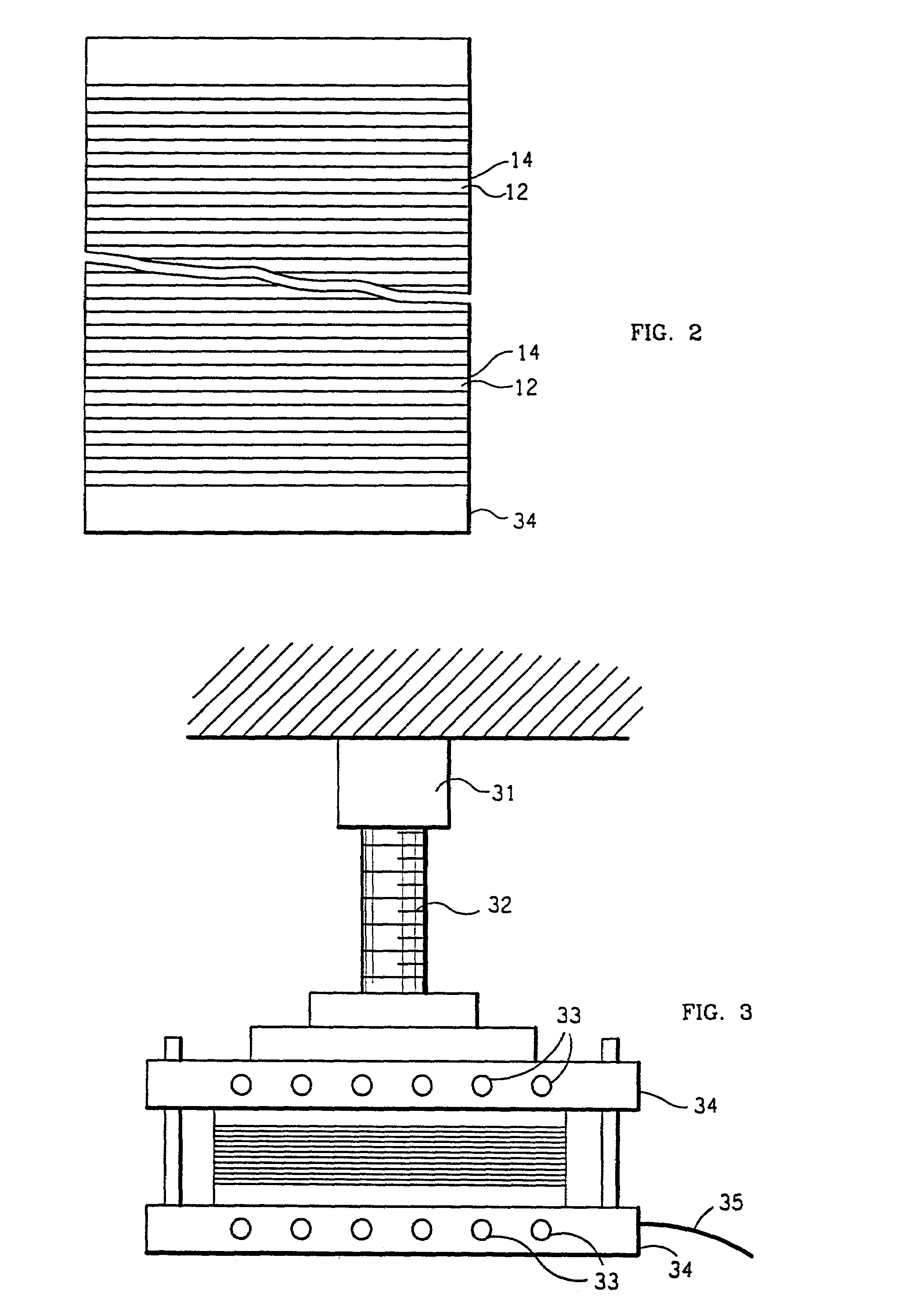

Fabrication of interleaved metallic and intermetallic composite laminate materials

InactiveUS7188559B1Well formedLimit cracking and fracturingWeapon componentsDomestic articlesGramComposite laminates

Typically 20–40 films of a tough first metal, normally 0.1–1.0 mm thick films of titanium, nickel, vanadium, and / or steel (iron) and alloys thereof, interleaved with a like number of films of a second metal, normally 0.1–1.0 mm thick films of aluminum or alloys thereof, are pressed together in a stack at less than 6 MPa and normally at various pressures 2–4 MPa while being gradually heated in the presence of atmospheric gases to 600–800° C. over a period of, typically, 10+ hours until the second metal is completely compounded; forming thus a metallic-intermetallic laminate composite material having (i) tough first-metal layers separated by (ii) hard, Vickers microhardness of 400 kg / mm2+, intermetallic regions consisting of an intermetallic compound of the first and the second metals. The resulting composite material is inexpensive, lightweight with a density of typically 3 to 4.5 grams / cubic centimeter, and very hard and very tough to serve as, among other applications, lightweight armor. Upon projectile impact (i) the hard intermetallic, ceramic-like, layers are confined by the tough metal layers while (ii) cracking and fracturing is blunted and channeled in directions orthogonal to the axis of impact.

Owner:RGT UNIV OF CALIFORNIA

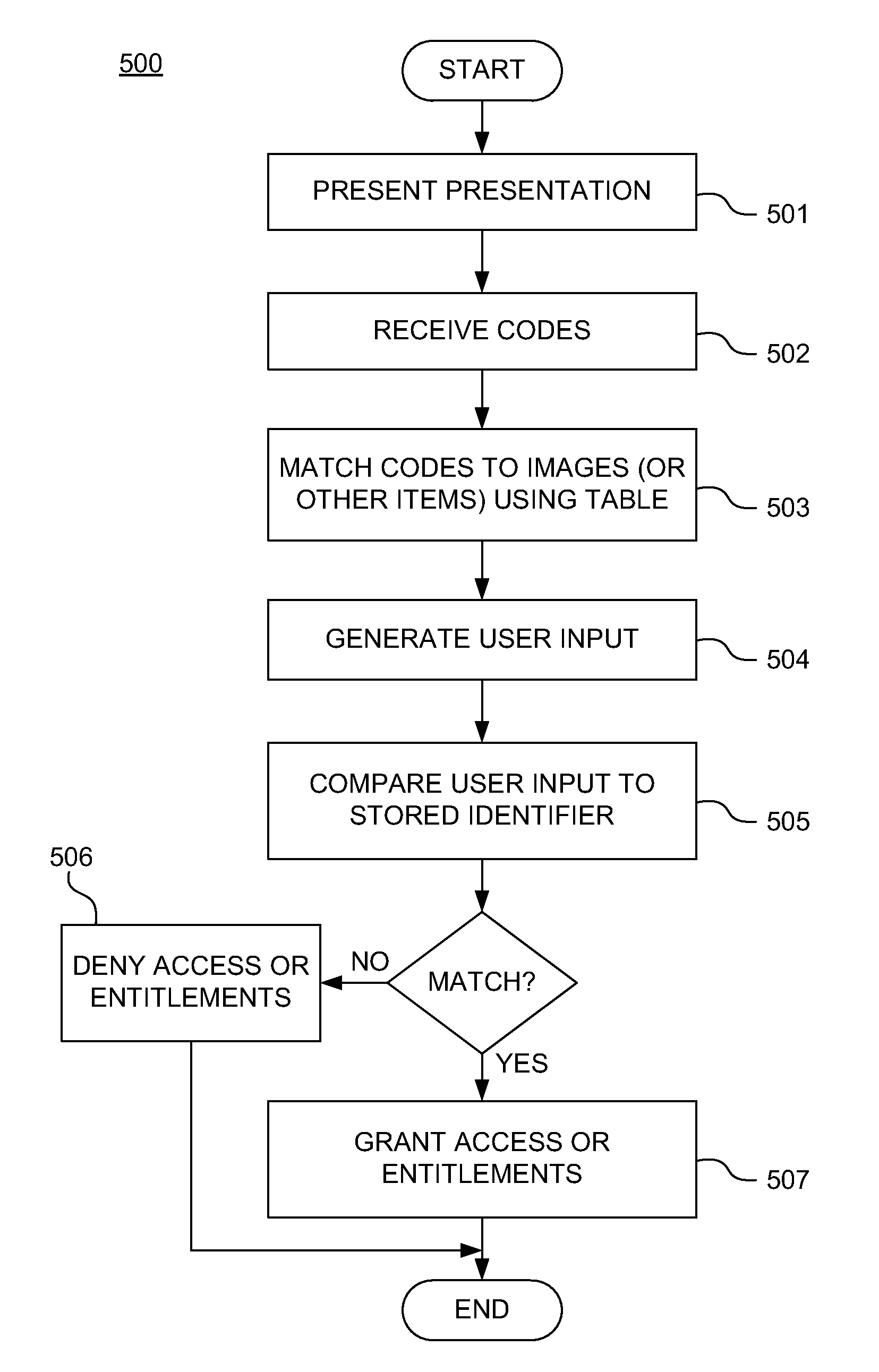

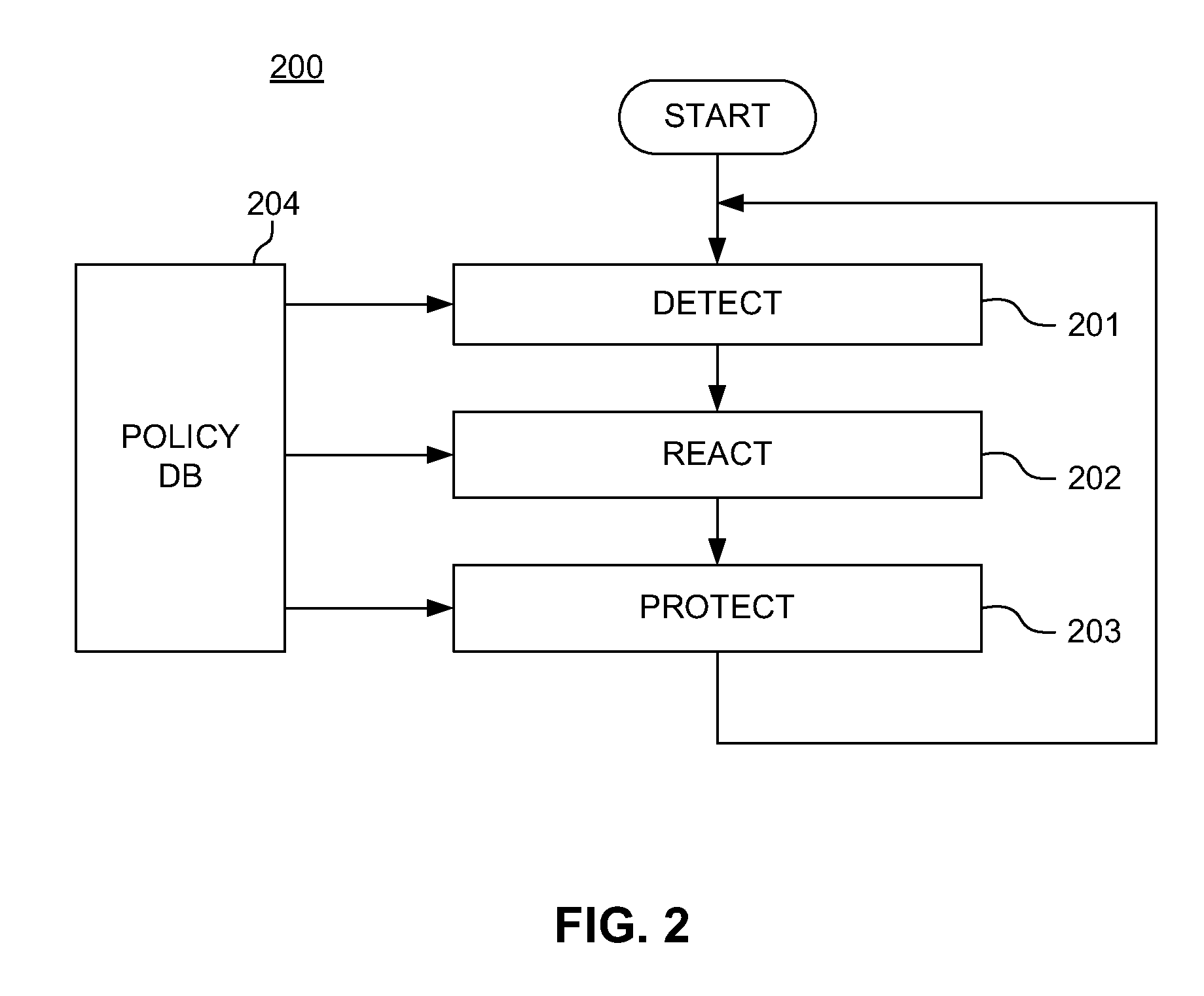

Adaptive policies and protections for securing financial transaction data at rest

ActiveUS20110314529A1Shorten the time to marketAcceptable levelDigital data processing detailsUser identity/authority verificationTransaction dataDisplay device

A system for challenge-response authentication is provided by receiving, from an external terminal over a communication network, a request for access to a service. A plurality of objects is presented to a user via a display. A plurality of codes is received over the communication network, each of the plurality of codes corresponding to one of the plurality of objects. The plurality of codes are matched to a plurality of alphanumeric characters according to a predetermined table. An alphanumeric string is generated from the plurality of alphanumeric characters and the alphanumeric string is compared to a user identifier stored in a database. Based on the comparing, a determination is made as to whether to grant the user access to the service.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

