Copper bonding wire and preparation method thereof

A copper wire and bonding technology, which is applied in the field of bonding copper wire and its preparation, can solve problems such as stress concentration, complicated process, and difficult control, and achieve the effects of improving surface oxidation resistance, improving comprehensive performance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

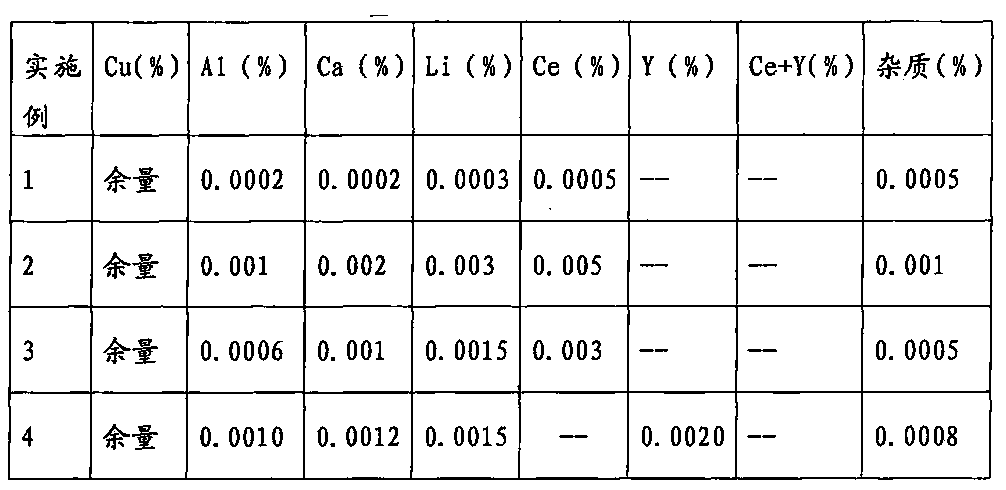

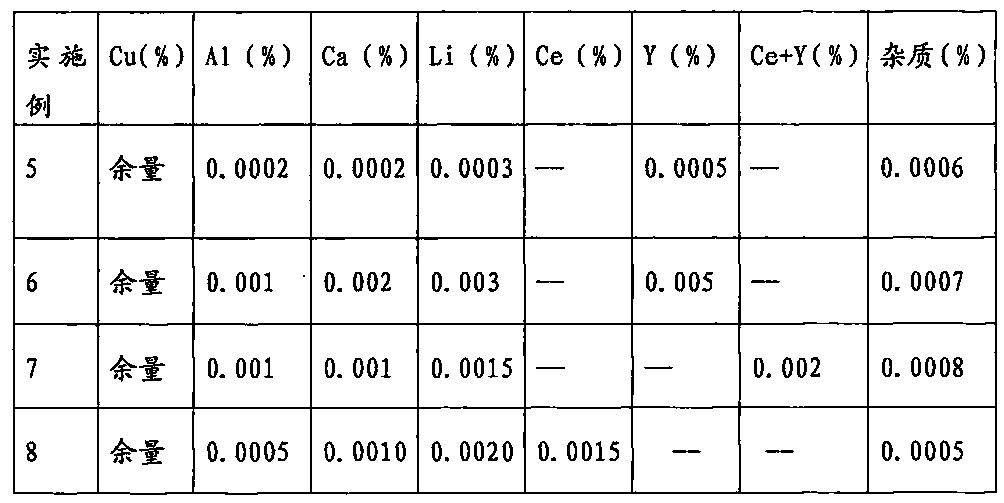

Examples

Embodiment approach 1

[0033] For the preparation method of bonding copper wire, see Figure 7 , the specific process is as follows:

[0034] 1. Preparation of master alloy: Take the preparation of Cu-Al alloy as an example to illustrate the preparation of master alloy: account for 1%-3% of the total mass of Cu-Al master alloy by elemental Al, and the balance is 6N copper ratio, weigh Good elemental Al and 6N copper. Put the weighed elemental Al into the feeding bin of the vacuum furnace, and then put the 6N copper into the melting crucible of the vacuum furnace. Vacuum down to 10 - 3 After Pa, backfill argon to the slight positive pressure in the vacuum furnace to start melting 6N copper. After the 6N copper is melted and cleared, add elemental Al to the copper melt through the feeding mechanism, and wait for the elemental Al to melt and mix with the copper melt. After uniformity, the copper liquid is poured into the mold to prepare the required Cu-Al master alloy. The same method can prepar...

