A special aircraft for intelligent repair of railway coupler tongue

An intelligent repair and hook tongue technology, applied in the field of special planes, can solve the problems of environmental pollution, affecting welding quality, large heat input, etc., to improve the level of flexibility and intelligence, save materials and labor, and achieve a high degree of intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

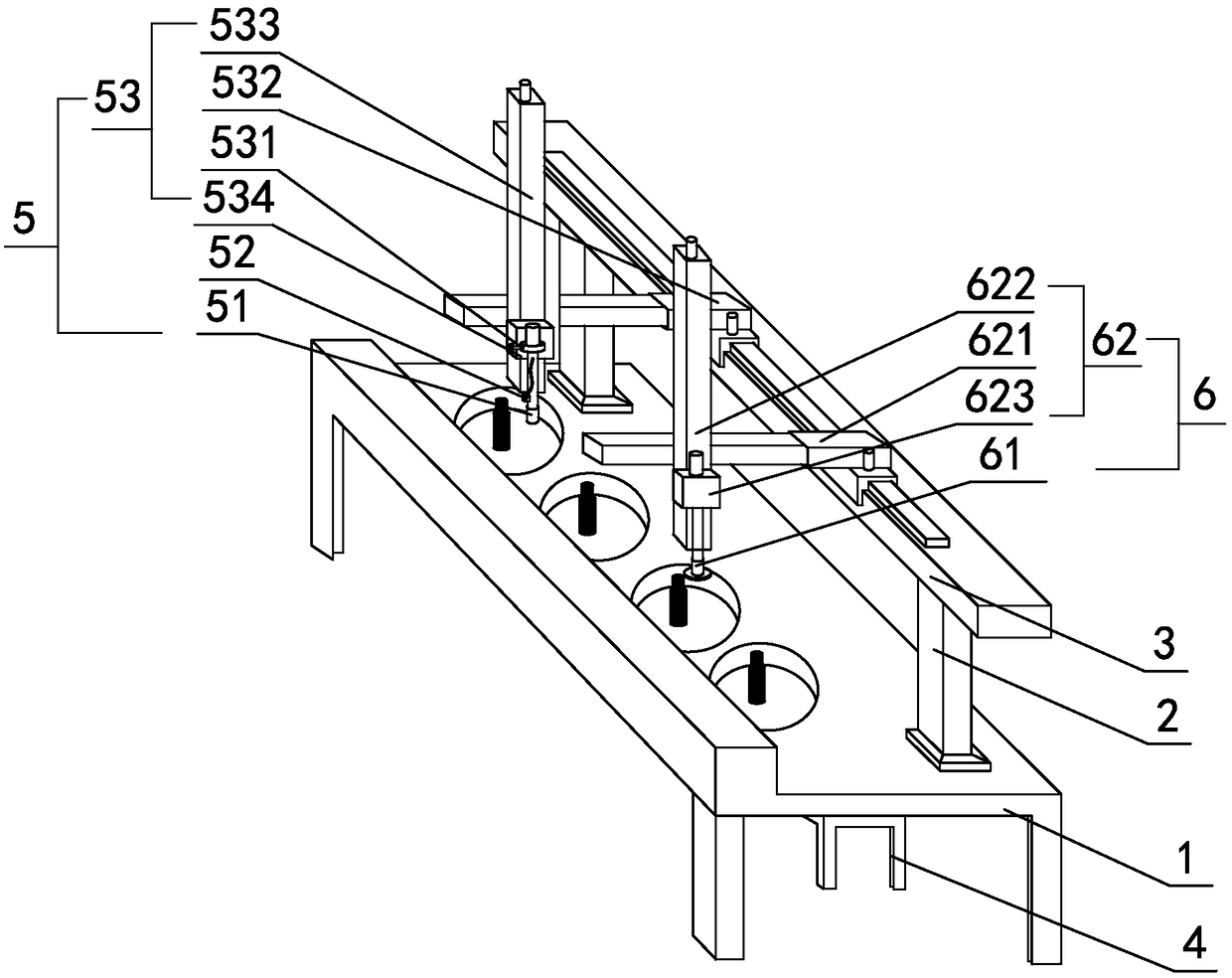

[0034] The invention provides a railway knuckle intelligent repair special machine, such as figure 1 As shown, the railway knuckle intelligent repair machine includes a base 1, a column 2, a slide rail 3, a knuckle positioning frame 4, a welding assembly 5, a milling assembly 6 and a control system. The slide rail 3 is installed on the base 1 through the column 2 , the knuckle positioning frame 4 is arranged on the lower part of the base 1, the knuckle positioning frame 4 is arranged on the lower part of the base 1, and is worn out from the base 1 for fixing the knuckle;

[0035] The welding assembly 5 includes a welding torch 51, a structured light sensor 52, and a welding torch adjustment mechanism 53. The structured light sensor 52 is arranged on the welding torch 51. The welding torch adjustment mechanism 53 includes an electric fine-tuning mechanism 531, a first beam 532, a first cross carriage 533 and a second A driving motor 534, the first cross carriage 533 is installe...