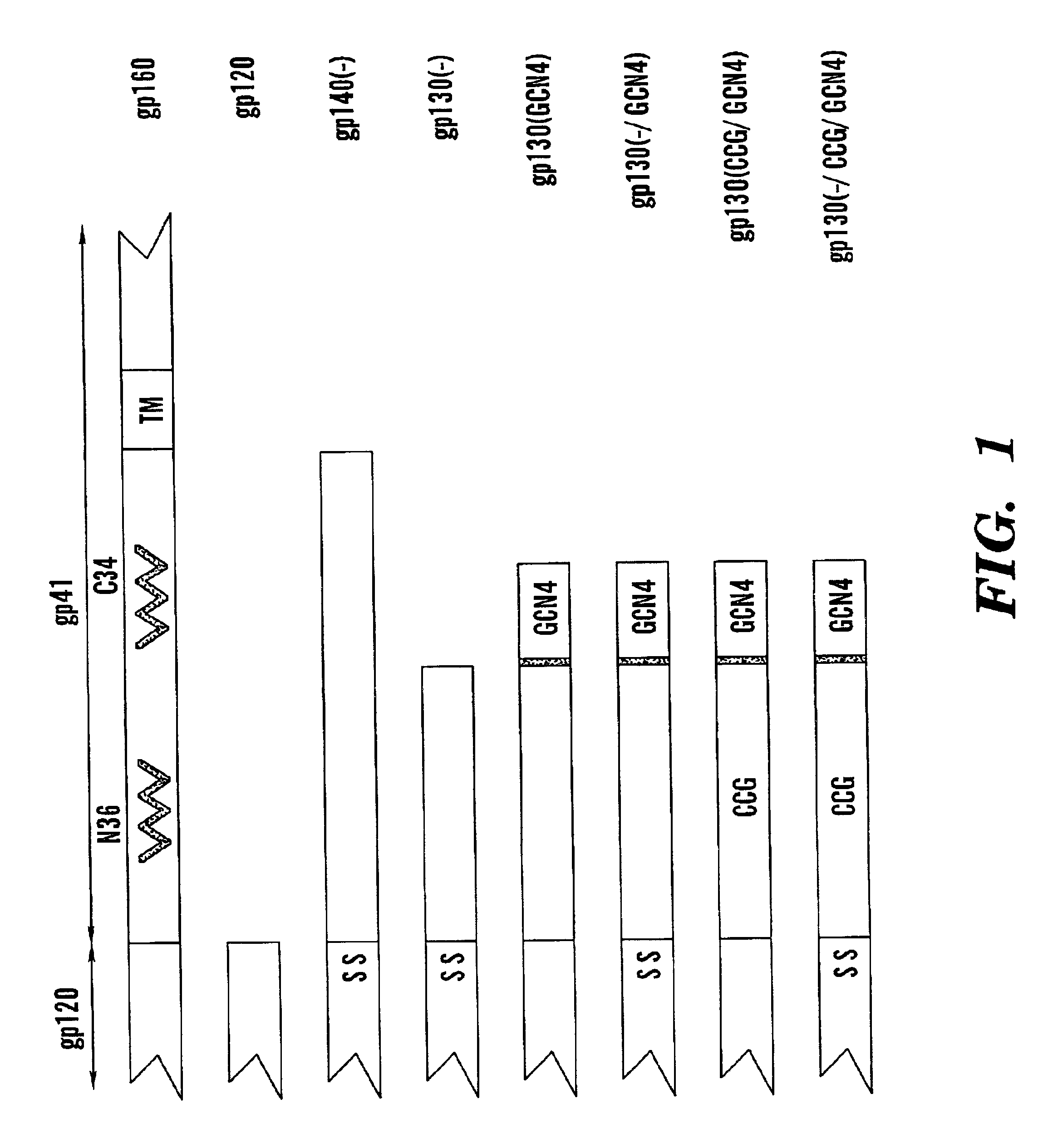

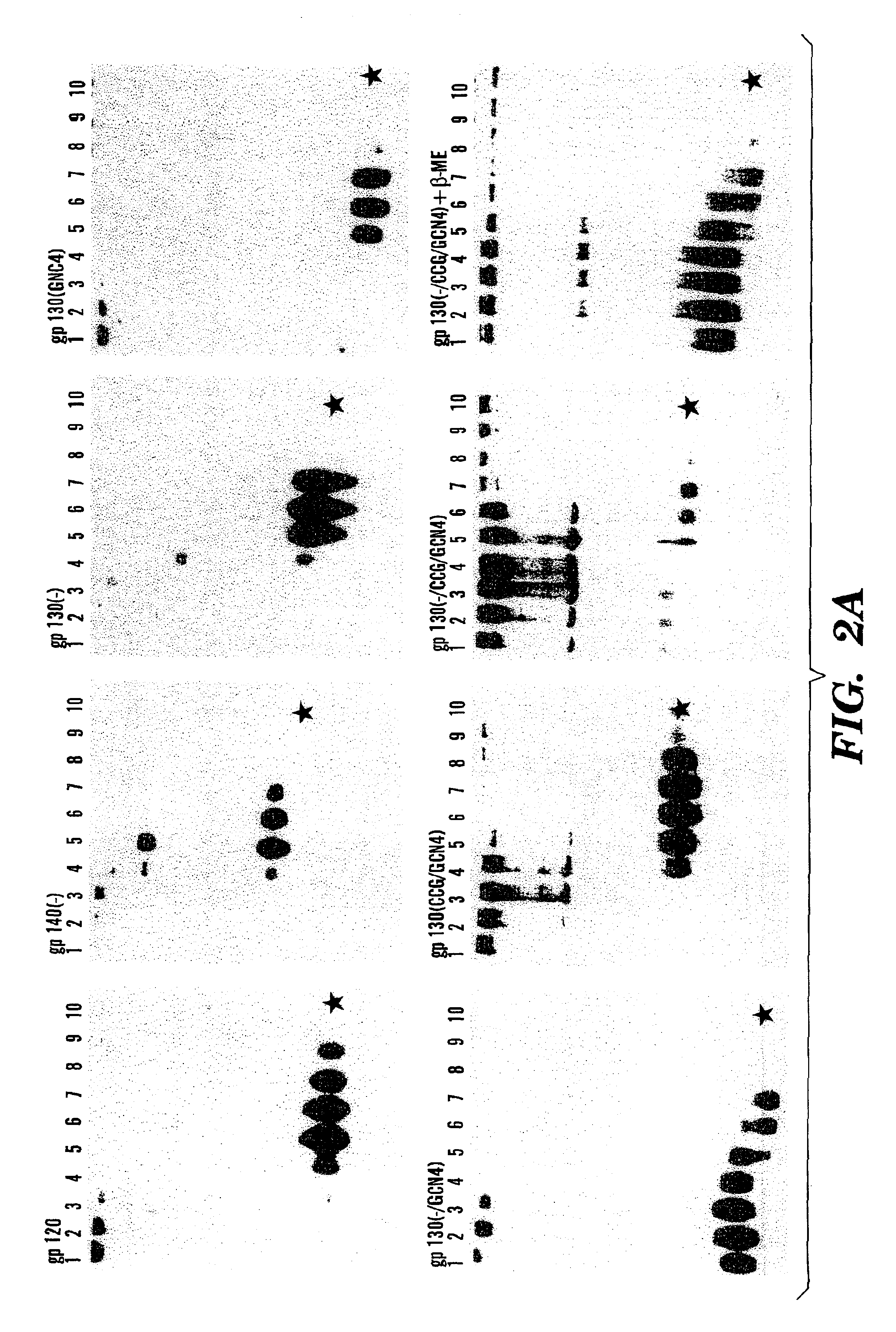

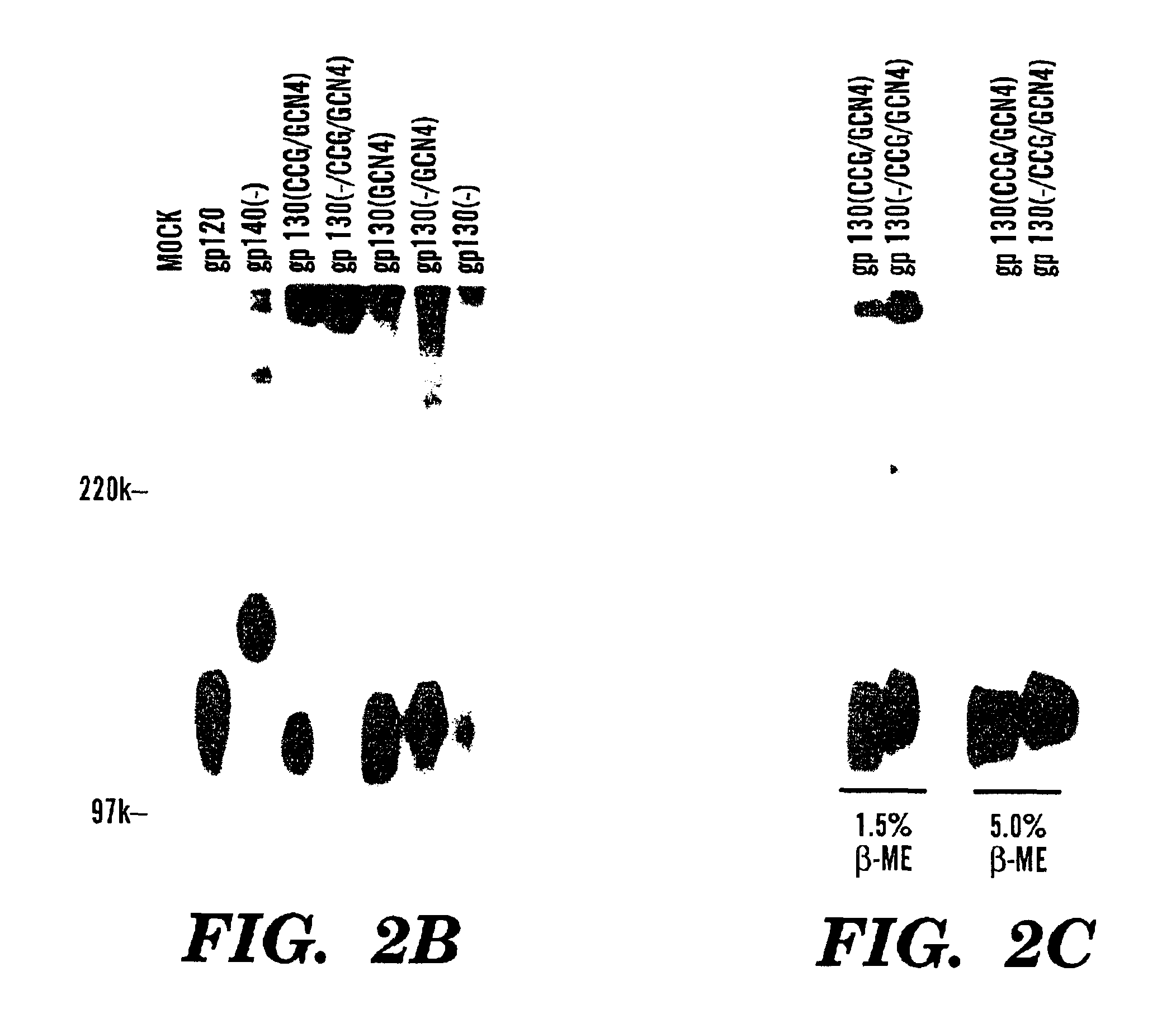

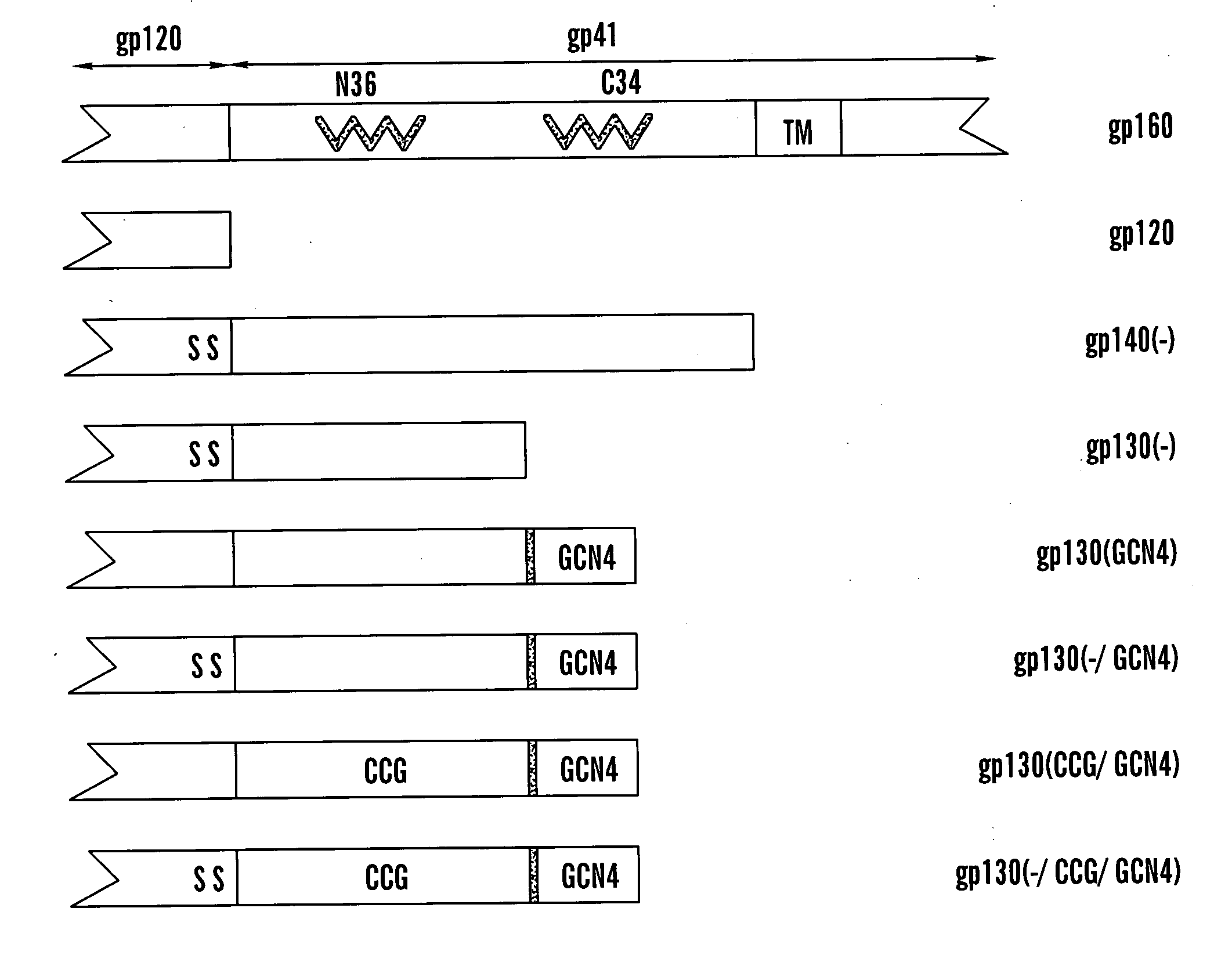

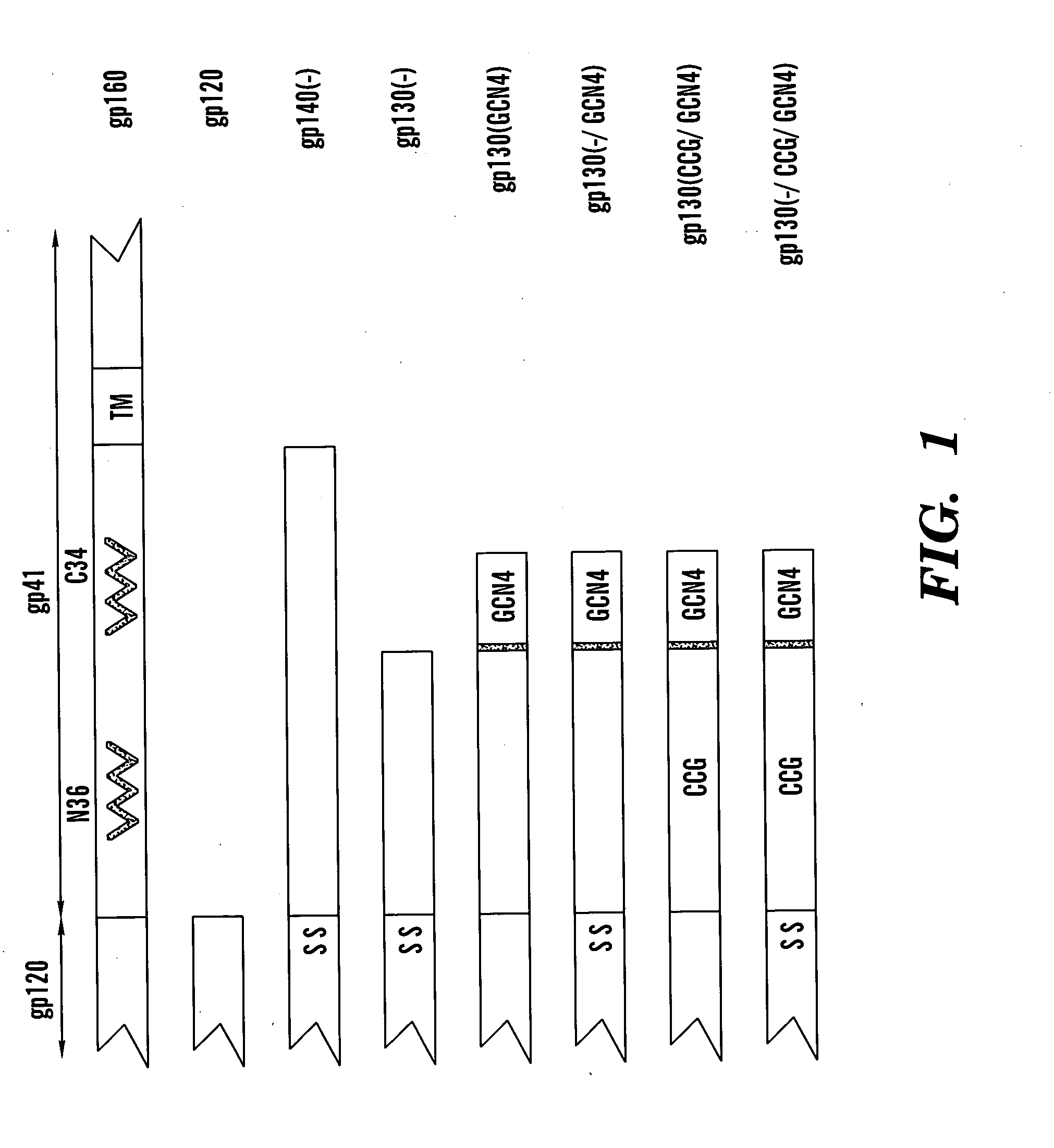

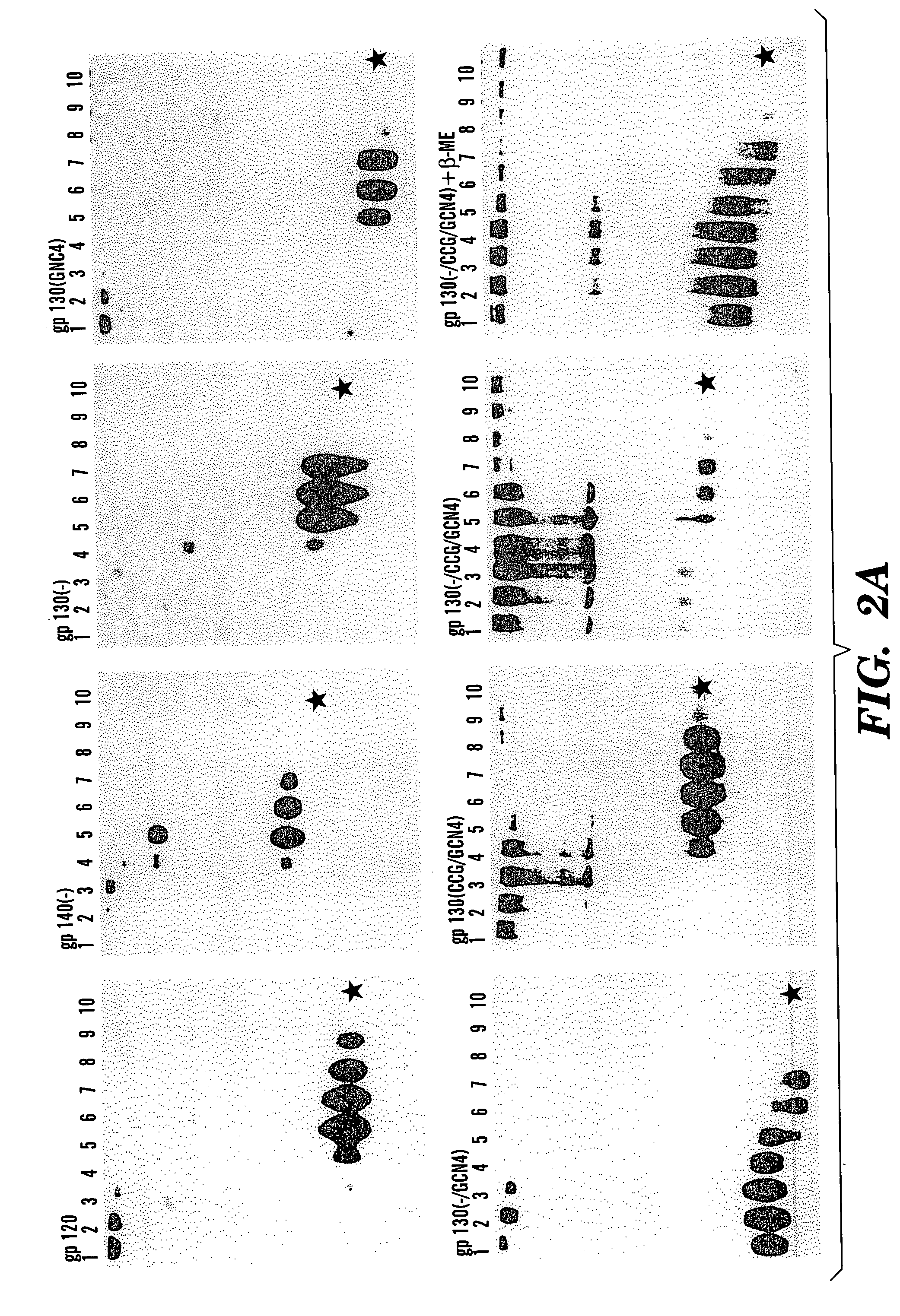

Stabilized soluble glycoprotein trimers

InactiveUS6911205B2Stabilize trimerSimplifies isolationPeptide/protein ingredientsAntibody mimetics/scaffoldsHiv envelopeGp41

