Inner wall supersonic laser composite deposition device

A supersonic laser and deposition device technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems that the surface coating of the inner hole cannot be prepared, the nozzle cannot be perpendicular to the inner wall, etc., and achieve improved surface roughness, improved surface performance, simplified The effect of experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 An inner wall supersonic laser composite deposition device according to the present invention, comprising:

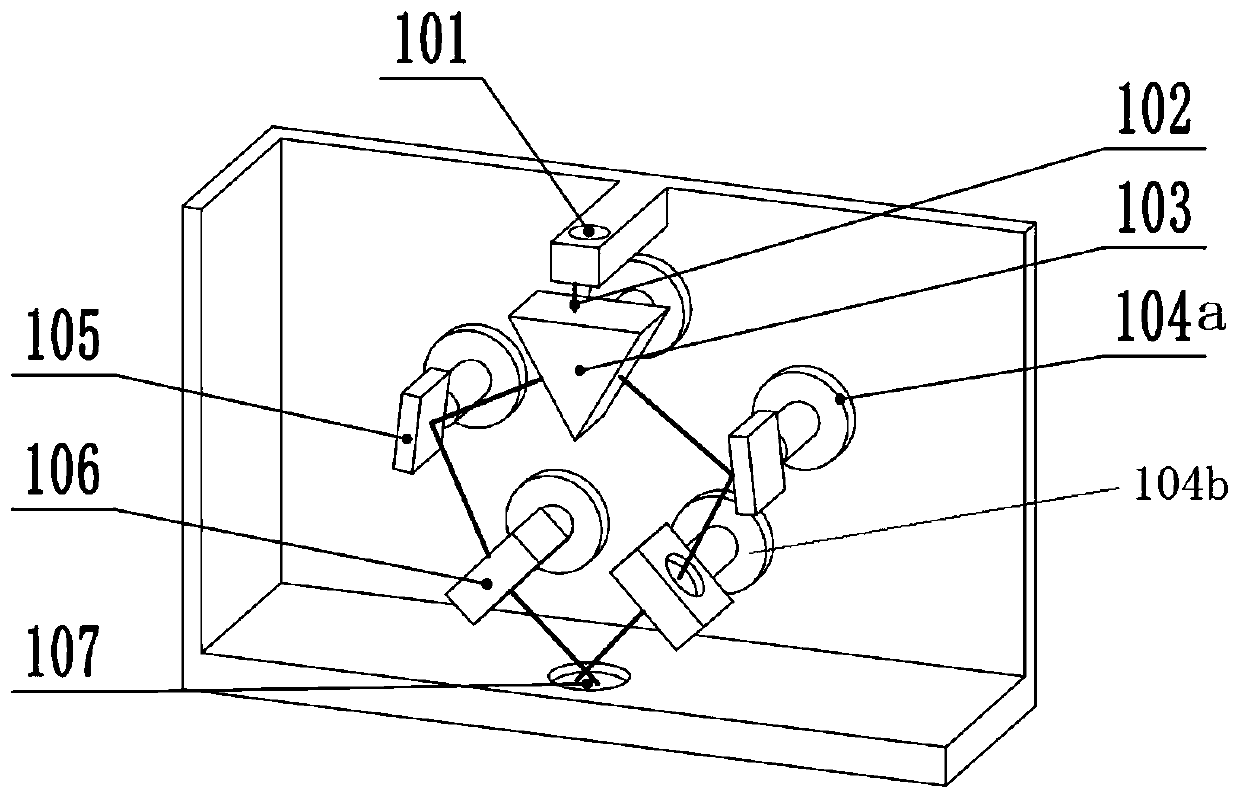

[0035] The galvanometer scanning unit 1 includes a mounting frame body 108 and a galvanometer scanning device. The mounting frame body 108 is installed on the inner wall supersonic laser deposition unit 2. The upper part of the mounting frame body 108 is provided with a light-transmitting port 101 for the laser beam to pass through. , the bottom is provided with a laser light outlet for the laser beam to pass through, and a protective mirror 107 is installed at the laser light outlet to support the vibrating mirror scanning device; the vibrating mirror scanning device includes a beam splitter and several sets of vibrating mirror scan parts, the beam splitter and The vibrating mirror scanning parts are all arranged on the mounting frame body 108, and the spectroscopic part is located directly below the light transmission port 101, and is used to receiv...

Embodiment 2

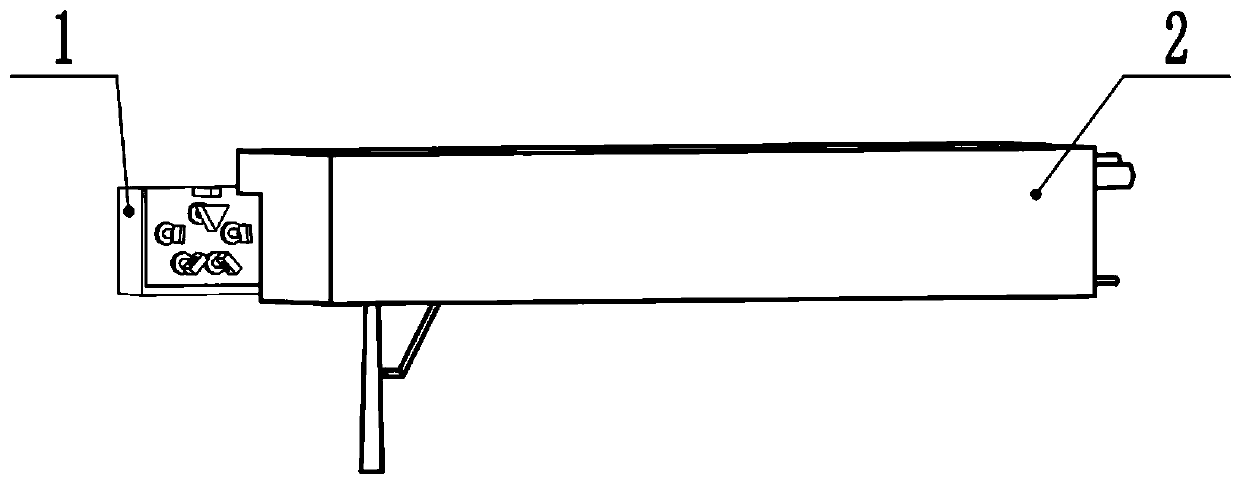

[0051] Embodiment 2 As shown in FIGS. 1 , 2 , and 3 , an inner wall supersonic laser composite deposition device is composed of a galvanometer scanning unit 1 , an inner wall supersonic laser deposition unit 2 and a laser 206 . The inner wall supersonic laser deposition unit 2 includes a nozzle, a laser passage 204, a cylinder 201, an air inlet pipe 205 and a powder feeding pipe 209; the upper side of the nozzle throat 213 of the nozzle is the nozzle constriction section 211, and the lower side is The nozzle expansion section 214, the nozzle is provided with a nozzle gas inlet 210 for high-pressure gas to enter and a light-transmitting hole 203 for the laser beam to enter on the nozzle contraction section 211, and the nozzle expansion section of the nozzle is provided with a nozzle for introducing powder The nozzle powder inlet 212; the laser passage 204 is a right-angle passage, and a beam splitter 202 is provided at the corner of the passage, and the laser beam emitted from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com