Method for preparing composite membrane for improving oxidation resistance of copper lead of integrated circuit

An integrated circuit copper and anti-oxidation technology, applied in the field of metal surface anti-oxidation, can solve the problems of poor matrix bonding, limited anti-oxidation ability, and insufficient surface density, so as to improve the anti-oxidation ability, inhibit further oxidation, and improve anti-oxidation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

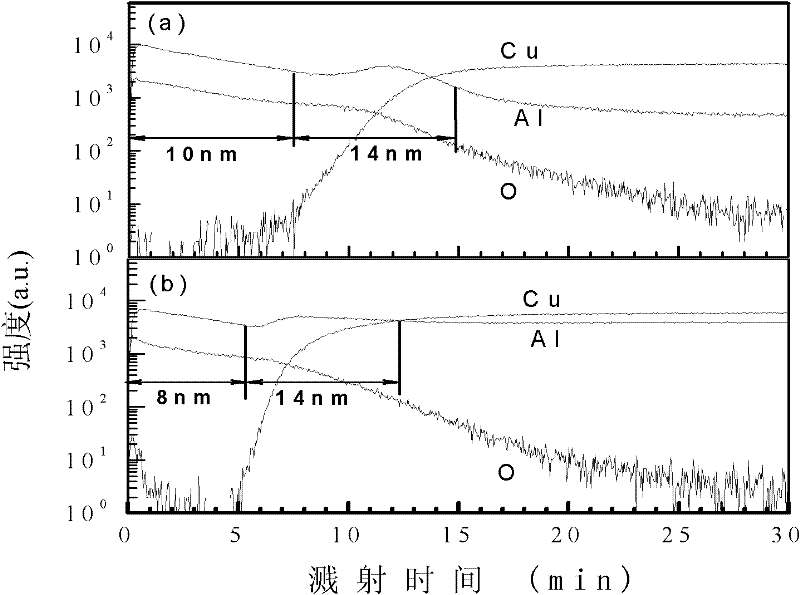

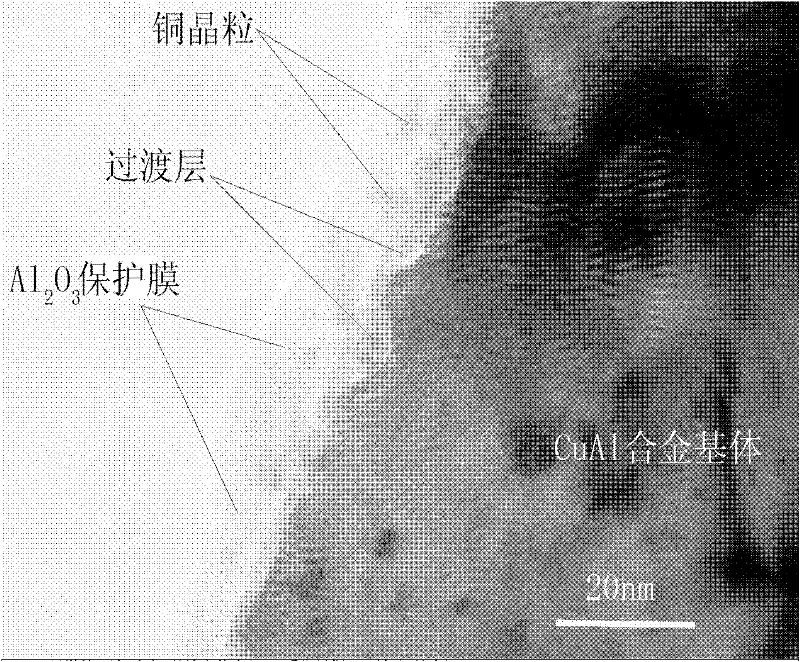

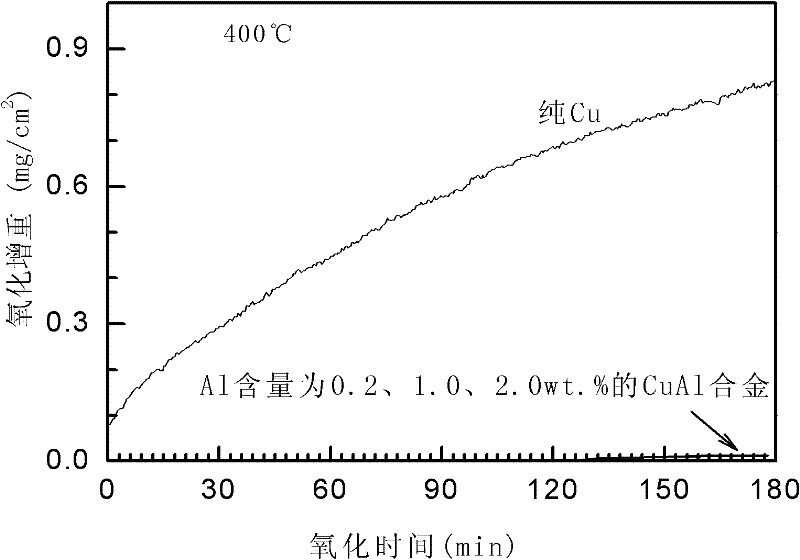

Examples

Embodiment 1

[0031] a, the purity of block is 99.99wt.% of pure Cu and granular purity of 99.99wt.% pure Al mixed, the content of pure Cu in the mixture is 99.8wt.%, and the content of pure Al is 0.2wt.%.

[0032] b. Put the mixed material in the electric arc furnace, close the furnace door, and then vacuumize the furnace body. When the vacuum reaches 0.5Pa, stop the vacuum pumping, and feed high-purity argon gas with a purity of 99.9999% into the electric arc furnace , the flow rate is 3000cm 3 / min, the air pressure is one atmosphere;

[0033] c. Start the electric arc furnace, set the discharge power to 2kW through glow discharge, heat up the Cu and Al alloy elements to 1200°C to melt, stop melting after melting at 1200°C for 5 minutes, cool down to room temperature, turn on the furnace, and turn it up and down After turning over the material, close the furnace door, and then vacuumize the furnace body again. When the vacuum reaches 0.5Pa, stop vacuuming, feed high-purity argon gas wit...

Embodiment 2

[0037] a. Mixing block-shaped pure Cu with a purity of 99.99wt.% and granular purity of 99.99wt.% pure Al, the content of pure Cu in the mixture is 99.0wt.%, and the content of pure Al is 1.0wt.%.