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

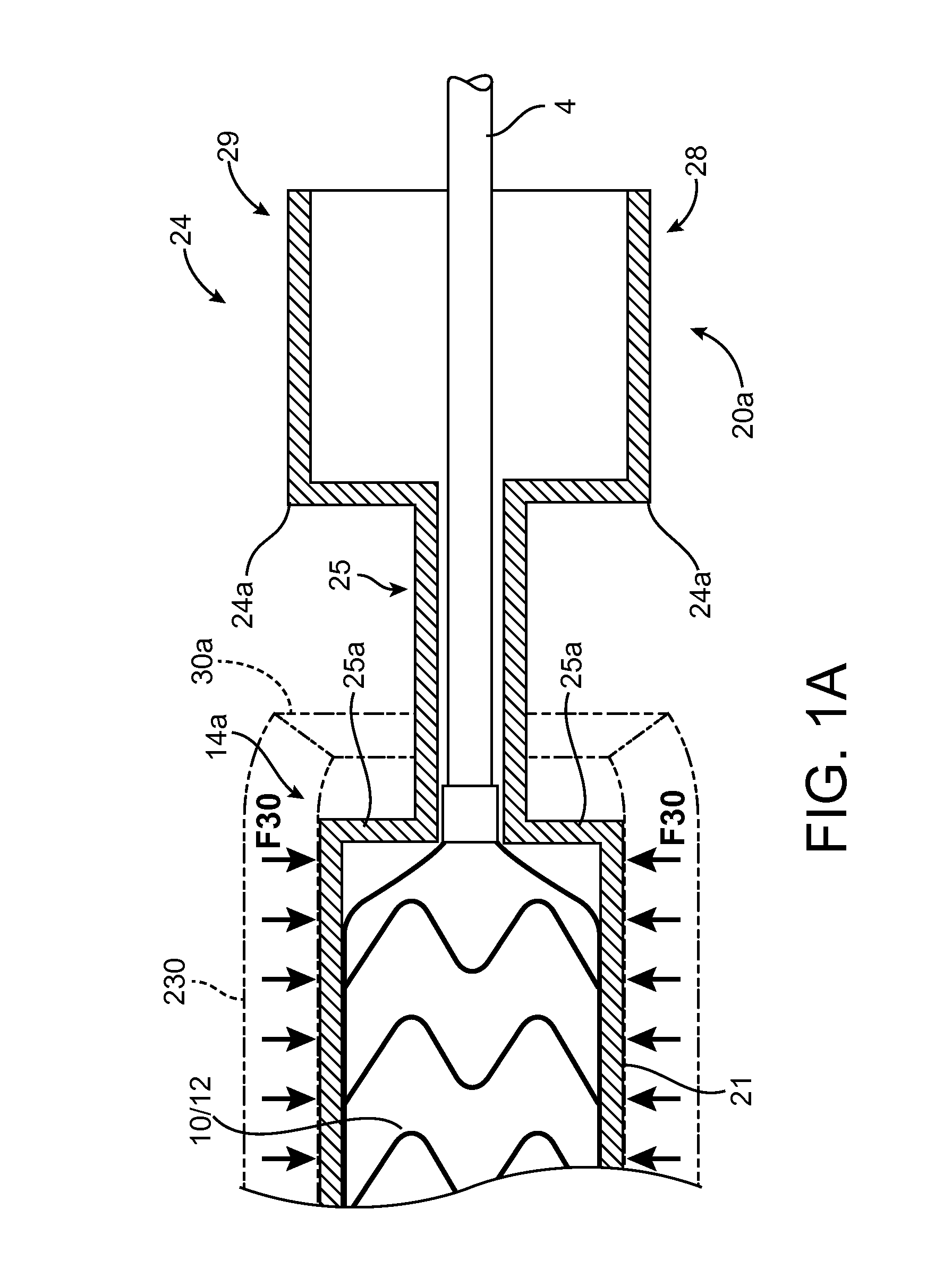

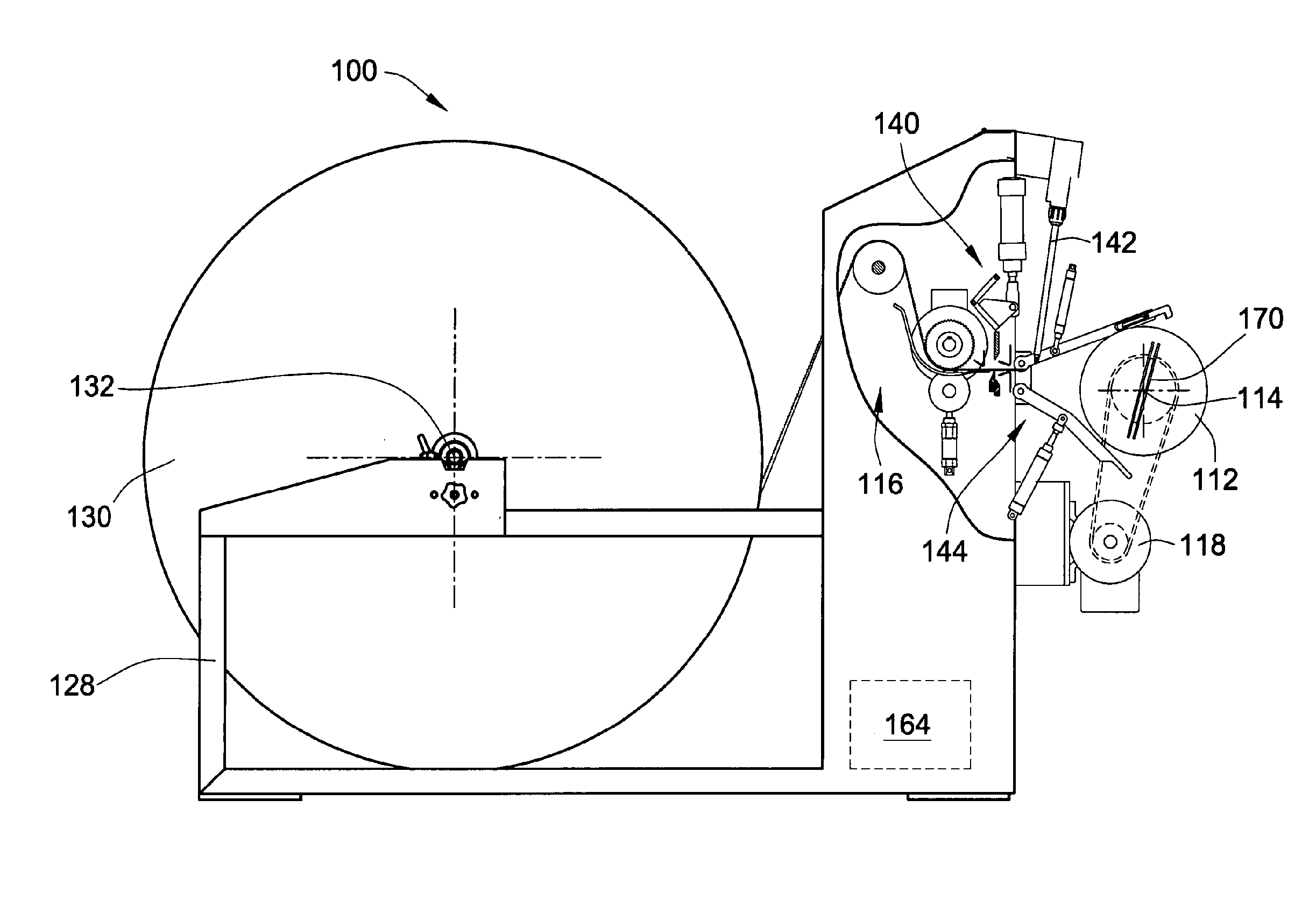

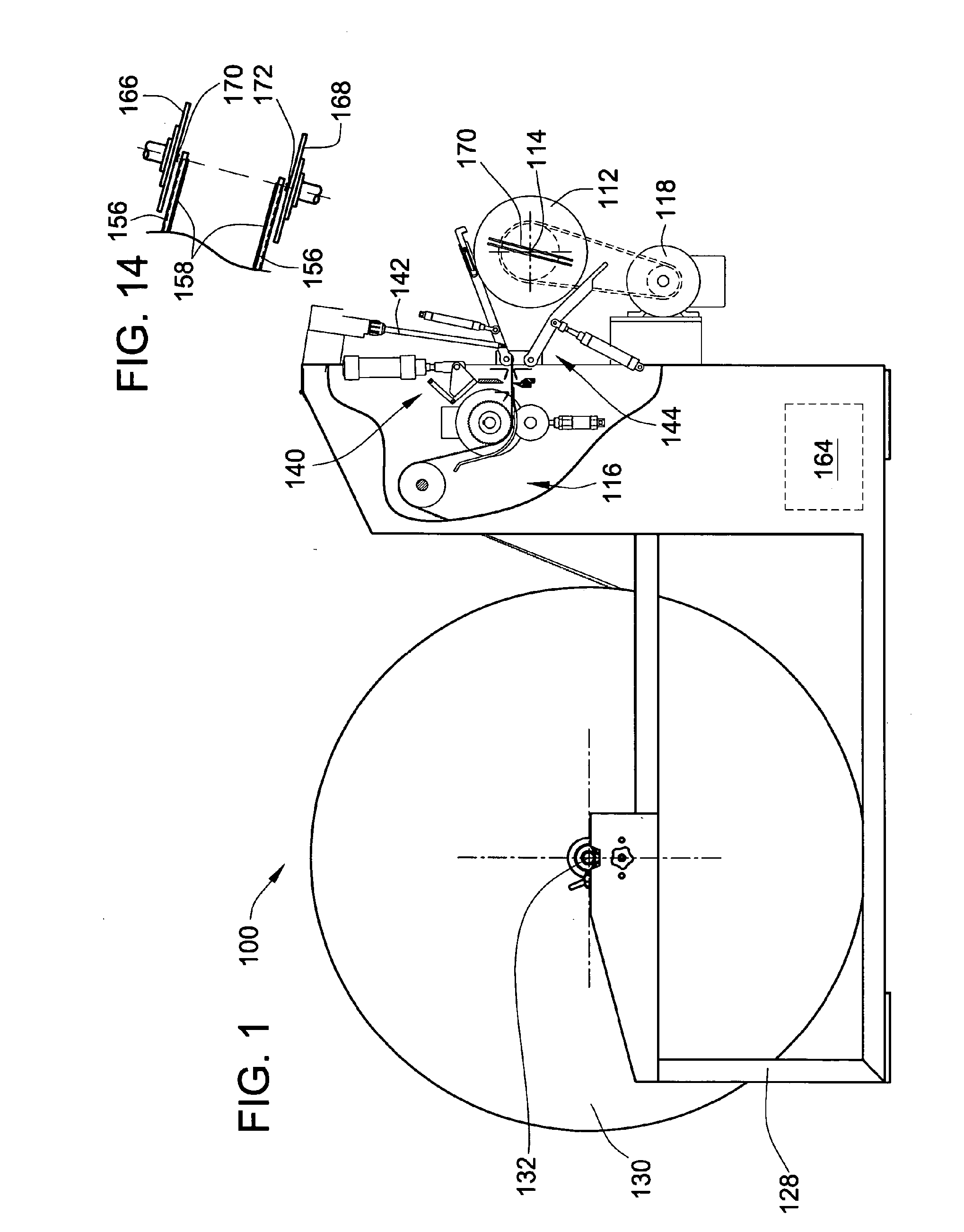

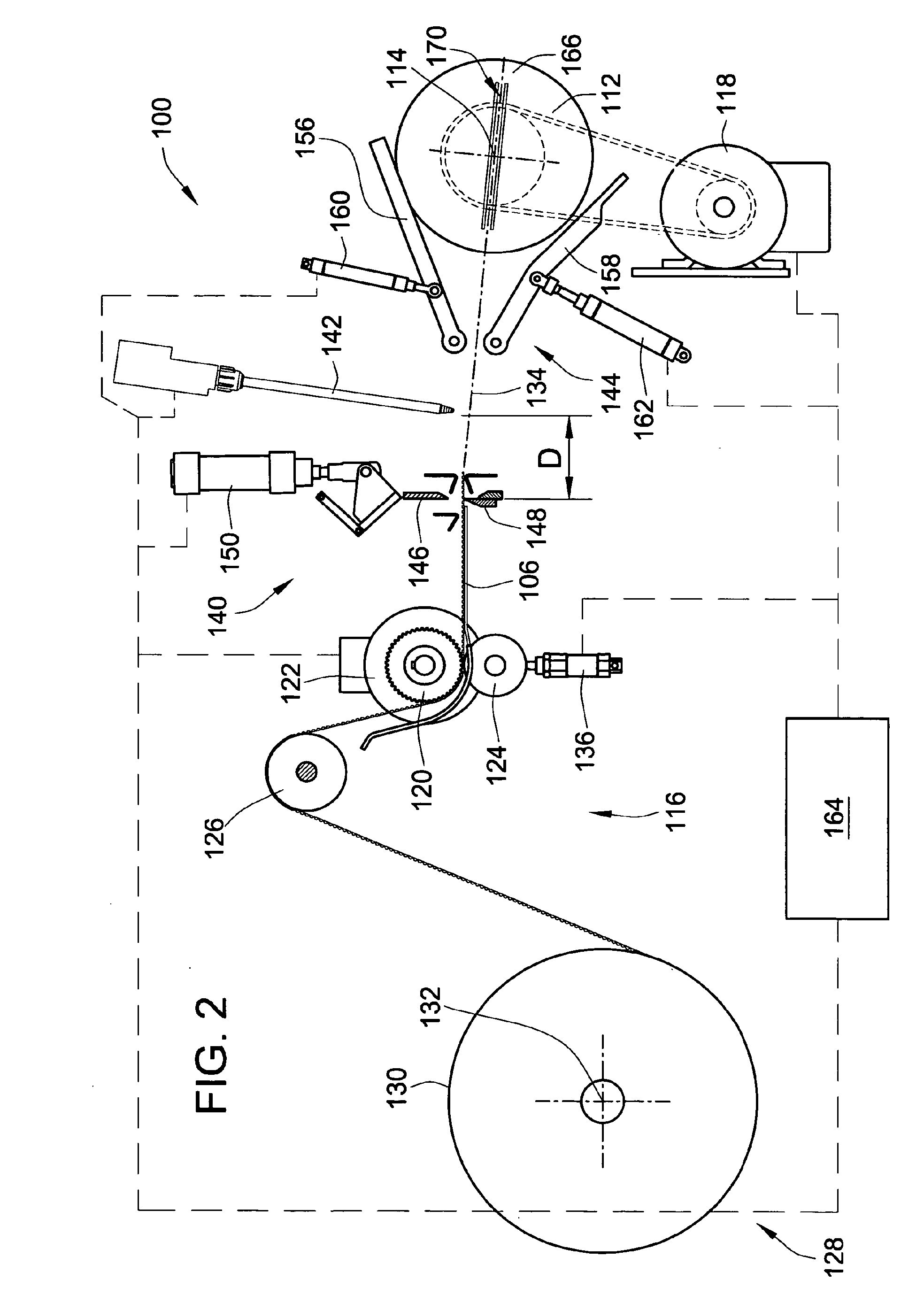

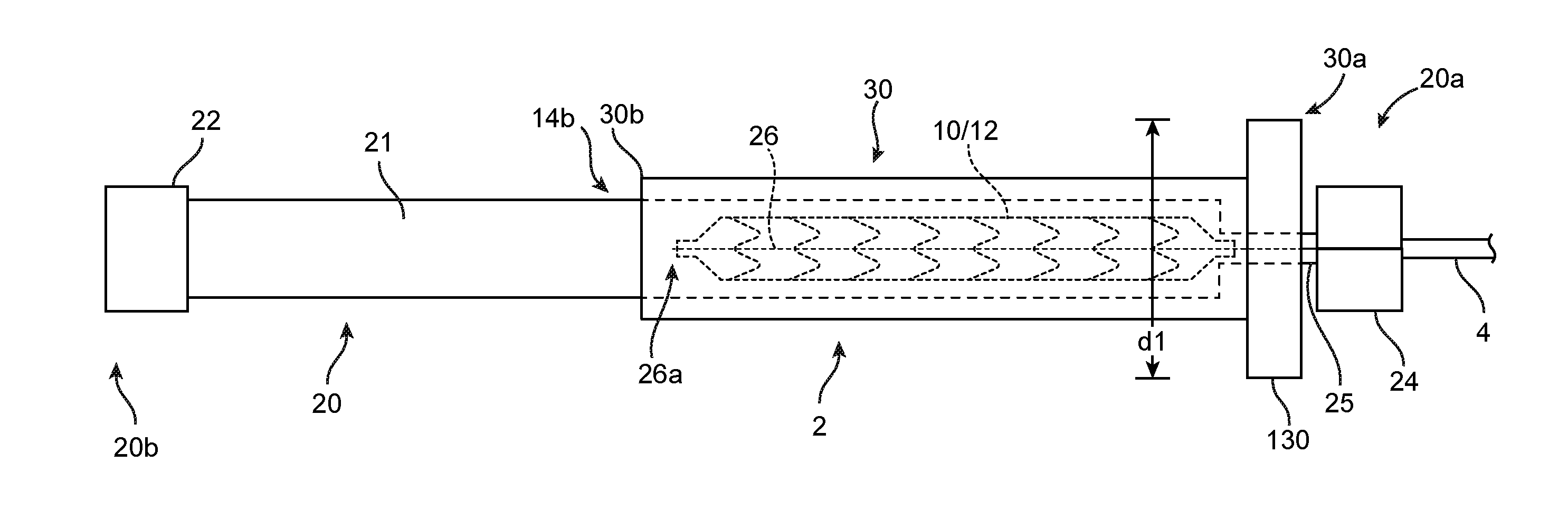

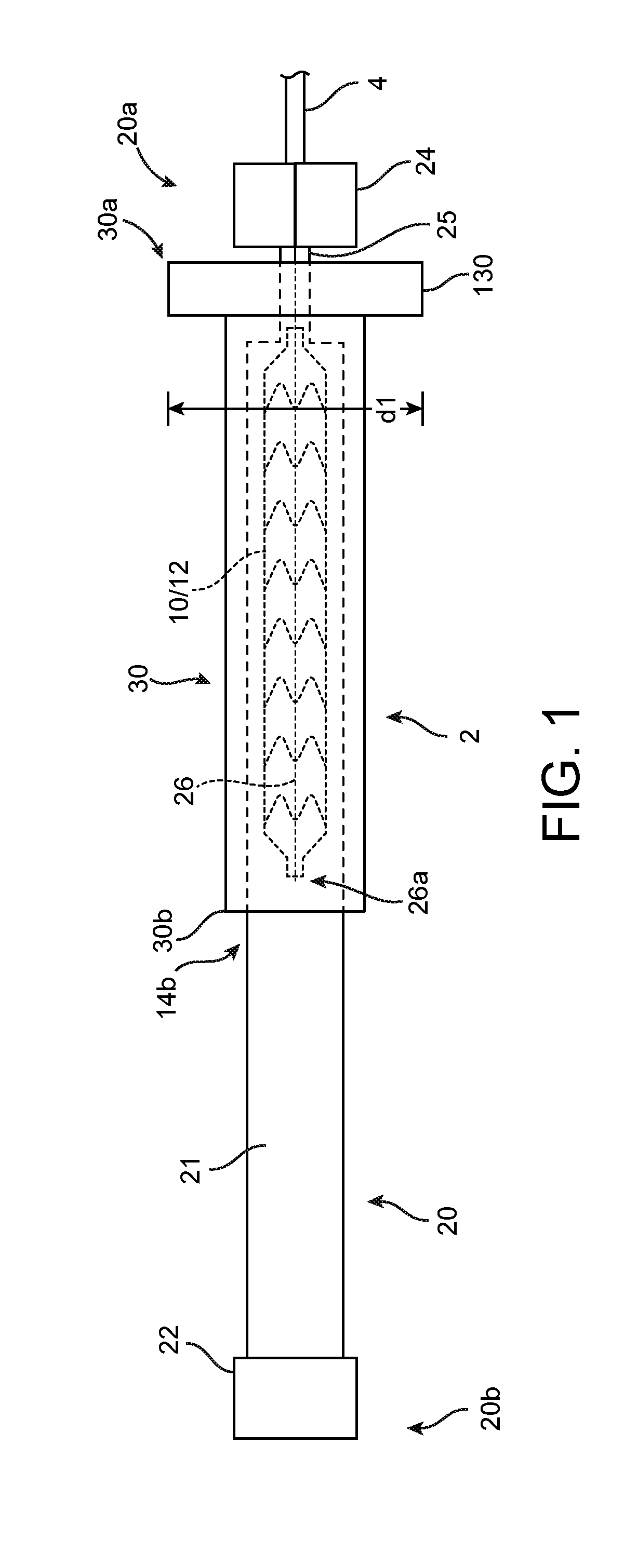

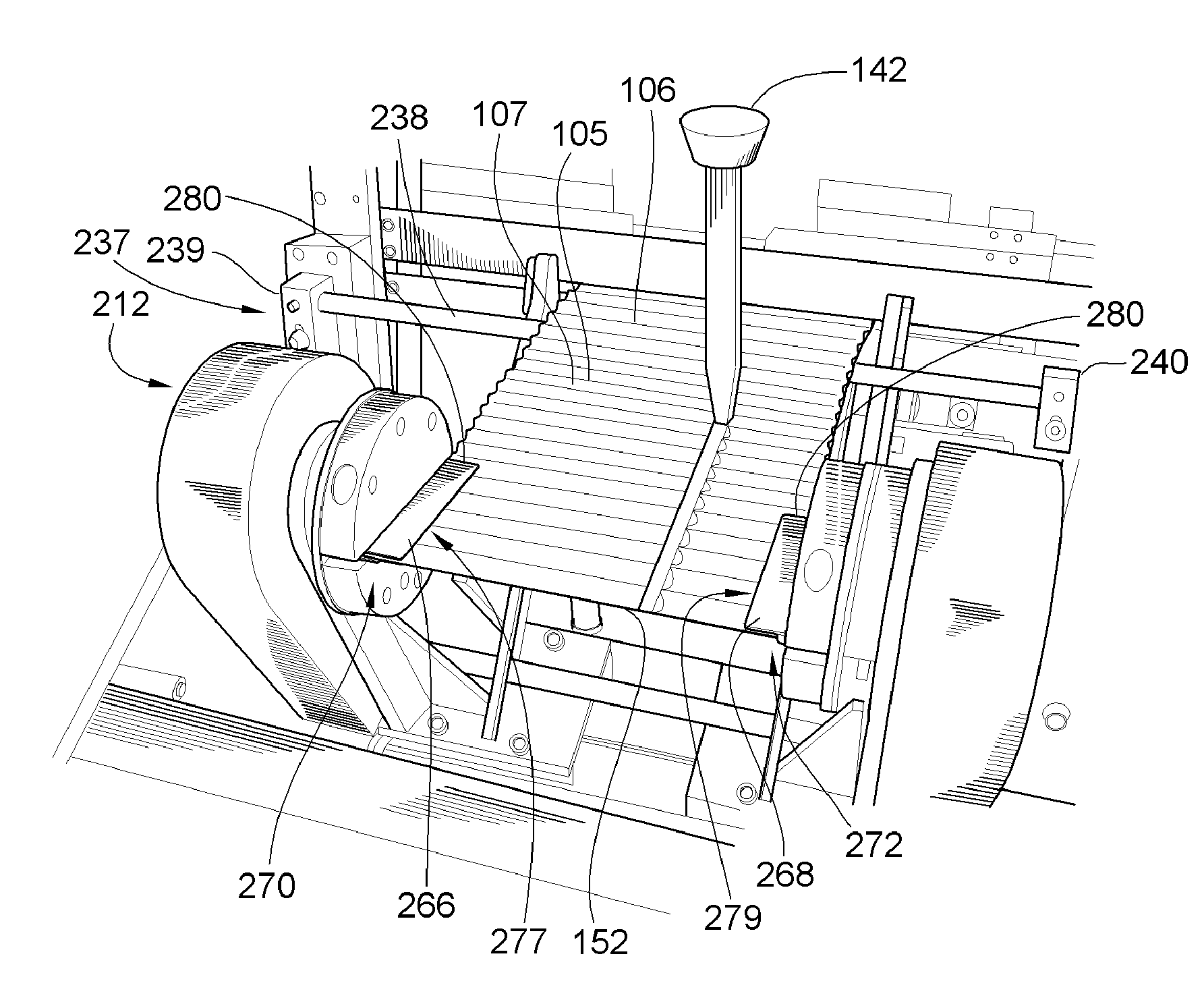

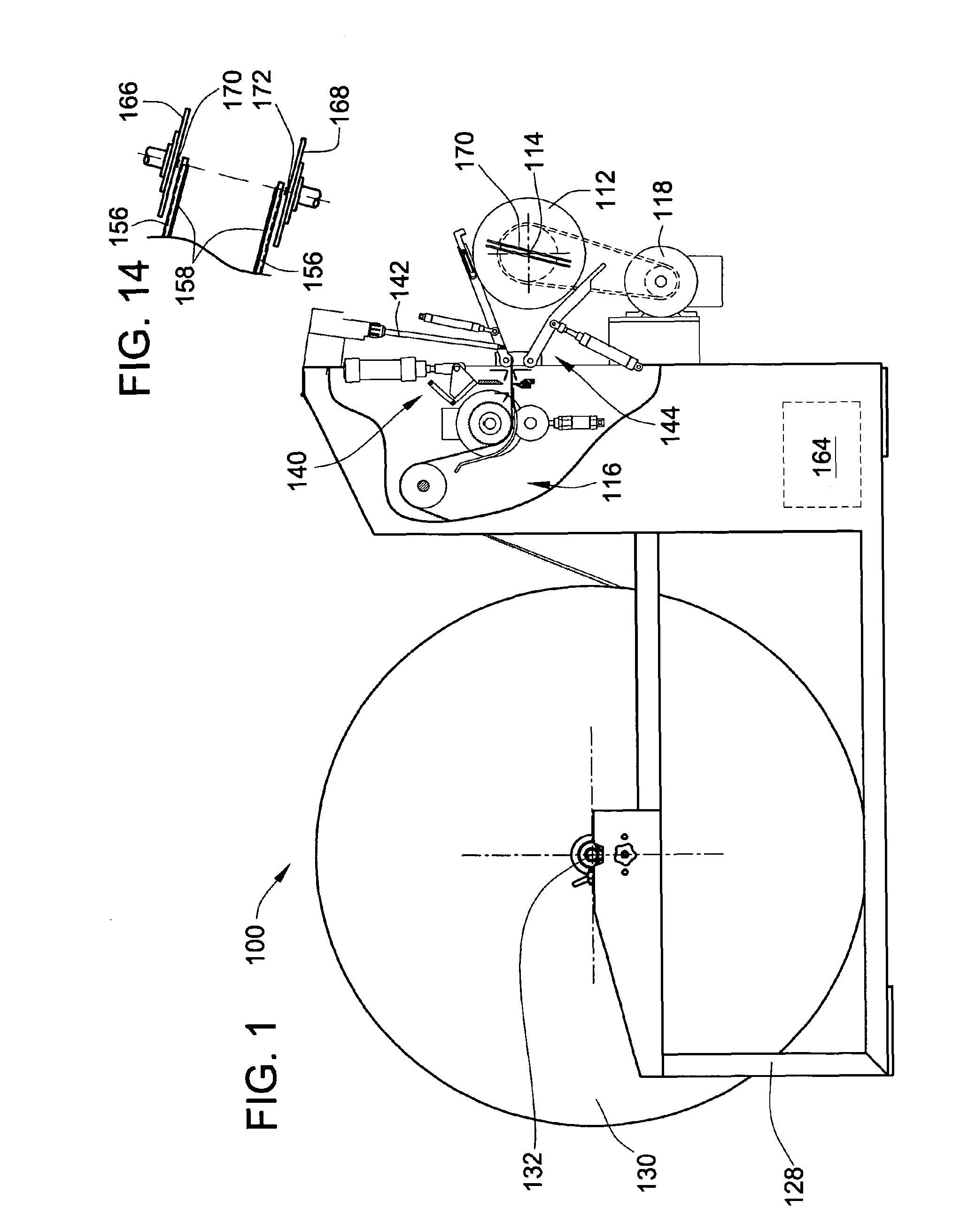

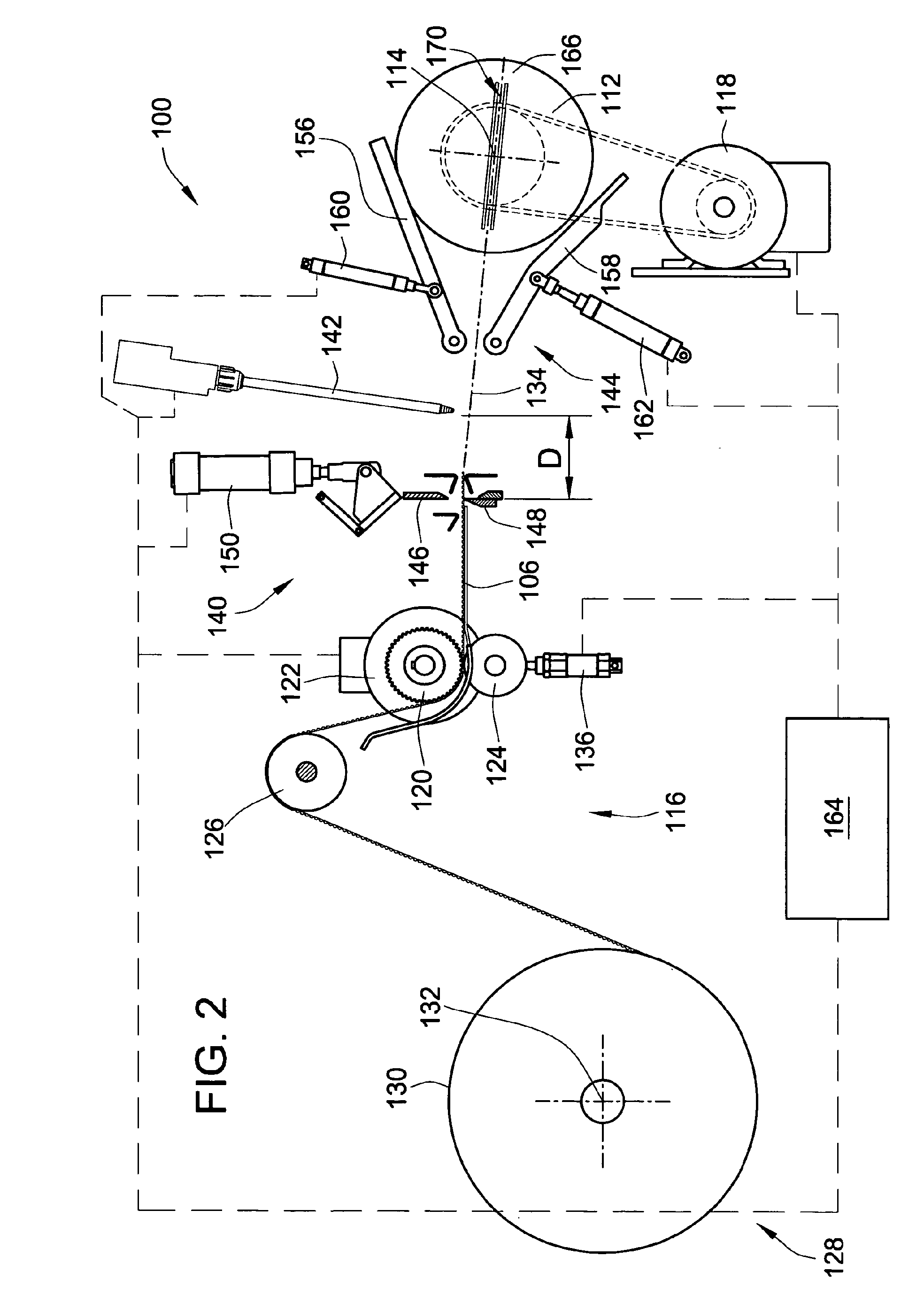

Method And Apparatus For Winding A Filter Media Pack

ActiveUS20080011896A1Increase propensityPrevent unwinding and unravelingDispersed particle filtrationPaper/cardboard wound articlesFilter mediaEngineering

A method and apparatus are provided, for forming a filter element including a media pack in the form of a coiled fluted filter media, by winding the web of fluted filter media around a pair of tools of a mandrel. The tools engage the sides of the filter media. The tools define a major to provide the media pack with a oblong or elongated shape. The web may be fed at constant linear speed, and / or a motor may be controlled in a manner to provide constant driving torque to maintain a constant tension on the web. The winding apparatus and methods may include apparatus or methods to modify the feed path of the web to adjust the tension of the web as it is being wound. Further, the coiled media packs can be fixtured to prevent relaxation. A method may form various shaped media packs with the same apparatus.

