Composite reinforcement method for TiC/TiB2 base metal ceramic on surface of roller

A roll surface and ceramic composite technology, which is applied in the metal material coating process, superimposed layer plating, coating, etc., can solve the problems of harsh use environment, uneven wear of rolls, long production cycle, etc., and achieve the improvement of steel Effects of improving surface quality, improving roll service life, and improving rolling operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Roller of the finished product stand of the threaded steel finishing mill

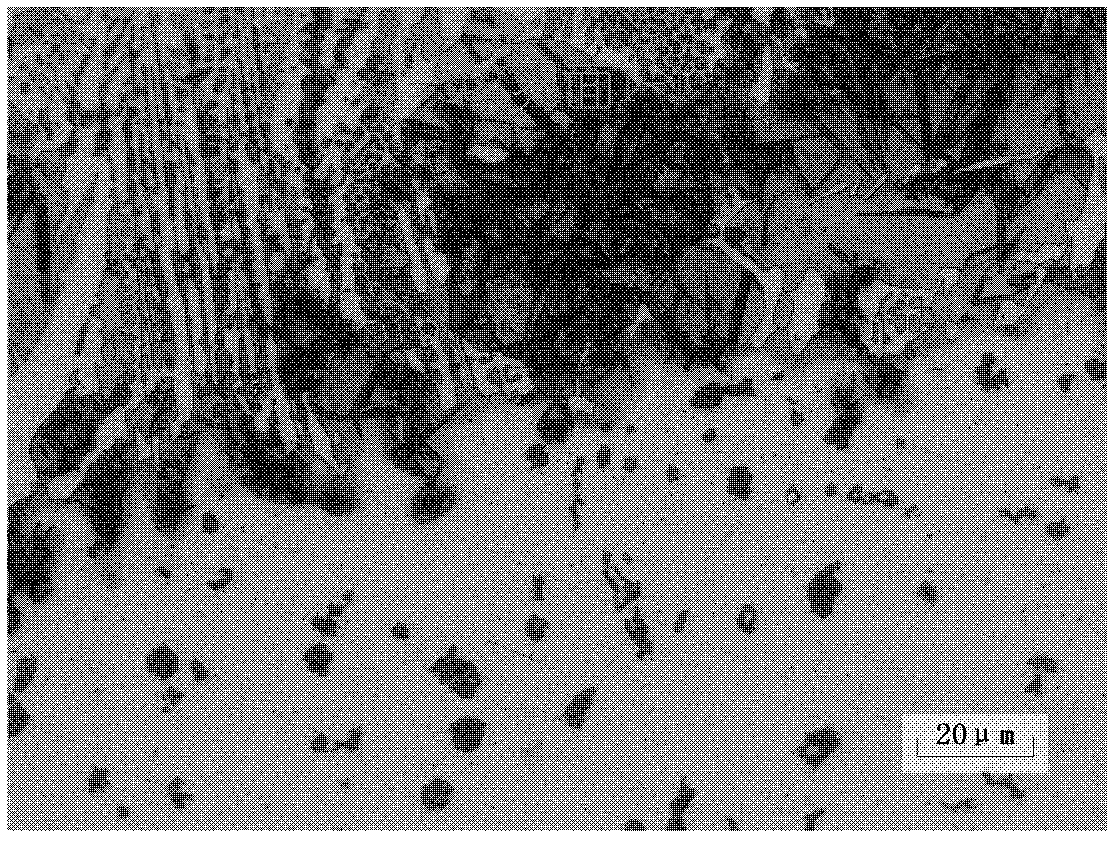

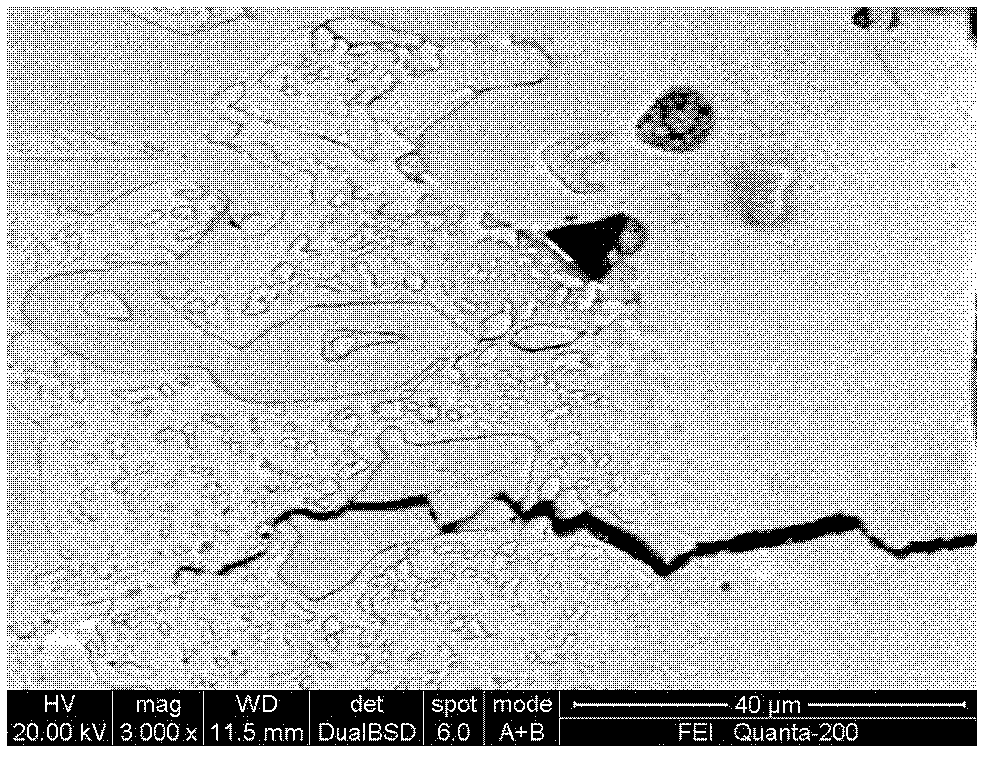

[0034] The finished product frame is the most critical frame for rebar production, and it is also the frame that consumes the most rolls. After the roll is grooved, plasma spray nickel-based alloy is carried out. The process parameters of spraying nickel-based alloy are current: 30A; voltage: 35V; main gas (99.999Ar): 0.9 (L / min); protective gas (97%Ar+3% h 2 ): 5.8(L / min); powder feeding gas (97%Ar+3%H 2 ): 2.5 (L / min); powder feeding speed: 20g / min; plasma arc length: 15mm; spray welding speed: 200mm / min; thickness is 0.5mm, nickel-based alloy layer composition (weight%): 1.2C, 4.0B, 13Cr, 6Mo, 4W, 1Co, 1.0Ti, and Ni; after finishing turning, electrode rods are used for EDM deposition, the thickness of the deposited layer is 30 μm, and the material composition of electrode rods is (weight%): 48TiB 2 , 32TiC, 14Mo, 1Cr, its sheath is Fe, the EDM deposition process is: output pow...

Embodiment 2

[0035] Embodiment 2 The roll of the first stand of the pre-rolling of rebar