Embodiment approach 2

[0043] For the preparation method of bonding copper wire, see Figure 7 , the specific process is as follows:

[0044] 1. Preparation of master alloy: Take the preparation of Cu-Al alloy as an example to illustrate the preparation of master alloy.

[0045] Weigh the elemental Al and 6N copper according to the ratio that the elemental Al accounts for 1%-3% of the total mass of the Cu-Al master alloy, and the balance is 6N copper. Put the weighed elemental Al into the feeding bin of the vacuum furnace, and then put the 6N copper into the melting crucible of the vacuum furnace. Vacuum down to 10 -3 After Pa, backfill argon to the slight positive pressure in the vacuum furnace to start melting 6N copper. After the 6N copper is melted and cleared, add elemental Al to the copper melt through the feeding mechanism, and wait for the elemental Al to melt and mix with the copper melt. After uniformity, the copper liquid is poured into the mold to prepare the required Cu-Al master a...

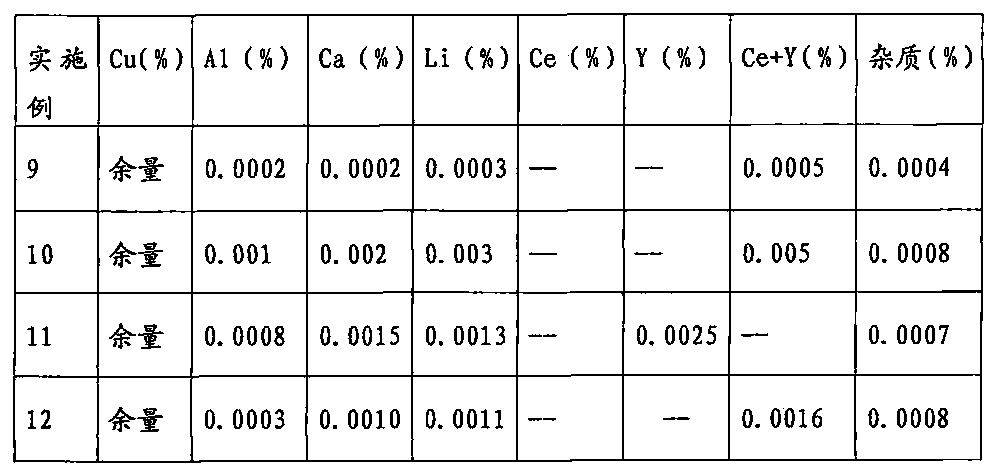

Embodiment approach 3

[0055] according to image 3 With the components and contents shown, a copper bonding wire with a diameter of 20 μm was prepared.

[0056] For the preparation method of bonding copper wire, see Figure 7 , the specific process is as follows:

[0057] 1. Preparation of master alloy: Take the preparation of Cu-Al alloy as an example to illustrate the preparation of master alloy. According to the proportion relationship that the elemental Al accounts for 1% -3% of the total mass of the Cu-Al master alloy, and the balance is 6N copper, the elemental Al and 6N copper are weighed. Put the weighed elemental Al into the feeding bin of the vacuum furnace, and then put the 6N copper into the melting crucible of the vacuum furnace. Vacuum to 10 -3 After Pa, backfill argon to the slight positive pressure in the vacuum furnace to start melting 6N copper. After the 6N copper is melted and cleared, add elemental Al to the copper melt through the feeding mechanism, and wait for the elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com