Owner:BALDWIN FILTERS

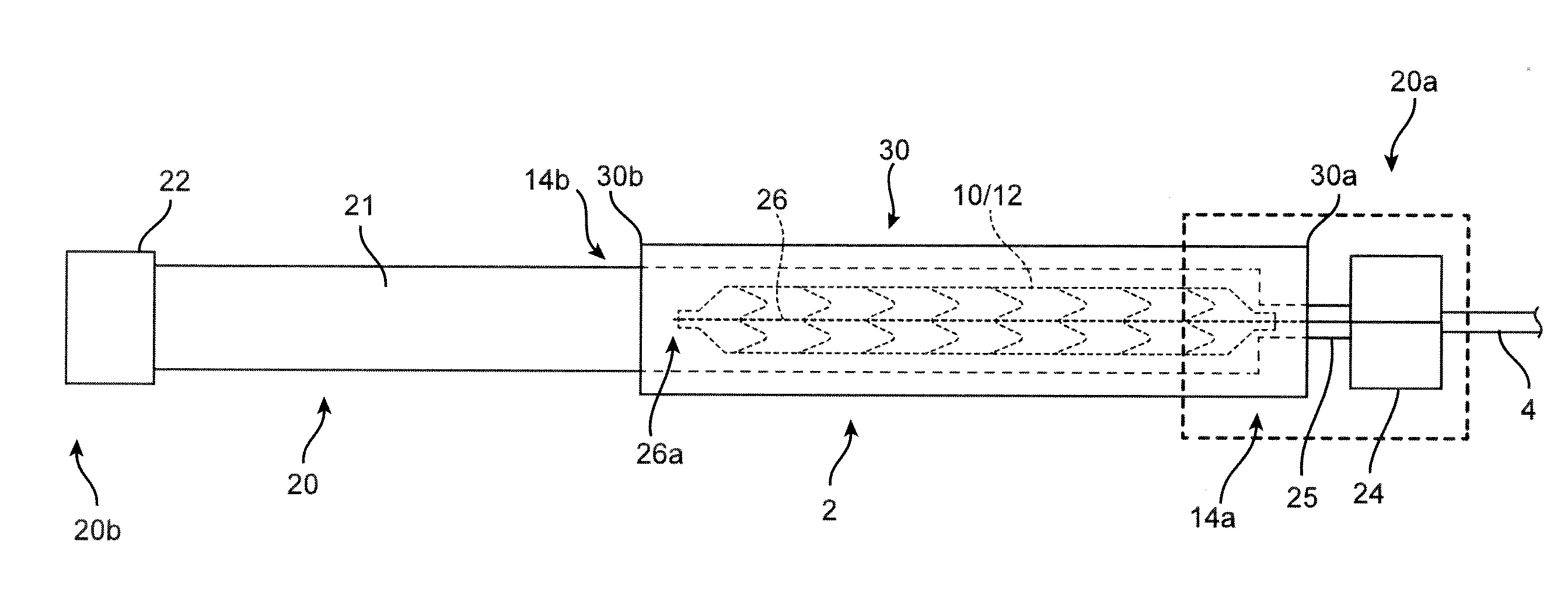

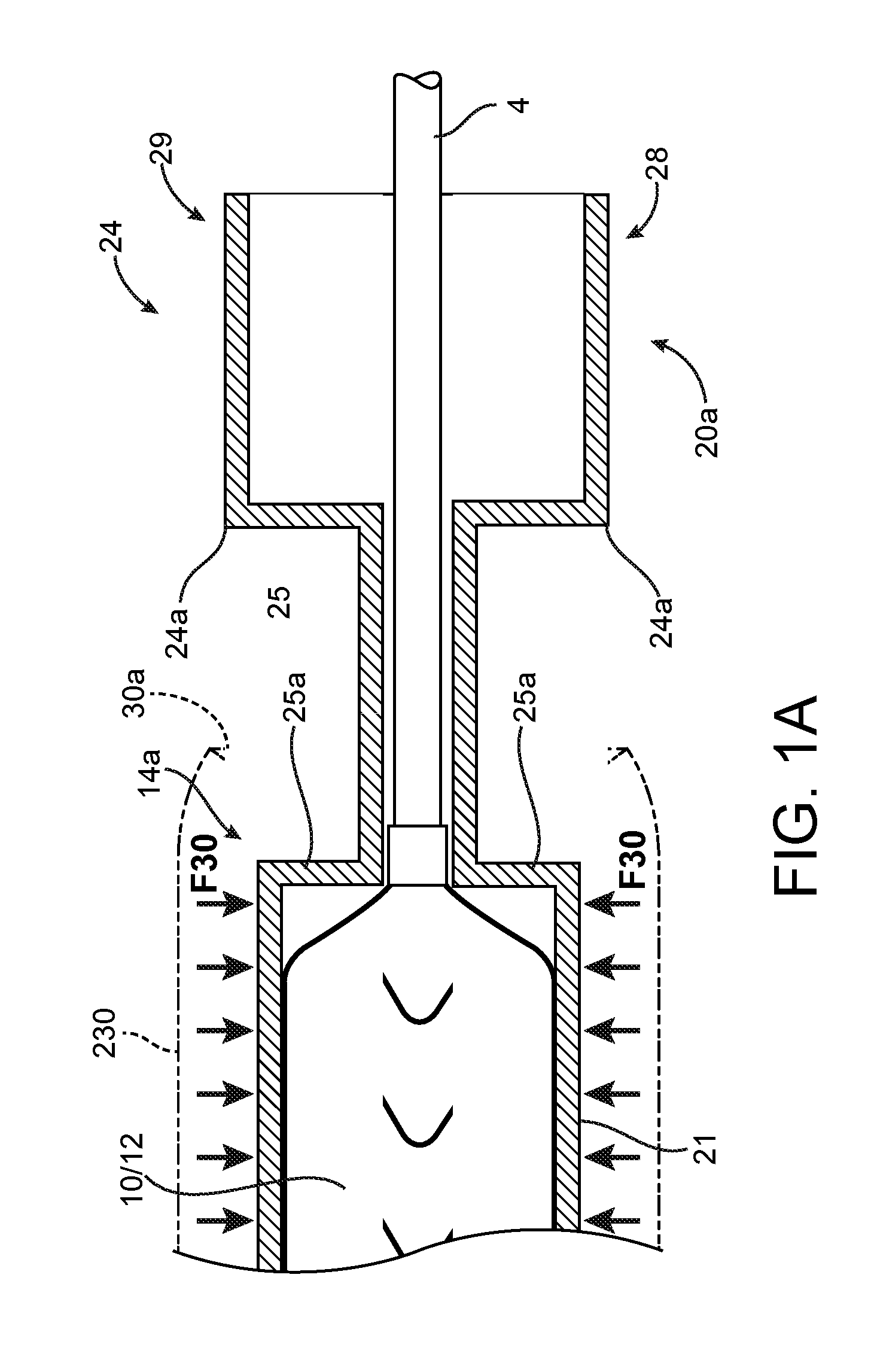

Sheaths Used With Polymer Scaffold

InactiveUS20120324696A1Easy to disassembleIncrease propensityStentsBalloon catheterPolymer scaffoldMedical device

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. A sheath pair is placed over the crimped scaffold after crimping to reduce recoil of the crimped polymer scaffold and maintain scaffold-balloon engagement relied on to hold the scaffold to the balloon when the scaffold is being delivered to a target in a body. The sheath pair is removed by a health professional before placing the scaffold within the body.

Owner:ABBOTT CARDIOVASCULAR

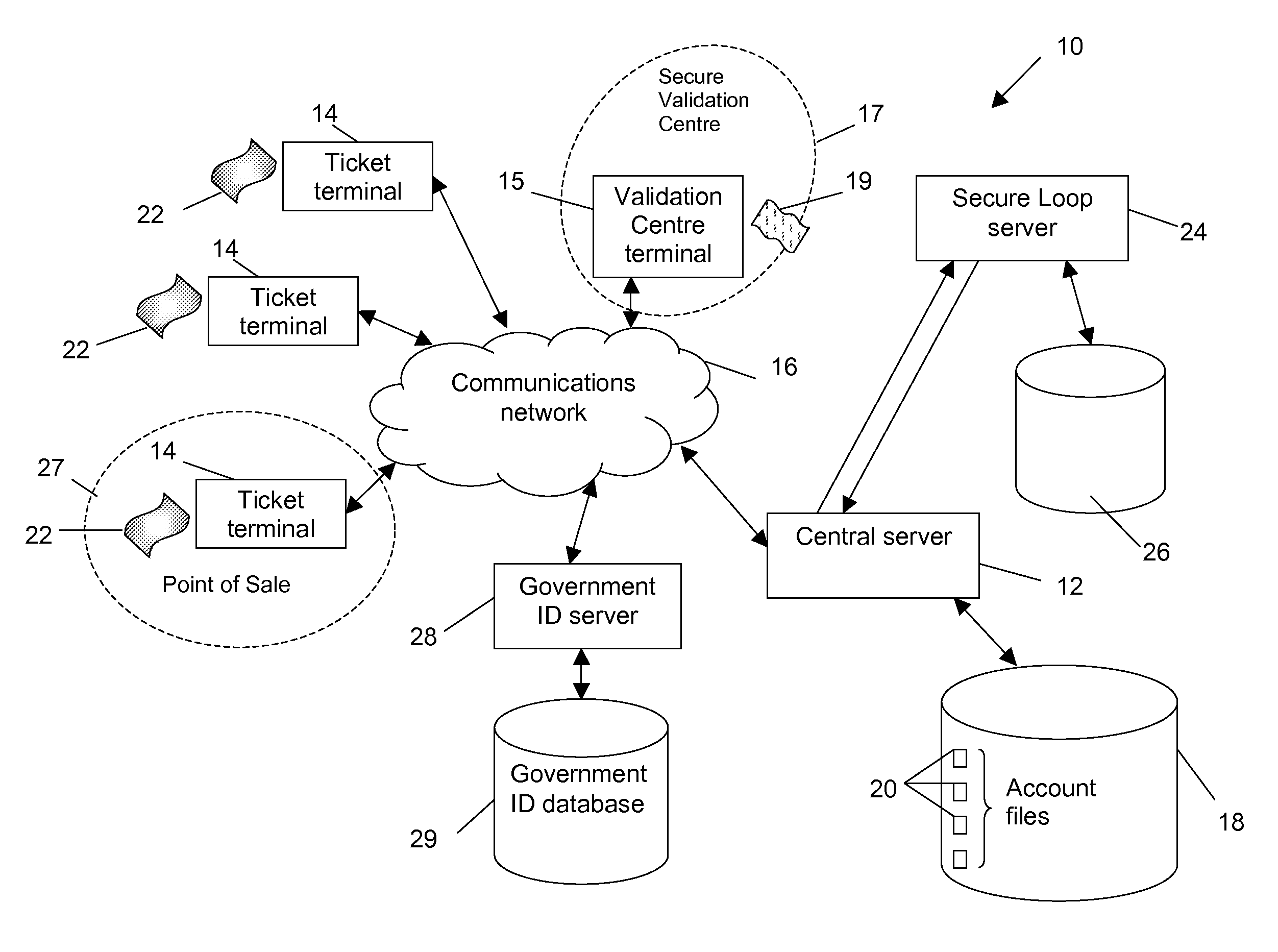

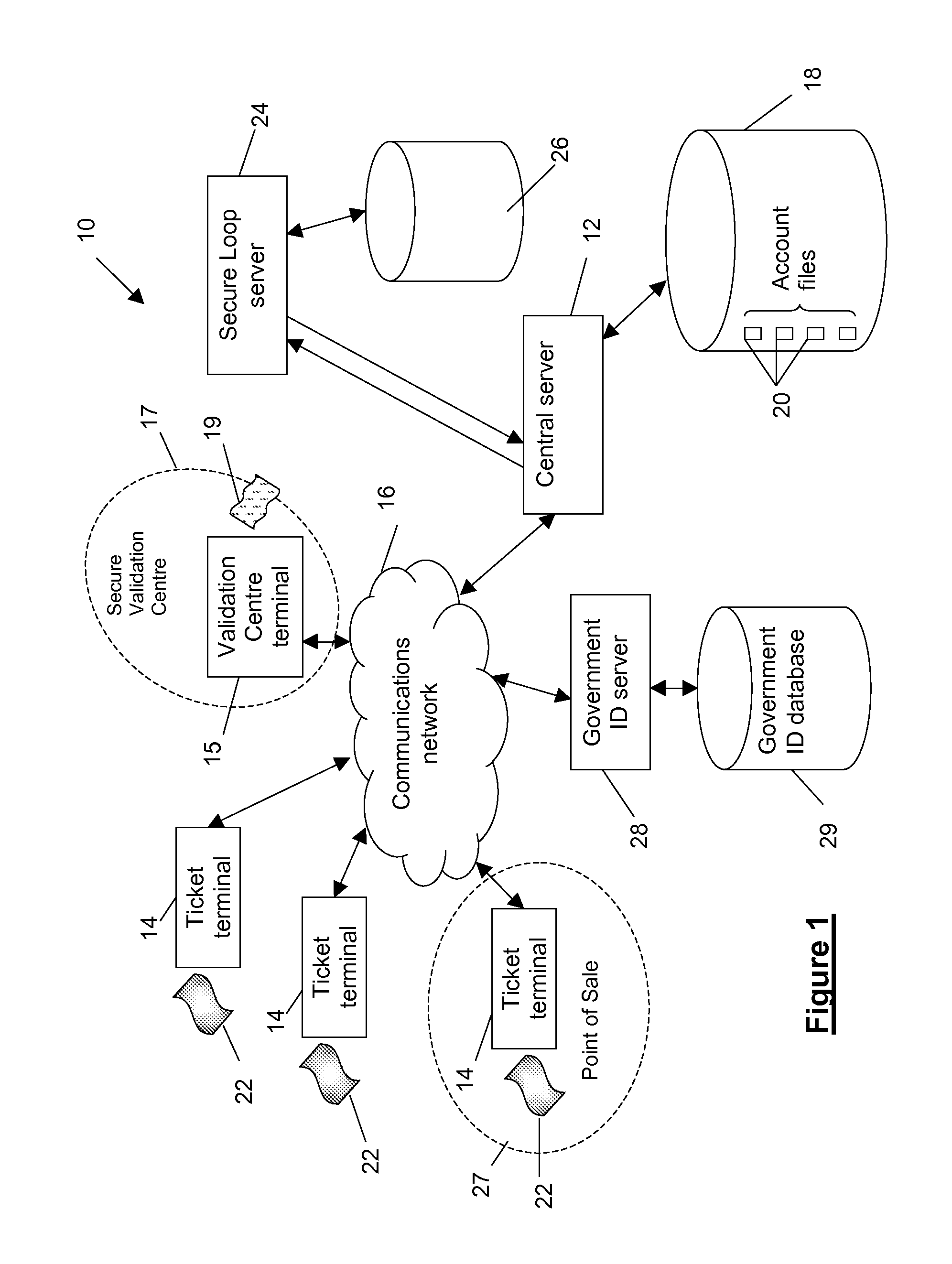

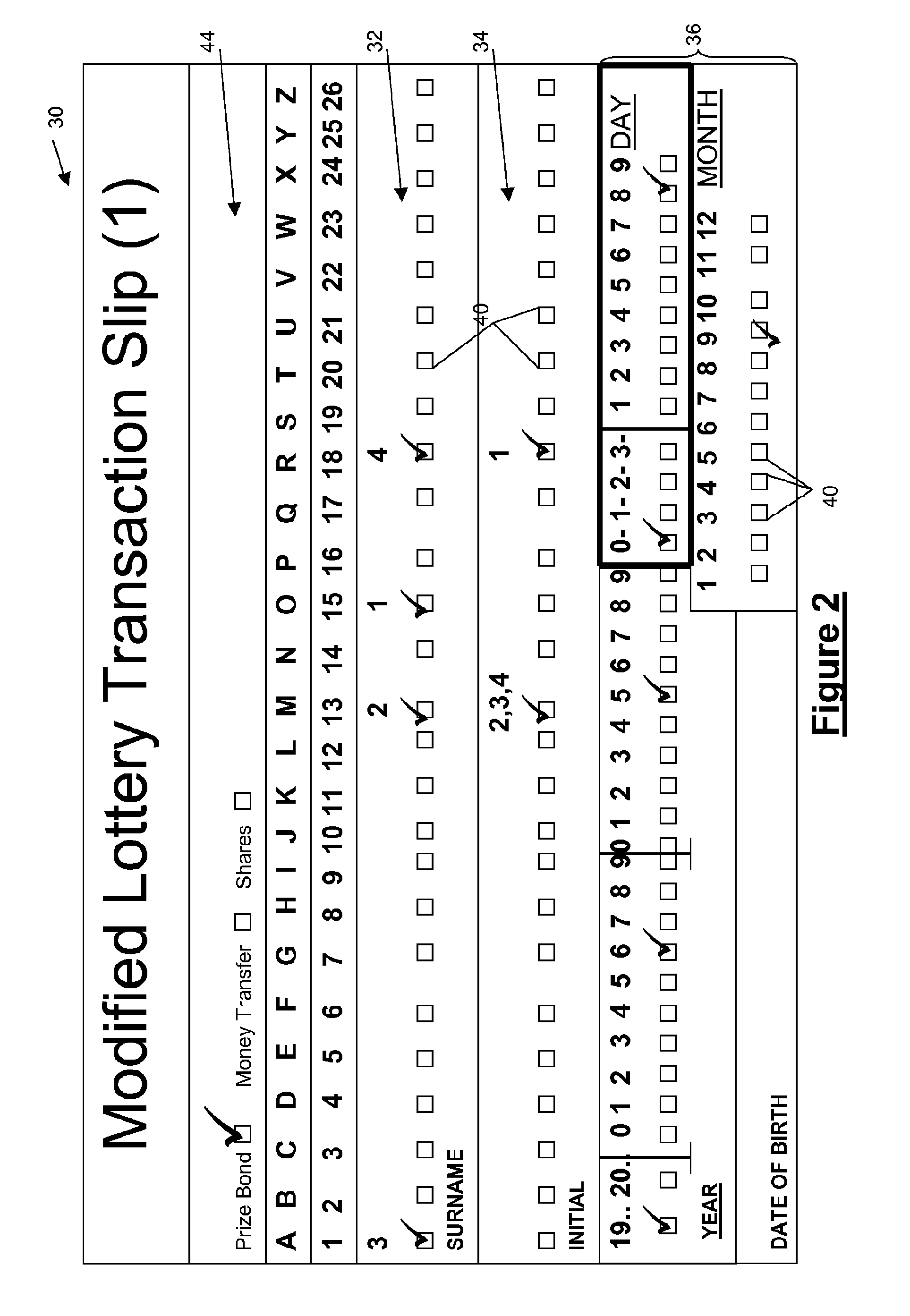

Multifunction authentication systems

InactiveUS20110281630A1Increase propensityShortening of accounting cycleDigital data authenticationApparatus for meter-controlled dispensingInternet privacyInformation device

A method of generating a personal authenticated transaction ticket with a registered-user redemption functionality is described. The method is inplemented using a remote transaction information device and a central authentication server. The method comprises receiving data at the remote transaction information device from a user, the data including i. a symbol key comprising at least one symbol selected from a plurality of symbols, and ii. personal information identifying the user, the personal information including at least the user name, digitising and encrypting the symbol key and the personal information, transmitting the encrypted data to the central server, receiving a unique transaction number associated with the symbol key and personal information, and providing the unique transaction number to the user as part of the transaction ticket, the unique transaction number confirming the registration of the user and the authentication of the transaction ticket with the central server.

Owner:OMARCO NETWORK SOLUTIONS

Polymer scaffold sheaths

ActiveUS8414528B2Easy to disassembleIncrease propensityStentsBalloon catheterHealth professionalsCatheter

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. A sheath pair is placed over the crimped scaffold after crimping to reduce recoil of the crimped polymer scaffold and maintain scaffold-balloon engagement relied on to hold the scaffold to the balloon when the scaffold is being delivered to a target in a body. The sheath pair is removed by a health professional before placing the scaffold within the body.

