Low-heat Portland cement with high early strength and preparation method and application thereof

A Portland cement, early strength technology, applied in the field of building materials, can solve problems such as restricting the application of high-speed rail projects and insufficient early strength, and achieve good resistance to chloride ion and sulfate corrosion, medium corrosion resistance. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

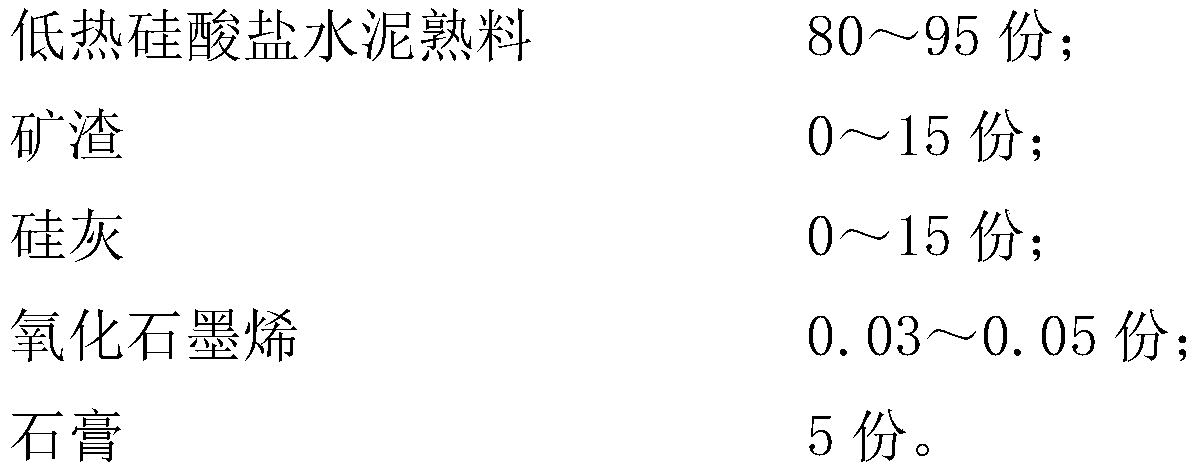

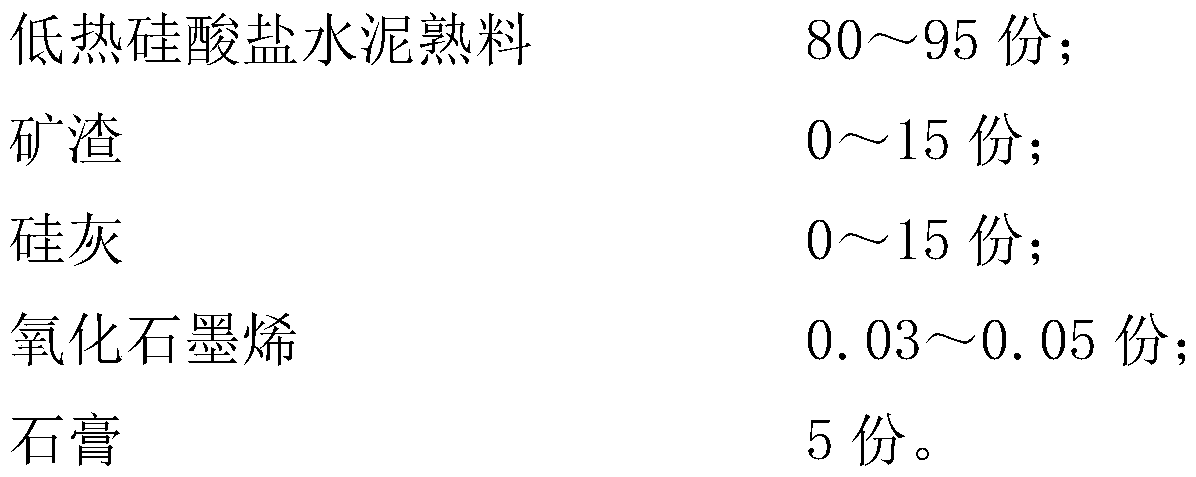

[0045] The present invention also proposes a method for preparing low-heat Portland cement with high early strength, which comprises the following steps:

[0046] 1) Using low-heat Portland cement clinker as the base material, slag and silica fume as the mixed material, graphene oxide as the modifier, and mixing with gypsum to obtain the mixture;

[0047] 2) Grind the above mixture together until the specific surface area is 300m 2 / kg~350m 2 / kg, to get low-heat portland cement with high early strength.

[0048] The invention also proposes the application of a low-heat Portland cement with high early strength in high-speed rail projects.

Embodiment 1

[0052] 1) Preparation of low-heat Portland cement raw meal:

[0053] The ingredients are prepared according to the following mass parts: 70 parts of limestone, 15 parts of clay, 5 parts of shale, and 10 parts of iron powder. Mix all components evenly and grind them to 150-200 mesh to obtain low-heat Portland cement raw meal. ;

[0054] 2) Preparation of low-heat Portland cement clinker:

[0055] The prepared low-heat Portland cement raw meal is calcined in a new cement dry process kiln system to obtain low-heat Portland cement clinker; the composition of the prepared clinker is shown in Table 2;

[0056] 3) Preparation of low-heat Portland cement with high early strength:

[0057] Take 95 parts of the calcined low-heat Portland cement clinker, 0.03 parts of graphene oxide, and 5 parts of gypsum, mix them evenly, and grind them until the specific surface area is 320m 2 / kg~350m 2 / kg, made into low-heat portland cement products with high early strength.

[0058] Performanc...

Embodiment 2-6

[0060] The preparation steps are the same as in Example 1.

[0061] Among them, the batching (in parts by mass) of the low-heat Portland cement raw meal is shown in Table 1; the composition (in parts by mass) of the prepared low-heat Portland cement clinker is shown in Table 2; the early strength is high The batching (in parts by mass) of the low heat portland cement is as shown in table 3;

[0062] The properties of the low-heat portland cements with high early strength prepared in each example were tested by conventional detection methods in this field, and the results are shown in Table 4.

[0063] The batching of each embodiment low-heat Portland cement raw meal of table 1

[0064] limestone clay shale iron powder Example 1 70 15 5 10 Example 2 80 10 6 4 Example 3 80 10 6 4 Example 4 85 5 7 3 Example 5 73 13 6 8 Example 6 76 12 6 6

[0065] The composition of the low heat portland cement clinker p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com