A kind of preparation method and application of self-healing membrane strengthening liquid

A technology of strengthening liquid and formula, applied in the field of optical materials, can solve the problems of waste of resources, affecting the service life of products, not environmental protection, etc., to achieve the effect of increasing the service life, restoring the experience of use, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the self-healing membrane strengthening liquid is prepared by adding the above-mentioned formula into a stirring container in a certain sequence, and then uniformly stirring and vibrating.

[0048] The following is a test performance comparison of the general ingredient strengthening solution and the ingredient self-repairing membrane strengthening solution of the present invention.

[0049]

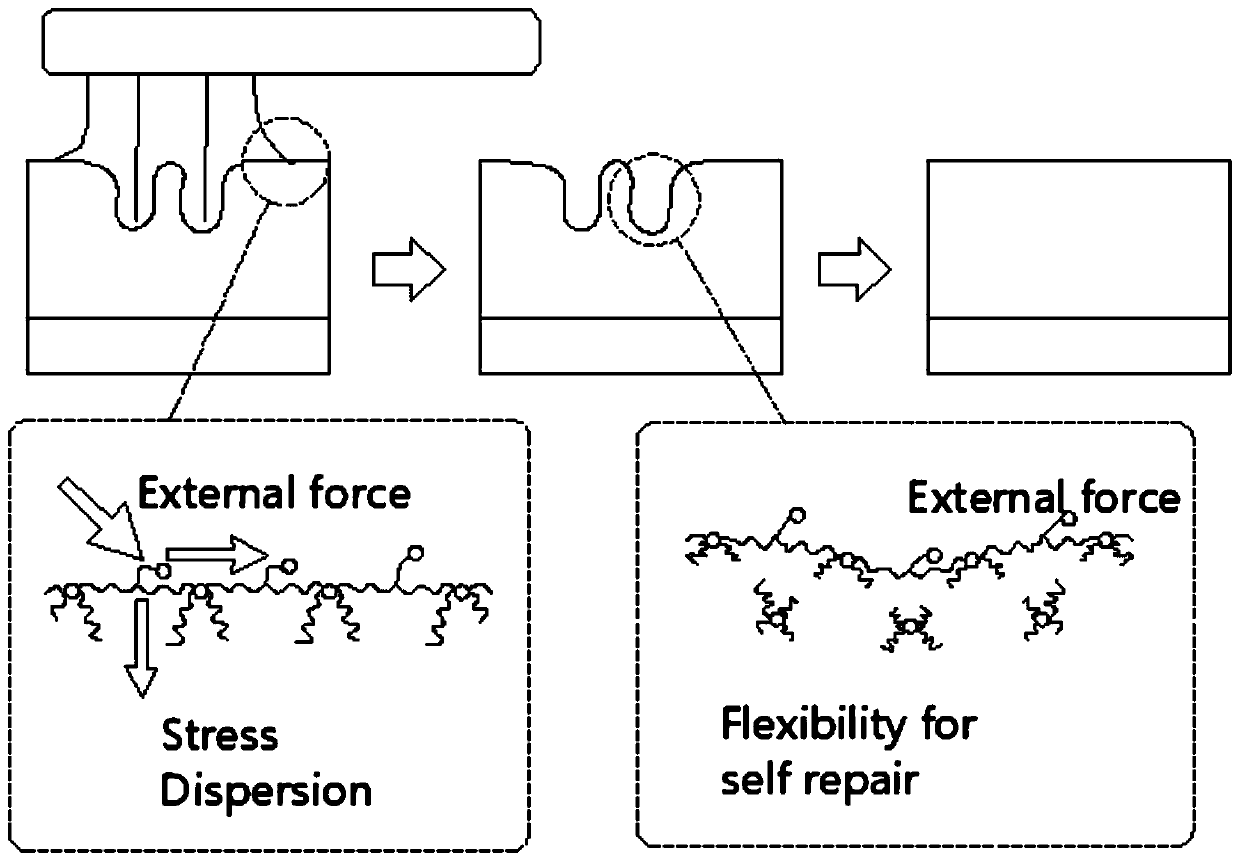

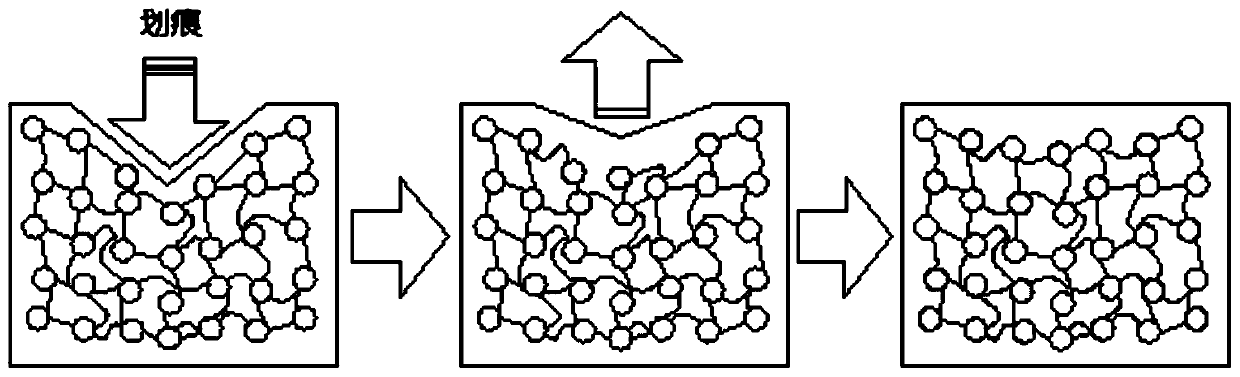

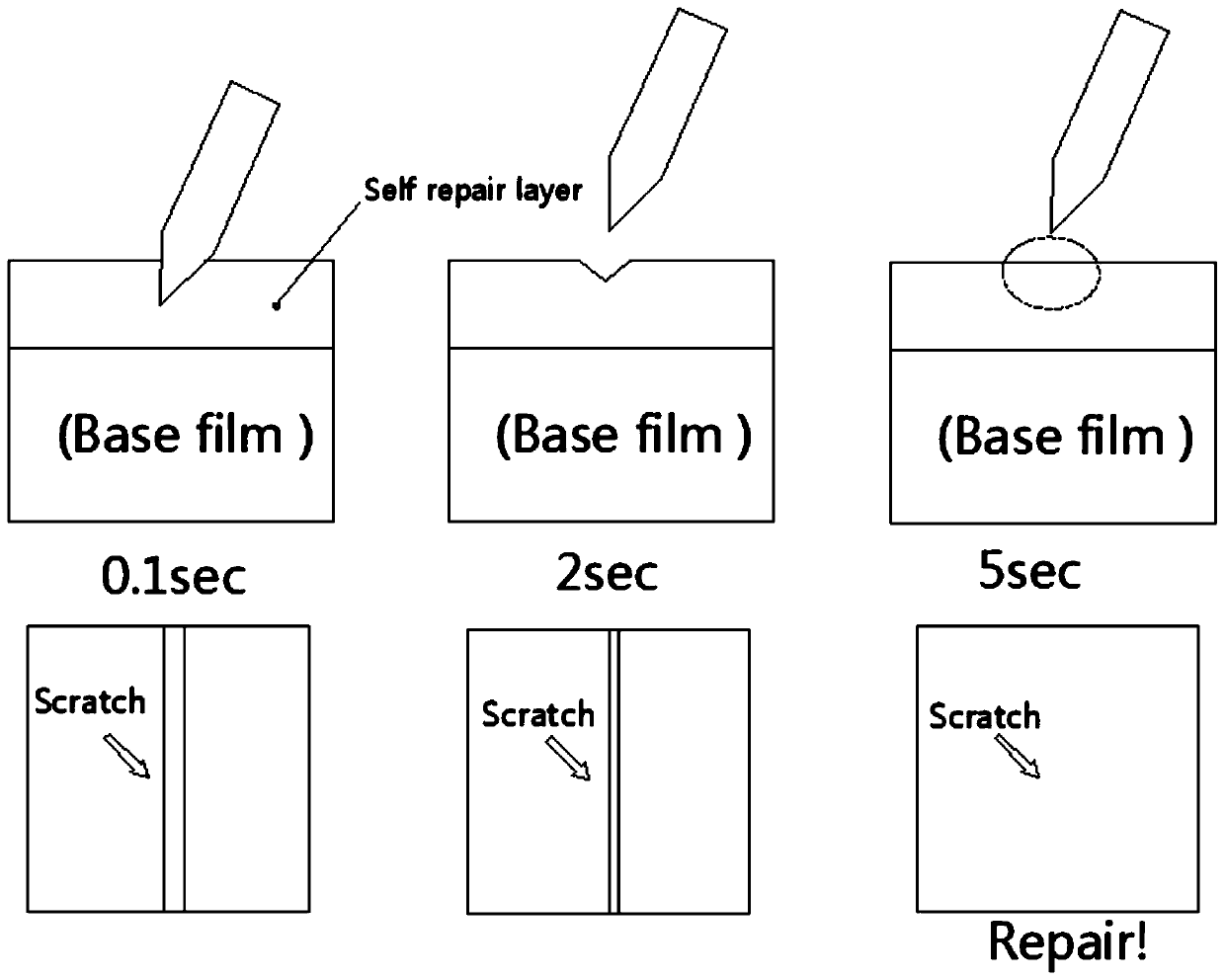

[0050] According to the above test data, the film produced by the strengthening liquid with general ingredients has a small elongation rate and cannot be repaired; the film produced by the self-repairing film strengthening