cleaning aerosol

A technology for cleaning aerosols and aerosols, applied in aerosol detergent compositions, detergent materials, detergent compositions, etc., can solve the problems of high technical requirements, time-consuming and labor-intensive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Please refer to Table 1, Table 1 is the composition and content of the cleaning aerosol embodiment 1 of the present invention:

[0024] component name

Content (W / W%)

effect

Remark

Fluorodichloroethane (R141b)

45

solvent, cleaning

none

Molybdenum Dialkyl Dithiophosphate

0.5

antiwear agent, antiwear

none

Turbine oil

5.5

none

isohexane

10.0

none

4.0

propellant, supercharging

none

1,1,1,2--Tetrafluoroethane (R134a)

35.0

propellant, supercharging

none

[0025] Table 1

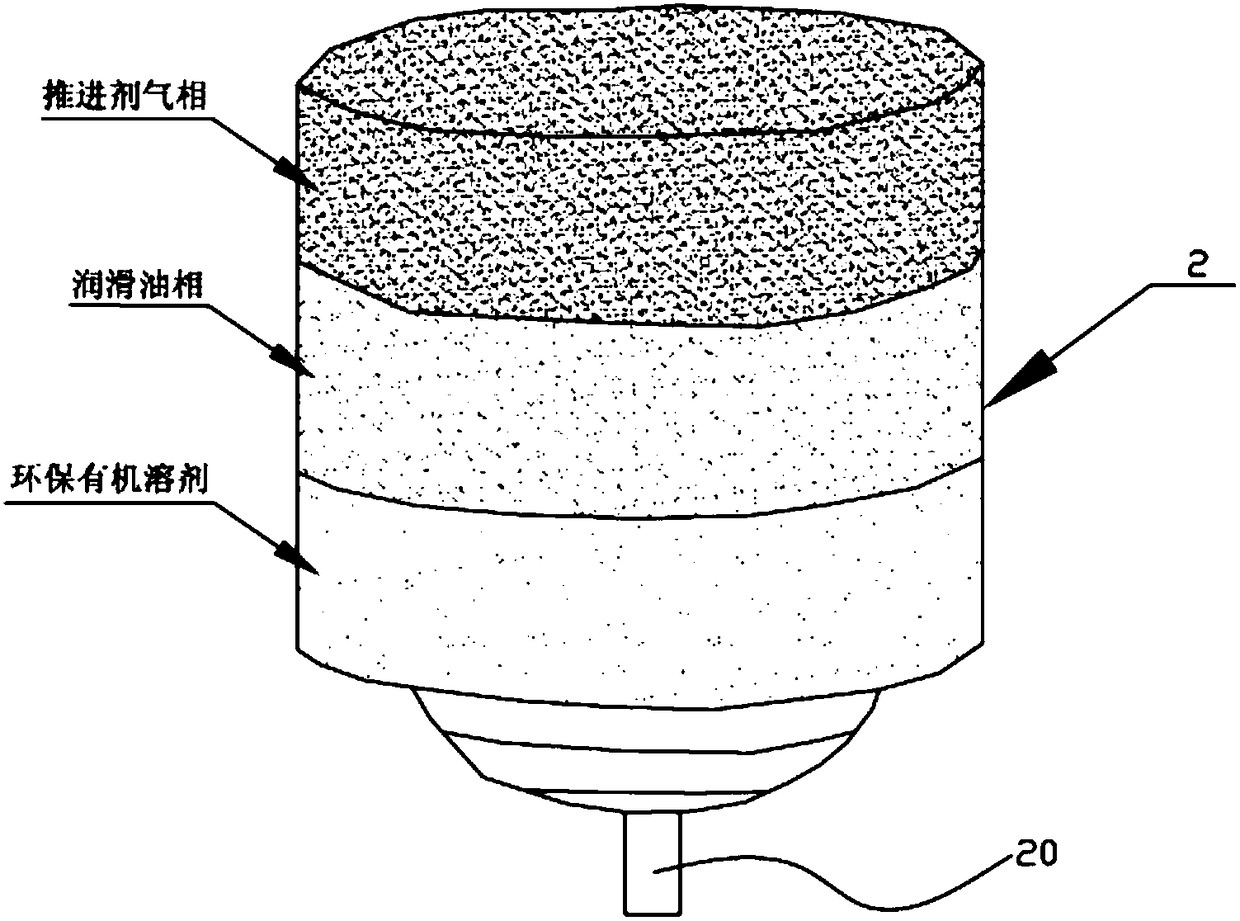

[0026] In this embodiment, the environmentally friendly organic solvent is fluorodichloroethane; the lubricating oil phase is composed of molybdenum dialkyldithiophosphate, turbine oil and isohexane; the propellant is composed of carbon dioxide and R134a. The propellant is a combination of carbon dioxide and R134a, which i...

