A permanent magnet motor remanufacturing repair process and assembly line with glued magnetic poles

A permanent magnet motor and remanufacturing technology, which is applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., can solve the problems of magnetic pole residue and long time, so as to achieve difficult oxidation and decarburization, small deformation, and realize cycle The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] like Figure 4 As shown, this embodiment discloses a permanent magnet motor remanufacturing repair line with glued magnetic poles, including a heating device 7 , a rotating and fixing device 6 , a cooling pool 4 , a conveying device 5 , a knocking device 41 and an operating table 9 . The conveying device 5 is arranged obliquely in the cooling pool 4 , one end of the conveying device 5 is located in the cooling pool 4 , and one end extends out of the cooling pool 4 and is connected to one side of the operating platform 9 .

[0046] like Figure 7 As shown, the transmission device 5 includes a transmission motor 51, a transmission wheel 52 and a transmission belt 53, the transmission motor 51 and the transmission wheel 52 are arranged on both sides in the cooling pool 4, and the transmission belt 53 is installed on the transmission wheel 52 and the transmission motor 51. The conveyor belt 35 is evenly provided with several convex strips 54 , and the convex strips 54 can ...

Embodiment 2

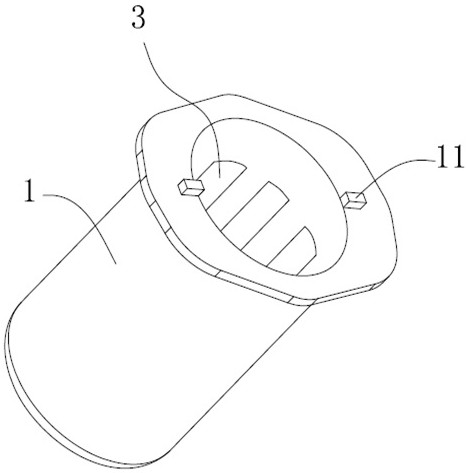

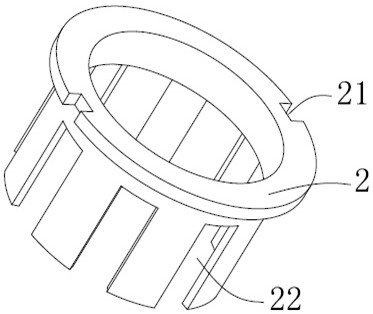

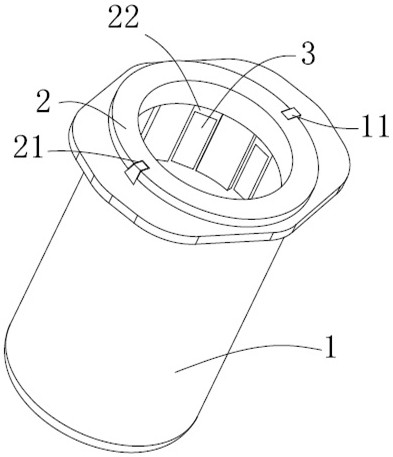

[0062] The difference between this embodiment and the first embodiment is that: Step 1: After taking out the rotor in the stator casing 1; cleaning the magnetic poles 3 in the stator casing 1, and detecting and identifying whether each magnetic pole 3 is damaged. Before detecting and identifying the magnetic pole 3 in the stator shell 1, it is sandblasted and cleaned, and the visual inspection system detects the outer surface of the magnetic pole 3 after sand blasting to check whether there are cracks, depressions and other adverse conditions on the appearance of the magnetic pole 3 .

[0063] The damaged magnetic poles are marked and classified, and the stator shell is divided into several heating areas and cooling areas. The surface of the stator shell corresponding to the damaged magnetic poles is the heating area, and the surface of the stator shell corresponding to the undamaged magnetic poles is the cooling area. like Figure 5 As shown, put the stator housing 1 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com