A high energy beam additive manufacturing method for a suspended structure of a metal part

A technology of suspended structures and metal parts, applied in the field of additive manufacturing, can solve the problems of reducing the complexity of manufacturing components, insufficient support, and inability to realize forming, so as to achieve small processing allowance, high processing efficiency, and high-performance repair and repair. The effect of remanufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] The base plate is fixed by means of process boss and welding, the specific steps are as follows:

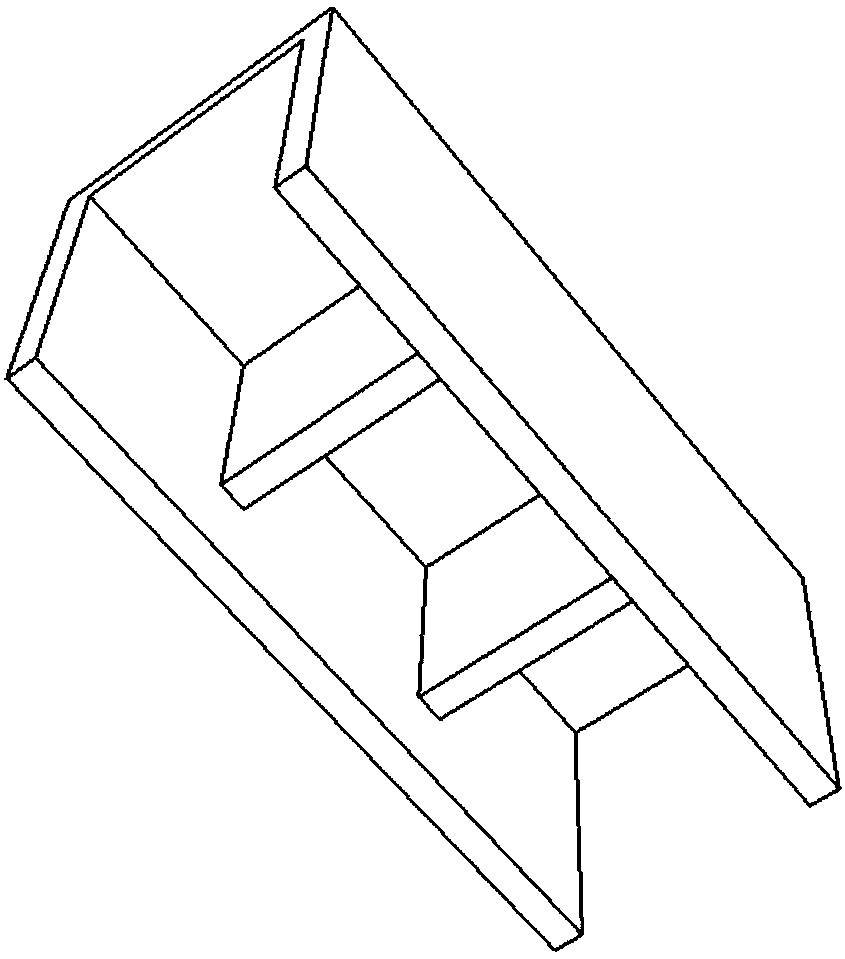

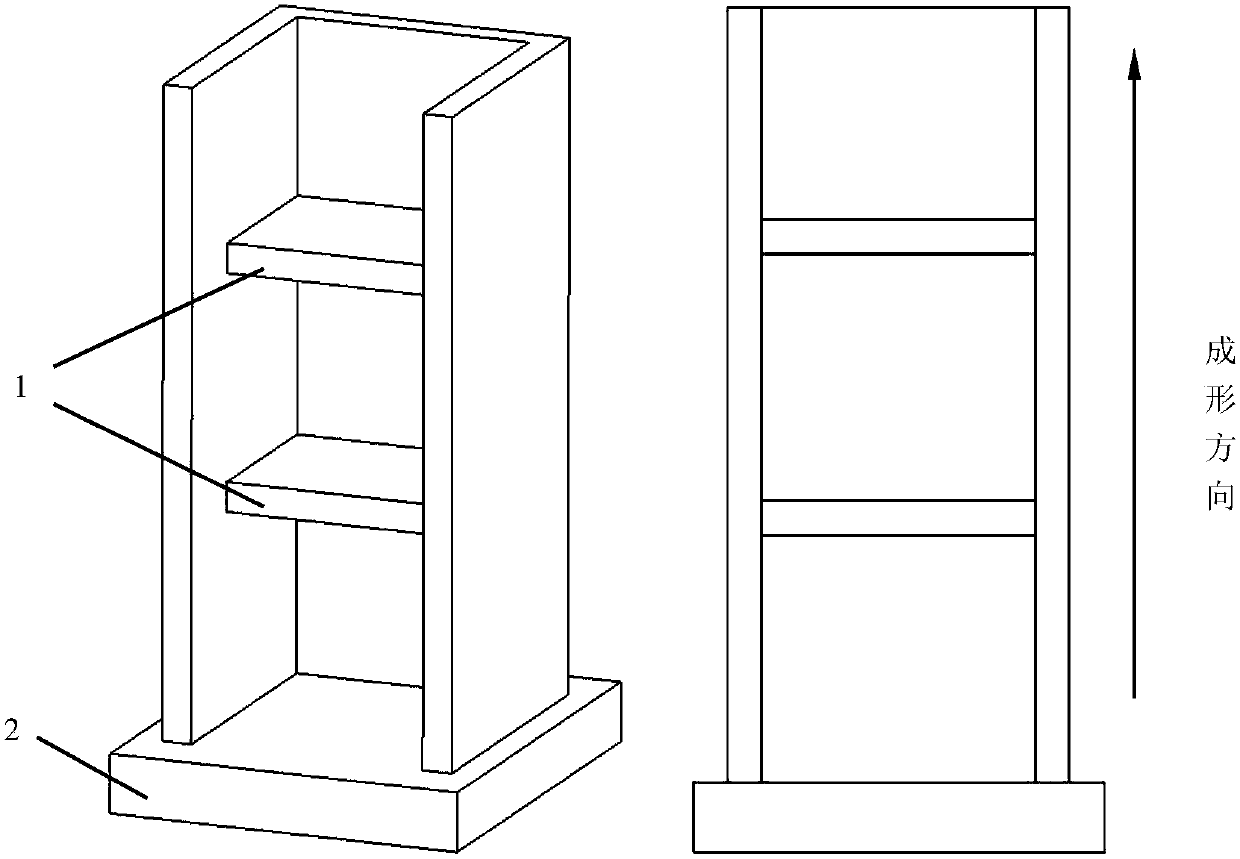

[0055] Step 1: Establish the overall forming process model. Part structure such as figure 1 As shown, according to the characteristics of metal parts with suspended structure, the best part forming direction is selected, and the overall forming process model of the part is established. The overall process model should include the position and size of the base material, such as figure 2 shown;

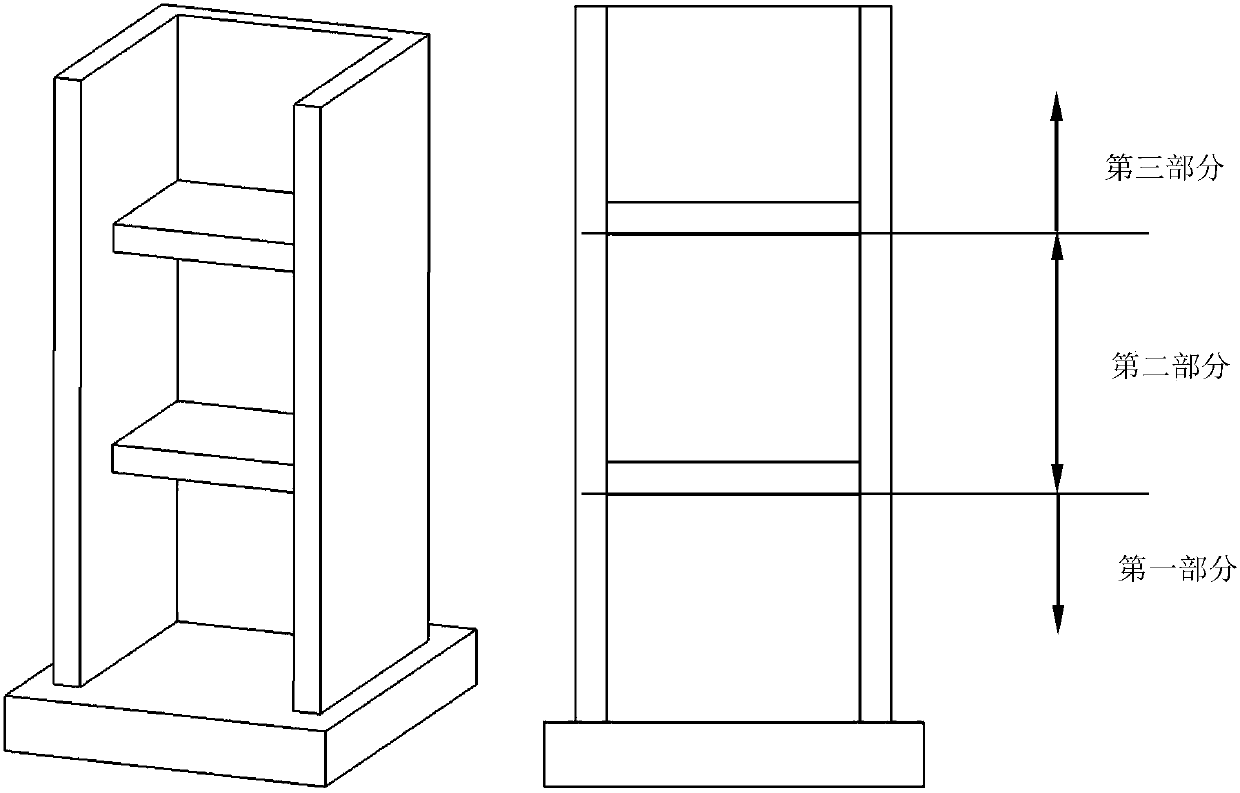

[0056] Step 2: Split the overall forming process model. According to the position of the suspended structure, the overall forming process model is split. Generally, the lower part of the suspended structure is used as the dividing interface, and the process model above the dividing interface includes the suspended structure, such as image 3 shown;

[0057] Step 3: Determine the fixing method of the supporting substrate for forming the suspended structure, the shape and size o...

example 2

[0062] Such as Figure 8 The main structure with a small inclination angle shown in the part has a suspended structure with a large inclination angle, and the substrate is fixed by means of tooling and clamping. The specific steps are as follows:

[0063] Step 1: Establish the overall forming process model. Part structure such as Figure 8 As shown, according to the characteristics of metal parts with suspended structure, the best part forming direction is selected, and the overall forming process model of the part is established. The overall process model should include the position and size of the base material, such as Figure 9 shown;

[0064] Step 2: Split the overall forming process model. According to the position of the suspended structure, the overall forming process model is split. Generally, the lower part of the suspended structure is used as the dividing interface, and the process model above the dividing interface includes the suspended structure, such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com