Owner:ABBOTT CARDIOVASCULAR

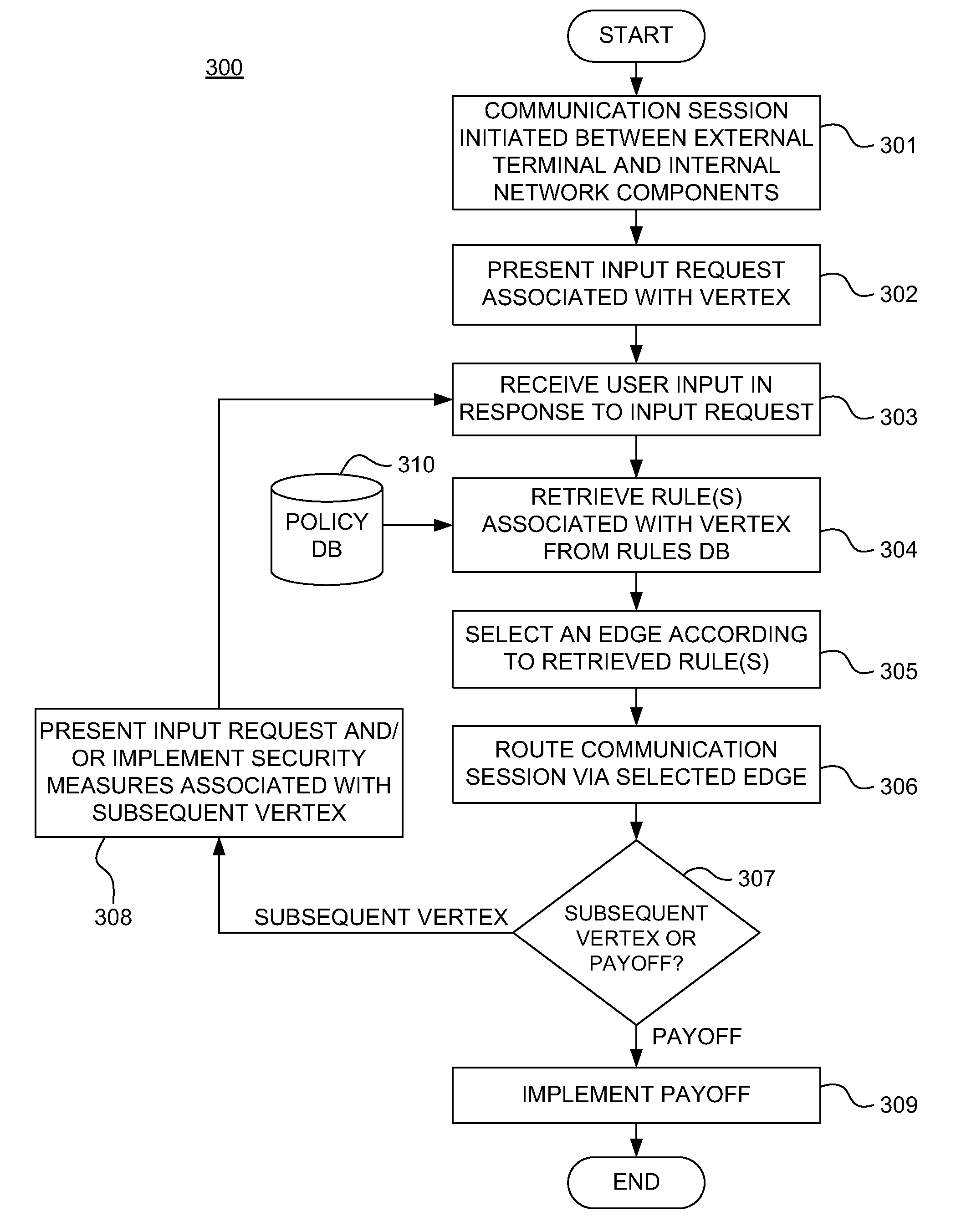

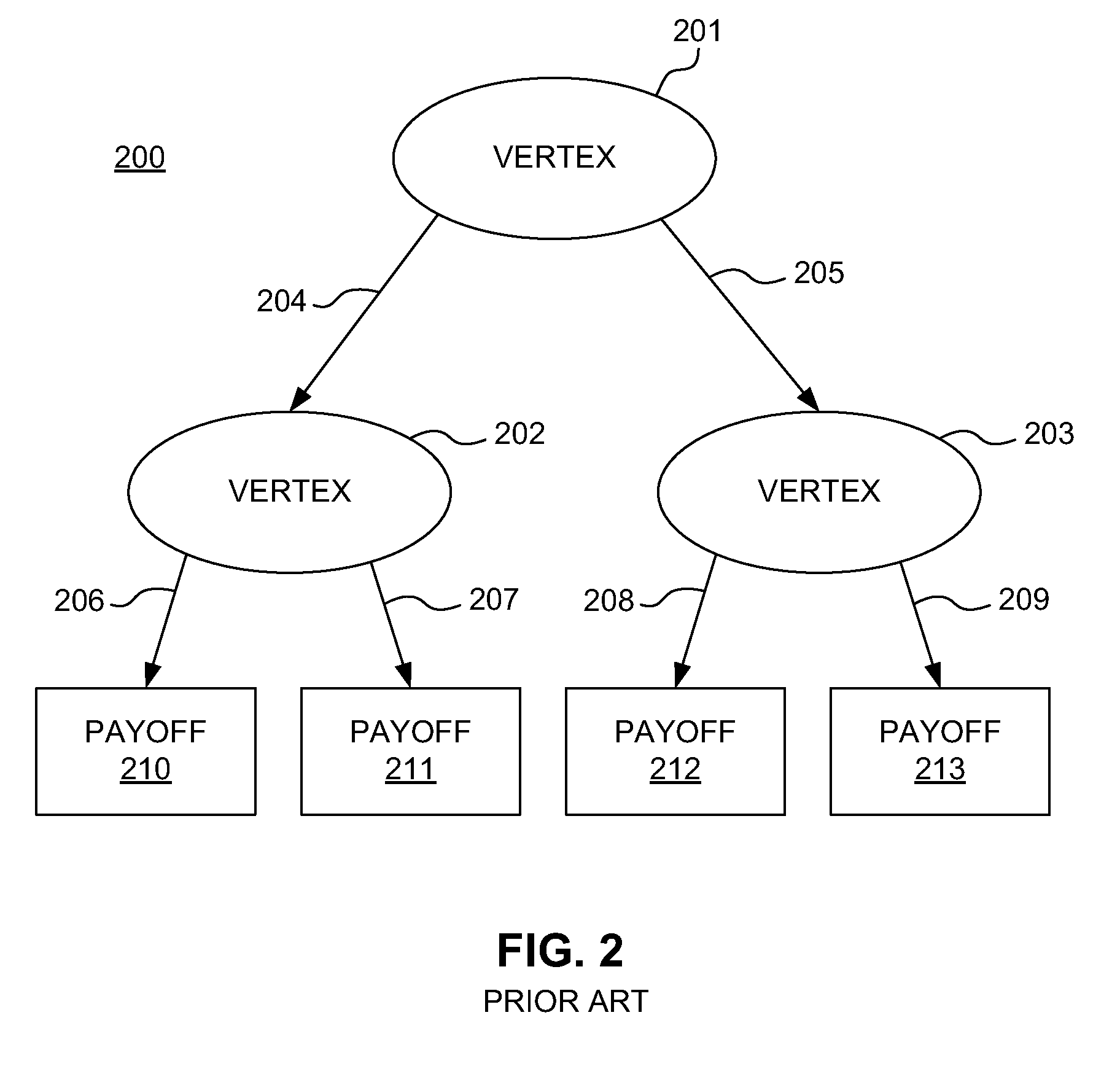

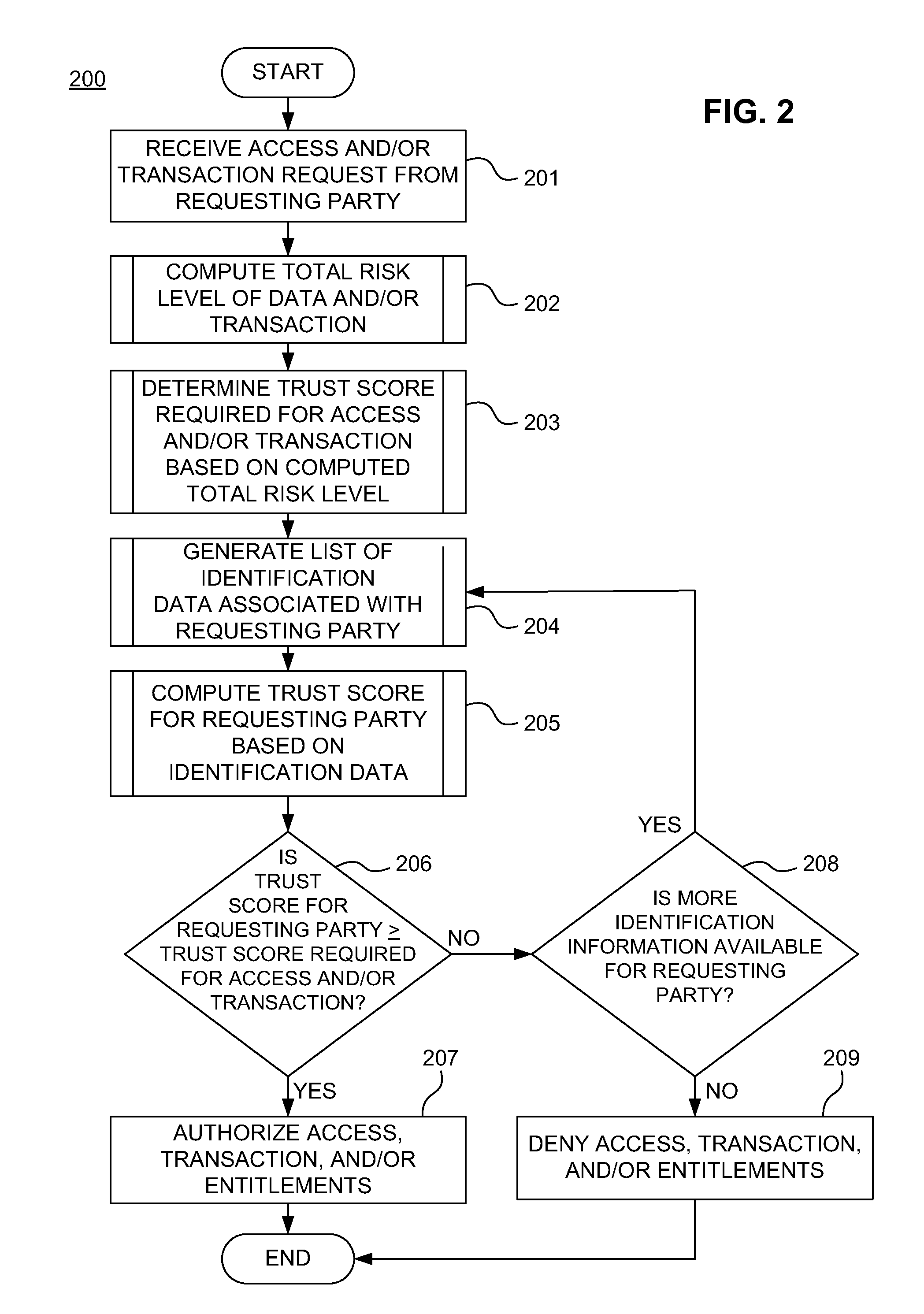

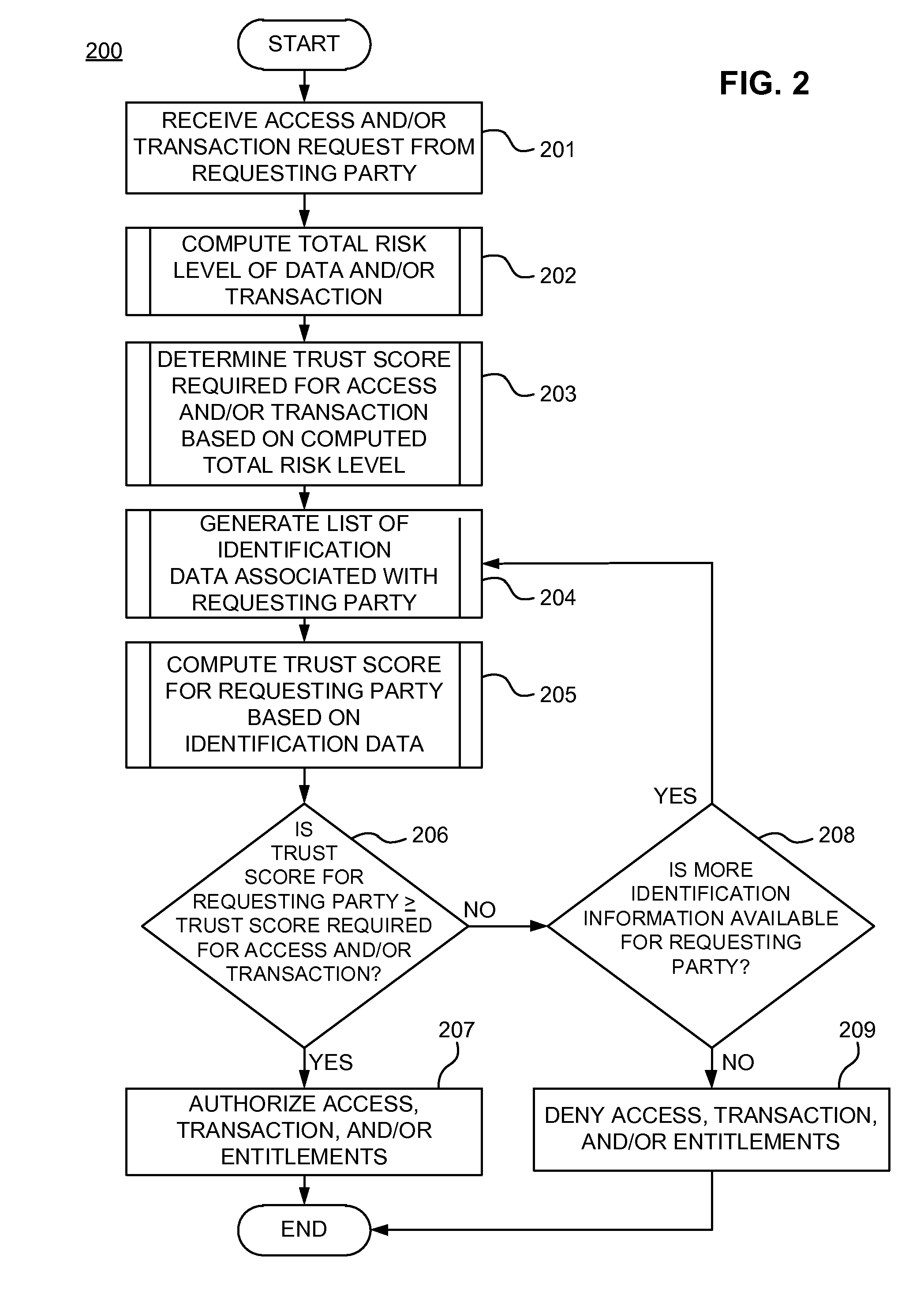

Dynamically adaptive policy management for securing mobile financial transactions

ActiveUS20110313930A1Shorten the time to marketIncrease propensityFinanceDigital data processing detailsAdaptive securityFinancial trading

A system for securing a mobile financial transaction using an adaptive security policy is provided by presenting, via an external terminal, an input request associated with a vertex of the security policy. User input is received via the external terminal in response to the input request. A rule associated with the vertex is retrieved from a database. An edge is selected from a plurality of edges associated with the vertex according to the retrieved rule. A communication session of the external terminal is routed to a subsequent vertex via the selected edge.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

Methods and systems for recommending an appropriate action to a patient for managing epilepsy and other neurological disorders

ActiveUS8868172B2Reduction tendencyEasy to manageElectroencephalographyPhysical therapies and activitiesNeurological disorderEpileptic seizure

Owner:CYBERONICS INC

Dynamic pairing system for securing a trusted communication channel

ActiveUS20110313925A1Shorten the time to marketIncrease propensityFinancePayment architectureTotal riskInternet privacy

A system for securing a trusted communications channel for a mobile financial transaction is provided by receiving, from a user via an external terminal, a request for an access control entitlement to complete a financial transaction. A total risk level associated with the financial transaction is computed. A required trust score is determined based on the total risk level. User identification data associated with the user is received from one or more data sources. The user identification data is validated. A user trust score associated with the user is computed based on the validated identification data. The user trust score is compared to the required trust score. The access control entitlement is transmitted to the user via the external terminal if the user trust score is greater than or equal to the required trust score.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

Polymer Scaffold Sheaths

ActiveUS20120302955A1Easy to disassembleIncrease propensityStentsBalloon catheterHealth professionalsPolymer scaffold

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. A sheath pair is placed over the crimped scaffold after crimping to reduce recoil of the crimped polymer scaffold and maintain scaffold-balloon engagement relied on to hold the scaffold to the balloon when the scaffold is being delivered to a target in a body. The sheath pair is removed by a health professional before placing the scaffold within the body.

Owner:ABBOTT CARDIOVASCULAR

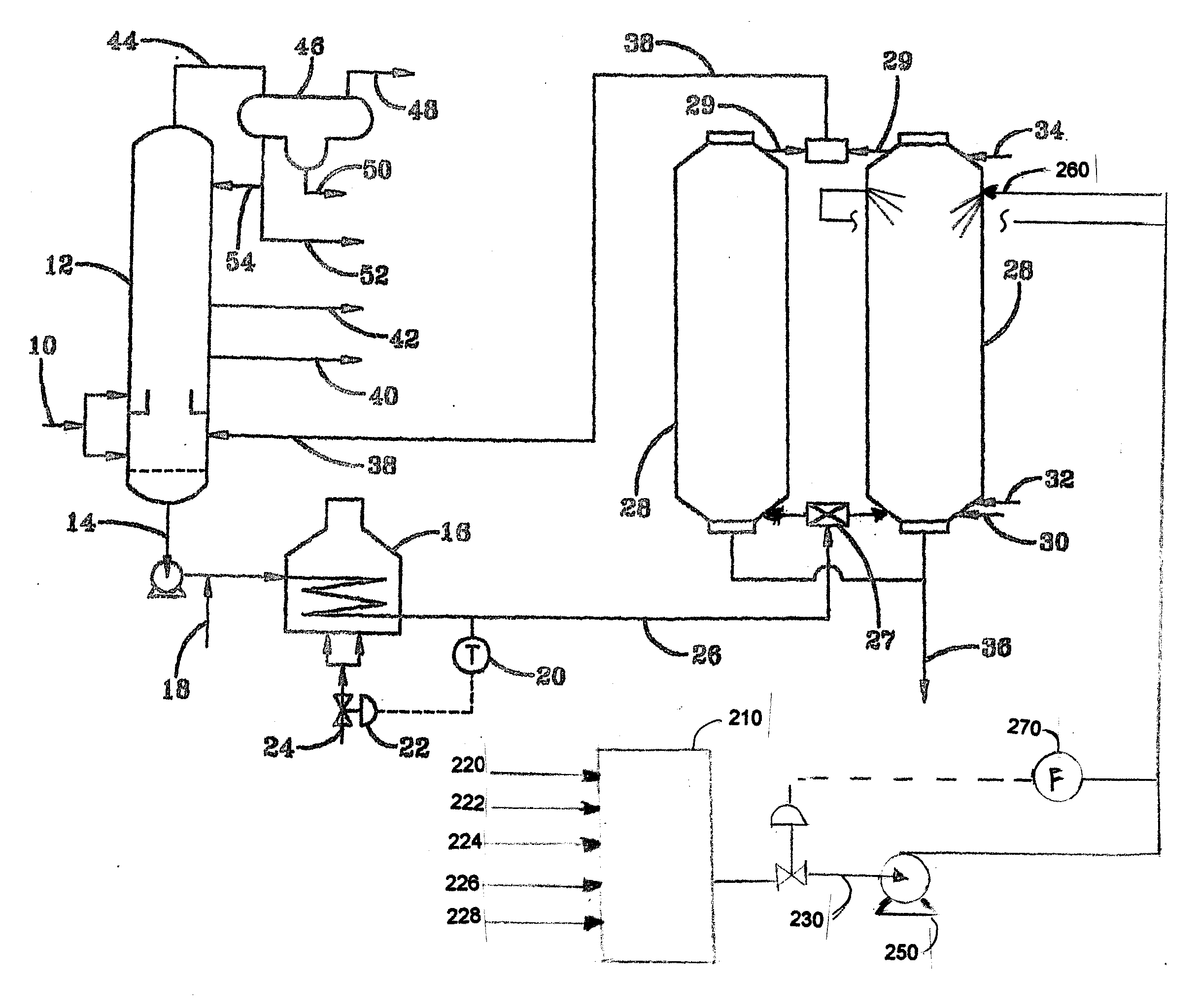

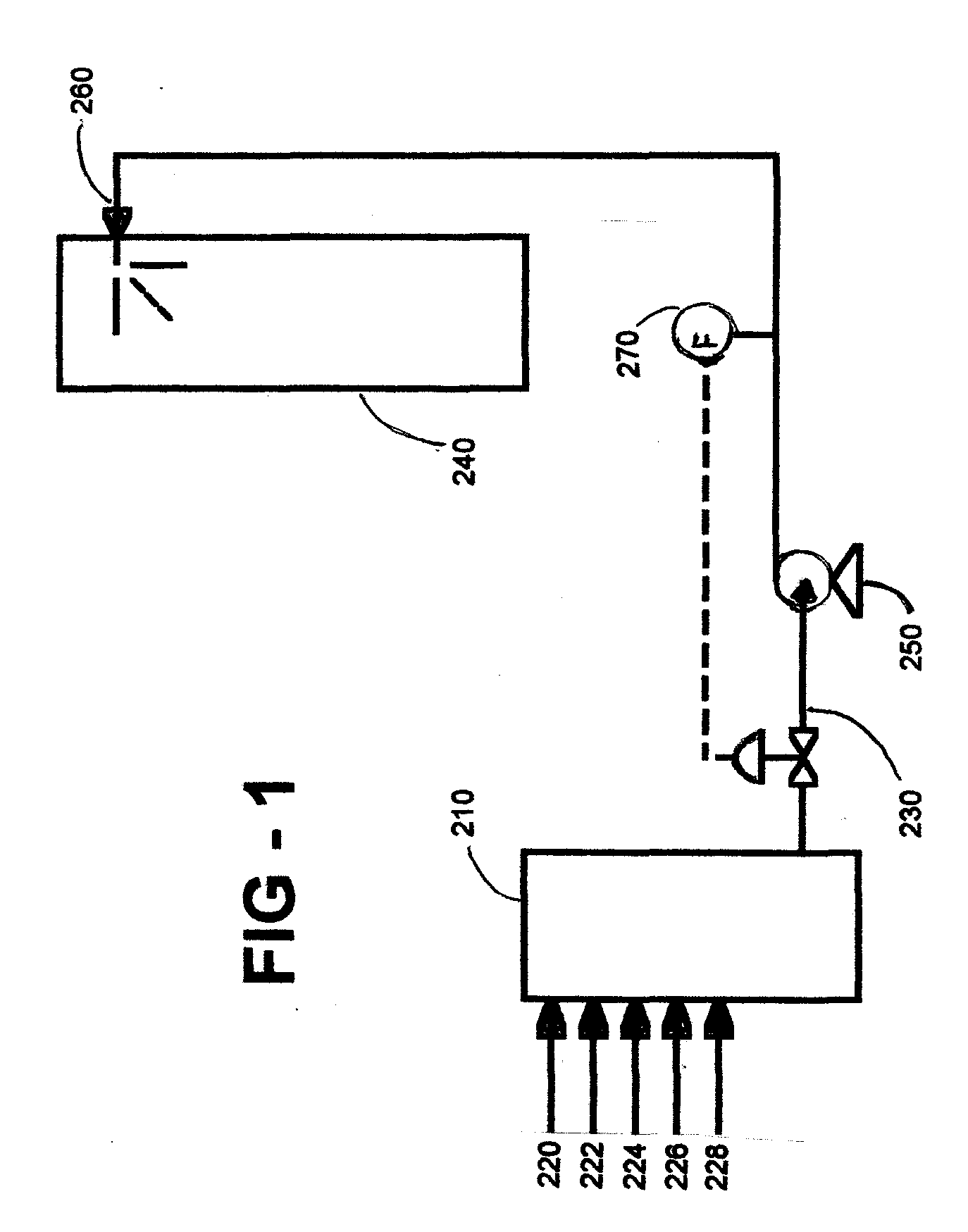

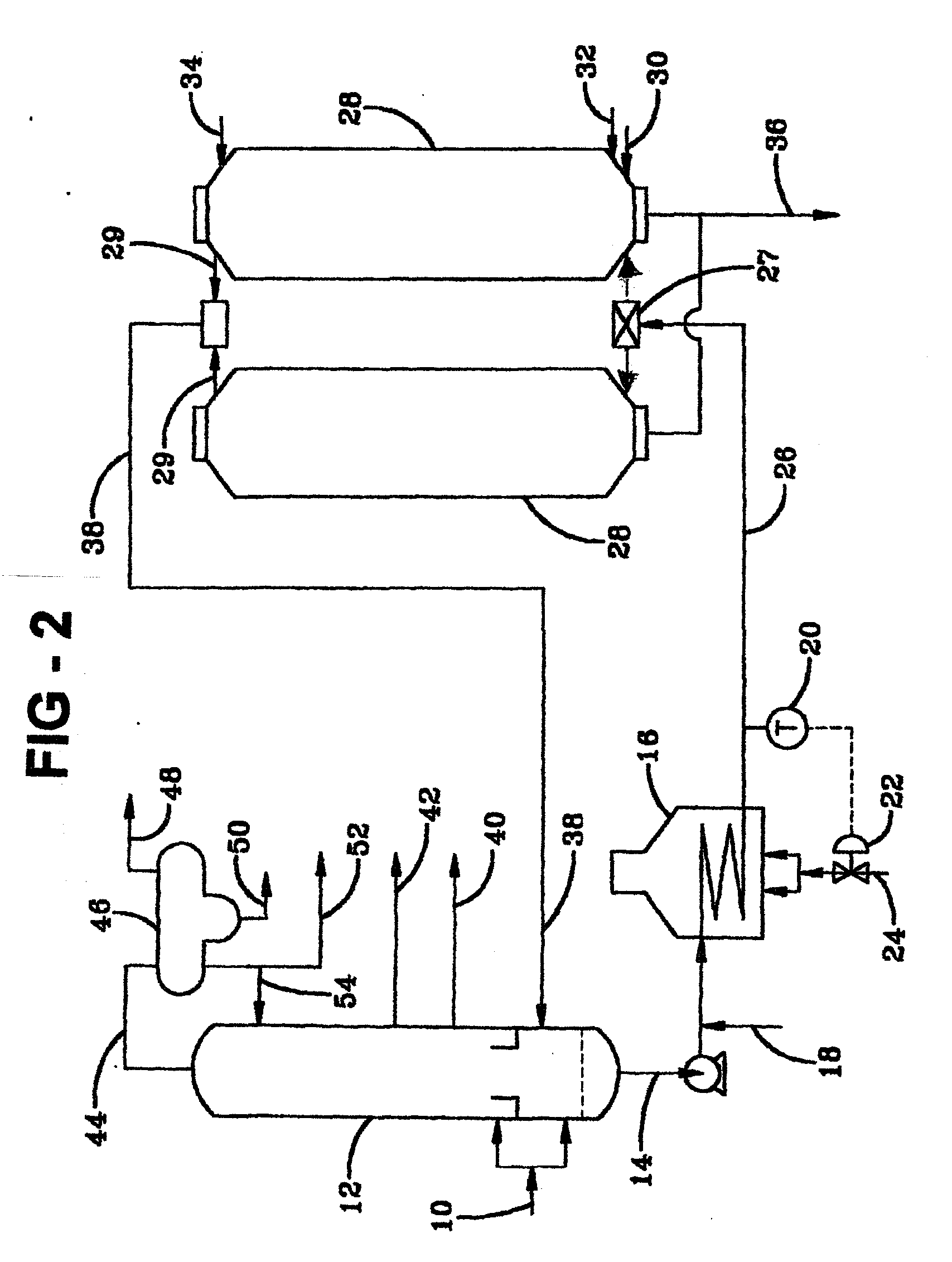

System and Method of Introducing an Additive with a Unique Catalyst to a Coking Process

InactiveUS20090209799A1High propensity to cokePromotes cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkyl transferNaphtha

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. Modifications of the catalysts in the additive improve performance for certain desired outcomes. One exemplary embodiment of the present invention uses the olefin production capabilities from newly developed catalysts to increase the production of light olefins (e.g. ethylene, propylenes, butylenes, pentenes) for alkylation process unit feed, the production of oxygenates, and petrochemical feedstocks, such as plastics manufacture. Another exemplary embodiment of the present invention is the use of the olefin production from newly developed catalysts to improve the coker naphtha quality. A third exemplary embodiment of the present invention uses the cracking characteristics of newly developed catalysts to optimize the production of light gas oils, naphtha, and gases from the coking process.