[0038] b. Put the mixed material in the electric arc furnace, close the furnace door, and then vacuumize the furnace body. When the vacuum reaches 0.5Pa, stop the vacuum pumping, and feed high-purity argon gas with a purity of 99.9999% into the electric arc furnace , the flow rate is 3000cm 3 / min, the air pressure is one atmosphere;

[0039] c. Start the electric arc furnace, set the discharge power to 2kW through glow discharge, heat up the Cu and Al alloy elements to 1200°C to melt, stop melting after melting at 1200°C for 5 minutes, cool down to room temperature, turn on the furnace, and turn it up and down After turning over the material, close the furnace door, and then vacuumize the furnace body again. When the vacuum reaches 0.5Pa, stop vacuuming, feed high-purity argon ga...

Embodiment 3

[0043] a. Mixing block-like pure Cu with a purity of 99.99wt.% and granular purity of 99.99wt.% pure Al, the content of pure Cu in the mixture is 98.0wt.%, and the content of pure Al is 2.0wt.%.

[0044] b. Put the mixed material in the electric arc furnace, close the furnace door, and then vacuumize the furnace body. When the vacuum reaches 0.5Pa, stop the vacuum pumping, and feed high-purity argon gas with a purity of 99.9999% into the electric arc furnace , the flow rate is 3000cm 3 / min, the air pressure is one atmosphere;

[0045] c. Start the electric arc furnace, set the discharge power to 2kW through glow discharge, heat up the Cu and Al alloy elements to 1200°C to melt, stop melting after melting at 1200°C for 5 minutes, cool down to room temperature, turn on the furnace, and turn it up and down After turning over the material, close the furnace door, and then vacuumize the furnace body again. When the vacuum reaches 0.5Pa, stop vacuuming, feed high-purity argon gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com