Remanufacturing method of polished rods of oil pumping units and polished rods of oil pumping units

A pumping unit and remanufacturing technology, which is applied in the manufacture of tools, drill pipes, earthwork drilling, etc., can solve the problems of waste of resources, wear and tear, lack of interchangeability, etc., and achieve cost saving, low manufacturing cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for remanufacturing a polished rod of a pumping unit, the specific operation steps are as follows:

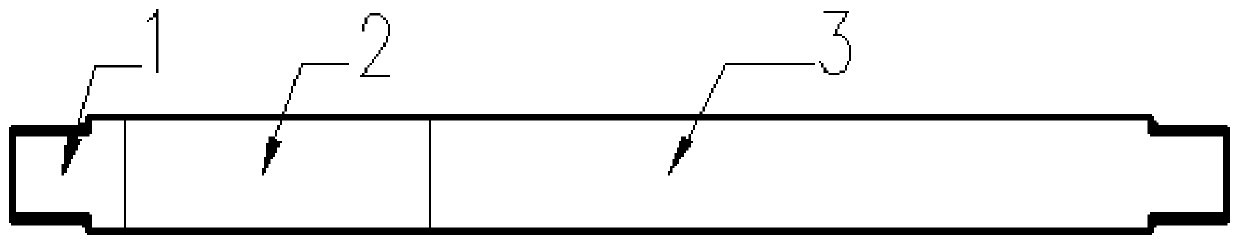

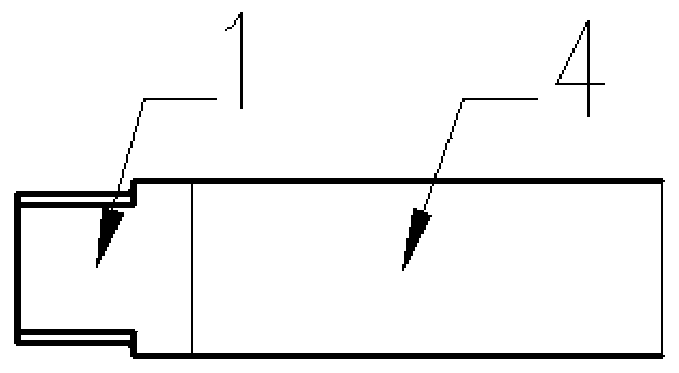

[0077] 1) Classify and sort the recovered waste polished rods, classify them according to size and type, and store the polished rods of the same size and specifications. After sorting, each polished rod of the pumping unit includes the front intact section 1, the worn section 2 and the rear intact section 3;

[0078] 2), as attached figure 1 As shown, the above-mentioned different types of polished rods are cut according to the maximum length of the worn section 2. After the worn section 2 is removed, the front intact section 1 and the rear intact section 3 are retained. The method used for cutting is mechanical processing. 1 shown in the figure is the unworn front intact section with a length of L1; 2 is the intercepted worn section with a length of L2; 3 is the unworn rear intact section with a length of L3; the total length of the polished rod is L0;

[007...

Embodiment 2

[0084] Provide the embodiment that carries out the polished rod recycling of pumping unit below.

[0085] (1) Select one specification and 10 polished rods of pumping units with a length of L0 for processing;

[0086] (2) After confirmation, the maximum length of the worn section 2 is L2, and all the polished rods of the pumping unit are intercepted according to the unified standard. For L1, L2, L3;

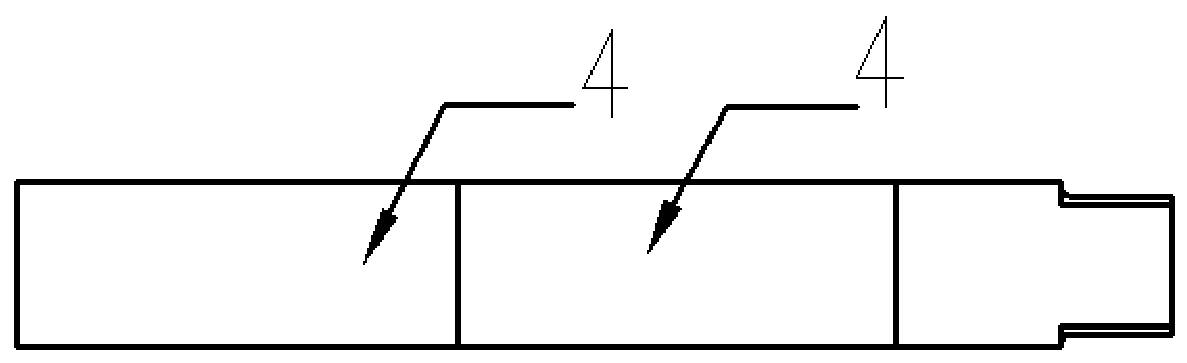

[0087] (3) Select three intact segments 3, cut out the connecting segments 4 corresponding to the worn segments, cut out three connecting segments 4 for each intact segment 3, and cut nine connecting segments 4 out of three intact segments 3, The length of each connecting section 4 is L2+50mm;

[0088] (4) The above steps obtain 10 front intact segments 1, 9 connecting segments 4 and 7 rear intact segments 3;

[0089] (5) A front intact section, a connecting section and a rear intact section are welded and connected into a complete polished rod of the pumping unit by the frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com