Owner:ETTER ROGER G +1

Protective sheath assembly for a polymer scaffold

ActiveUS20140379064A1Minimize disruptionEasily removeStentsSurgeryHealth professionalsBiomedical engineering

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. A sheath is placed over the crimped scaffold after crimping to reduce recoil of the crimped polymer scaffold and maintain scaffold-balloon engagement relied on to hold the scaffold to the balloon when the scaffold is being delivered to a target in a body. The sheath is removed by a health professional either by removing the sheath directly or using a tube containing the catheter.

Owner:ABBOTT CARDIOVASCULAR

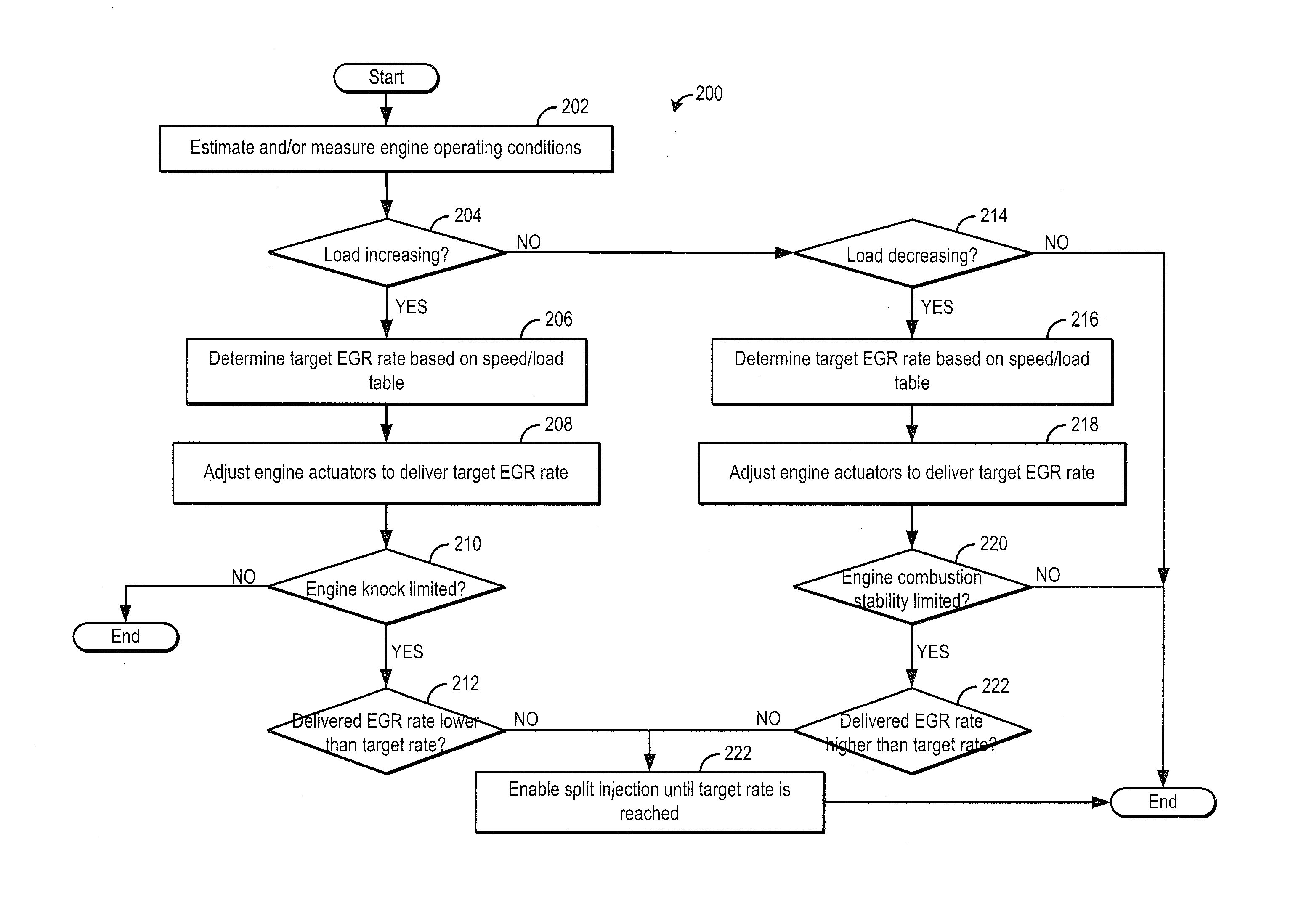

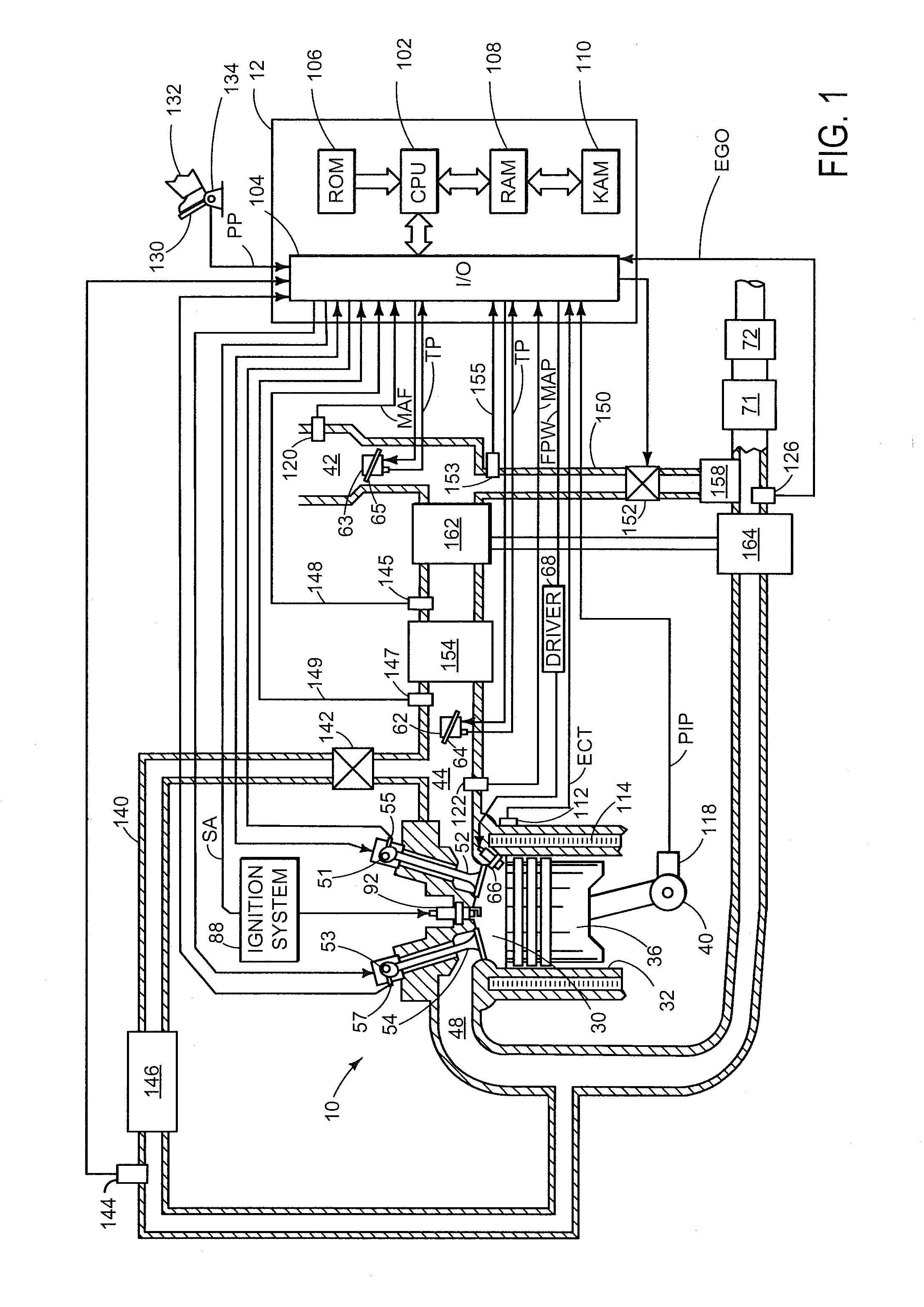

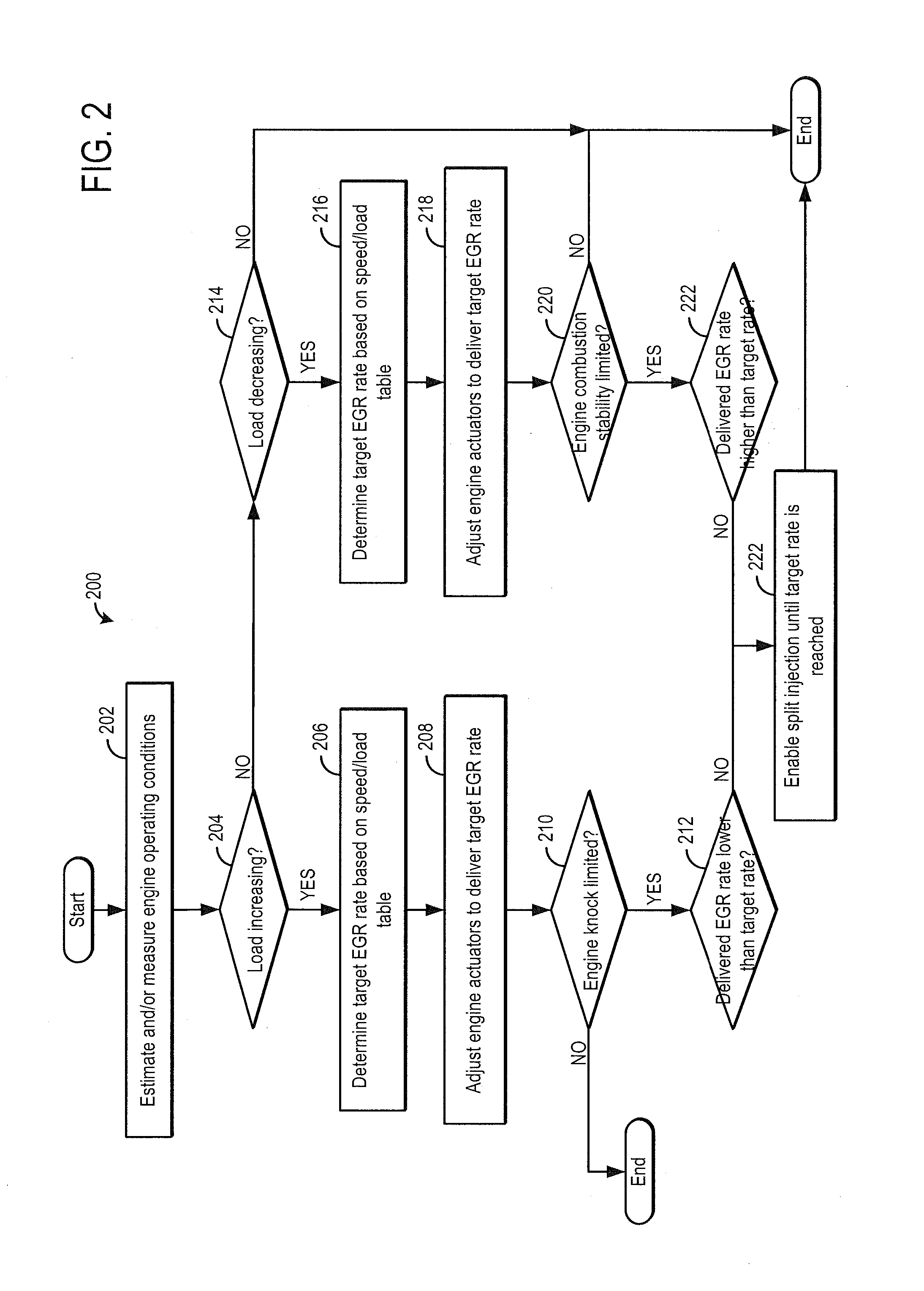

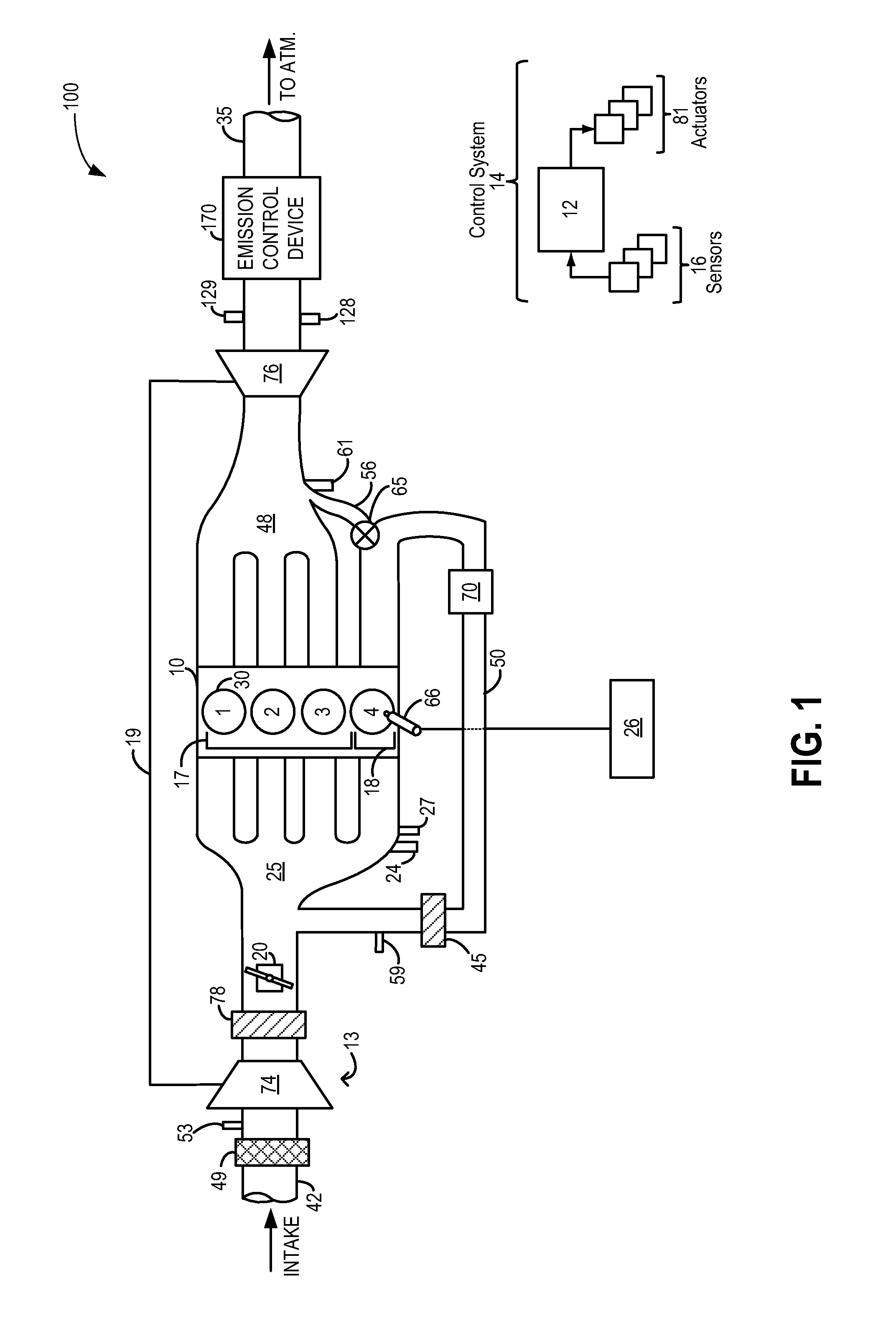

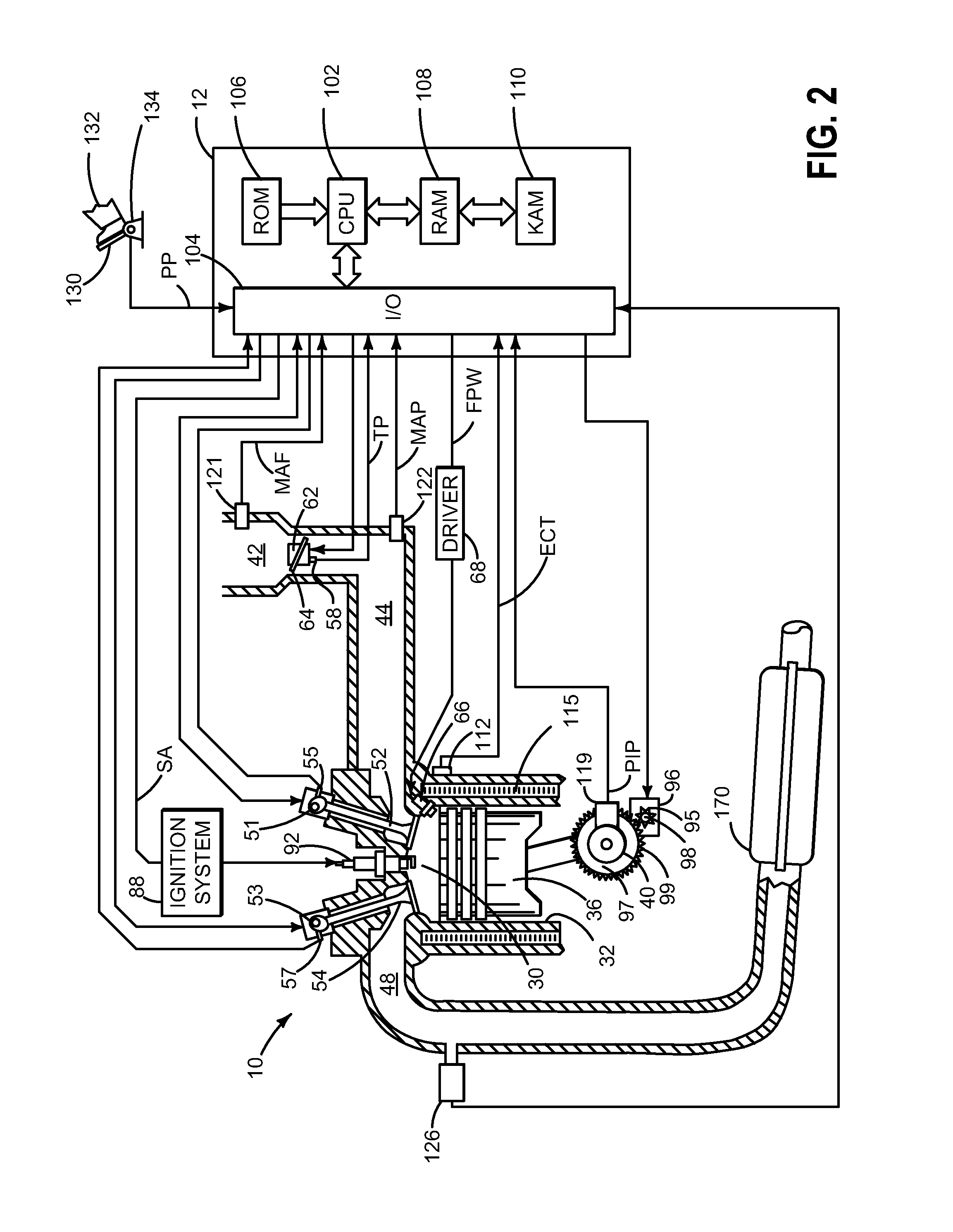

Method and system for improved dilution tolerance

ActiveUS20150057911A1Improve fuel economyImprove vehicle emissionElectrical controlInternal combustion piston enginesCombustionLow load

Methods and systems are provided for improving combustion stability, in particular during transient operations such as tip-out to lower load conditions, when EGR is being purged. Until a desired LP-EGR rate is achieved, fuel may be delivered as a split injection with at least an intake stroke injection and a compression stroke injection. Subsequently, single fuel injection may be resumed.

Owner:FORD GLOBAL TECH LLC

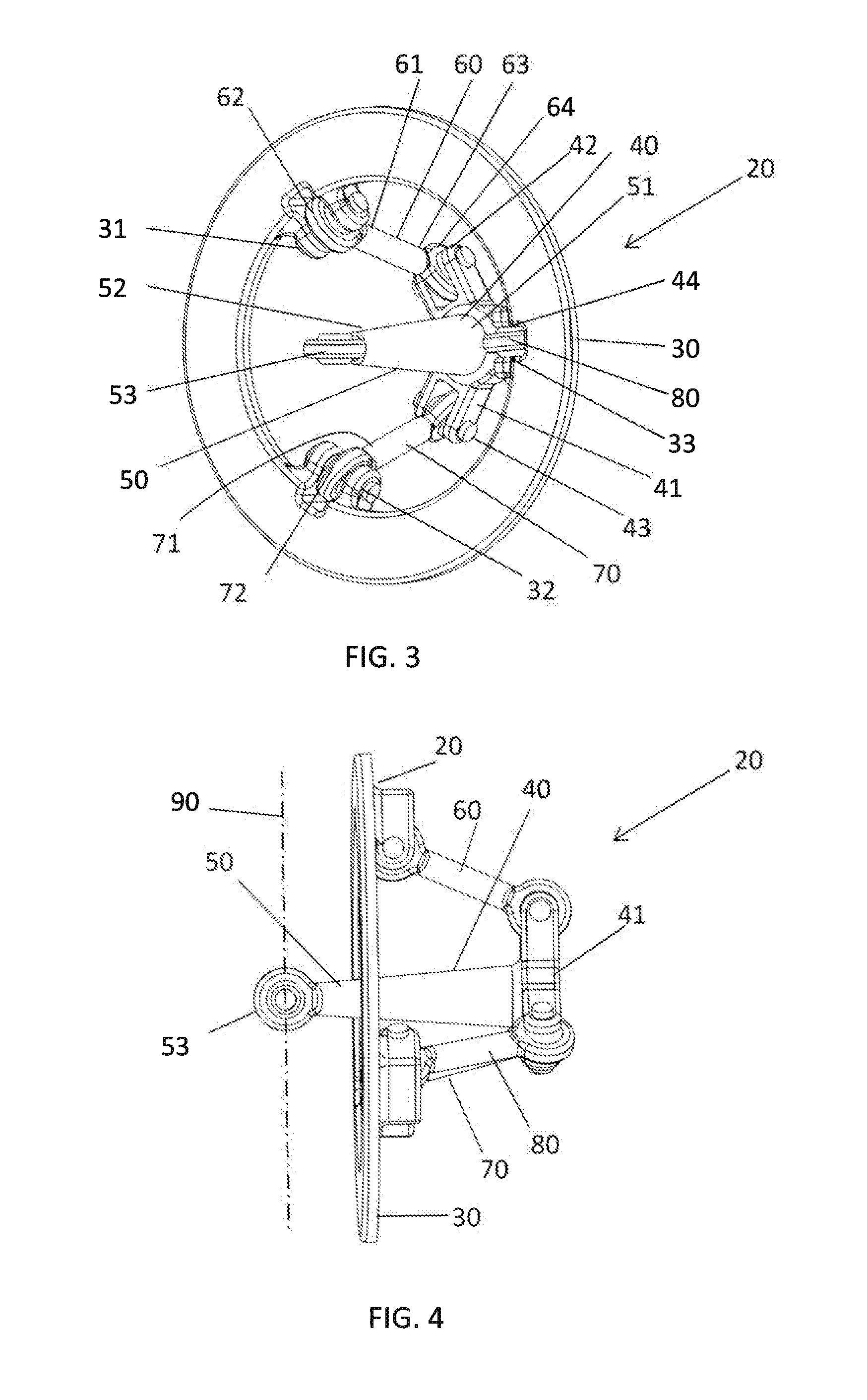

Planar Linkage, Methods of Decoupling, Mitigating Shock and Resonance, and Controlling Agricultural Spray Booms Mounted on Ground Vehicles

ActiveUS20140263766A1Span to be maximizedMaximize utilizationLiquid fertiliser distributionWatering devicesTerrainResonance

The current invention discloses several methodologies that mitigate shock loading and propensity to resonance in agricultural spray boom structures. These include a near planar linkage for decoupling the boom assembly from the vehicle. This serves to permit further aspects of the invention to: Use the combined mass of the booms and center section as the tuned mass of a tuned mass damper: Act as an enabling part of a boom compliant suspension system to mitigate shock loadings otherwise imposed on the boom system, and: Act as an enabling part of an active boom height and roll control systems to permit the accurate navigation of the boom over undulating terrain. Further aspects include the incorporation of tuned mass dampers in the boom structure and components; and the use of the mass and operation of the boom outboard “breakaway” sections as tuned mass dampers.