[0036] The rolls of the blooming stand are 70Mn2 steel rolls, which have poor wear resistance and a large amount of wear. After the roll is used off-line, the pass is directly processed, and the processed pass is surfacing with nickel-based alloy. The surfacing welding process parameters: preheat to 380°C; temper at 550-560°C after welding, and hold for 8 hours; The composition of the nickel-based alloy layer is (weight%): 0.9C, 2.8B, 12Cr, 4Mo, 2W, 1Co, 0.5Ti, and its sheath is Ni; EDM deposition is carried out after finishing turning, and the thickness of the deposited layer is 20 μm. The composition is (weight%): 40TiB 2 , 30TiC, 10Mo, 4Cr, whose she is Fe, the amount of steel used is about 5 times higher than that of the original roll.

Embodiment 3

[0037] Embodiment 3 Strip Steel Finishing Flat Second Roller

[0038] The second roll of the strip steel finishing flat is a nodular cast iron roll, which has poor thermal cracking resistance and wear resistance, severe surface cracks, and large wear. After the roll is used off-line, the pass is directly processed. The processed pass is plasma sprayed with nickel-based alloys. The process parameters for spraying nickel-based alloys are current: 50A; voltage: 35V; main gas (99.999Ar): 0.9(L / min ); protective gas (97%Ar+3%H 2 ): 5.8(L / min); powder feeding gas (97%Ar+3%H 2 ): 2.5 (L / min); powder feeding speed: 20g / min; plasma arc length: 20mm; spray welding speed: 200mm / min; B, 10Cr, 5Mo, 3W, 1Co, 1.0Ti, the other is Ni; cladding with electrode rod after finishing turning, the thickness of the cladding layer is 20-40μm, and the cladding electrode material composition is (weight%): 45TiB 2 , 35TiC, 10Mo, 4Cr, whose she is Fe, the amount of steel used is about 3 times higher tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com