Embodiment 2

[0028] Please refer to Table 2, Table 2 is the composition and content of the second embodiment of the cleaning aerosol of the present invention:

[0029] component name

Content (W / W%)

effect

Remark

Trichlorotrifluoroethane (R113)

50.0

solvent, cleaning

none

Molybdenum dialkyldithiocarbamate

0.3

antiwear agent, antiwear

none

gasoline engine oil

5.7

none

10.0

lubricant solvent

none

carbon dioxide

3.0

propellant, supercharging

none

1,1,1,2--Tetrafluoroethane (R134a)

31.0

propellant, supercharging

none

[0030] Table 2

[0031] In the present embodiment, the environment-friendly organic solvent is trichlorotrifluoroethane; the lubricating oil phase is composed of molybdenum dialkyldithiocarbamate, gasoline engine oil and cyclohexane; the propellant is composed of carbon dioxide and R134a composition. The propella...

Embodiment 4

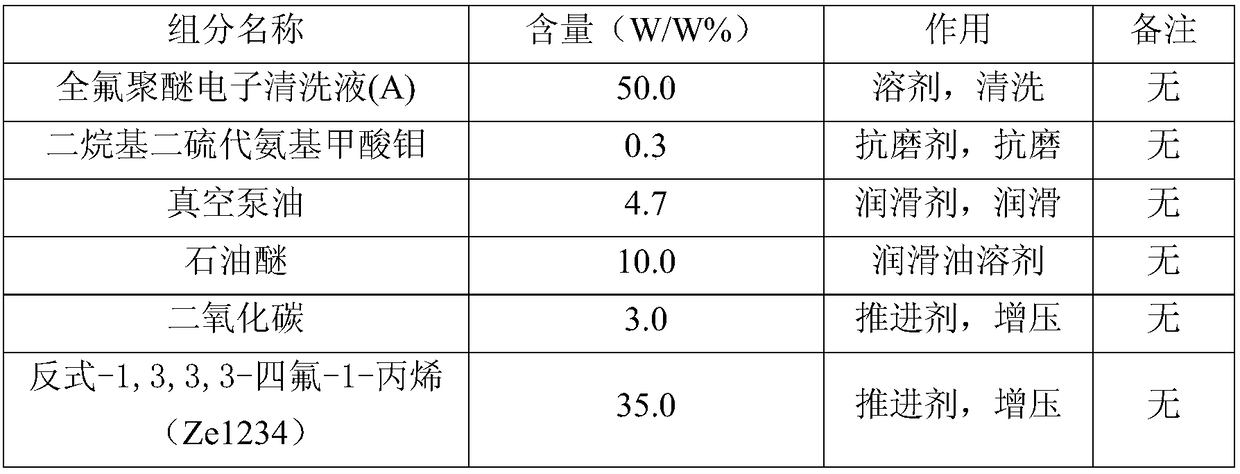

[0038] Please refer to Table 4, Table 4 is the composition and content of Example 4 of the cleaning aerosol of the present invention:

[0039] component name

Content (W / W%)

effect

Remark

Fluorine and chlorine special cleaning fluid

42.0

solvent, cleaning

none

Molybdenum dialkyldithiocarbamate

0.5

antiwear agent, antiwear

none

Turbine oil

9.5

lubricant, lubrication

none

7.0

lubricant solvent

none

Isopropanol

3.0

lubricant solvent

none

1,1,1,2--Tetrafluoroethane (R134a)

38.0

propellant, supercharging

none

[0040] Table 4

[0041] In this embodiment, the environmentally friendly organic solvent is a special cleaning solution for fluorine and chlorine; the lubricating oil phase is composed of molybdenum dialkyldithiocarbamate, turbine oil, cyclohexane, and isopropanol; the propellant is R134a. The cleaning aerosol in this embodiment ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com