Owner:CNH IND AMERICA LLC

Aggregating compositions, modified particulate metal-oxides, modified formation surfaces, and methods for making and using same

ActiveUS8466094B2Improved self-aggregating propertyIncrease propensityConstructionsFluid removalParticulate metalMaterials science

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treating composition and treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

Stabilized soluble glycoprotein trimers

InactiveUS20050106177A1Stabilize trimerSimplifies isolationPeptide/protein ingredientsAntibody mimetics/scaffoldsHiv envelopeGp41

The present application is directed to stabilized HIV envelope glycoprotein trimers. The trimers are stabilized by introducing trimeric motifs, preferably the GCN4 coiled coil or the fibritin trimeric domain, at certain sites, for example in the gp41 ectodomain. These stabilized trimers or DNA molecules encoding such trimers can be used to generate an immunogenic reaction. The trimers can also be used in assays to screen for molecules that interact with them—and to identify molecules that interact with specific sites.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Sheaths used with polymer scaffold

InactiveUS8852257B2Easy to disassembleIncrease propensityStentsBalloon catheterCatheterPolymer scaffold

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. A sheath pair is placed over the crimped scaffold after crimping to reduce recoil of the crimped polymer scaffold and maintain scaffold-balloon engagement relied on to hold the scaffold to the balloon when the scaffold is being delivered to a target in a body. The sheath pair is removed by a health professional before placing the scaffold within the body.

Owner:ABBOTT CARDIOVASCULAR

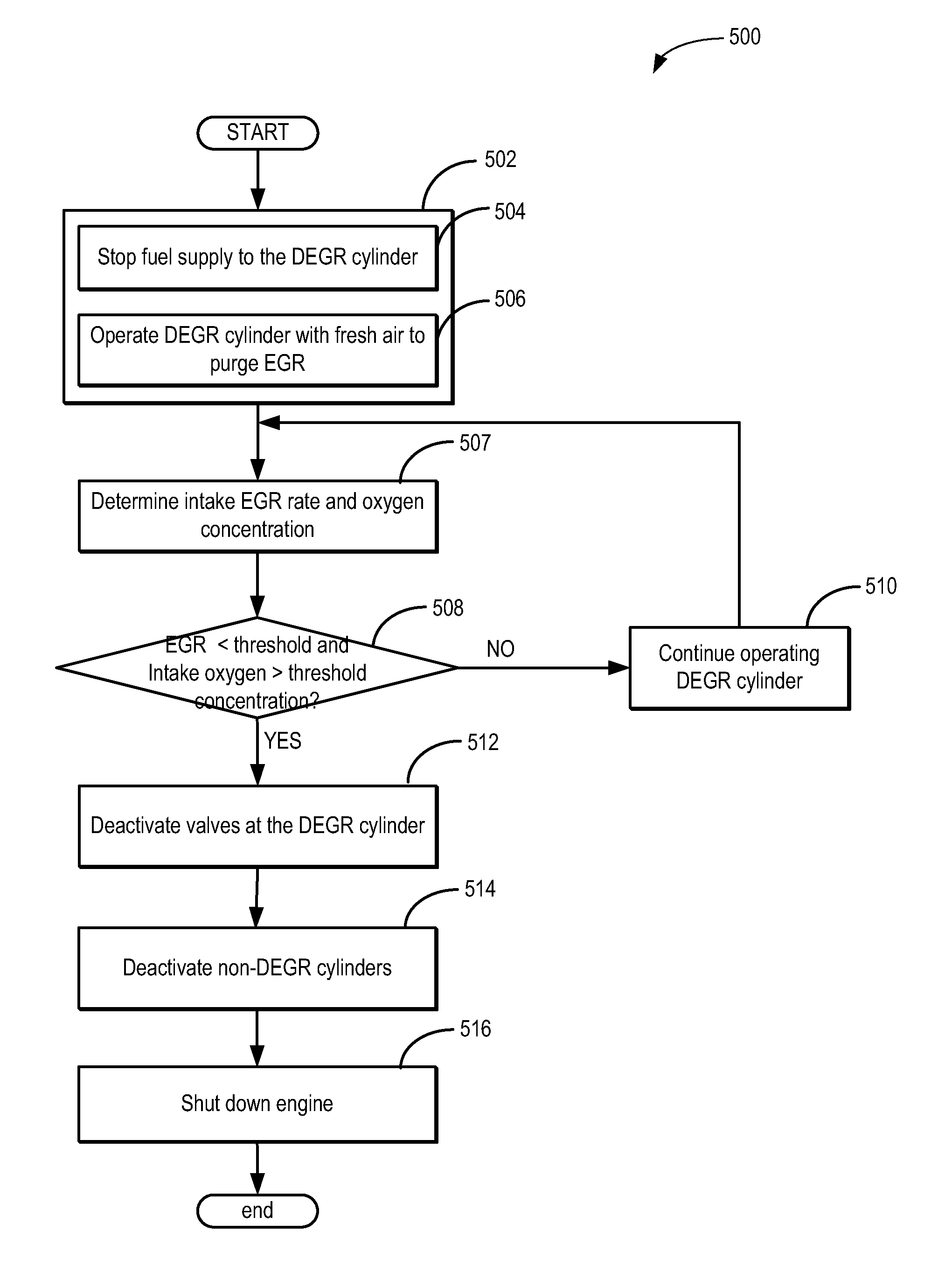

Systems and methods for stopping and starting an engine with dedicated egr

ActiveUS20150369180A1Reduce the temperatureImprove economyElectrical controlNon-fuel substance addition to fuelStart stop

Owner:FORD GLOBAL TECH LLC

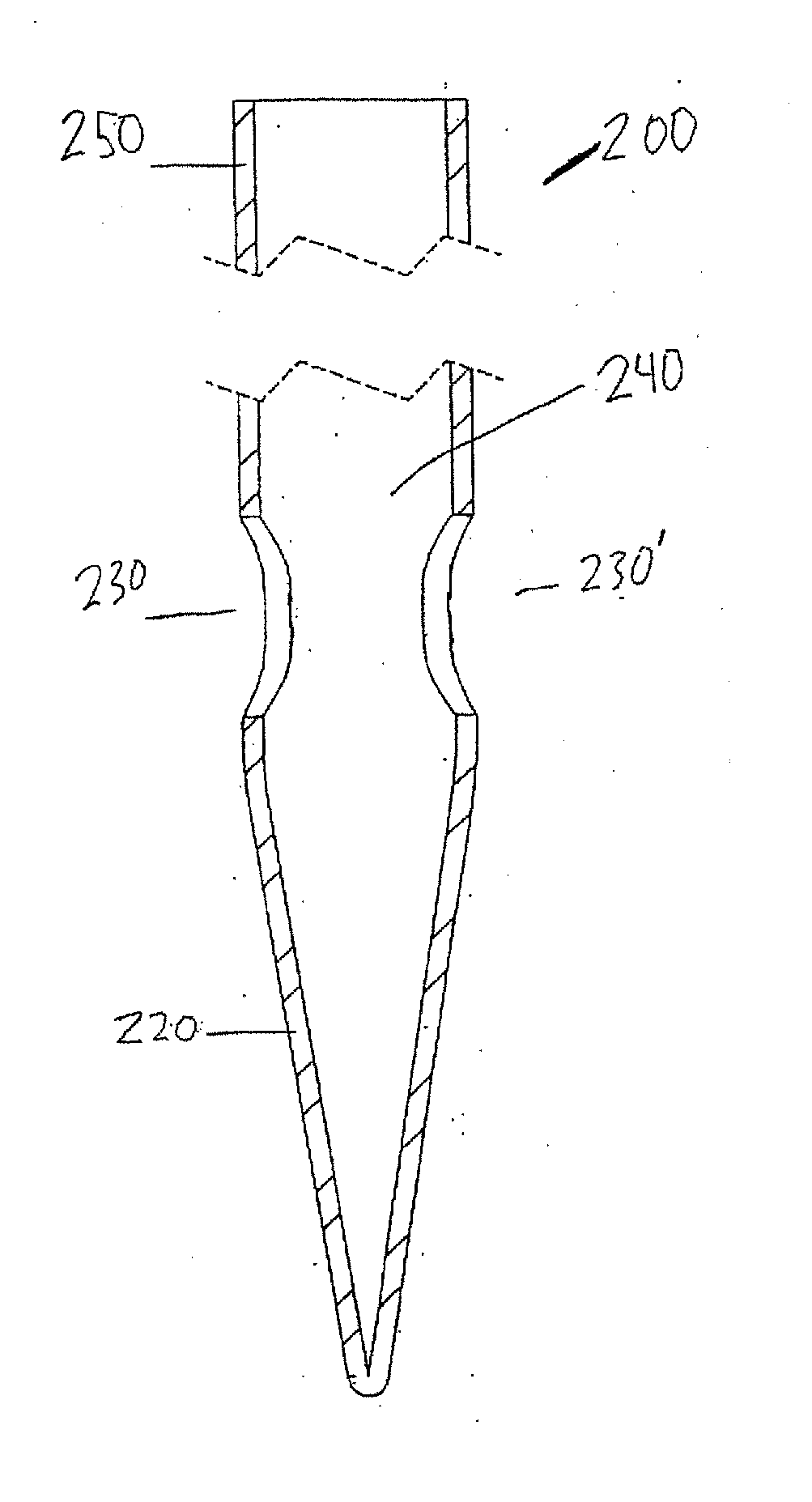

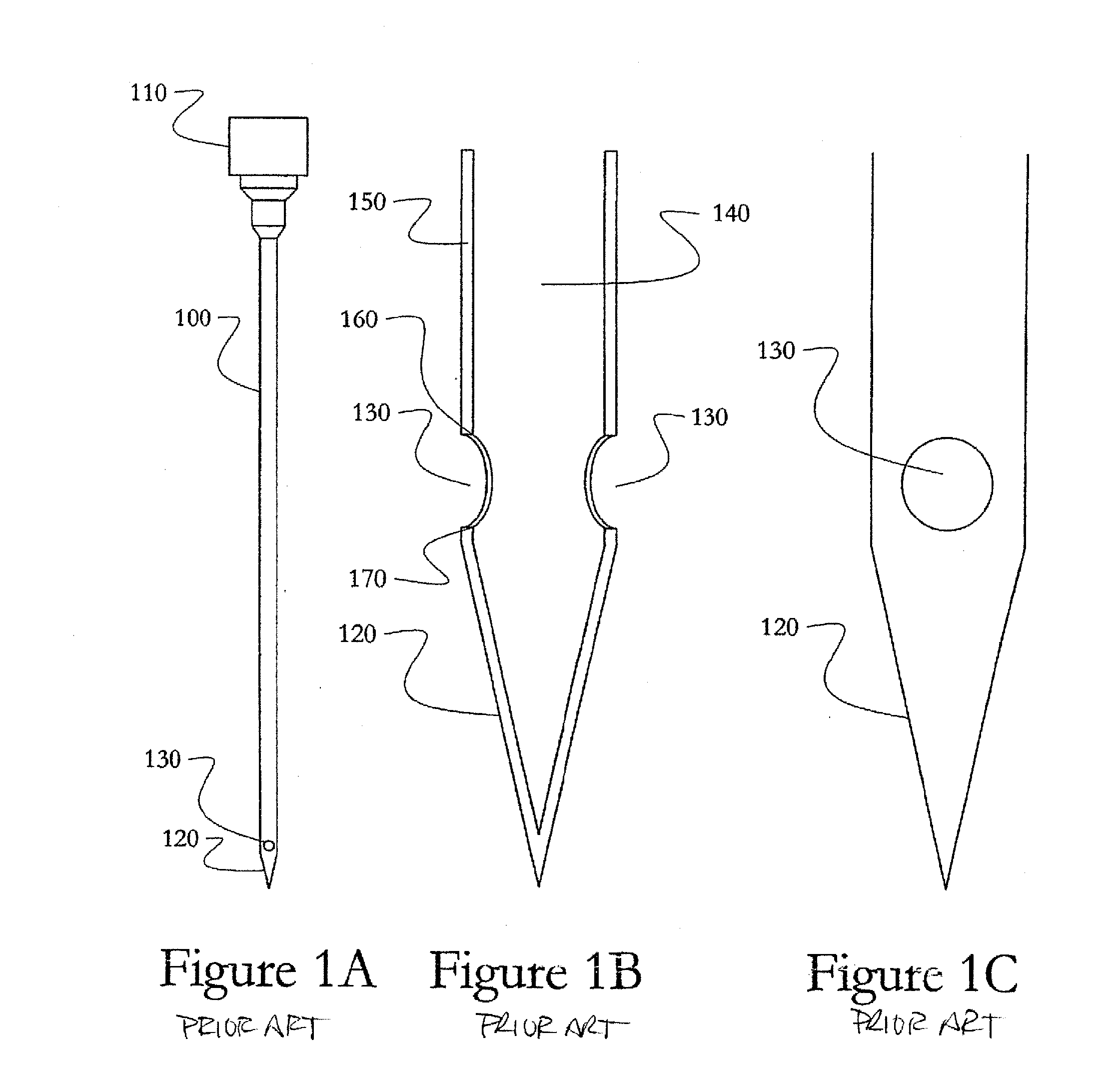

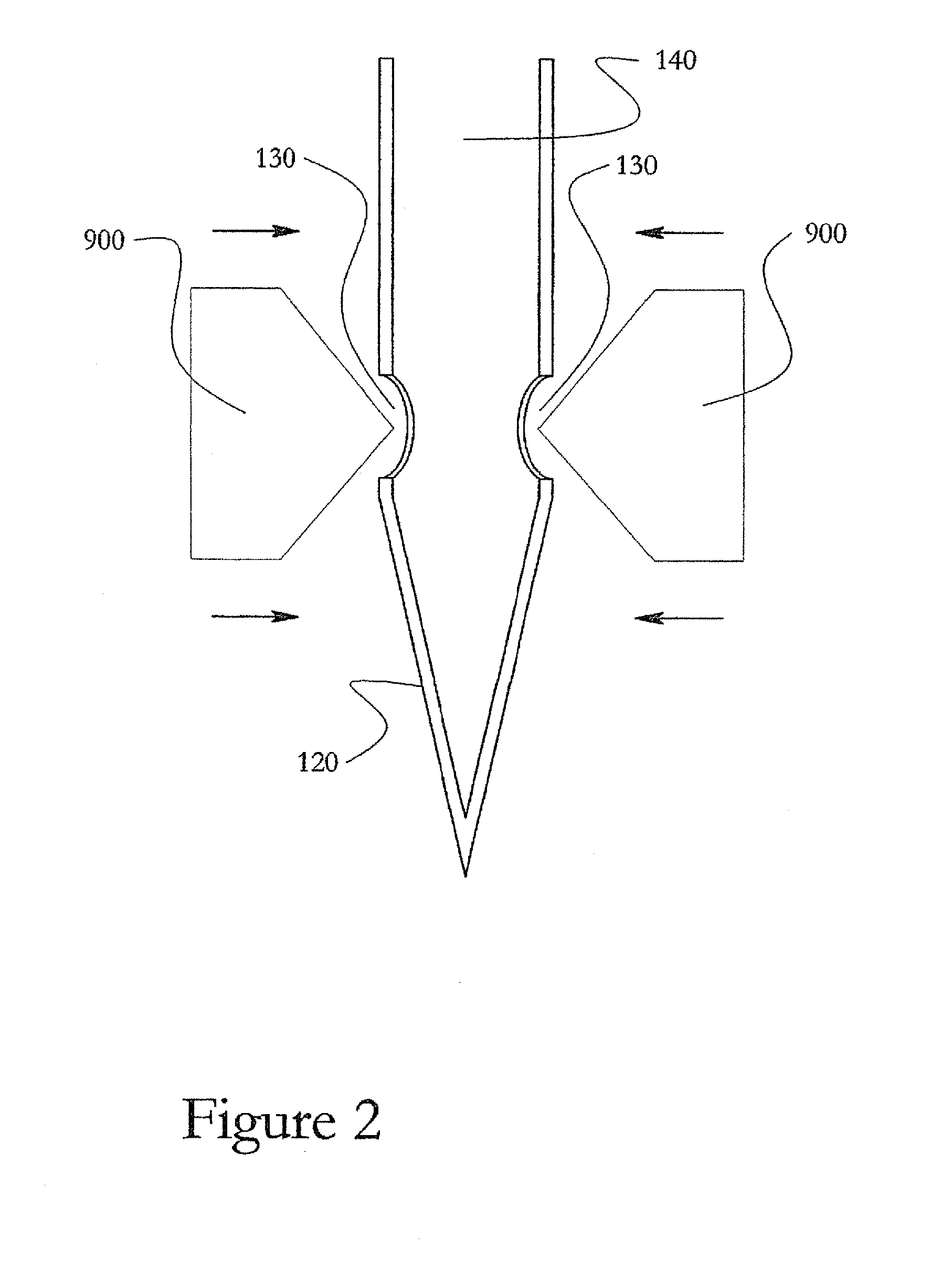

Non-coring reduced shearing needle

InactiveUS20140103065A1Avoiding unwanted blockageImprove flow resistancePinsNailsLeading edgeEngineering

Method and apparatus for beverage extraction needle side holes or apertures. The leading and trailing edges of the apertures may be shaped or otherwise configured to help reduce the possibility of coring or shearing of material as the needle is inserted into and / or withdrawn from material, such as a cork. Convex leading and / or trailing edges may help deflect material away from the aperture, reducing shearing. Concave leading and / or trailing edges may help prevent entry of material into the aperture, again reducing shearing.

