Laser cladding repairing method for aircraft end-journal part surface

A technology of laser cladding and repair method, applied in the field of laser cladding, can solve the problems of large depth of heat affected zone, large heat input, difficult to meet, etc., and achieves reduced mechanical processing workload, small heat input, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Analysis of the defects of the aircraft end journal:

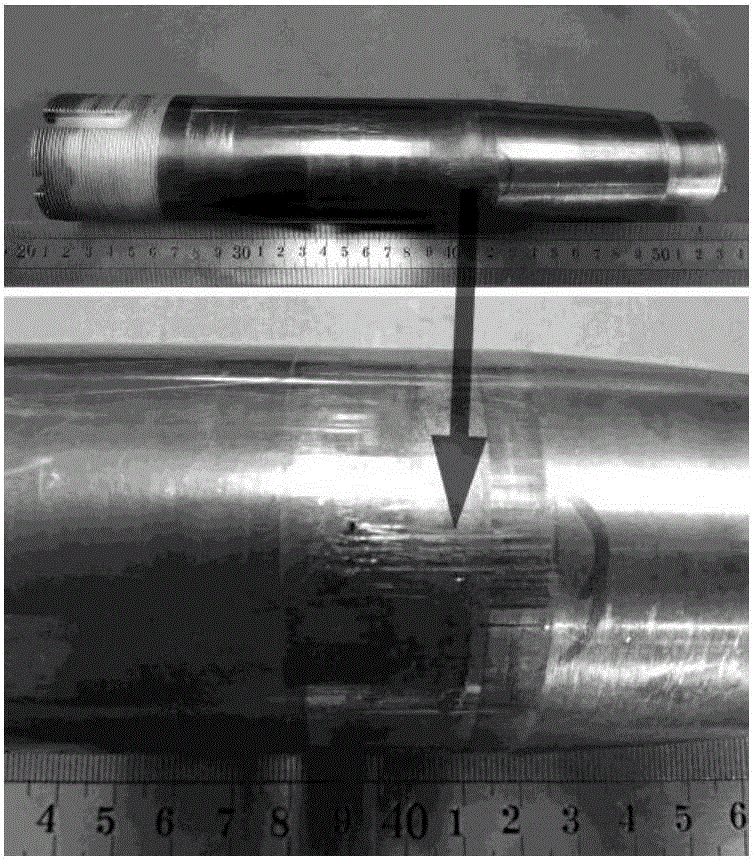

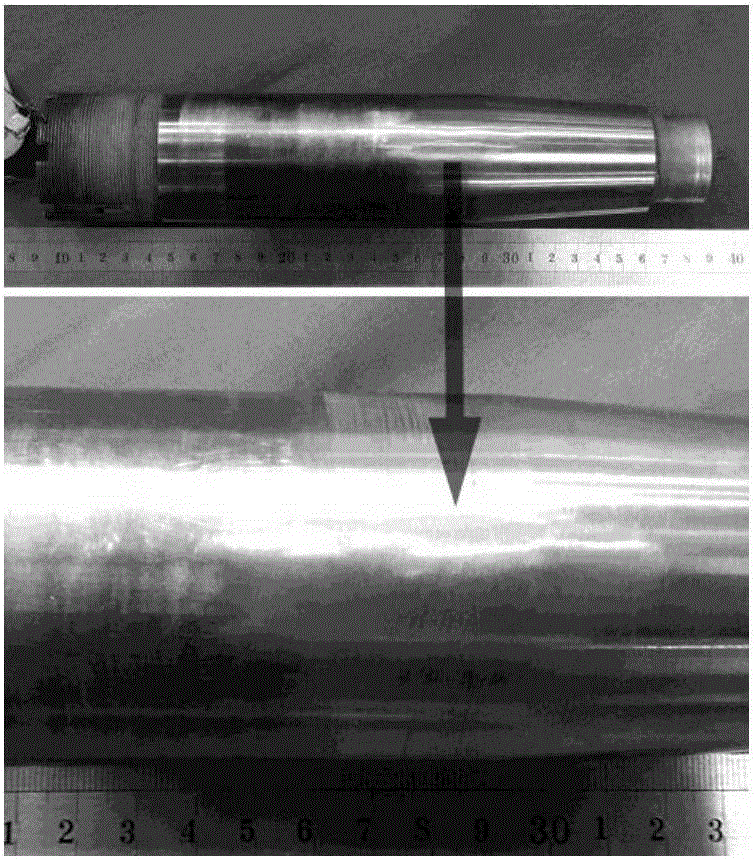

[0028] The end journal is the key load-bearing part of the fixed aircraft engine, which is precision cast and forged from 1Cr15Ni4Mo3N precipitation hardened stainless steel. When the aircraft is in the refurbishment cycle, due to long-term use, obvious mechanical wear or scratch defects appear on the surface of the journal parts at this end, such as figure 1 shown. Due to the different depths of defects on the surface of the end journal, the maximum depth is close to 2.0mm. In order to ensure the mechanical properties of the repaired area of the end journal, and considering the matching of the expansion coefficient of the cladding layer and the base material, it is determined to use a material with a similar expansion coefficient. Precipitation-hardening stainless steel metal powder as filler material for laser cladding repair of end journals.

[0029] 2. Repair of aircraft end journal defects

[0030] (1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com