Device for prolonging service life of oil-containing filter cloth of continuous casting plate frame

A continuous casting slab and continuous casting technology, which is applied in the field of devices for improving the service life of continuous casting slab frame oil-containing filter cloth, can solve the problems of poor water permeability of filter cloth, heavy workload of workers, high cost, etc., and achieve recovery of performance, The pipe structure is clear and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

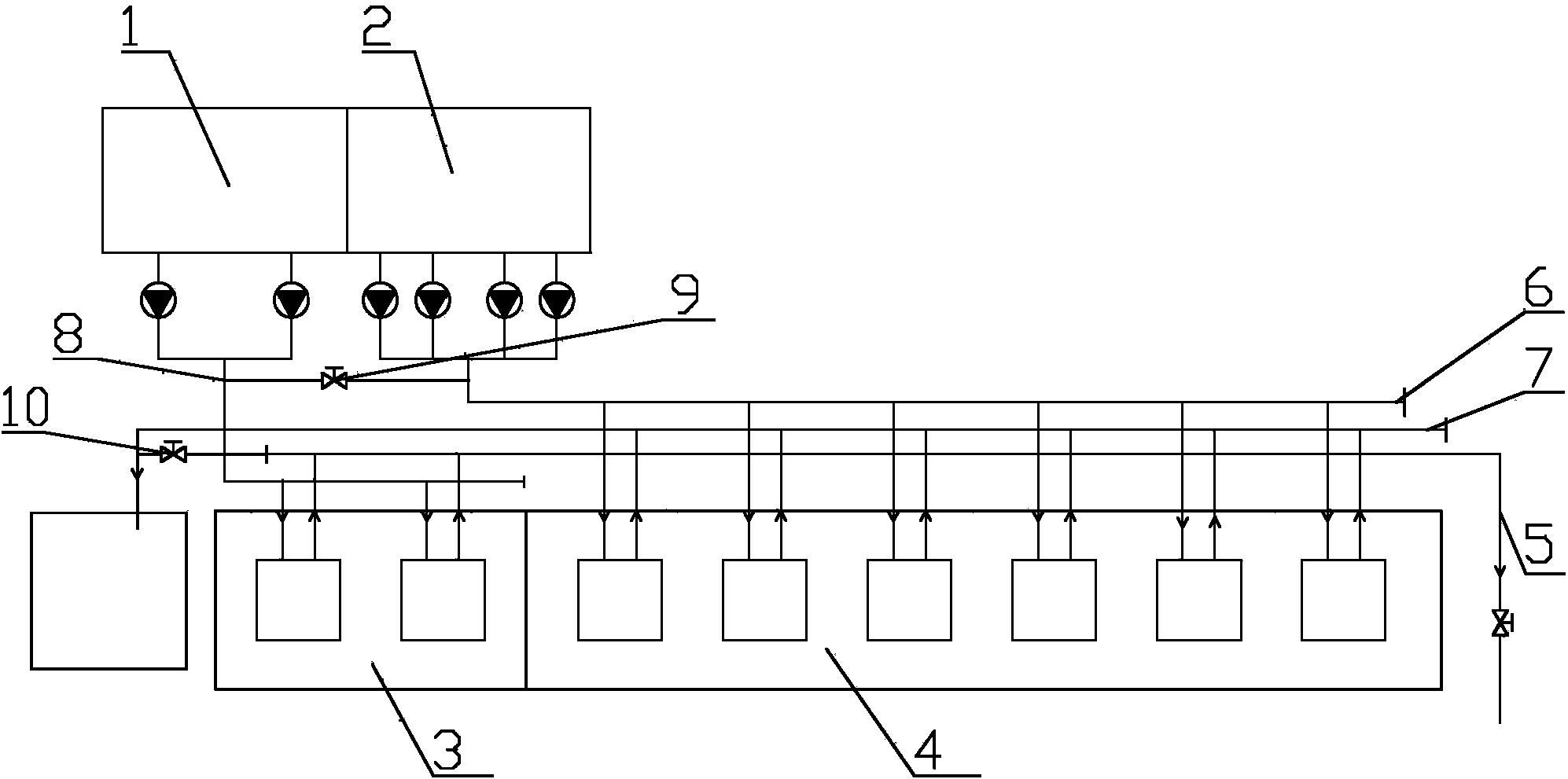

[0009] This embodiment provides a device for improving the life of the oil-containing filter cloth of a continuous casting plate frame, and the structure is as follows figure 1 As shown, it includes a continuous casting slurry adjustment tank 1, a steelmaking slurry adjustment tank 2, a continuous casting plate frame 3, and a steel plate frame 4. The continuous casting slurry adjustment tank 1 and the continuous casting plate frame 3 pass through the continuous casting plate frame. The material main pipe 8 is connected with the continuous casting plate and frame filtrate return pipe 5; the steelmaking slurry adjustment tank 2 and the steel plate frame 4 are connected by the steel plate frame feed pipe 6 and the steel plate frame filtrate return pipe 7; A pipeline with a feed branch valve 9 is provided between the casting plate frame feed main pipe 8 and the steel plate frame feed main pipe 6, and the continuous casting filtrate return pipe 5 and the steel-making filtrate return p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com