Owner:CORAVIN

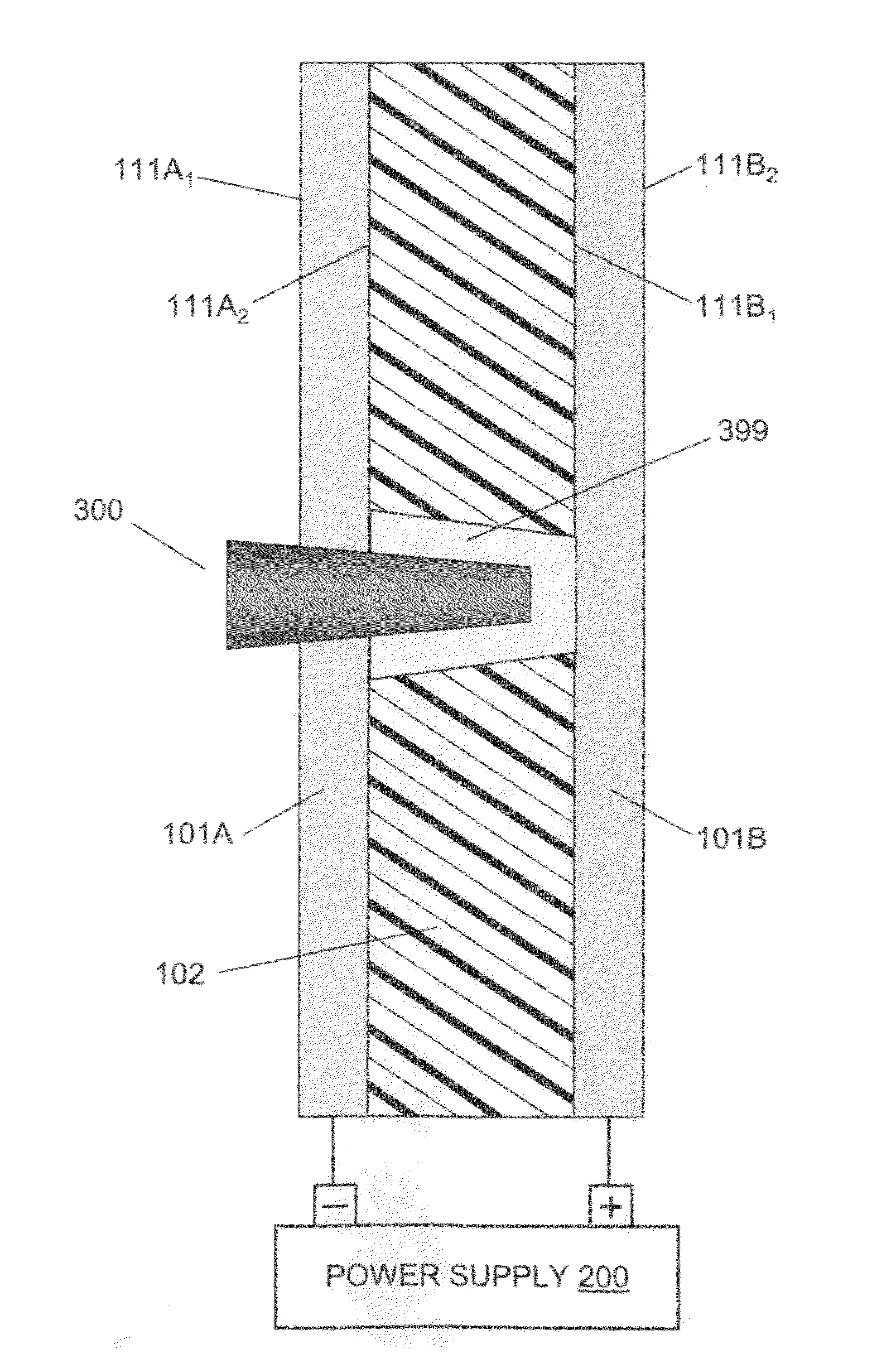

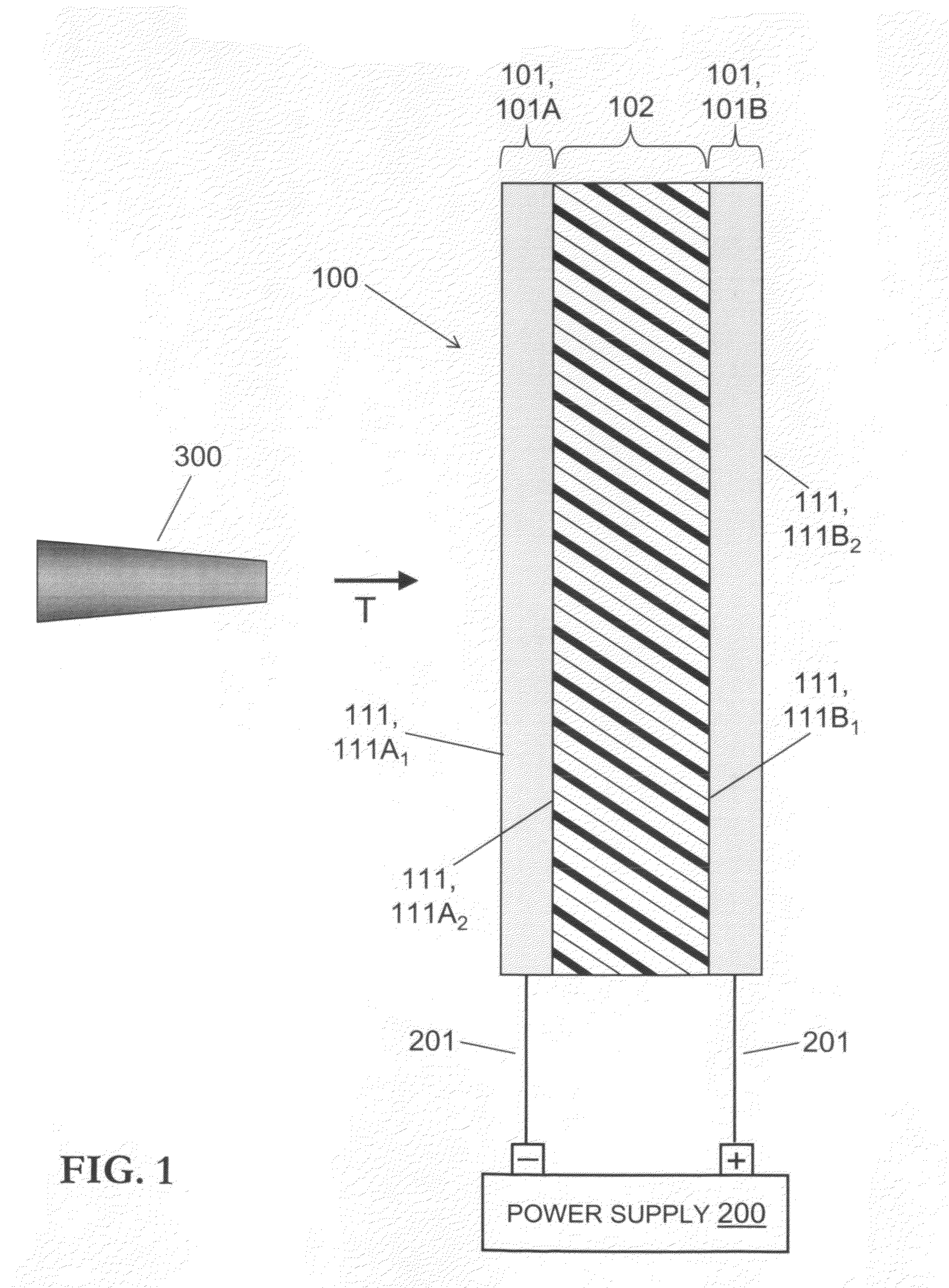

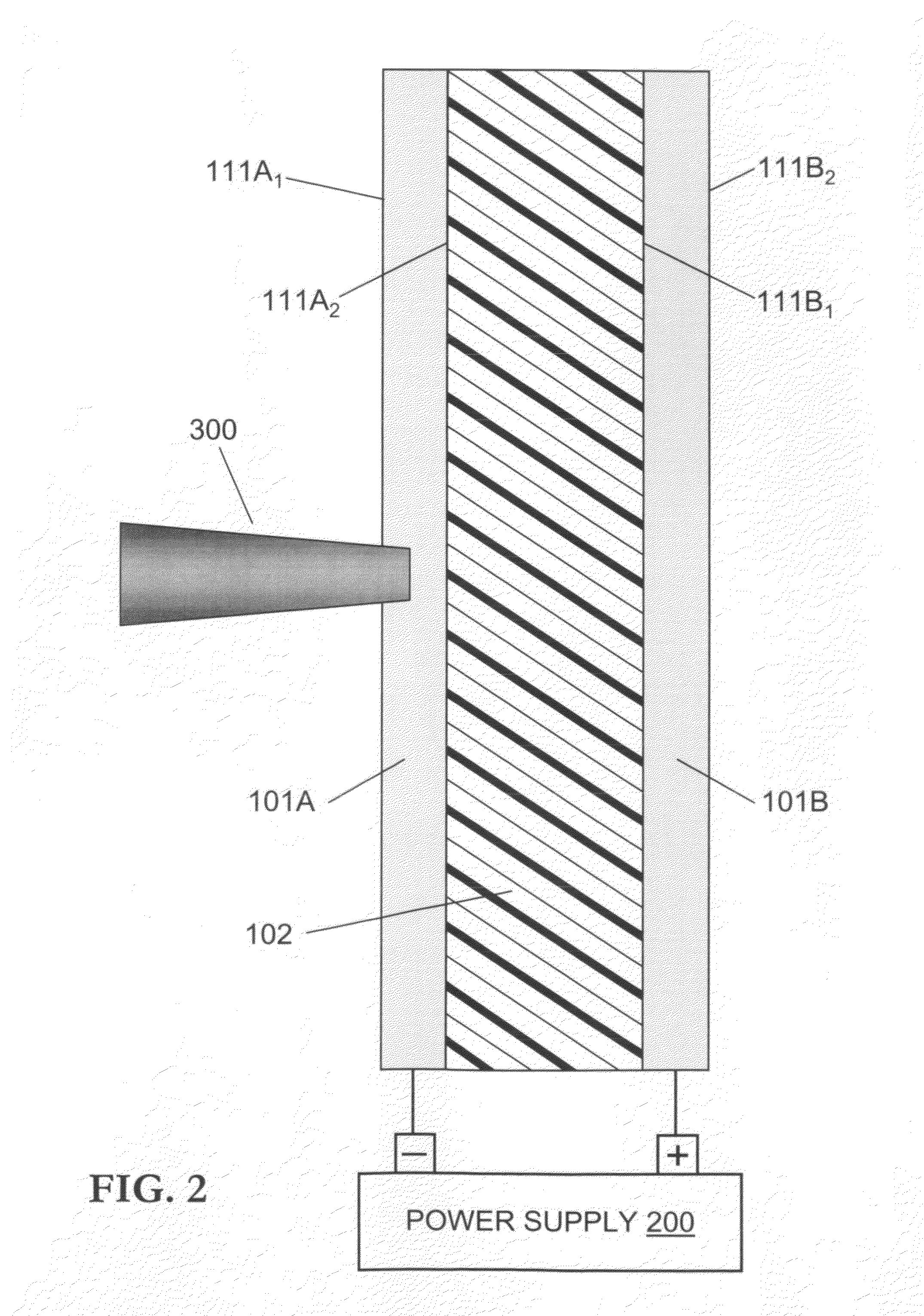

Electrical and elastomeric disruption of high-velocity projectiles

InactiveUS7946211B1Improve protectionFacilitate the strain-rate-sensitivity hardening of the elastomerDefence devicesProtective equipmentElectricitySupercapacitor

According to typical inventive practice, an armor structure includes n≧1 highly-rate-sensitive elastomeric layers and n+1≧2 metallic layers, alternately configured. Each metallic layer is electrically connected to a power supply that includes, e.g., battery(ies) and / or supercapacitor(s). Each adjacent pair of metallic layers sandwiches a highly-rate-sensitive elastomeric layer and forms, with the power supply, an uncompleted electrical circuit. A high-velocity projectile that penetratively encroaches upon a highly-rate-sensitive elastomeric layer is subjected to electrical current by virtue of completion of the uncompleted circuit that includes the two sandwiching metallic layers. The circuit is completed by physical (and hence, electrical) contact, bridging the two sandwiching metallic layers, of the projectile and / or its plasma sheath (which at least partially surrounds the projectile's outside surface due to friction between the projectile and the highly-rate-sensitive elastomeric layer). The highly-rate-sensitive elastomeric layer's projectile-hindering mechanical influence temporally lengthens the projectile-hindering electrical influence.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Systems, methods, and computer program products for collecting and reporting sensor data in a communication network

ActiveUS8621636B2Shorten the time to marketIncrease propensityFinanceMemory loss protectionComputer networkData reporting

A system for collecting and reporting sensor data in a communication network includes a microprocessor coupled to a memory and an electronic storage device. The microprocessor receives sensor data from sensors, and stores the sensor data for each sensor in the electronic storage device. The microprocessor also receives, via the communication network, a data reporting instruction defining a data reporting technique corresponding to the sensor data associated with one or more of the sensors. The data reporting instruction is stored in the electronic storage device, and the microprocessor transmits, to a trust mediator over the communication network, at least a portion of the sensor data based on the data reporting instruction. The trust mediator maintains an acceptable level of security for data throughout the communication network by adjusting security safeguards based on the sensor data.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

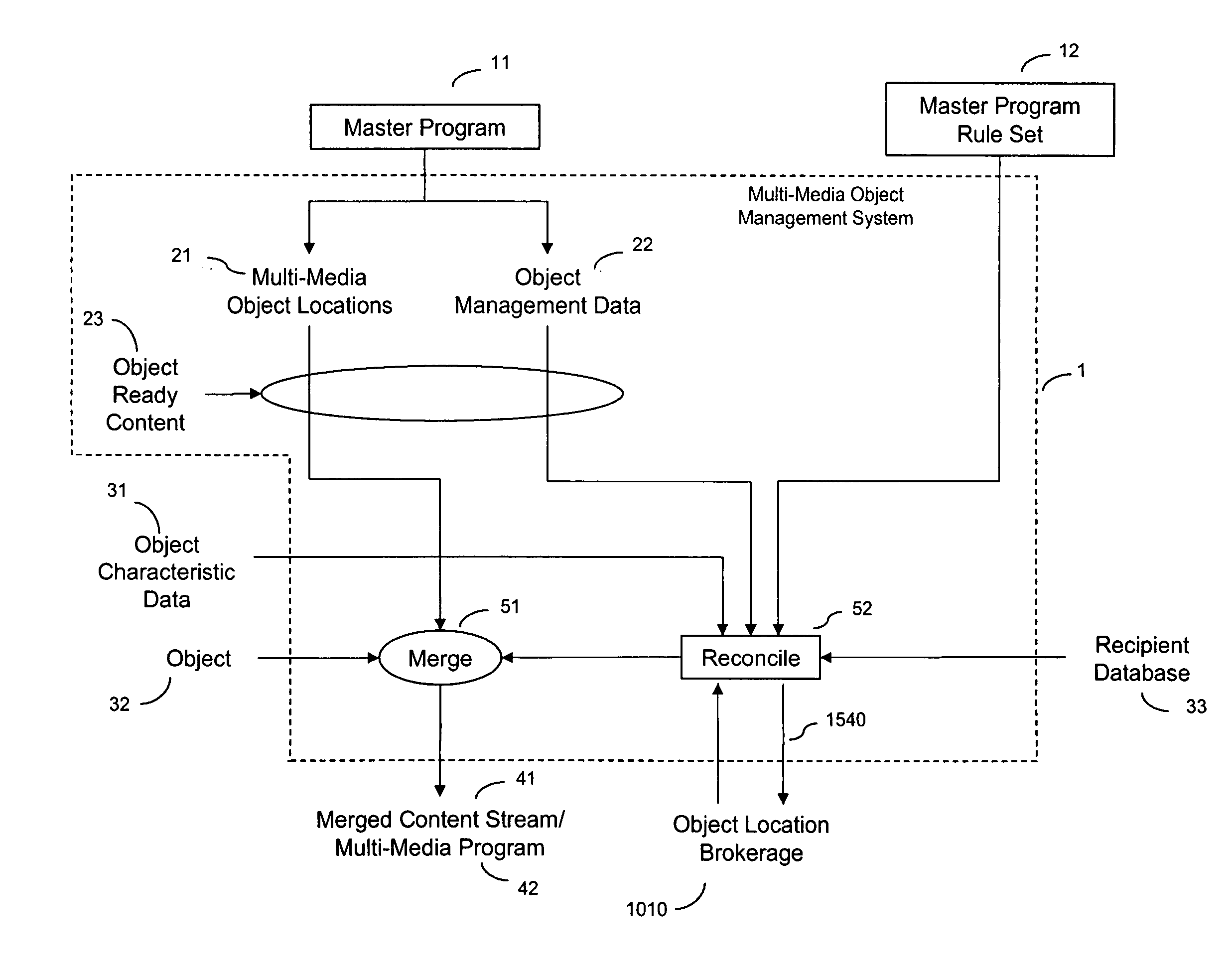

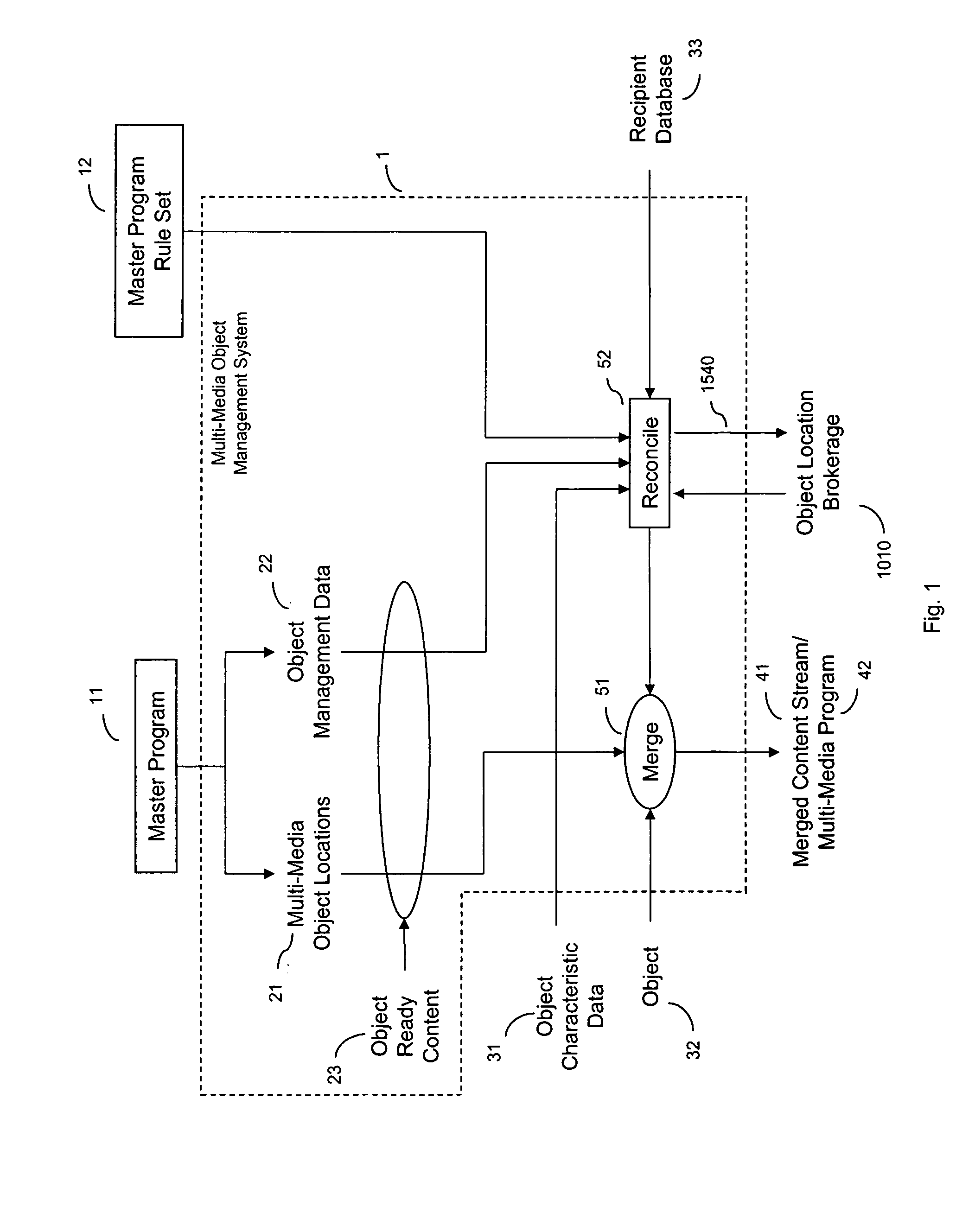

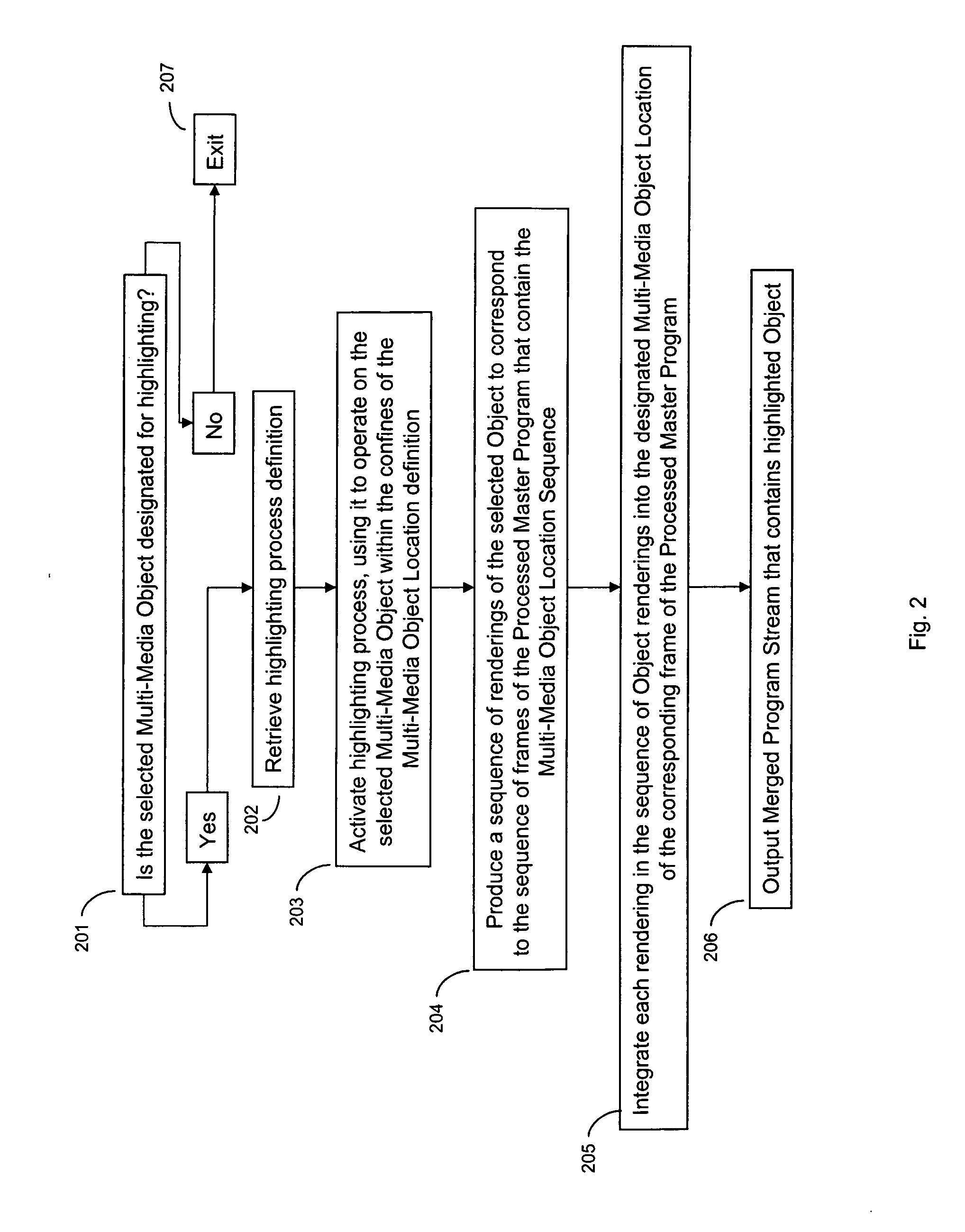

System for highlighting a dynamic personalized object placed in a multi-media program

InactiveUS20080033812A1Increase propensityEfficiently spentElectronic editing digitised analogue information signalsSelective content distributionPersonalizationColor representation

The present System For Highlighting A Dynamic Personalized Object Placed In A Multi-Media Program functions to manage the delivery of Object (product) placements in a Multi-Media Program. The multi-media object highlighting system controls the retrieval of Object data that comprises a product representation and the integration of this Object data into a corresponding selected one of the predetermined Multi-Media Object Locations which are components of the Multi-Media Program. In addition, the multi-media object highlighting system produces a representation of the object that highlights the object in the scenes in which it appears. The highlighting can be any human sensible characteristic, such as, but not limited to: flashing, changes in brightness, movement, change in representation, and the like. The highlighting can also include the use of an anomaly, such as a color representation in a black and white multi-media program or vice versa, or out-of-context object.

Owner:VULANO GROUP

Dynamic pairing system for securing a trusted communication channel

ActiveUS20140379581A1Shorten the time to marketIncrease propensityFinanceProtocol authorisationRisk levelComputer network

A system, method, and computer-readable medium for securing a mobile financial transaction are provided. A table matches each one of a plurality of transaction risk levels to a corresponding one of a plurality of required user trust scores, correspondingly. A financial transaction risk level associated with a financial transaction is computed. A user trust score associated with the user is computed based on user identification data associated with the user. The financial transaction risk level is matched to a corresponding one of the plurality of transaction risk levels stored in the table. The one of the plurality of required trust scores that corresponds to the corresponding one of the plurality of transaction risk levels stored in the table is identified. If the user trust score is greater than or equal to the identified one of the plurality of required trust scores, then the financial transaction is authorized.

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

Method and apparatus for winding a filter media pack

ActiveUS7909954B2Media may be wound more quicklyWound quicklyDispersed particle filtrationPaper/cardboard wound articlesFilter mediaEngineering

A method and apparatus are provided, for forming a filter element including a media pack in the form of a coiled fluted filter media, by winding the web of fluted filter media around a pair of tools of a mandrel. The tools engage the sides of the filter media. The tools define a major to provide the media pack with a oblong or elongated shape. The web may be fed at constant linear speed, and / or a motor may be controlled in a manner to provide constant driving torque to maintain a constant tension on the web. The winding apparatus and methods may include apparatus or methods to modify the feed path of the web to adjust the tension of the web as it is being wound. Further, the coiled media packs can be fixtured to prevent relaxation. A method may form various shaped media packs with the same apparatus.

Owner:BALDWIN FILTERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com