A kind of reactive powder concrete mixed with waste glass powder and its preparation method

A technology of waste glass powder and reactive powder, applied in the field of concrete, can solve the problems of high temperature curing of reactive powder concrete, and achieve the effects of accelerating strength growth, accelerating hardening and promoting hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

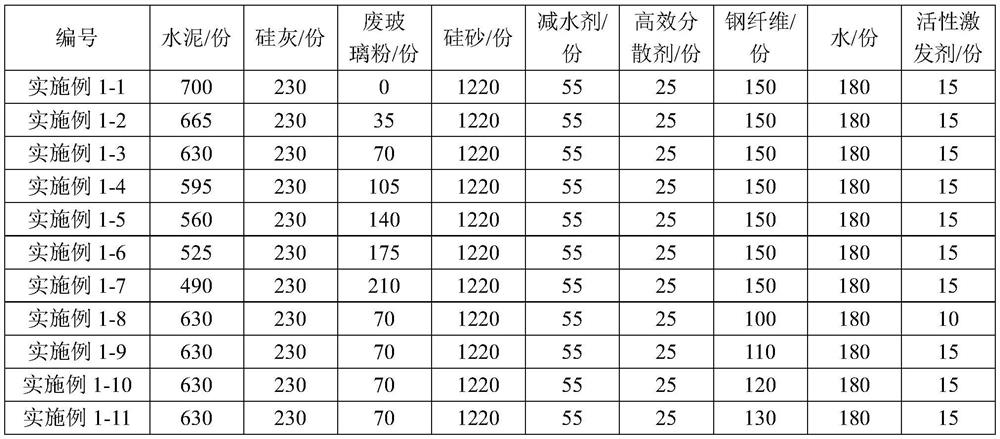

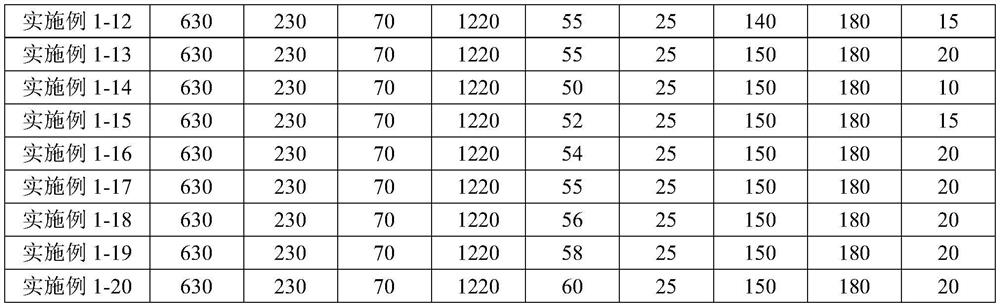

[0045] The active powder concrete mixed with waste glass powder according to the present invention comprises by weight: 450-810 parts of cement, 160-240 parts of silica fume, 35-240 parts of waste glass powder, 1200-1250 parts of silica sand, and 50 parts of water reducing agent. ~60 parts, 18~30 parts of high-efficiency dispersant, 100~150 parts of steel fiber, 158~200 parts of water, 10~20 parts of activity stimulating agent.

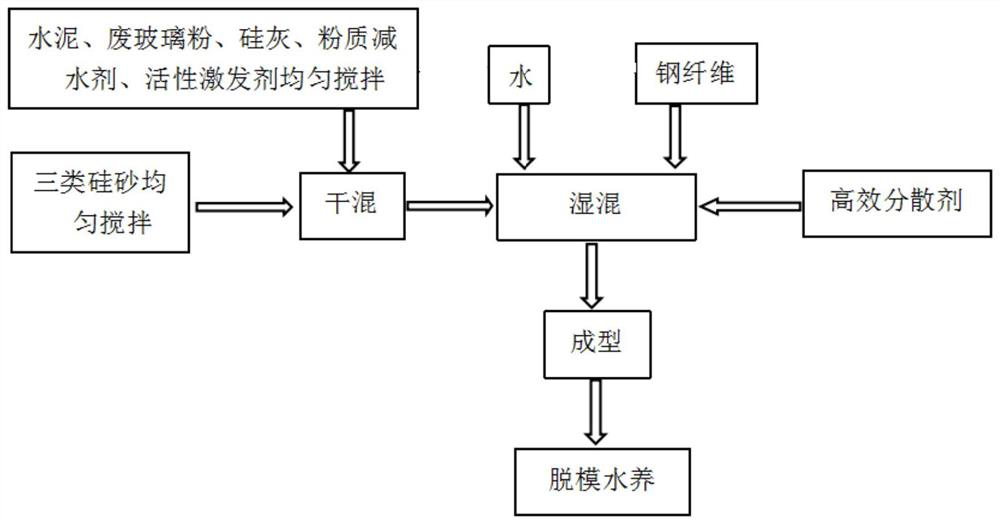

[0046] Its preparation method is as figure 1 As shown in the flow chart, it includes the following steps:

[0047] (1) First, measure and batch according to the ratio shown in Table 1, stir the silica sand of three types of particle sizes evenly in the mixer; mix cement, silica fume, waste glass powder, active activator and silty After the water reducer is mixed and stirred, it is poured into a mixer for dry mixing with uniform silica sand, and the mixture is evenly stirred to obtain a dry mixture;

[0048] The cement in Table 1 is P.O42.5R cement; ...

Embodiment 2

[0064] According to the weight ratio shown in Tables 3 and 4, metering and batching, using the same preparation method as in Example 1, the active powder concrete mixed with waste glass powder was prepared, and its properties are shown in Table 5.

[0065] Table 3. Embodiment 2 active powder concrete proportioning (by weight)

[0066]

[0067] Table 4. Embodiment 2 active powder concrete raw material properties

[0068]

[0069]

[0070] Table 5. Embodiment 2 active powder concrete properties

[0071] serial number 90d compressive strength / MPa 90d tensile strength / MPa Fluidity of the mixture 90d burst temperature / ℃ Example 2-1 190.3 31.2 228 636 Example 2-2 179 29.1 242 628 Example 2-3 193 32.7 231 704 Example 2-4 191.4 32.9 231.5 712 Example 2-5 189.6 32.1 237 693

[0072] It can be seen from Table 5 that there is no special rule between the performance of concrete and the physical properties of raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com