liquid with the ingredients of the present invention has a large elongation rate and a fast repair speed. Only the membrane produced by the ingredients of the present invention has the characteristics of self-repairing and fast repairing speed. Such as figure 1 , figure 2 , image 3 shown.

[0051] After the above formulas are a...

Embodiment 1

[0055] Application of a self-healing membrane strengthening solution The production process steps for preparing a self-healing membrane are as follows:

[0056]S1. Pre-prepared self-healing membrane strengthening solution; raw materials in weight percentage: 55% acrylate oligomers, 0.7% leveling agents, 7% butyl acetate, 30% methyl ethyl ketone, 0.5% defoamer, Starter 5% and surfactant 1.8%; add to the stirring container in a certain order, and then stir and shake evenly;

[0057] S2. Select the required main substrate film plate;

[0058] S3. Introduce the self-healing film strengthening liquid into the groove of the coating machine, and let the coating roller stick to the self-healing film strengthening liquid and run idling to remove air bubbles;

[0059] S4. Place one side of the main substrate film plate selected in step S2 on the coating machine tank, and let the coating roller evenly coat a thin layer of liquid; obtain a semi-finished self-repairing film;

[0060] S5....

Embodiment 2

[0062] Application of a self-healing film strengthening solution The steps of the immersion production process for preparing self-healing lenses are as follows:

[0063] S1. Pre-prepared self-healing membrane strengthening solution; raw materials in weight percentage: 55% acrylate oligomers, 0.7% leveling agents, 7% butyl acetate, 30% methyl ethyl ketone, 0.5% defoamer, Starter 5% and surfactant 1.8%; add to the stirring container in a certain order, and then stir and shake evenly;

[0064] S2. Select the required lens, such as: PC lens, PA lens, acrylic lens, etc.;

[0065] S3. Ultrasonic cleaning of the selected lenses;

[0066] S4, drying the lens after cleaning in step S3;

[0067] S5, pre-cooling the lens after step S4 is dried;

[0068] S6, cleaning the lens pre-cooled in step S4 with IPA;

[0069] S7. Soak the lens cleaned in step S6 in the self-repairing film strengthening solution in step S1; obtain the crude self-repairing lens;

[0070] S8, pre-drying the crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com