Embodiment 2

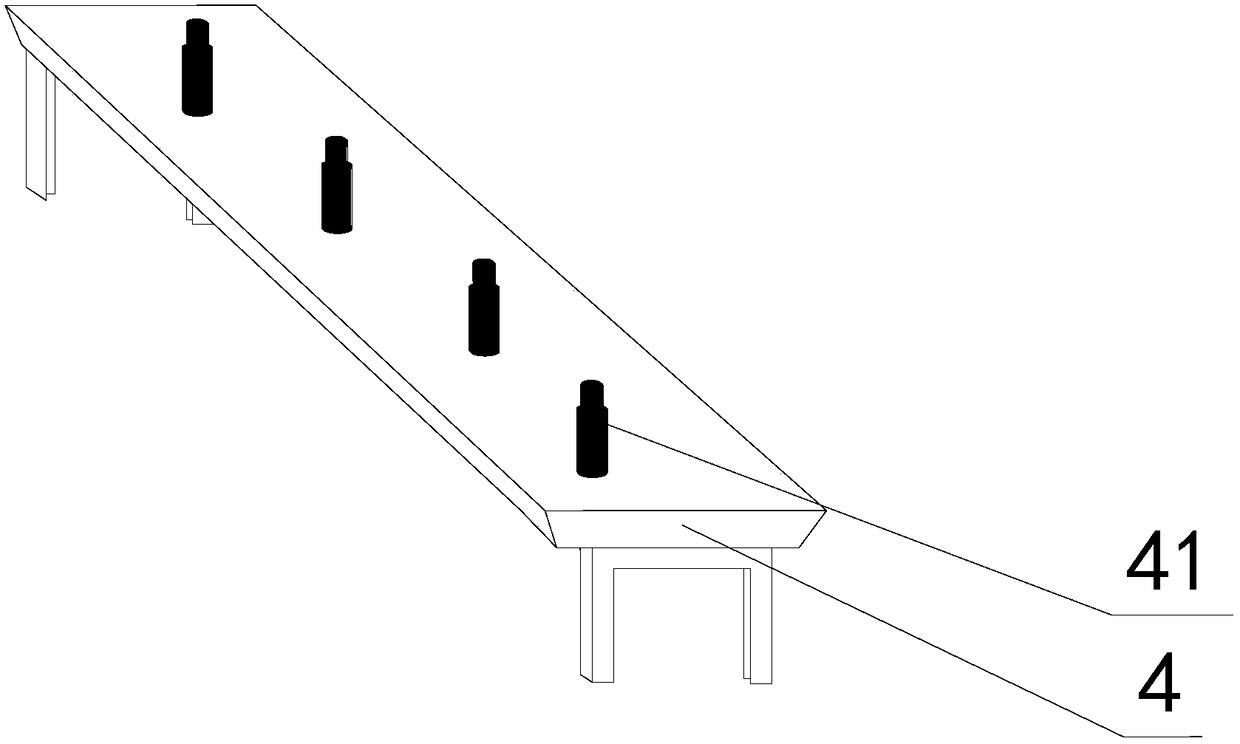

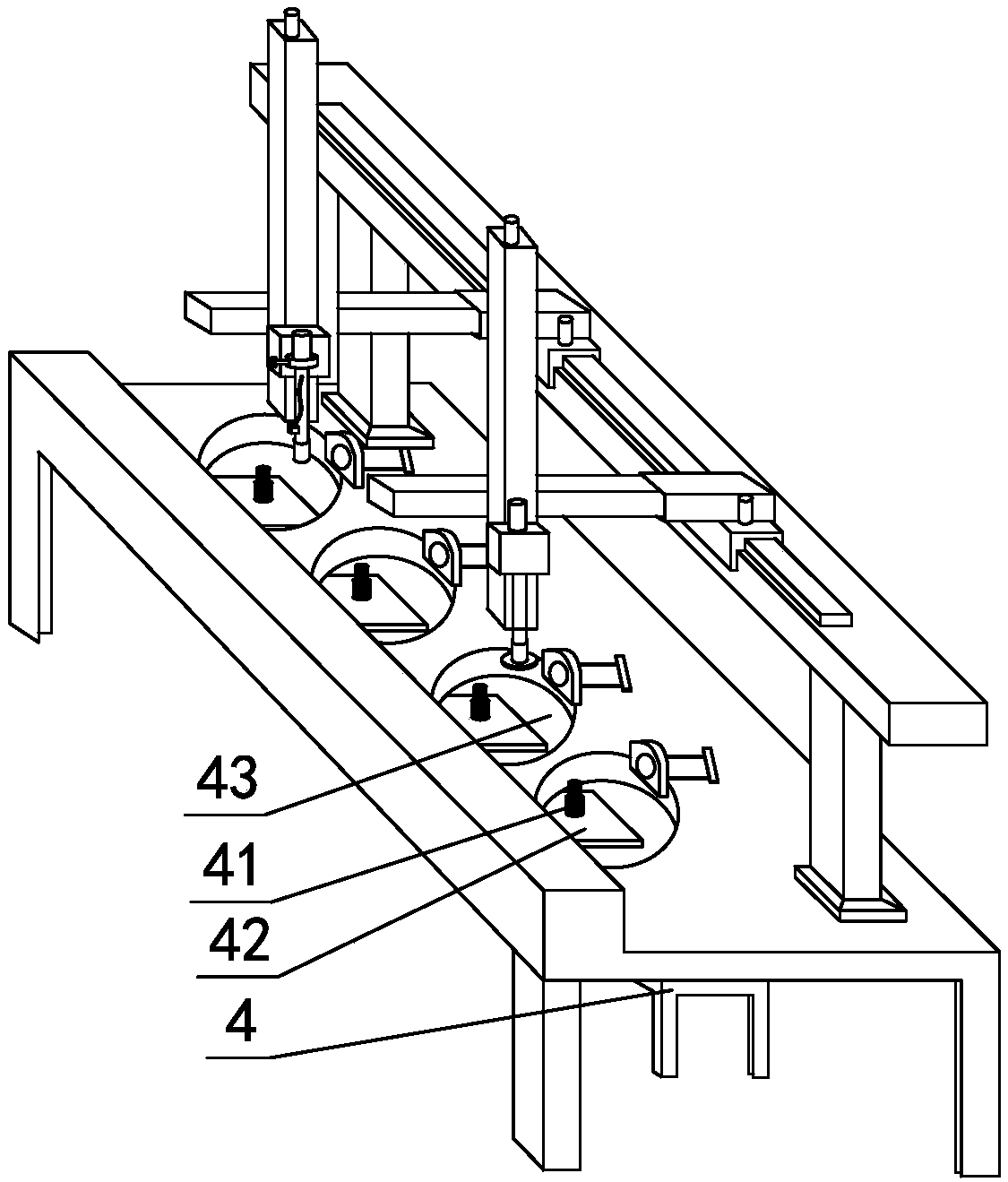

[0040] The present invention provides a railway knuckle intelligent repair plane, which is different from Embodiment 1 in that: Figure 2 to Figure 3 As shown, the knuckle positioning frame 4 is provided with several knuckle positioning pins 41, the base 1 has a mounting hole for receiving the knuckle positioning pin 41 to pass through, and a knuckle that cooperates with the knuckle positioning pin 41 is provided above the mounting hole. Liner 42, one side of knuckle liner 42 is provided with top wire 43.

Embodiment 3

[0042] The present invention provides a railway knuckle intelligent repair machine, which is different from Embodiment 2 in that the welding assembly 5 also includes an automatic wire feeder, a plasma power supply and a powder feeding system, and the automatic wire feeder is installed on on rail 3.

[0043] Such as Figure 4 to Figure 5 As shown, the welding assembly 5 and the milling assembly 6 also include a feeding and blanking mechanism 7 respectively. The feeding and blanking mechanism 7 includes a conveyor belt 71 and a blanking manipulator 72. The conveyor belt 71 is arranged on one side of the base 1, and the blanking robot 72 is arranged on the On the base 1, it can be used to transfer the knuckle on the conveyor belt 71 and the knuckle positioning frame 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com